Drainage pipes (drains) are considered the main component of deep drainage, which is a structure for draining an area by drainage. The system has the form of pipelines laid with a slight slope towards the water intake. Its work allows you to protect territories, buildings and any structures from excess moisture, which can cause damage to them.

Why is a drainage system needed?

The construction of any facility should begin with a study of the soil characteristics and the level of groundwater. If you do not carry out a set of measures that will allow you to drain excess water from the soil, then the following negative processes may occur:

- subsidence or destruction of the foundation;

- freezing of the walls of a residential building;

- flooding of basements and cellars;

- the formation of mold and fungi on the surface of walls and floors (the microclimate inside such a room is very harmful and can cause allergic reactions and respiratory diseases);

- waterlogging of the land on the site (it leads to the death of plantings);

- icing and accumulation of water on garden paths.

Important! Excessive saturation of the soil with moisture causes a change in its chemical composition and microflora.

Drainage pipe with holes for collecting water Source vse-o-kanalizacii.ru

Types of drains

There is a large selection of drainage pipes on sale. All of them are designed to work in certain conditions. When choosing suitable drains, it is necessary to take into account their operating conditions, the magnitude of the loads and other factors.

If the pipe material is not suitable for the task, water drainage will not be effective enough (or will stop altogether).

Let's look at the features of drains made of different materials:

PVC

Plastic pipes are lightweight, which makes them easier to install during the construction of a private house . However, they are not able to withstand heavy loads. This is especially pronounced in winter, when the temperature drops close to zero.

Vinyl pipes become brittle, lose their elasticity and may break. As a rule, PVC drains are used to remove moisture from shallow levels.

Polyethylene

Polyethylene drains have properties similar to PVC . However, they have an important advantage - when the temperature drops, the material does not lose elasticity and the ability to independently compensate for external influences.

Because of this, polyethylene drainage pipes are used to drain groundwater from deeper horizons.

Polypropylene

Polypropylene pipes have all the advantages of plastic products - lightness, low weight, high speed of installation work. In addition, they withstand loads well and almost never clog , thanks to the smooth surface of the inner walls.

This makes polypropylene drains the most attractive for use in any system, both deep and located closer to the surface.

Ceramic

Ceramic pipes are highly resistant to water. They are durable and resist external loads well . However, they also have disadvantages.

For example, a large weight requires the use of lifting mechanisms during installation, which is not always convenient if there are already buildings or structures on the site. In addition, the assembly of ceramic channels requires a separate seal for each connection. This takes a lot of time and requires experience and skills.

Ceramics are fragile and do not withstand sudden mechanical stress. Another limiting factor is the price of ceramic pipes, which significantly exceeds the cost of alternative options.

Asbestos-cement

This type of pipe is currently practically not used. The reasons for this attitude were:

- the presence of asbestos, which has been widely phased out due to its negative impact on human health;

- high weight of pipes;

- fragility, which often causes breakdowns even at the installation stage.

Asbestos-cement drains do not have perforations, since they have a porous structure. Water is simply absorbed into them through the walls and removed to the discharge points. The durability of asbestos-cement drains does not exceed 30 years, which is too short for a building’s drainage system.

With winding

There are drainage pipes that are equipped with a winding made of coconut fiber or geotextile at the factory. This greatly simplifies and speeds up installation work, since builders only need to lay and sequentially connect drains into a single channel.

The main pipe is usually plastic. The winding forms a filter that protects the internal space from sand, silt and other foreign particles. This increases the service life of the pipes, but requires taking into account the specifics of the soil.

For areas with clay or loam, it is necessary to create a filter layer of sand and gravel around the pipe, otherwise the winding will quickly become saturated with liquid clay and stop letting water through.

Concrete

Concrete pipes are used for drainage mains or large diameter channels.

The minimum size is 300 mm, but in practice drains of 500-600 mm are most often used. Concrete is heavy, so this material is practically not used for laying in private housing construction. Basically, such lines are collected to drain water from industrial facilities . For such conditions, concrete drains are optimally suited; they are strong, durable, and can be cleaned from the inside using special devices.

Metal

Metal is not the best material for drainage systems. Any alloy is somehow susceptible to corrosion, if not ordinary, then electrochemical. An undeniable advantage of metal drains is their high strength. If you use pipes made of non-ferrous metals, the cost of the system will be too high.

These disadvantages limit the use of metal pipes, whose service life does not exceed 40 years (in practice, much less). In addition, the cost of a system of this type will be several times higher than that of plastic drainage.

What should the pipes be like?

Drainage pipes with full or partial perforation are used. When fully perforated, the entire surface has holes located around the circumference at equal distances. Products with partial perforation are water permeable only from the top; they have only 3 rows of holes. In order for the water drainage system to be effective, it is necessary to competently draw up a project and select the optimal type of pipe for drainage.

