Residential sewer systems are usually gravity-fed. The drains move through the pipes under the influence of gravity, that is, no pressure is created in the pipeline. Therefore, to seal the joint, it is enough to use an O-ring for the sewer pipe. Let's figure out what cuffs there are and how to use them correctly.

When assembling pipelines, it is important to pay attention to sealing joints. For sewer pipes in which liquid moves without pressure, it is sufficient to use elastic cuffs for sealing. These parts prevent leaks from occurring. And if over time the sealing ring ceases to perform its functions, it can be easily replaced.

Sealing with rubber seals

Rubber seals for sewer pipes are most often used. They are easy to use, reliable and durable. They are used when installing sewerage systems in country houses and apartments, industrial buildings. The composition of rubber seals includes the following substances:

- rubber compound;

- rubber;

- polyurethane;

- silicone;

- paronitis

The result is durable, elastic rubber seals that ensure tightness and reliability of sewer pipe connections. The products are resistant to temperature changes, aggressive chemicals, non-concentrated acids and alkalis.

Rubber seals are classified depending on their purpose. They can be universal, rod, or piston. Three-lobe seals ensure a smooth transition from a cast iron pipe to a plastic one.

Rubber cuffs have a number of advantages. They are inexpensive, reliable, durable, and prevent groundwater from entering the sewer system. Thanks to the seal, the wastewater does not escape to the outside, and there is no unpleasant odor in the area.

How to properly install a foam shell

How to insulate a water pipe with polystyrene foam? To install the shell correctly, you do not need to have any specific skills. Thermal insulation of water supply in this way can be done with your own hands in a short period of time.

The cylinder halves are put on the pipe and secured with special tape. The parts must be installed with an overlap (at least 10 cm). Also, all joints are carefully sealed with tape and a protective layer is applied to the tape.

Shaped shells are used for corner segments, nodes and turns.

Dismantling the insulation is carried out in the reverse order, removing the protective layer, adhesive tape, and then the shell itself.

Thermal insulation Energoflex

This heat-insulating material is made of foamed polyethylene. Thermal insulation for water supply pipes from the Energoflex company has a cellular structure and is ideal for thermal insulation of outdoor water pipes.

Energoflex thermal insulation guarantees high-quality insulation of outdoor water supply and is manufactured using advanced technologies using the latest equipment. The range of products offered is constantly increasing depending on customer demand.

Practice using cuffs

Using cuffs, plumbing equipment (sinks, sinks, bathtubs, toilets, etc.) and household appliances (washing machines, dishwashers) are connected to the sewer network, and sewer pipes are connected. Plastic is connected to plastic using special fittings equipped with rubber sealing rings, and cast iron is connected to plastic using either adapters, couplings, or just cuffs.

To join cast iron and plastic pipes, both external and internal cuffs are used (for socketed and socketless structures). They work in stages:

- clean the connecting part of the cast iron pipe - it must be absolutely clean to ensure proper adhesion of the sealant;

- apply sealant to the cuff and insert it into the socket;

- A plastic pipe is inserted into the cuff.

If pipes have to be cut, this must be done correctly - the cut must be smooth (no nicks, even if they seem microscopic and are difficult to detect). After cutting, the part is chamfered.

In terms of the procedure for joining smooth pipes, it is not much different from socket pipes - the sealant must be applied to the collar on both sides, since the coupling is placed on top of it.

Scheme for installing a cuff on a sewer pipe (connection of smooth pipes)

Siphon connection

For this purpose, the use of a sealing collar is mandatory (there is always water in the siphon - it serves as a kind of seal). There are no difficulties in connecting the siphon - you can easily do it yourself without any special knowledge. First, the siphon itself is assembled according to the instructions (the accompanying documentation must be available, otherwise you should not buy the equipment: the configuration is different, and the assembly instructions vary accordingly). Then connect the pipe:

- to the siphon;

- to the sewer (simply inserted into the fitting hole intended for this purpose).

If the fitting on the riser is equipped with an O-ring, the collar is used only to connect the pipe to the siphon.

O-rings produced and supplied by our company

O-rings DIN 3771

Rings of rectangular (square) section

O-rings GOST 9833-73

Wrapped rings

What is needed to organize internal sewerage

The internal sewer system collects wastewater from throughout the house and discharges it into the riser.

