Among the pipe designs used in industrial enterprises, the Venturi pipe can be singled out. It differs significantly from chimneys and has its own special characteristics. This structure takes its name from the Italian hydraulic specialist Giovanni Battista Venturi and is based on a steel structure with a circular cross-section, manufactured by welding. Using such a flow meter, you can measure the speed and flow rate of liquid and gas flows. If we compare it with other devices that measure losses, it has a neck structure that allows it not only to maintain the pressure value, but also not to significantly reduce its level.

Venturi tube design and purpose

The Venturi tube performs two main tasks:

- it is used to measure the speed of movement of gas or liquid through the system;

- the real consumption of the resource moving through the system is calculated.

A special feature of the pipe structure is its unique neck, which is built into most industrial pipelines. It has a minimal pressure loss when considering similar products. Also, such a design narrows the flow of the transported substance.

So, a Venturi tube (atomizer) is almost an ordinary pipe, but it differs in that a special clamp has been added to its design. In the pinch zone, special nozzles are installed, through which the transported gas is abundantly moistened with water, which increases its speed by 250-350 percent.

Other nuances of the operation of the Venturi pipe:

- water flows enter the gas stream at right angles;

- there is a modification of the pinch in the form of a rectangle, where nozzles are placed along its length in order to reduce the linear dimensions of the jet of supplied liquid;

- Gas purification can be carried out at a level from 20 to 100 mg/m2, and the change in the purification level does not depend on how dusty the gas is initially;

- in fact, the operating principle of a Venturi tube involves changing the efficiency of the system, taking into account the following factors: water flow (optimal value 0.6-0.7 l/nm.sq.) and gas velocity (the higher, the more effective the cleaning);

- the clamp has linear dimensions from 45 to 60 centimeters;

- maximum tube capacity – 180 thousand cubic meters/hour.

The described principle of operation of a Venturi pipe is implemented by assembling it from the following structural elements:

- Cone-shaped entrance to the pipe.

- Cylindrical central segment (neck).

- Cone-shaped outlet from the pipe (diffuser).

At the entrance to the pipe and directly in the central neck segment, special averaging chambers are installed, which allow water to be drained to equalize the pressure in the peripheral parts of the system.

The Venturi tube is suitable for insertion into pipelines with a diameter of 5 to 140 centimeters. The Venturi tube is correlated with the main pipeline in cross section with a coefficient whose value ranges from 0.1 to 0.6. When calculating a Venturi tube before its installation, it is worth considering that pressure losses can range from 5 to 20 percent, and the measurements taken can have an error of 2 to 10 percent.

Design

Pipe example

The design of the Venturi pipe (spray pipe) is a vertical pipe equipped with a pinch (in rare cases it can be horizontal).

In the pinch, the gas is abundantly wetted from the nozzles with water, and its speed increases significantly (2.5-3.5 times):

- Pipe operation diagram

Water jets are directed perpendicular to the gas flow;

- Sometimes the clamp can be rectangular in shape, and the nozzles are located on its long side, which makes it possible to reduce the height of the water jets;

- Gas purification can reach a degree from 20 to 100 mg/m2, and its fluctuations are not affected by the initial dust content;

- The effectiveness of cleaning in a Venturi pipe depends on factors such as water flow (recommended 0.6-0.7 l/Nm3) and the speed of the gas moving in the neck (higher speed improves cleaning);

- The pinch size ranges from 450 to 600 mm;

- Productivity can reach 180,000 m3/h.

The Venturi tube design includes an inlet cone (1), a cylindrical middle part (neck) and an outlet cone (diffuser). The inlet cone and neck are equipped with annular averaging chambers with devices that drain water at the bottom, which allows equalizing the pressure at the periphery.

In the case when the diameter of the pipeline is greater than the final diameter of the diffuser, the pipe is called short, and in the case of equal diameters - long. In accordance with the nominal diameter of the neck, a distinction is also made between processed and untreated necks.

To select pressure at the inlet and outlet, holes are made in the pipe wall. The number of holes is four or more depending on the diameter of the pipe.

Important: in case of a large nominal diameter, it is recommended to connect the holes using a ring connection.

Venturi pipes are used in pipelines with a diameter of 50-1400 mm. In this case, the ratio between the neck cross-section and the pipeline cross-section lies in the range between 0.1 and 0.6. When operating Venturi pipes, pressure losses can be 5-20%, and the measurement error can be 2-10%.