In areas where groundwater comes high to the foundation, systems must be built to drain it. Pipes for the drainage system are located lower than the ground freezes. Their diameter is determined in accordance with the individual parameters of the site.

The products used must meet the following requirements:

- ensure unhindered flow of water;

- have high mechanical strength;

- internal surface with maximum slip and smoothness;

- with a large flow, they can withstand significant pressure inside;

- able to withstand large temperature changes.

In addition to internal pressure, the drainage pipeline should not bend due to soil pressure or seasonal displacements. When products are made of a material that does not withstand low temperatures, insulation technologies are used.

Insulated drainage pipe Source cabel-set.ru

Important! If there is a possibility of foreign objects entering or clogging, then coarse filters are installed in the discharge system.

To minimize internal pressure, a storm drainage system is installed in the ground along with drainage elements; it is called surface. It is part of the general drainage network and removes water coming from precipitation.

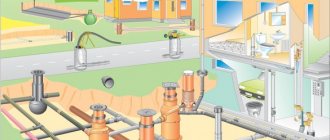

The drainage system consists of interconnected pipes with holes, drainage trenches, wells, connecting fittings and additional elements. Water is collected and discharged through holes in the pipes.

Structural design and principle of operation of drains

Typically, pipes for the drainage system are products made of various types of materials with holes in the shell. Conventionally, they can be divided into two groups - those that collect and transport water from the soil over a certain distance and those that distribute liquid into the ground.

In the first case, drainage pipes have perforated holes on a segment of the pipe shell with a standard filling of 120 or 180 degrees. The pipeline is laid under the ground with a certain slope with the holes upward; water from the soil enters through the perforations inside the pipe shell and is transported along it to the discharge point, which can be a drainage well, an aeration field or a ditch outside the site.

Thus, underground drainage of large areas of land occurs, which, unlike external storm drainage when draining water through surface gutters with gratings, does not spoil the appearance and does not create additional inconvenience when using the site.

When discharging purified or settled sewage in a septic tank into the soil, drains with full circular perforation throughout the entire shell of 360 degrees are used. In many drainage pipe designs, additional outer shells made of synthetic or natural materials are used to prevent silting of the slots and increase the degree of filtration.

Rice. 2 Scheme of drainage of treated wastewater

What you need to consider when installing a drainage system

The installation of drainage networks is carried out after the completion of construction of the main facilities. But in some cases it can and should be installed at the preparatory stage:

- The plot is flat with no minimum slope. Groundwater will accumulate in large quantities.

- The groundwater level is less than 150 cm to the ground surface.

- The main thickness of the soil consists of loamy rocks and clay, which do not allow moisture to pass through well.

- The land plot is located in a region where, according to statistics, precipitation levels are above normal.

The design must take into account the depth of the foundation of the main objects on the site.

Draining water from the foundation using a drainage pipe Source homerenovates.com

Attention! If an object with a buried foundation is built next to a residential building, it can disrupt the natural drainage of groundwater and cause its accumulation. This will lead to flooding of the basement of a residential building.

When there is a concrete pavement around the foundations of buildings, there are many asphalt paths on the site, the natural circulation of water is disrupted. In this case, a stormwater system connected to a drainage system must be installed.

Service

Drain pipes should be periodically checked for dirt accumulation inside and cleaned as necessary. For these purposes, inspection wells are created. The audit should be carried out at least once a year. After heavy rains, floods and floods, it is worth checking the drainage system unscheduled.

Stagnation of water in the inspection well may indicate that it is time to clean the pipes. Dirt, silt, and sand accumulate here.

Cleaning is scheduled to be carried out once every 3 years if the system is installed correctly and has the necessary filters. Otherwise, clean as needed. There are two types of drain cleaning: mechanical and hydrodynamic.

- In the first case, using a pneumatic unit, solid contaminants are crushed and all dirt is mechanically removed.

- In the second, the system is flushed with water and air under pressure using a compressor and pump. The second method is more expensive, but also more reliable.

Types of drainage pipes

All drainage pipes can be grouped according to different criteria. Based on the type of material from which they are made, there are six varieties.

Ceramic. They are made from refractory clays with mineral additives.

Ceramic drainage pipes Source unblocked.to

Asbestos-cement. They are made with a diameter of 10–20 cm. One drainage pipe made of asbestos cement can weigh up to 52 kg. For connections, couplings made of the same material are used. Increasing water permeability is achieved by making cuts in the surface of the pipe, located in a checkerboard pattern.

Asbestos-cement drainage pipes Source expanc.ru

Metal. They have significant weight and can be subject to corrosion.

Metal drainage pipes Source agrisovgaz.ru

Plastic . They are made from low or high pressure polyethylene (HDPE and LDPE), polypropylene, polyvinyl chloride. The presence of corrugated walls and stiffeners allows the external pressure to be evenly distributed.