Sewerage accessories include:

- water seals connecting plumbing fixtures to the pipeline;

- a pipeline that discharges wastewater from the floor into the collector;

- ventilation tube;

- actually, the riser itself;

- sewer bed - a horizontal section of the pipeline through which wastewater flows further from the riser.

When laying pipes, you will need such shaped elements as revisions, tees, elbows, plugs, etc. Without them, it is impossible to ensure drainage according to all the rules.

Shaped elements

Shaped parts for sewerage can otherwise be called connecting parts; they are produced in the following configurations:

coupling - a short piece of pipe with sockets on both sides. Used to connect 2 parts of the pipeline;

adapter (reduction) – used to connect pipes of different diameters. Reduction can be coaxial or eccentric;

tee - this element is indispensable in situations where you need to create a branch extending from the main sewer system, for example, when laying out floors with your own hands;

revision - the same tee, only the outlet is closed with a plug, and the branch itself is small. Used when the sewer is clogged to clean it;

crosspiece - the purpose is the same as that of a tee, but with its help a more complex unit is organized;

- elbow

(bend) – used when turning the pipeline; - non-return valve

- necessary in emergency situations, thanks to it wastewater will not flow back in the event of a malfunction of the drainage system;

plug - during repairs, used to block the sewer.

Sewer fittings are a vital element when laying out the system. Without them, it is impossible to install pipes across the floor or connect them to the riser.

Features of connecting plumbing fixtures

The connection of any plumbing fixture must be organized so that unpleasant odors from the sewer do not leak into the room. The simplest method is to connect through a water seal (or siphon).

The siphon looks like an ordinary pipe in the shape of the letter S, thanks to the water plug, protection against odors is guaranteed. If you do not plan to live in the house regularly, for example, in a country house, then you can consider other methods of protection against odors (dry sewer siphon).

Sewer repair

When repairing the above elements will not be enough. In particular, when replacing a section of a pipeline, sewer pipes will be needed.

There are often situations when part of the old pipe is rotten or simply cracked; in this case, it will be necessary to replace not the entire drainage system, but only a small section. In order to connect the new pipe to the existing drainage system, pipes are used.

Externally, the sewer pipe looks like a small section of pipe, on one side it is smooth, and on the other there is a socket. Accordingly, on the one hand, the connection is made using a socket method, on the other - in a joint, using a coupling.

Sometimes, when repairing an old cast-iron sewer, it is necessary to join plastic and cast-iron pipes. At the same time, to achieve the required tightness, one sealant is not enough. First, you will need to insert a rubber cuff into the cast-iron socket and then a plastic pipe into it.

Tightness of the junction of plumbing fixtures and pipelines

A sewer seal is used to reduce the likelihood of leaks in the area between the plumbing fixture and the pipeline. Externally, the cuff looks like a rubber ring that is placed over the joint.

To achieve greater elasticity, the cuffs do not contain polymers; only natural rubber is used for their production. True, during operation, because of this, it is necessary to use lubricant so that the rubber does not crack.

If you plan to use a rubber cuff, you will also need lubricant for sewer pipes. If you try to insert the end of the pipe into the cuff without lubrication, the rubber can be easily damaged. And after installation, the cuff must be periodically lubricated.

As for the specific lubricant, there are many options, some prefer to use automotive lubricant, which is used for rubber inserts in car doors in the winter. But even ordinary plumbing lubricant can keep the rubber safe and sound.

Tow

Sealing plumbing pipes with tow (dry flax) was fully justified for threaded connections of metal profiles, but the use of this sealant for PVC pipes did not justify itself. This is especially true for small threads. The fact is that tow begins to decompose under the influence of water, thereby weakening the sealing effect. But what was it like with metal pipes before? To seal the threads of metal pipes, tow was impregnated with paint and, as a result, it (the tow) did not collapse under the influence of moisture.

If paint had not been used, then, in addition to the fact that the tow itself would lose its properties, the pipe at the threaded connection would be destroyed by corrosion. Using dry flax to seal plastic pipes makes no sense due to the fact that these pipes are not susceptible to corrosion. And the paint itself has minimal adhesion (penetration) upon contact with plastic, and, therefore, there will be no seal. As a way out in this situation, you can use tow with sealant.

