1

Various types of fire-fighting shut-off valves are installed on external fire water supply systems and internal fire-fighting water supply systems (ERW). According to the Code of Practice SP 10.13130.2009 “Fire protection systems. Internal fire water supply. Fire Safety Requirements”, residential, administrative and public buildings and premises are equipped with such systems.

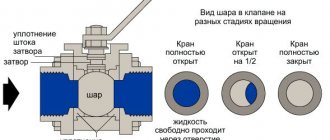

Gate valve design:

A gate valve

is a type of shut-off pipeline valve designed to shut off a non-aggressive working environment, mainly with high temperatures and pressures.

The shut-off element

in the valves moves perpendicular to the axis of the flow of the working medium.

The flow

is blocked due to the translational-rotational movement of the spindle, which moves the wedge from the upper position to the lower one.

Unlike taps and gates, which open when the spindle is turned 90°, gate valves are multi-turn fittings. Smooth gradual blocking of the flow ensures the absence of sudden pressure changes, and smooth opening prevents the occurrence of water hammer. It is because of these properties that valves are used primarily in main technological and transport pipelines with diameters from 15 to 2000 mm. Based on the design of the shut-off element, valves can be divided into wedge and gate valves. In wedge gate valves

, the seats in the body are located at a slight angle to each other, and the gate is a device in the form of a wedge - rigid, elastic or double-disk, which in the “closed” position fits tightly into the space between the seats. Over time, the tightness of such a valve may be compromised due to strong friction in the extreme closed position.

Gate valves with rubber wedge

are a modification of wedge valves. Valves with a rubber wedge have a smooth full passage, so that at the moment of shutting off the working flow, there is no strong friction. The rubber-coated wedge of the valve is designed to ensure high levels of tightness and strength, as well as uninterrupted operation of the shut-off valves, even with sudden changes in temperature. Another feature characteristic of valves of this type is low control torques.

Gate valves

are a type of parallel valve. Slide valves are used in cases where a one-way direction of flow of the working medium is allowed and high tightness of the shut-off element is not required. They are intended for installation as shut-off devices on pipelines transporting sewage, sludge and other media contaminated with mechanical impurities. Sometimes the valve is made with a knife type to destroy particles in the working environment; in this case, the valves are called knife gate valves.

The location of the running unit is of great importance for the operation and scope of application of the valves. It can be located inside the valve in the operating environment or outside the body cavity. In other words, there are valves with a rising stem and a non-rising stem.

Types of fire shut-off valves

The design of fire water supply systems and fire-fighting water supply systems is carried out in accordance with SNiP 2.04.01-85* and SNiP 2.04.02-84*. The code requires the installation of fire shut-off valves in the following locations:

- At each input to the internal network;

- At the base and at the top of the risers, looped vertically;

- On a ring distribution network - to disconnect sections of it during repair work.

Fire-fighting shut-off valves on supply and inlet pipelines must be equipped with a light indication informing about the position of the shut-off valve.

The following shut-off valves are installed in fire protection systems:

- Fire shut-off valve (valve) with a nominal diameter of DN 40, 50 or 65 mm - as a component part of a fire hydrant;

- Butterfly valve;

- Valve.

A number of requirements are put forward for fire extinguishing shut-off valves, formulated in the relevant GOSTs and other regulatory documents.

Rising stem valves:

In rising stem

The spindle thread and the running nut are located outside the valve body. The lower end of the spindle is connected to the shutter and when the running nut is rotated to open the valve, it makes only translational movement together with the shutter, while the upper end of the spindle extends by the amount of stroke of the shutter. To allow movement of the spindle, the running nut is raised above the top of the cover (that is, above the stuffing box) by approximately the amount of stroke of the shutter in a design called a yoke assembly.

The advantages of this design are the absence of harmful effects of the working environment on the running unit and free access for its maintenance, and therefore less wear of the gland seal and higher reliability of the threaded pair and gland. The disadvantage of such valves is the increase in construction height and weight due to the spindle coming out of the cover by no less than the diameter of the passage, and for this reason, during installation, it is necessary to leave free space for the spindle to come out.

Fire damper with electric drive

The high requirements for reliability of an electrically operated valve used for fire extinguishing are understandable. Having received a signal from a button near the fire hydrant, or from fire-fighting automatics, the electric drive must immediately open the valve, ensuring the supply of water.