Plastic drainage pipes Source besplatka.ua

See also: Catalog of companies that specialize in water supply and sewerage.

Concrete. They are difficult to perforate and have a lot of weight.

Made from porous expanded clay glass or plastic concrete. Moisture enters through the pores in the walls.

According to their structure, drainage pipes are divided into single-layer flexible corrugated pipes and double-layer pipes with a corrugated surface on the outside and smooth inside. Some models of the latter have built-in geofabric filter shells with stiffeners that prevent sand from contaminating the holes. Single-layer ones are used for deep burials.

Single-layer flexible corrugated drainage pipe Source aqua-tor.com

Double-layer drainage pipe, corrugated on the outside and smooth on the inside Source pinsk.deal.by

The most popular models are pipes with a diameter of 110 mm with a protective layer of geotextile. They are installed without an additional filtration system.

Drainage pipe with a protective layer of geotextile Source raptorr.ru

Depending on the rigidity, drainage pipes are divided into two types.

Flexible models. Suitable for creating curved flows. Such elements are characterized by lower ring rigidity. Some are sold in reels of 40–50 meters.

Flexible drainage pipe Source resttrade.ru

Rigid drainage pipes. Used for straight laying. They are produced thin-walled with a diameter of 5–15 cm and thick-walled with a diameter of 15 cm. The latter are made up to 6 m long, and when laid they are joined with connectors and rotating elements.

Rigid drainage pipe Source plastipes.co.uk

Ceramic and asbestos-cement

Drainage pipes made of asbestos-cement mixture are 10–50 cm in diameter and 3.95–5 m long. As a rule, such pipes are partially perforated. An asbestos cement drainage pipe is easy to maintain, but due to its excessive weight and complex installation, it is rarely used. The service life is no more than 20 years.

Large diameter asbestos-cement drainage pipes Source izhevsk.ru

Ceramic products are made using kilns. The press produces molding from a sand-clay mixture with the addition of alloying substances. At this stage, perforation is performed. Then the blanks are hardened in furnaces at temperatures up to 1300ºC.

Ceramic drainage pipes, measuring 50–70 cm, are connected with couplings. The diameter of the products is 5–30 cm, length up to 0.3–1.5 m. A ceramic drainage pipe has the following advantages:

- service life up to 30 years;

- resistant to seismic and chemical processes;

- internal and external friction coefficient is minimal.

Ceramic products are actively used in landscape design to drain desired areas.

Laying ceramic drainage pipes near the house Source stroi-baza.ru

Principle of operation

Pipe products for drainage are divided into two types according to their intended purpose - for collecting moisture and for removing it. The collecting elements are equipped with perforations. Holes are created in the pipe body along the entire circumference or in one of the sectors through which moisture enters the pipeline. Such communications are installed at an angle around the drained area or throughout its entire area. They are usually placed near buildings, otherwise excess water can destroy the foundation of the building and cause mold to form on the walls. Excess moisture goes to well structures.

Products for diversion do not have perforations. They have a different operating principle. They are needed to empty drainage tanks. The water goes into collector devices or specially equipped ditches. A characteristic feature of such highways is that they can be buried more than 10 m into the ground.

Pipes are also often laid in storm ditches near the road, connecting them to the general drainage system. This will ensure comfortable passage of vehicles.

An option for moisture-collecting products are models with a filtering effect due to winding with coconut fiber or geotextile. The filters do not allow suspended matter to pass through, preventing the formation of plaque, which increases the service life of the entire system. This is especially important in clayey areas where groundwater contains many impurities.

The main advantages of plastic drainage pipes

Plastic drainage pipes, varieties of which have a corrugated surface, are the most commonly used in modern construction. This popularity is due to the large number of advantages of products of this type:

- service life up to 50 years;

- high resistance to corrosion processes;

- low weight with high strength;

- do not collapse under the influence of aggressive environments;

- easy to transport and install;

- the smoothest structure of the inner surface prevents blockages;

- affordable price.

When using drainage pipes with a geotextile filter layer, regular flushing of the system is not required. For networks with normal and low loads, products with a diameter of 110–200 mm are suitable; pipes with a diameter of 300 mm can withstand increased loads.

Corrugated plastic drainage pipe Source cabel-set.ru

Advice! If pipes with a diameter of 10–11 cm are left from the installation of the sewer system, then drainage can be made from them. The surface is perforated with a drill, then the products are wrapped in geotextile along the entire length.

Types of plastic drainage channels

Several types of plastic drainage channels are produced:

- Corrugated single-layer products with or without holes (HDPE). Models of hardness class SN2 are used at depths of less than 2 m, class SN4 at depths up to 3 m.