How to seal pipes

Rubber sealant for sewer pipes is used most often. The sequence of installation work depends on whether the internal or external sewage system is being installed. When arranging an internal pipeline, installation consists of the following steps:

The connection is sealed and the pipeline is now ready for use. It should be remembered that if silicone sealant is used, it should not be applied to the outside of the sewer pipe.

If sealing of the external pipeline is required, installation work is carried out in the following sequence:

- the sealing compound is applied to the inner surface of the rubber cuff;

- the fitting is put on the pipe;

- When the sealant hardens, you can connect the pipeline.

Sealing sewer pipe connections is an important step when performing sewer installation work. It is at the joints that blockages, leaks and other unpleasant problems most often form, which help reduce the service life of the sewer system. You can prevent any problems if you follow the advice of professionals and carry out all work carefully and diligently.

In order for the sewer system to function efficiently and effectively, it must be installed correctly. It’s easier for residents of multi-storey buildings who install only an internal pipeline. But owners of country mansions will have to take care of laying external sewerage and arranging an autonomous system.

Sewage installation consists of several stages:

- drawing up a sewer system project;

- procurement of materials;

- pipe connection;

- sealing joints;

- sealing connections.

Sealing sewer pipes is necessary to avoid leaks and breakthroughs during system operation. Most often, rubber cuffs are used to seal the joints of plastic sewer pipes. Seals prevent water from getting in or out and protect the sewer from the penetration of insects and small rodents. High-quality sealed connections are a guarantee of long-term and efficient functioning of the sewer system.

Plumbing thread

Plumbing thread is suitable for sealing pipes with any thread and in any condition.

It consists of polyamide microfibers coated with silicone. Very durable, impossible to tear with your hands.

Advantages:

- seals any thread equally well: old, corroded, wet, damaged;

- After compaction, adjustment up to 180° is possible;

- the tightening torque is less than when using flax, it is easy to assemble and disassemble;

- less FUM tape gets dirty.

Disadvantage: several times more expensive than flax, the price is comparable to FUM tape.

Even a non-professional can work with thread; technically, it is the simplest sealant. Can be used without restrictions on all types of connections, especially convenient for threads with fine pitches. For plastic parts, the thread must be used quite carefully.

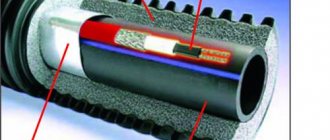

What types of cuffs are there for sewer pipes?

This is predominantly a round wide o-ring, sometimes with a corrugated part. The cuffs are internal and external. Internal ones are used to connect socket structures, external ones - for smooth pipes (in addition to the seal, a coupling is installed).

Sealing cuffs with corrugated part

Cuffs are most often made of rubber - an elastic material that fits tightly, providing a reliable flexible connection. The shape of a part depends on its function.

Rubber cuffs

Eccentric cuff

The eccentric cuff consists of pipes connected to each other with an offset, that is, the centers of both parts are in different planes. Traditionally, the part is called a cuff, but this is a special shaped part for connecting to the toilet network. It is equipped with O-rings and does not require the use of sealant (with the exception of connection to an old cast-iron riser, when sealant is used for greater reliability, given the difference in materials).

Unfortunately, due to too much displacement of the connected elements, it is not always possible to use the eccentric cuff (although some craftsmen manage to insert one into the other, building a strange structure) - in such cases, the toilet is connected using a corrugation.

Eccentric cuff

The parts come in different configurations, but sometimes such a displacement is required that connection with their help is impossible - in such cases a corrugation is installed.

Pleated cuff

The corrugation is similar to an eccentric cuff, but the implementation of the displacement is different - it is achieved through a flexible corrugated sleeve, and not by positioning the parts relative to each other. Thus, the displacement can be large, but it is necessary to set the desired bending angle of the corrugated part so that the drains flow freely (otherwise blockages are inevitable).

Connection via corrugation

The main advantage of corrugation is flexibility. Thanks to this property of the part, it is almost always possible to connect a toilet to the sewer without errors. The main disadvantage is the short service life. Due to the same flexibility, the walls quickly wear out and the part becomes unusable. When choosing corrugation, you need to give preference to thick-walled, reinforced.