Existing types of Venturi tubes and their classification

When talking about what a Venturi tube is, you need to take into account the structural features of the cone-shaped inlet, on the basis of which the main types of the product are distinguished:

- cast raw cone-shaped inlet , made by melting steel into a special shape and other methods that do not involve processing the pipe inlet itself. The neck segment of the Venturi pipe and the transition between it and the adjacent section are subject to processing;

- the machined cone-shaped entrance is still manufactured using mold casting. All structural elements of the pipe and transitions between them are processed (they can either be rounded or left in their original shape);

- a welded cone-shaped entrance made from a piece of sheet steel, which, as the name implies, is created using a welding machine. Only the neck is processed, and only if it has a small diameter. This is the case when you create a Venturi tube with your own hands without any problems, but you need to have a welding machine and some set of tools for metal processing.

Venturi pipes are also classified according to the length of the diffuser:

- shortened;

- normal.

If we consider the type, design and material of the pipe, we can distinguish the following types:

- solid;

- composite - elements are fastened together using flanges or threaded connections.

It is also worth highlighting a separate type of Venturi pipe under the abbreviation HVPV (high-speed direct-flow gas scrubber). The marking of this type usually includes the cross-sectional area of the neck segment of the Venturi pipe. If the marking contains the designation “01”, then the pipe has been modified and its specific degree of irrigation has been increased.

Specification

Venturi pipes are classified according to the inlet cone: - It can be cast or untreated. They are made in the following way - cast in a sand mold or some other method in which the inlet conical part is not processed. But in this situation, those places where the conical part turns into a cylindrical part are processed.

— The diffuser part is made by casting. In this case, both conical, cylindrical, and neck parts are processed. Transitions between parts are made rounded or not rounded. — The upper conical part can be steel and made by welding. There is another classification - according to the length of the outlet cone: - Shortened. - Normal. The division can be carried out using other characteristics - typical, according to the materials from which they are made, according to the structures of the structure: - One-piece structure. - Composite design. There is also something called a “high-speed direct-flow Venturi gas scrubber.” They have the abbreviation GVPV.

Main characterizing parameters

Venturi flowmeters differ in parameters: - Such a characteristic as the dust content of the gas that is being purified should not exceed thirty grams per cubic meter. — The temperature of such gases should not exceed four hundred degrees. — The amount of water consumed is from half a liter to two and a half liters per cubic meter. — Resistance to gas movement – ranging from six to twelve kilopascals. If the pipe has a circular cross-section, it will consist of an expanding part (diffuser), a tapering part (confuser), a passage, and a pipe with nozzles that supply water for irrigation. Such channels have the following characteristic features: - The length of the passage is calculated by multiplying its diameter by 0.15. - The opening angle for the expanding part is twenty-eight degrees, and for the tapering component - seven degrees. — Tubes can be used in any plane – vertical, horizontal, inclined.

Technical characteristics and functional parameters

The Venturi pipe is characterized by the following technical characteristics:

- the gases being purified can be dusty no more than 30 g/m2;

- the gas temperature for cleaning does not exceed 400 degrees Celsius;

- specific water consumption – from 0.5 to 2.5 l/sq.m.;

- hydrodynamic resistance in the pipe is from 6 to 12 kilopascals.

If we consider a drawing of a Venturi tube with a circular cross-section, then it will necessarily contain:

- diffuser;

- confuser;

- neck;

- fittings for nozzles through which irrigation liquid is supplied.

Other functional parameters:

- the relative length of the neck is equal to its diameter multiplied by a factor of 0.15;

- the confuser opens at an angle of 28 degrees, and the diffuser - 7 degrees;

- during operation, it is possible to install a Venturi tube in any straight pipeline, regardless of its direction;

- in the manufacturing process of the Venturi pipe, steel grades 12X18H10T or VSt are used, and nozzles are made from 08X13.

Device

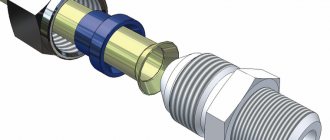

This is a small pipe-shaped device, the design of which provides for the presence of technological sections designed to perform measuring operations. As a rule, the middle, that is, the central part of the nozzle, is tightened with a clamp, from which a special chamber for measurement extends to one side, as well as a hole for taking pressure. On the other hand, the shape of the tube becomes a cone and forms a neck. There are several pressure tapping holes here, as well as a diffuser. Typically, the jet pump is connected on this side either directly or using special plumbing fittings.