- Corrugated two-layer products made of HDPE or LDPE with smooth walls inside. Hardness class SN6, used at depths of less than 4 m. Such pipes are easy to transport and install.

- Corrugated flexible products with hardness SN8 are used for laying at depths of up to 10 m.

- Double-layer corrugated HDPE pipes with a smooth interior, hardness class SN8. The products do not have a filter layer and are used at depths of up to 8 m.

Double-layer drainage pipes are most often used for installation at shallow depths. The smoothness of their internal walls ensures maximum service life and efficient water drainage. The corrugated top layer with stiffening ribs is highly durable.

Double-layer drainage pipe with a corrugated outer layer Source s-narodom.ru

Size range

According to GOST, drainage pipelines are produced in sections of 6 or 12 meters. Flexible options can be longer and are rolled into coils. Products are also distinguished by diameter - 110, 160, 200 mm.

For systems with high loads, pipes with a large cross-section are produced - up to 300 mm.

In a small area with low groundwater, products with a minimum diameter can be installed. But if the drainage consists of many branches, even in a small area it will be necessary to use both large and small sections of the pipeline.

Video description

Watch the video of the types of drainage pipes:

PVC products

The use of pipes of this type is typical for the installation of a surface system. Models with a diameter of 5–30 cm are produced, with corrugated single-layer or double-layer walls. Most products are perforated. PVC pipes are easily connected to the pipes of wells made of concrete and plastic. Connecting elements are used with snap mechanisms.

Installation of networks from such pipes is simple and quick, but it is necessary to install a cushion of crushed stone and a geotextile protective layer. Products are produced with hardness classes SN 2,4,6,8,16.

An example of installing a PVC drainage system Source gid-str.ru

HDPE drainage pipes

The physical characteristics of HDPE products ensure their use in any networks. Different types of pipes have hardness SN4 and SN8. Depending on the structure, there are HDPE products with one or two layers; there may be a perforated pipe for drainage or without perforation.

The diameter can be 5–70 cm; pipes with a maximum diameter can withstand heavy loads. To install the drainage system, sockets, couplings or welding are used.

When giving preference to these drainage pipes, it is worth remembering that the material used in the production of HDPE products is flammable.

HDPE drainage pipes Source trubamaster.ru

Famous brands

Nowadays, the domestic construction market offers a large selection of drainage pipes. In our country, they are produced by the companies Ruvinil, Nashorn, Politek and others. Popular brands of pipes include:

- Perfokor - drains with a double wall, so they are very durable. Products are produced both in coils and in sections with a stiffness class from SN4 to SN8. Pipes with a diameter of 110 to 160 mm are connected with ECOPAL couplings without O-rings.

- Korsis are double-wall corrugated pipes produced by Poliplastik. Enterprises of this brand operate not only in Russia, but also in the CIS countries. In addition to drains, this brand produces shaped parts for connecting them.

- Pragma - products are used in the construction of storm, municipal and industrial drainage. They are made from polypropylene, which can withstand extreme temperature changes and is shock-resistant. In addition, drains made of this material are easy to cut and connect to each other. It is possible to install them with HDPE and PVC pipes. Installation of Pragma products is carried out manually, which provides clear savings during construction work.

- Softrock - products are manufactured using the technology of the company of the same name. Perforated pipes are made with polystyrene foam filler. The products are laid without the use of crushed stone, which reduces construction time and increases the efficiency of drainage.

Among foreign manufacturers, Polieco, Uponor, Wavin and Rehau are especially famous.

How to determine the slope of pipes

The slope of the drainage pipe depends on various factors:

- diameter of the pipes used;

- types of drainage system;

- features of the surface of the local area.

If you make the calculations incorrectly and choose an angle larger than necessary, then an excessively fast flow of water and the appearance of silt will begin to occur. The system will become clogged frequently.

If the angle is set less than necessary, water will stagnate inside the channel, which will cause it to overflow and stop functioning. Excess moisture will remain in the soil.

Drainage pipe slope levels Source spm-mos.ru

Important! The calculated slope value has a fractional value. It is obtained by dividing the required slope of the pipe by its length, expressed in meters. An indicator of 0.003 will mean that the level of difference in the meter section of the pipe should be 3 mm.

This indicator is prescribed in construction regulations, SNiP. Here are specific values for drainage systems from the standards:

- with a pipe diameter of 200 mm, the minimum angle of inclination is 0.007 m/m, with a pipe diameter of 150 mm – 0.008 m/m;

- the type of covering of the natural area also matters: asphalt - 0.003, paving stones - 0.004, crushed stone - 0.004, large stones - 0.005 m/m;

- for separately placed trays, the optimal indicator is 0.005 m/m;

- for drainage channels – 0.003 m/m.

Installing pipes at an angle is necessary even for land plots with a slope, despite the natural outflow.