Reinforced corrugation

Installation is theoretically simple (the parts are simply inserted into each other according to the attached instructions), but we do not recommend installing them yourself (unless you have the skills): the cuff functions normally under certain conditions (bending angle, slope, stretch length), and if they are not created, the system will not work will be disrupted (which can lead to floods due to blockages).

So you won’t be able to read a newspaper/memoir while sitting on the toilet, looking out of the window from time to time - or you’ll have to erect a plumbing miracle on a pedestal and screw a ladder to it (here it’s not far from the attic window).

On a pedestal

There is a solution to this problem as well - installing a pumping system that forcibly sends wastewater into the sewer system. However, such drastic changes will require permission for redevelopment, and this is:

- development of a project (yes, just to move the toilet a few meters);

- payment for the project;

- its approval by the authorities and everything related to it;

- payment of the approval fee;

- the commission accepting the transfer of equipment (they look at how far they have moved away from the project, if they have moved away);

- payment of commission fees.

We recommend using the cuffs exclusively for their intended purpose - for connection and nothing more.

Everything is easy in the text - the text cannot convey the effort made. However, we all know what is transported by sewer pipes (that is, what will flood an apartment/house when incorrectly installed cuffs cause a flood), and therefore, when it comes to sewerage, we strongly recommend that you contact specialists, even those with restless hands

Especially when it comes to cast iron risers: cast iron is fragile - it must be handled with extreme caution

Thread for sealing threaded connections

Sealing threaded connections in heating, water and gas supply systems is perhaps the most important task for a plumber or gas equipment installer. Not only the normal functioning of the system, but also the safety of the structure in which it is installed depends on the quality of the work performed. The threaded connection itself is very strong, but it is not capable of holding liquid or gas without special treatment. There are quite a few means for sealing, one of them is a special polymer thread for sealing threaded connections, which will be discussed.

“Moment Germent”, length 15 m.

How to install the cuff correctly

The easiest way is to connect a corrugated pipe to a plastic riser. This is due to the specifics of such a joint: it is quite easy to insert an elastic band into the socket, after which the tip of the flexible pipes is placed in the hole.

A more complex option is to connect a plastic riser to a cast iron one. This is due to the fact that for a high-quality joint it is necessary to almost perfectly clean the cast iron socket from old residues of sealants and other possible contaminants.

It is not particularly difficult to join the sewer section of pipes with the presence of internal sealing collars.

The uncut type pipe end easily and simply penetrates into the socket area, in which the seal must first be correctly placed. When a section of the highway is cut, then at its end it is necessary to make a cone-shaped edge, after which the elastic will easily take its place. Plain water can be used as a lubricant.

Risers with a diameter of 110 mm (it is best to buy those manufactured by Rossiya) are more difficult to connect, even if you moisten the joint with water. Therefore, to facilitate the installation of the connecting collar, it must be lubricated with automobile oil and other available lubricants that will facilitate the installation process.

Similarly, it is possible to install valves for differential pressure regulators.

Since our hardware stores have a sufficient number of connecting adapter sleeves for metal, polypropylene, and plastic, it is not particularly difficult to assemble the pipeline hermetically. You just need to correctly determine the internal diameters. After this, connecting cast iron to plastic, plastic to plastic, or making any other connection will not be a problem.

Rubber cuffs for sewerage can be made from different materials, and there are also different types of devices. Hydraulic seals are used in industry, for equipping sewage systems in private houses, cottages and apartments.

Cuffs for cast iron sewers are made of polyurethane and rubber compounds such as rubber, paronite, silicone and rubber. In production, only 100% rubber is used, no polymer is mixed. Thanks to this composition, high elasticity, strength and tightness of fastening with the connected parts are ensured. Polymer and rubber also provide resistance to increases and decreases in temperature, are resistant to aggressive substances, and can be used when exposed to acids and with increased rigidity of working resources.

The sealing cuff for sewerage also comes in different types:

- rod;

- piston;

- universal (for rods and pistons).

Also, the rubber sealing cuff for sewerage can be internal or external. The internal seal is used in cast iron pipes to connect plastic pipes with different diameters. Also used to connect a corrugated hose to the drain of household plumbing fixtures (for example, connecting to the sewage system of a washing machine or dishwasher). The external seal, in turn, is used to connect to a socketless sewer structure.