Among the design advantages of this product, experts note the efficiency of work in cramped pipeline conditions. However, there is also a significant advantage for inexperienced craftsmen. It consists of a simplified nozzle installation model.

The main advantages and applications of the Venturi pipe

The Venturi pipe, when used as a flow meter (for steam, liquids or gases), has a number of positive qualities:

- There is virtually no pressure loss;

- pipe elements are not clogged with various deposits;

- the measuring planes wear very little;

- the product has high strength;

- producing such a tube is quite simple and not difficult, if we talk about making it yourself;

- the design as a whole is very reliable;

- it has a long service life.

First of all, it is worth mentioning the household use of such a product. A Venturi tube is often found in gas boilers, since it copes with the task of cleaning fuel at the highest level. In industry, one of the most famous units in which this tube is built is the Venturi scrubber - a high-speed gas purifier.

In such a plant, purification is carried out with high efficiency and can eliminate even microscopic particles from the gas. The Venturi tube is also relevant as a structural element of any injector.

Bottom line

The article discusses in detail the features and principles of operation of the Venturi tube. If previously a narrow circle of specialists knew about the features of this product, now anyone who reads this article will easily understand the topic and will be able to understand the essence of the operation of most units: from a conventional gas boiler to more powerful pipelines in boiler houses and other industrial enterprises.

How does a Venturi nozzle work?

The device was named after the Italian scientist precisely because he discovered the effect of reducing pressure when the working fluid passes through a narrowed area. It is on this principle, supplemented by Bernoulli's law, that such tubes operate. In practice, this means that the liquid bypasses the constricted area, during which pressure is taken off in special annular chambers with which the Venturi nozzle is supplied. The operating principle also involves interaction of the outlet channels with direct measuring instruments. For accurate measurements, in particular, a pressure gauge is used, which can be presented either as an analog device or as a digital device.

Advantages of the device

The photo shows some of the features of Venturi pipes. With their help, the technical characteristics of the pipeline are optimized. The products are installed during the installation of flow meters; they have a number of advantages. The drawing developed by specialists is optimized for the needs of production. The Venturi tube has the following features:

- colossal pressure losses are eliminated,

- no blockages,

- minimum wear,

- increased strength,

- ease of installation,

- reliability,

- long service life.

About application

Venturi's characteristics make it possible to expand the range of their applications. Often the pipe is installed when installing a scrubber - a device that represents a gas scrubber. It is used to clean the gas from dust and foreign particles.

Component part

The design is designed in such a way as to increase cleaning efficiency, leaving standard dust collectors far behind. The photo shows some details of the device's operation. The Venturi pipe is also installed when installing injectors - jet-type pumps, with the help of which gas and steam are compressed and the resulting liquid is then pumped into special containers, from where the supply is made. In the process, thermal and kinetic energy are converted into potential energy.

Application

The Venturi tube is integrated into internal combustion engines, feed boilers, irrigation systems, etc. Not everyone knows its name. Even experts do not always know that some chimneys for boiler units are formed according to the Venturi principle.

Areas of application

The design features are due precisely to the non-standard methods of using the nozzle. In particular, fittings of this type have found application in injection units that work in conjunction with the mentioned jet pumps. Such mechanisms are used to compress gas mixtures, liquid vapors, and also to subsequently send them to places with high pressure. The gas cleaning system in some variations cannot do without such a nozzle. For example, the nozzle is equipped with a high-speed gas scrubber, which filters the serviced mixtures from submicron and micron particles. Devices of this type are also used in some thermal and steam boilers, but mainly from the industrial sector.

Varieties

The main differences are structural in nature in the sense that individual technological parts have a special design. For example, a common type are nozzles that have a cast conical part without machining. Such models are produced by injection molding using special sand matrices, and only the rounding of the part and the neck are processed. A more complicated modification is the model, which also provides for pre-treatment of the inlet areas with which the jet pump interacts in different versions. In this case, the central base can be made without special processing.

Fundamental differences from the above-mentioned types have a device made not by casting, but by welding. In this case, the conical part can be implemented in both straight and rounded shapes.