Installation diagram of a drainage pipe at an angle Source mdf-pokraska.ru

If this is not done, groundwater will gradually liquefy the soil, reducing its strength. They will similarly affect the foundation of buildings. On sloping areas it is rational to install a combined open and closed system.

Nuances of drainage installation and operation

Nuances of installation and operation of drainage.

Typically, pipeline installation begins during site development. To ensure effective operation of the drainage system, it must be provided with sufficient water flow. To do this, the drains are sprinkled with filtration materials - crushed stone, gravel, small stones.

If this is not done, the drainage will flood and will not work. During operation, it is necessary to periodically check the functionality of the pipelines, as they may become clogged.

The degree of clogging is determined through the inspection well. Cleaning is carried out in two ways: mechanical and hydraulic. In addition, it is advisable to monitor the level and quality of groundwater in the area, as this will help determine the effectiveness of the drainage system.

Determination of drainage sewer parameters

In order for the drainage pipeline to be effective, it is important to make correct calculations of its parameters. The most popular is the ring scheme, when the channels are located along the perimeter of buildings.

The calculations determine the depth of the foundation of the building and the angles of inclination. For any type of materials used in installation, the laying is carried out 0.3–0.5 m deeper than the foundation pad of the building. The recommended channel drop at the drainage point should be more than 1% per meter of pipe.

In what cases is a drainage device necessary?

All of the above problems associated with high soil moisture can be eliminated or prevented with the help of a properly designed drainage system that promptly removes excess moisture outside the site or into a special container. There are a number of signs that clearly indicate the need for drainage:

- after rain, puddles and dirt remain on the site for a long time;

- garden trees and house plants die for no apparent reason;

- intensive mold formation in basements;

- the soil remains moist even during short-term droughts;

- a large number of weeds that love moisture, for example, nettles or cattails;

- location of the site in a wetland or near a body of water.

Important! There are signs by which it can be clearly determined that groundwater flows no more than 1.5 m from the ground surface. With such a depth of the aquifer, a mandatory drainage system is required

Video description

For more information about drainage systems and the rules for their installation, watch the video:

In ring systems, the distance of the upper parts of the trenches from the foundation or walls of the house should be at least 3 m. The concrete blind area around the walls of the building should be no less than 1 m.

When carrying out calculations, the lowest point of the system is first planned where water will be discharged. Based on the obtained value, the depth of laying the upper part of the channel is determined. Measure the distance of the highest point from the bottom and set the slope to 1%.

The upper point, as a rule, is located at the level of the corner of the building, and the lower one at the installation site of the collector well.

For systems where it is impossible to install a well at the required depth, it is recommended to use drainage pumps that will forcibly pump out the incoming water.

Diagram of a drainage system with a pump Source kanalizaciya-expert.ru

Stages of network installation work

Before installation work begins, the site is marked out, indicating the location of drainage channels. Taking into account differences in heights, recesses for the trench are prepared.

Preparation of trenches is the first and very important stage of work on installing a drainage system

The main task of the ditch network is the unhindered and rapid outflow of water.

Note! To check, you can run a certain volume of water and make sure that it does not accumulate in certain areas.

Before installing the drainage pipe, the bottom of the trench must be thoroughly compacted. Next, filter material is laid, the ends of which should extend beyond the ditch, as well as river sand and crushed stone to a maximum thickness of 20 cm.

Drainage pipes are cut with a jigsaw or pipe cutter and connected with fittings. When they are wrapped with geotextile, the joints are secured with thin wire or rope. In addition to throughput, the function of the filter material is to protect the perforation holes from clogging.

When laying pipes, a slope is maintained, and their ends are connected to inspection wells. Wells are divided into 2 types:

- sealed - allow the collected water to be used for technical purposes;

- absorbent - to drain water back into the soil.

The surface of the pipe is covered with an absorbent layer of sand or crushed stone. At the final stage, the structure must be wrapped in a sheet of filter material and covered with soil.

Sequence of installation of the drainage network

Work on installing the drainage system is carried out in the following order:

- The site is marked, the locations of drainage channels are determined.

- Trenches are dug for rectangular or trapezoidal pipes. Their width should be 0.4 m greater than the diameter of the pipeline. The distance of the trenches depends on the type of soil.

- The bottom of the trenches is compacted.

- Layers of sand and crushed stone are laid down. The thickness of the layers must be at least 0.2 m. For systems where pipes without filters are used, it is necessary to lay filter geotextiles on a crushed stone bed.

- The pipes are cut to the required length and laid in trenches using connecting fittings. Partially perforated pipes are laid with the holes facing down.

- The pipes are wrapped in geotextile, which is secured with a cord.