There is also a three-leaf transitional sewer cuff, which facilitates the transition from a cast iron pipeline to a plastic one.

How do sealing materials for paronite plumbing work?

Another common sealing material for plumbing is paronite. It is a plastic substance that is made from asbestos, minerals, rubber, sulfur compounds and carbonaceous solvents. It is made by pressing into sheets with a thickness of 0.004 to 0.6 cm, the standard size of which is in the range from 30x40 cm to 300x150 cm. This material can be used in temperatures from -600°C to +4500°C. The main condition for the use of paronite materials is that the sealed connectors must be flat

.

To install household plumbing elements, general purpose paronite (PON) is used. This material is allowed for use in systems with working media such as steam, saline solutions, hot water, and petroleum products. Almost all sealing gaskets for flanges in pipelines with operating temperatures exceeding 1000°C are produced from it. Before installation work begins, sealing materials based on paronite must be wetted and treated with graphite mixed with drying oil.

Benefits of paronite

consist in high levels of resistance to acid-base compounds and temperature variations. It is necessary to take into account the peculiarities of storing this sealing material. During storage, contact with organic solvents, acids and oils is prohibited.

Read material on the topic: Metal-plastic pipes wholesale from

Elements of external sewerage

In addition to the pipes themselves, revisions and bends, the outer section of the drainage system also includes several specific elements. In the case of an autonomous sewer system, wastewater needs to be stored somewhere while it is being cleaned, so you will need to build a septic tank, or better yet, a septic tank.

Construction of a settling tank

Sewage settling tanks are a regular pit in which wastewater settles, large particles settle to the bottom, after which the clarified wastewater moves to the next stage of treatment. Externally, the sump looks like a pit with reinforced walls and bottom (or a special container).

If the sump is built independently, then the instructions look like this:

- a hole is dug in the ground (depth approximately 2.5 m, cross-section at least 2.0x2.0);

- a cushion of a layer of gravel is poured onto the bottom of the pit, on top of which a sand layer is placed;

- after this you need to seal the bottom and walls of the pit. You can build formwork, place a reinforcement frame in the pit and fill the walls and bottom of the pit with concrete mixture; you can reinforce the walls with brickwork;

when the concrete hardens, all that remains is to concrete the ceiling and arrange ventilation for the sump.

You can go the other way; instead of labor-intensive concreting, many use large-volume plastic containers for sedimentation tanks. These can be Eurocubes, plastic barrels, metal barrels in which paint and varnish materials were previously stored. The price of installing a sump in this case is low, but tightness is ensured.

There are also budget options for settling tanks. From ordinary truck tires, you can build a septic tank suitable for irregularly used sewage systems.

Septic tanks stand apart. Externally, such a container looks like a large barrel with ventilation pipes, and the internal space is divided into separate zones: first, the wastewater settles, then through the overflow system the liquid enters the second section, where final cleaning occurs.

Fluoroplastic pipes and barrels for sewerage

Separately, it is worth mentioning fluoroplastic barrels for sewerage. PTFE itself is an interesting material. Pipes and barrels made from it can be used in the temperature range from -100ᵒС to +250ᵒС. In addition, fluoroplastic is strong and durable.

Note! Fluoroplastic is an inert material; it does not react even with very aggressive substances; in this indicator it even surpasses platinum and gold. Therefore, using it in ordinary sewerage is not entirely justified.

Most often, fluoroplastic pipes and barrels are used in the chemical industry.

Why is flax better than other sealing materials for plumbing?

Most often in practice, flax is used to seal threaded connections, which is available for sale in construction markets and plumbing stores. High-quality linen consists of thin strands, is elastic in structure, odorless and does not contain debris. As a sealing material, it is not very good, since it is susceptible to rotting and burning out in the heating system, and also does not prevent the formation of corrosion on the metal threads of connections.

In order to eliminate the shortcomings of flax as a sealant, it is impregnated with various compounds, which include pastes. SNiP standards provide for the use of a mixture based on thickly ground red lead or white on natural drying oil. This substance is not sold in finished form, so it is prepared independently: add a little drying oil to a certain amount of white or red lead and mix thoroughly until it reaches the consistency of rich sour cream. Such a paste should be dense enough so that it does not spread when spread.