An electrically operated fire water pipeline valve will supply water as quickly as possible. Remote control of the fire valve allows you to do this without direct access to the fittings, which is especially important in a fire situation.

Non-rising stem valves:

In valves with a non-rising stem

the running thread is located inside the valve cavity and when opened, the spindle does not move out of the cover, maintaining its original height position. The running nut in these valves is connected to the shutter and, when the spindle rotates to open the passage, it seems to be screwed onto it, dragging the shutter along with it. In valves with a non-retractable spindle, the running assembly is immersed in the working environment and is therefore susceptible to corrosion and abrasive particles in the working environment, access to it is closed and there is no possibility of maintenance during operation, which leads to a decrease in the reliability of the running and stuffing box units.

In this regard, such valves have limited use - for pipelines transporting mineral oils, oil, water, which are not clogged with solid impurities and do not have corrosive properties. Since valves with a non-rising spindle make it difficult to observe and maintain the running gear, they are not recommended for critical facilities. The advantage of this design is the lower construction height, which makes it advisable to use them for underground communications, wells, oil wells, etc.

Main advantages of valves:

- comparative simplicity of design, low hydraulic resistance;

- relatively short construction length;

- the symmetry of the valve allows the working flow to pass in any direction;

- possibility of use in various operating conditions, high tightness;

- well-free installation, long service life under adverse conditions;

- the ability to repair and replace components when they break or wear out;

- low torque when controlling an electric drive;

Areas of application for valves:

Valves are used primarily in main pipelines, in housing and communal services systems, gas and water supply, oil pipelines, energy facilities and many others, to shut off working environments with high temperature and pressure.

Masterprom company sells valves

, classifying them

by areas of application

: heating, heat supply and hot water supply, cold and drinking water supply, sewerage and wastewater disposal, fire fighting, paper and pulp industry, pipelines of petroleum products, abrasive materials, industrial liquids. Manufacturers of valves Jafar, Stafsjo, Hawle, Orbinox, MZTA, Granard have been on the pipeline valves market for quite a long time, product quality and delivery times are justified by reasonable prices, all products are certified and comply with international standards.

Automation of valves, additional equipment:

Using its own production capabilities and developments, the Masterprom company offers its services for the automation of pipeline fittings

— installation of electric drive equipment of imported and Russian production. To connect the electric drive and manually operated valves, special docking assemblies are used for valves with a rubberized wedge, and worm-bearing assemblies for gate valves with a sliding stem.

It is also possible to extend the rod

valves in cases where installing an electric drive directly on the valve is impossible, for example, due to a narrow well. The SHFV series of rod extensions (fixed-length rod for valves with a retractable spindle) allows you to install the actuator at a height of up to 3500 mm, the SHTN series of rod extensions (telescopic rod for valves with a non-retractable stem) allows you to adjust the mounting point of the electric actuator within 500 mm with a maximum height of 3500 mm.

To automate the wellless valve, the Masterprom company has developed a special control column that allows you to install the electric drive at a height of 500 - 800 mm above the ground.

Features of use

The need to use fire-fighting shut-off valves in general and electrically operated fire valves in particular is prescribed in the rules and requirements for equipping industrial, commercial, commercial, entertainment and other public facilities. Such products are usually one of the key elements of the internal water supply system and can be used (wedge version) in various outdoor installations:

- automatic;

- water;

- foam.

The main difference between a fire damper with an electric drive and any other is its red color.

Requirements

A fire extinguishing valve is an element without which it is impossible to supply water to quickly eliminate the source of fire and bring the fire under control, therefore the most stringent requirements are put forward for it and the conditions of its operation.

- Fire damper with electric driveused in the fire protection system of any facility must:

- be made of a reliable, corrosion-resistant material (usually stainless steel or durable cast iron);

- have a quality certificate;

- be designed to work with filtered water or liquid with active additives;

- show operating efficiency with irregular and infrequent use of the water supply.

- The connection of fire valves is carried out strictly according to the agreed project, which provides for the installation of shut-off valves in all public buildings (apartment buildings, factories, industrial enterprises) with the installation of electric fire valves on each floor.