Laying drainage pipes in a trench Source sbagry.com

- The ends of the pipeline are led to inspection wells, which will allow the collected water to be used for technical needs or distributed back into the soil.

- The laid channels are backfilled with crushed stone and sand, the thickness of the layers is at least 0.2 m.

- The ditches are completely filled with soil.

With the right choice of materials and high-quality installation, the service life of the assembled system will be up to 50 years.

Elements for storm drainage

In a storm drainage system, liquid is drained by gravity, i.e. no external compression action is applied. Therefore, there are no special pressure requirements for such a sewer network. Only one strength parameter is important here - the storm drainage, when buried, must withstand the weight of the backfill.

There are also minimal requirements for the thermal resistance of products. Operation of the storm drain does not occur at high temperatures. The only condition is that the drains should not lose strength in winter, at negative temperatures. In a well-designed and installed storm drainage system, moisture will not stagnate. Therefore, there will be no risk of network freezing.

When the underground method of laying pipes is used, they are exposed to aggressive chemicals that are dissolved in water or located in the ground. Based on this, the most important condition for choosing drainage elements is their inertness to such compositions and resistance to corrosion.

The most important quality of a storm network is its throughput . The required drain cross-section is determined at the system planning stage. Most often, elements with a diameter of at least 11 cm are used for drainage.

Watch the video

How to choose a drainage pipe

Another condition for the effective functioning of storm sewers is the lowest possible level of hydraulic resistance inside the pipes. The walls of the products should be as smooth as possible. Then almost no dirt and debris will settle on them.

The length of storm drains can vary. However, it is best to choose elements with the maximum length. This way you will reduce the number of interfaces in the system - this will increase its efficiency and reduce installation costs.

Selection of drainage products for groundwater drainage

The foundation of buildings can be washed away by subsoil moisture at depths of up to 2 meters. At the same time, substances that contribute to the destruction of building materials may be dissolved in groundwater.

Waterproofing can help little in this case. The best option is to bury the drainage pipeline. When designing it, it is necessary to take into account the type of soil and its level of moisture.

Increased liquid content in the soil leads to freezing, rotting, diseases of plant crops, and waterlogging of the farmstead. To prevent this from happening, for drainage it is necessary to choose corrugated products made from low-density polyethylene.

The optimal types of pipes for different types of soil are presented in the table:

| Soil type | Recommended pipe type |

| Crushed stone | perforated products not wrapped in filter textiles |

| Sandy, sandy loam | pipes wrapped in a geotextile filter in a crushed stone embankment |

| Clayey | products without a filter wrapper or with it in a crushed stone embankment 20 cm thick |

| Loamy and combined | products in a filter wrapper made of geotextile material |

Watch the video

Do-it-yourself site drainage | part 1

Drainage pipe manufacturers

Now more and more factories are opening that produce pipes, including for drainage systems. However, most often they use products that are produced by trusted and well-known manufacturers. Among Russian companies these are:

- SK-Plast;

- Corsis;

- Polytek;

- Ruvinyl;

- Nashorn;

- Perfocor;

- Kama-Polymer.

Among foreign manufacturers, the products of the following companies are in demand:

- Rehau (Germany);

- Wavin (Netherlands);

- Uponor (Italy);

- Ostendorf (Germany);

- Polieco (Italy).

In fact, the technology for making drains is the same everywhere. Therefore, all factory products have approximately the same quality. The only difference is the cost of the products.

Do-it-yourself drainage pipe installation

Before laying the drainage structure, it is necessary to calculate it and select the optimal type of pipes. The project will require a site plan. As well as geodetic data, they can be obtained from the regional land use department:

- Seasonal depth of subsoil water.

- Features and structure of the soil.

- The average annual volume of precipitation and flood moisture falling on the site.

Knowing these parameters, professionals will carry out the necessary calculations and determine at what depth to bury drainage pipes and their diameter.

Watch the video

Site drainage. Tips and recommendations // FORUMHOUSE

The arrangement of a network for drainage of liquid is carried out as follows:

- First of all, the courtyard is marked out according to a plan drawn up in advance. The cords are pulled along the marked lines.

- A trench is dug along these axes. Its depth is determined by the calculation performed. To find out the width of the ditch, 0.4 m is added to the cross-section of the pipes.

- Before making a ditch, it should be taken into account that the slope of the pipeline must be at least 3 degrees towards the inspection wells.

- A cushion of river sand (10 cm thick) and crushed stone (20 cm layer) is poured along the bottom of the dug ditch. All this is carefully compacted.

- Next, drainage pipes are installed on the bedding to drain groundwater. They are first wrapped in geotextiles.

- If necessary, the water drainage elements can be sawed with a hacksaw. Couplings should be used to connect parts.

- After installing the structure for draining groundwater, it is necessary to check that it is tilted correctly. For this purpose, a construction cord is stretched along it.