Excerpt describing the Venturi tube

Every time I see a steam locomotive moving, I hear the sound of a whistle, I see the opening of a valve and the movement of the wheels; but from this I have no right to conclude that the whistle and movement of the wheels are the causes of the movement of the locomotive. The peasants say that a cold wind blows in late spring because the oak bud is unfurling, and indeed, every spring a cold wind blows when the oak tree is unfurling. But although the reason for the cold wind blowing when the oak tree unfurls is unknown to me, I cannot agree with the peasants that the cause of the cold wind is the unfurling of the oak bud, only because the force of the wind is beyond the influence of the bud. I see only the coincidence of those conditions that exist in every life phenomenon, and I see that, no matter how much and in what detail I observe the hand of a clock, the valve and wheels of a locomotive and the bud of an oak tree, I do not recognize the reason for the bell, the movement of the locomotive and the spring wind . To do this, I must completely change my point of observation and study the laws of the movement of steam, bells and wind. History should do the same. And attempts to do this have already been made. To study the laws of history, we must completely change the subject of observation, leave kings, ministers and generals alone, and study the homogeneous, infinitesimal elements that lead the masses. No one can say how much it is possible for a person to achieve an understanding of the laws of history through this way; but it is obvious that on this path only lies the possibility of grasping historical laws and that on this path the human mind has not yet put one millionth of the effort that historians have put into describing the acts of various kings, generals and ministers and in presenting their considerations on the occasion of these acts . The forces of twelve languages of Europe rushed into Russia. The Russian army and population retreat, avoiding a collision, to Smolensk and from Smolensk to Borodino. The French army, with ever-increasing speed, rushes towards Moscow, towards the goal of its movement. The strength of its swiftness, approaching the target, increases, just as the speed of a falling body increases as it approaches the ground. A thousand miles away is a hungry, hostile country; There are dozens of miles ahead, separating us from the goal. Every soldier of the Napoleonic army feels this, and the invasion is approaching by itself, by sheer force of swiftness. In the Russian army, as they retreat, the spirit of bitterness against the enemy flares up more and more: retreating back, it concentrates and grows. There is a clash near Borodino. Neither one nor the other army disintegrates, but the Russian army immediately after the collision retreats just as necessarily as a ball necessarily rolls back when it collides with another ball rushing towards it with greater speed; and just as inevitably (although having lost all its strength in the collision) the rapidly scattering ball of invasion rolls over some more space. The Russians retreat one hundred and twenty versts - beyond Moscow, the French reach Moscow and stop there. For five weeks after this there is not a single battle. The French don't move. Like a mortally wounded animal, which, bleeding, licks its wounds, they remain in Moscow for five weeks, doing nothing, and suddenly, without any new reason, they run back: they rush to the Kaluga road (and after the victory, since again the battlefield remained behind them near Maloyaroslavets), without engaging in a single serious battle, they ran even faster back to Smolensk, beyond Smolensk, beyond Vilna, beyond the Berezina and beyond. On the evening of August 26, both Kutuzov and the entire Russian army were confident that the Battle of Borodino had been won. Kutuzov wrote to the sovereign in this way. Kutuzov ordered preparations for a new battle in order to finish off the enemy, not because he wanted to deceive anyone, but because he knew that the enemy was defeated, just as each of the participants in the battle knew it. But that same evening and the next day, news began to arrive, one after another, about unheard-of losses, about the loss of half the army, and a new battle turned out to be physically impossible. It was impossible to give battle when information had not yet been collected, the wounded had not been removed, shells had not been replenished, the dead had not been counted, new commanders had not been appointed to replace the dead, people had not eaten or slept. And at the same time, immediately after the battle, the next morning, the French army (due to that rapid force of movement, now increased as if in the inverse ratio of the squares of the distances) was already advancing by itself on the Russian army. Kutuzov wanted to attack the next day, and the whole army wanted this. But in order to attack, the desire to do so is not enough; there needs to be an opportunity to do this, but this opportunity was not there. It was impossible not to retreat to one transition, then in the same way it was impossible not to retreat to another and a third transition, and finally on September 1, when the army approached Moscow, despite all the strength of the rising feeling in the ranks of the troops, the force of things demanded so that these troops march for Moscow. And the troops retreated one more, to the last crossing and gave Moscow to the enemy.