A valve is a pipeline fitting. The classification of valves is quite diverse. But we will talk about the wedge one. Its design is intended to block the flow of the working medium in the pipeline. A wedge valve has a gate, which, when performing actions aimed at opening or closing it, is located perpendicular to the flow of the working medium.

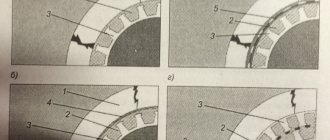

Diagram of self-sealing wedge valves.

Its feature is the direct locking element, which has the shape of a wedge. The locking parts of the valve are tapered towards the end and cover the valve seats, which are located at an angle relative to each other.

The functions of wedge valves are as follows. This is a category of shut-off valves designed to completely shut off the flow of the working medium. The wedge valve has only two main positions: open and closed.

How does a wedge valve work?

Steel wedge gate valve with extending spindle.

The valve has a special seat (hole), through which the working medium can move. The gate in the wedge gate valve design is a movable element. It can go up and down.

If the bolt is raised up, the seats (holes) on both sides are in the “open” position. This position allows the working medium to flow freely through the valve and further through the fittings into the general system. If the wedge is in the lowered position, the holes of the seats overlap, which means that the movement of the working medium stops.

How is the wedge gate lifted?

It rises as a result of being screwed onto the spindle. This is a threaded part of the valve; the valve is attached to it with a nut. At the moment when the spindle performs rotational or rotational-translational movements, the wedge rises with it. In turn, the spindle rotates due to the movement of the handle (if it is manual control) or an electric drive.

A button gets stuck or stuck: what to do?

To the listed malfunctions of the flush tank, you can add sticking or sticking of the button. This is when you press the button, release it, and it remains in the socket, so the draining does not stop. You have to press the button mechanism several times to return the button to its original position. The problem is solved by cleaning the buttons themselves from rust and dirt. Monthly use of cleaning products to maintain the sanitary condition of the buttons allows you to get rid of this problem once and for all. Some people simply pour a small amount of detergent directly into the push-button mechanism. Under the influence of special means, all dirt dissolves and the buttons do not stick.

As you can see, it is quite possible to independently repair a toilet cistern with a button. By spending a little time studying the structure and operating principle of the valve mechanisms, you can repair the cistern without outside help. Of course, if plumbing work does not bring you any pleasure, then you should turn to professional craftsmen who will cope with any malfunction of the tank and toilet in a matter of minutes. Real professionals only need to take one look at the toilet to understand the nature of the problem. To troubleshoot a problem, plumbers usually always have everything they need with them.

Classification of wedge valves

Gate valve diagram.

The classification of wedge valves implies their division into narrowed and full bore.

Full bore ones have a diametrical hole size of the rings (sealing rings) equal to the diameter of the pipeline hole. If we are talking about a narrowed version, then the diameter is smaller than the hole in the pipeline system.

Another classification is possible in accordance with the nature of the spindle (rod) movement. In this case, wedge valves can be with a retractable or non-retractable spindle. If the stem is retractable, then when the valve is opened, its height (construction height) increases, while the spindle itself performs a screw-type movement. The non-retractable spindle allows the valve not to change its construction height. The movements of the rod in this case are rotational in nature.

As for the design of the shutters, they can also be different. For example, a conventional wedge valve may have either a rigid gate, or an elastic gate, or a double-disc gate. And now in more detail.

A rigid wedge is a solid piece. Its design allows for a fairly tight fit to the holes of the saddles. But in this case, it is difficult to fit it to the saddles and there is a possibility of jamming. This, of course, is a disadvantage of this type of wedge.

The second version of the wedge in the valve is a double-disc one. This is a design of fixed disks located at an angle. This arrangement forms a wedge.

But the elastic wedge basically also consists of two disks, but its difference is expressed in the movable connection. This is the most airtight version of the valve, since its use ensures a very tight fit of the wedge valve to the holes of the seats. And one more advantage of this type: such valves break much less often than others.