The scope of use of red lead is determined by its chemical properties, which, when interacting with iron, oxidize it to water-insoluble oxide FeO. Also, this substance does not allow oxygen to pass through and the compaction process is similar to the method of blueing steel. In everyday practice, this type of sealing uses a composition of flax and oil paint. When sealing ferrous metals, this method does not protect them from corrosion processes, but is quite reliable as waterproofing.

The main advantages of flax as a sealing material:

- Application for sealing various types of joints.

- Swelling of flax fibers when wet, which contributes to its increase in volume and better sealing of joints. Even with a small leak, after sealing the threads, water seepage quickly stops.

- The resistance of flax fibers to mechanical stress, which allows you to adjust actions during work within a full turn when rotating the thread while maintaining absolute tightness.

Among the disadvantages of using flax for seals, two significant points are noted:

- When interacting with air in conditions of high humidity, sealing materials for linen plumbing fixtures are prone to rotting. To prevent such processes, it is necessary to use special materials (oil paint, lithol, etc.), which subsequently complicate the disassembly of plumbing elements, as they increase the adhesiveness of the joints.

- Linen sealing materials are demanding in terms of application technology, so their use must be carried out by experienced, highly qualified craftsmen.

Despite the noted shortcomings, flax strands remain the most popular sealing element for installing plumbing fixtures. This is due to the constant availability and favorable price of such material.

When installing plumbing fixtures, the sealing flax strand is rolled into a thread, which is wound onto a threaded spiral. To prevent the thread from unscrewing along the turns, it is necessary to use lubricants that promote its tighter fit. This will increase the friction force between the linen sealing material and the threaded connection (for example, on a pipe). This technique is used by qualified plumbing installers. For its effectiveness, it is important to be able to choose the right lubricant.

Pros and cons of cuffs

The sealing rubber cuff for sewerage 100 has a number of advantages.

It is characterized by:

- reliability, which eliminates the possibility of water flowing out of the sewer line, since the plastic can be perfectly fixed in a cast iron pipe;

- ability to withstand sudden pressure changes ranging from 50 to 150 kPa;

- breadth of the model range. Since hydraulic seals come in different diameters, they can also be used to connect risers of different diameters;

- budget. The price of the seals is so low that it is completely affordable for the average citizen.

The negative aspects include the fact that in order to mount the cuff in the right place it is necessary:

- the presence of sockets at the ends of cast iron pipes;

- bring the inner surface to almost perfectly flat and smooth.

A sealing collar is necessary when connecting the siphon to the sewer system. You need to remember that you should first start assembling the siphon itself, and only after that – connecting the device to the main line.

Which pipe winding is better: flax or FUM tape

As a rule, when they talk about winding and sealing pipe joints, they mean winding for water pipes. If you install steel pipes for cold water, then neither flax nor FUM tape will have any advantages. All that is required is to wind the material correctly. But when a similar water supply system consists of plastic or metal-plastic devices, then it is worth giving preference to FUM tape. The main advantage will be speed. Since a plastic pipeline is installed faster than a metal one, it is not advisable to reduce the pace due to laying. Flax will require significantly more time. FUM tape is also more effective on smooth and neat threads of plastic fittings. Moreover, if the diameter of the connections exceeds 20 mm, then the quality of sealing will be higher with linen winding.

As for the installation of pipes for hot water supply, there are subtleties and requirements that also apply to sealing. In a hot water supply, the winding of joints is influenced not only by the water itself, but also by its temperature. But FUM tape does not react the best to the influence of temperature. The principle of its operation is such that during packaging it splits into fibers, which clog the voids, preventing water from leaking. However, when the temperature rises, these threads begin to shrink, which in a fairly large number of cases leads to a violation of the tightness of the joint. Linen winding does not have this disadvantage and tolerates temperature increases well.

As for the other properties of these materials, it is necessary to note the difference in price. Linen will be cheaper, even taking into account the necessary impregnation. FUM tape is not much more expensive, but if you plan on extensive installation, this difference can be significant. But, as mentioned above, connecting pipes using FUM tape will be faster.