- Where the outlet ditch turns and where the angle of inclination of the pipeline changes, inspection wells should be installed. They must be closed with lids to prevent clogging with debris. Wells serve to control and clean the structure.

- At the final stage, the deep drainage is covered with backfill. Crushed stone is scattered on top of the pipeline, then a layer of sand follows, and lastly the excavated soil is placed. All layers are carefully compacted.

The structure is discharged into a ditch, a nearby reservoir or storm drain. A check valve is installed at the end of the outlet pipe. When it is impossible to arrange such an exit, a storage well is installed. When it is completely filled with water, it is pumped out using a pump.

When arranging drainage to drain liquid on a site, do not forget that the entrance to it must also be equipped with a pipe. There, it will be necessary to bury a product with maximum annular rigidity in the ditch.

When installing a drainage system, you should avoid making mistakes that could lead to disruption of its operation. The most common of them:

- Insufficient drainage depth. This may lead to a disruption in the water balance of the area.

- The use of liquid drainage products that are not suitable for the site conditions. This leads to a rapid shutdown of the network.

- Incorrectly selected network slope angle. This will lead to problems with groundwater drainage on the site.

Cleaning the drainage system

When maintaining a structure for draining groundwater, it is necessary to periodically check whether it is clogged or damaged. When problems arise, they are promptly resolved.

You should also regularly check the level of subsoil water in the courtyard of the site. This way you will be aware of how effectively the drainage copes with removing excess fluid. Thanks to timely preventive and repair measures, you will be able to not only extend the life of the drainage, but also prevent the risk of accidents.

The drainage structure should be washed regularly. This way you will stop it from clogging or get rid of it if it has already happened. For maximum washing efficiency, it is necessary to choose the method that will be most suitable in each individual case. There are three such methods in total.

The first one uses an ordinary watering hose. It is inserted into the drainage pipeline and supplies water jets under pressure. They wash away deposits and blockages from the inner walls of the network.

The garden hose is flexible and the water pressure from the household tap is not too strong. Therefore, this method is used to clear minor blockages in short sections of the drainage network.

The second washing method uses a compressor. It is more effective than a regular hose. It supplies mixed air and moisture inside the drainage structure. They effectively and quickly clean the network from the inside. When using a compressor, it is possible to regulate the pressure. Therefore, this method can be used in most cases of blockage.

The third method is hydrodynamic. It uses a compressor pump and a hose with special nozzles. With their help, water is supplied into the drains under strong pressure. Its jets cut deposits from the pipe walls. The system is then flushed under high pressure to remove any remaining dirt. This cleansing method is the most effective.

By choosing any of the three methods above, you will need to gain access to both sides of the drainage branch. Jets of water will flow from one end, and its removal will be ensured from the other.

Application of pipes in air conditioning systems

The products have expanded use; they are actively used in air conditioning systems to remove condensate formed on the internal parts of air conditioners. Moisture is removed to the sewer network or to the street. At the same time, the connection with the sewer allows you to get a completely autonomous system.

Using a drainage pipe to remove condensate Source trubamaster.ru

Such systems use plastic products that are moisture resistant, durable, and have high throughput. Their surface can be smooth or corrugated. The first ones have a low cost, but require connecting elements at the corners. Corrugated pipes are more flexible and easier to assemble.

Ceramic and asbestos-cement products

Ceramic drainage pipe is made from a special type of clay using the firing method. It is distinguished by durability and strength. The molding of a pipe from quartz sand, alloying components and clay is carried out on a press. At this stage, the body of the product is perforated. Next, the workpiece goes through the hardening stage in a furnace at 1200-1300 ºС.

Finished products have a length of 30-50 centimeters, a diameter of 5-30 cm and are characterized by a low coefficient of friction both inside and outside. The latter quality makes it difficult to equip ceramic channels with a filter.

Asbestos-cement drainage pipes are used extremely rarely due to their large weight, which is almost one order of magnitude higher than plastic or ceramic analogues. Its service life is no more than thirty years.

The installation of drainage sewerage using ceramic or asbestos-cement pipes is complicated by difficult installation work. Significant material resources are spent on installation, manual perforation of products is practically impossible, and the process itself is slow. The finished drainage system has low performance characteristics.

Common system installation mistakes

Carrying out incorrect calculations and choosing poor materials can completely disrupt the functioning of the system. The most common mistakes made are:

- The type of soil is not taken into account when choosing the type of pipeline.

- Absence or incorrect calculation of the angle of inclination of the channels.

- The system does not provide for the drainage of collected water from the well into a natural reservoir or sewer.

- Absence or insufficient layer of filter filling, geotextile.

- There are no holes in the pipes.

- Poor installation.

How does soil type affect?

The type of soil is the main criterion for choosing drainage pipes. It determines the degree of moisture saturation, the rate of water distribution, and the possibility of silting of the drain surface.

Selection rules:

- for sandy soil, fabric-wrapped pipes with gravel backing are required (minimum 30 cm around the pipe);

- on clay soils, drains without wrapping are used, but with crushed stone backing (fraction up to 30 mm);

- Wrapped pipes are laid on loams; bedding can be dispensed with;

- on chernozem a layer of bedding is required around drains without a filter;

- for rocky soils, the use of perforated pipes without additional elements is allowed.

Before purchasing and laying drainage, it is necessary to conduct reconnaissance and find out the composition of the soil layers in this area.

Do-it-yourself step-by-step installation

To perform the installation correctly, you need to understand how the drainage pipe works and how the entire system functions.

Materials and equipment you will need:

- perforated pipes;

- components and connecting fittings;

- roulette;

- shovel;

- geotextile;

- crushed stone fraction 20-40 millimeters;

- sand (10 millimeters);

- gravel (16 millimeters).

The bottom of the trench is compacted and sand or crushed stone is poured. Then a geofabric is laid, which is sprinkled with a 20-centimeter layer of gravel.

The pipes are cut to size and connected according to the diagram using fittings.

At the turns of the highway, inspection wells are installed to determine whether drainage pipes need to be cleaned or not. The pipes are placed on gravel, providing a 2-3 cm slope for each linear meter. A layer of gravel is poured on top, on which geotextiles are laid. The trenches are filled with sand and earth taken from the ditches. This completes the do-it-yourself drainage installation.

Criterias of choice

When purchasing a pipe for driving through a ditch, you should take into account the following indicators:

- Ability to withstand heavy loads. Trucks and special equipment can enter the construction site, so such a product must have high mechanical strength to withstand the pressure of heavy vehicles and embankment material weighing several tens of tons.

- Trench dimensions. The volume of passing wastewater directly depends on them. To ensure that the drains do not erode the embankment, but completely leave the ditch, the pipe must be of a suitable diameter.

- Cost indicators. There are many types of pipes on the construction market that can be used for laying in ditch. The choice often depends on the financial capabilities of the owner.

Filter layer

Typically, a drainage system is constructed in a filter layer, which consists of two layers of different materials: geotextiles and crushed stone. The first forms external protection, the second internal. This is how they are arranged - first, geotextiles are laid in the trench, a layer of crushed stone 15 cm thick is poured into it, a pipe is laid on it, then another crushed stone layer and all this is wrapped with the ends of the geotextile. This results in a multilayer structure.

In a geotextile shell

Today, manufacturers offer ready-made drains, wrapped in filter material, which uses the same geotextile or coconut winding. To determine which one is better, you need to understand that geotextiles are a non-woven fabric made of polyester, that is, an artificial material based on a polymer. Therefore, it has a long service life. At the same time, the polymer material easily tolerates various loads, it does not rot or corrode.

In this regard, coconut winding is inferior in many respects. It has a short service life and can only be used in sandy soils. At the same time, the throughput of coconut fiber is 700 microns, and that of geotextiles is 450÷700 microns. That is, in many respects the second material is better. Therefore, if there is a choice, then it is better to give preference to geotextiles.

In a coconut shell

Design Features

The efficiency of the drainage and wastewater disposal system on the site is inextricably linked to the features of the project

When choosing or creating a project yourself, special attention should be paid to the following parameters:

- depth of installation of drainage pipes;

- minimum distance between trenches intended for laying pipes;

- slope of drainage channels;

- the topography of the area where the drainage system will be installed;

- depth of aquifers;

- physical and technical properties of the special materials used.

The method of installing the drainage system is selected taking into account the geological properties of the soil at the work site. The maximum distance between equipped drainage channels should not be more than 11 m for clay soils. If work is carried out on sandy and sandy loam soils, this distance can be increased to 22-25 m. In general, the distance between the channels is inextricably linked with the depth of the drainage trench.

Important! It is advisable to select a place for drainage of drainage water in advance. For these purposes, the nearest ravine or reservoir can be used, if there is one in the immediate vicinity of the site

The depth of the ditch intended for laying the pipe should be in the range from 0.5 to 1.2 m. This value is determined by a number of factors: the magnitude of the slope, the size of the area, its topography and other objective features. The slope for each linear meter of pipe should be in the range from 15 to 20 mm.

The throughput of a pipe is determined by its diameter. The smaller the pipe diameter, the greater the slope required to increase throughput characteristics. In addition, a small diameter drainage pipe is more susceptible to clogging.

To install any type of drainage system, you will need the following tools and building materials:

- gravel;

- crushed stone or pebbles (preferably of different fractions);

- sand;

- coconut fiber;

- set of perforated pipes;

- set of drainage wells;

- shovel.