Not so often, but it happens when both of these types are used. Several turns of FUM tape are laid with linen winding. Or vice versa - a couple of turns of flax are wrapped with FUM tape. This decision is made by plumbers on site, based on the operating conditions of the pipe and pipeline installation.

The last thing worth mentioning is that using linen winding requires some skill. FUM tape is much easier to use.

Properties of sealing elements and materials of manufacture

For sealing to be effective, cuffs must have the following properties:

- elasticity;

- elasticity;

- ability to withstand temperature changes within certain limits;

- strength and long service life.

Rubber products fully possess these properties, therefore sealing couplings and cuffs for sewage pipes and transitional shaped elements are made of varieties of this material, such as:

- the actual rubber;

- paronitis;

- rubber;

- silicone

Sometimes manufacturers add polymer substances to the rubber composition, which makes rubber seals for sewer pipes more rigid, less convenient during installation work, but at the same time wear-resistant and durable.

Some types of cuffs, for example those that are equipped with adapter couplings for connecting the toilet flush to the sewer pipe, are made of polyethylene. In conditions of large diameter connecting holes (at least 110 mm) often of irregular geometry, this material demonstrates better tightness and wear resistance (rubber cuffs after dismantling have to be replaced with similar ones).

Anaerobic adhesive sealant

The latest generation of sealant hardens only after twisting and hardens within 20 minutes.

The viscosity, hardening speed and fixation strength of the compositions vary. The thinner the glue, the smaller the thread it is designed for. The connection, mounted using a strong anaerobic sealant, can be disassembled only when heated.

Advantages:

- fastest installation;

- assembled without keys, with just one hand;

- fills the entire inter-threaded space;

- when tightening, no distortion occurs, the load on the thread is transferred evenly;

- before setting begins, adjustment to any angle is possible;

- the connection does not have to be tightened, as is the case with flax, ribbons or thread;

- there are no protruding parts of the seal;

- protects against corrosion;

- resistance to increased water pressure.

Flaws:

- the most expensive seal;

- the junction must be perfectly clean and grease-free;

- You can use the water supply only after the sealant has cured;

- difficult disassembly of the connection;

- after heating during dismantling, a leak may occur at the junction of dissimilar materials;

- Gets your hands dirty.

Used for assembling new threaded connections made without the use of lubricant. Anaerobic sealant for water supply pipes is convenient for installing connections in hard-to-reach places. Considering the complexity of disassembly, it is better to use for units that are not planned to be disassembled.

About bellows connections for mixers

Flexible connections to faucets have different options. One of the most popular is bellows-type eyeliner. It has a number of advantages in comparison with other similar devices.

4.1. Advantages

Among the many positive characteristics, the following can be highlighted:

- made from high quality stainless steel;

- reliably protected from water hammer;

- high-quality operation is possible for a long time;

- resistant to possible sudden temperature fluctuations, can fully function at temperatures up to 230-250⁰C;

- hygienically clean, safe for health, device;

- does not burn.

4.2. Flaws

There are several negative aspects associated with the use of bellows liner:

- the appearance of hum, noise, vibration processes of corrugated tubes;

- When several consumers are connected simultaneously, increased vibration is observed.

Interestingly, the larger the diameter of the liner, the less the hum becomes. Excess noise disappears with plastic sleeves.

The option of eyeliner with non-toxic rubber braid is also quite popular.

If the sewer line becomes clogged, residents of the lower floors will suffer from contaminated water that pours out through the toilet or bathtub. This problem can be solved quite simply: install a check valve. This device can only pass wastewater in one direction and eliminates the possibility of the medium moving in the opposite direction. The principle of its operation is the same as a similar brass device that is used in drinking water lines.

Application

Rubber seals are a ring with a circular cross-section. During installation, it is usually placed in a special landing groove. Such products are made from synthetic rubber and similar materials. The sealing effect is achieved through both axial and radial compression of the product.

Rubber seals are widely used; they are used when installing the following types of pipelines:

- Sewage systems;

- Storm water drainage systems for melt and rain water;

- Domestic plumbing systems. Note that most of the pipes for installation of this system are already equipped with rubber seals;

- For industrial pipelines, the installation of which is carried out using flanges;

- For oil and gas pipelines.