All about gas transport

INTRODUCTION

General information about shut-off valves

Pipeline fittings are devices that are mounted on pipelines, boilers, tanks and other devices under pressure to turn on and off individual sections of the pipeline, regulate the flow and pressure of the medium, indicate and regulate the levels of liquids, change the direction of movement of the medium transported through pipelines and etc. The most common type of valve is shut-off valve.

Advantageous characteristics of a wedge gate valve

The first thing I would like to note as a significant advantage is the simple design of the wedge gate valve (WVG). But that is not all. The hydraulic resistance of this type of valve is quite weak, and, of course, one cannot help but mention the small construction height.

Now about the cons. Here we can safely point out the need to use a lot of force in order to completely open or close the working body. Well, the construction height, when compared with the valves, is much greater.

The reliability of wedge valves during operation directly depends on the correct selection of design and compliance with the required characteristics.

Symptoms of deterioration in the condition of shut-off valves:

- Loosening of packings and sealing gaskets;

- Lack of complete tightness;

- Wedging of moving parts;

- Leaks at installation sites;

- Rust damage.

You can try to put the equipment in order yourself, but the consequences can be disastrous. Repairing shut-off valves without special equipment and skills can damage the equipment and components. This will lead to the need to replace expensive components or the entire product as a whole. Based on the above, entrust these activities to specialists.

How to repair a wedge valve correctly?

Scheme of a wedge valve.

The fact that wedge valves require regular maintenance, of course, adds a number of inconveniences to the operation process. But the fact that repair of a wedge valve is possible speaks of its advantages over other types. Repair technology varies depending on the current situation. Let's look at a few of the most common faults that can be repaired.

It happens that when using a wedge valve, we pay attention to the insufficient tightness of shutting off the flow of the working medium. What could contribute to this?

This problem can occur as a result of possible defects in the surfaces of the body and shutter. This could be various deposits or damage, such as scale or scratches. What to do in this situation, what repairs to carry out?

To achieve good tightness, it is necessary to grind in the sealing surfaces.

This applies to the bolt and body. Most often their surfaces are made of bronze. First you need to dismantle the valve cover, pull out the valve (body) and grind it. You can use a variety of diamond pastes. The grain size should have a gradual transition from coarser to finer.

Another type of problem occurs when liquid flows through the rod from under the seal. Here, most likely, the rod is not sealed enough. The repair will consist of the following. To correct the situation, you need to tighten the seals, and if necessary, completely replace their packing. If, after replacing the oil seal, the leak still remains, then the problem may be in the rod. This means that shells of a corrosive nature could form in it. If this is the case, then it is unlikely that it will be possible to avoid replacing it.

Inability to turn the flywheel. Everything here is quite simple: the shutter is jammed. This situation occurs in those valves that are not regularly serviced and whose opening is most likely done no more than once a year.

As a result of such operation, scale deposits form on the sealing surfaces.

The technology for such repairs is as follows.

To eliminate this problem, the top cover of the valve is removed and the sealing elements are cleaned. If necessary, the contact surfaces are ground in. Do not knock on the spindle (rod) under any circumstances, as such actions will most likely lead to the guide nut being torn off.

Another common problem: the flywheel can rotate, but the valve does not open. This indicates a broken shutter. Rising stem valves are subject to this fault.

This means that the “cam” of the rod, which is supposed to hold the bolt, has worn out, or the thread on the nut that guides the rod has broken off. The repair will include the following: With the latter option, the worn out “cam” is replaced. Another repair option is to weld it. The nut must also be replaced, if, of course, the design of the valve allows this to be done.

If your valve has a non-retractable spindle, then the valve will fall out when the nut holding it in place is removed. To fix this problem, you need to replace the shutter.

Do not forget that all actions to disassemble the valve if it is under pressure are strictly prohibited.

After installation is completed, air is removed from the valve. To do this, you need to loosen the bolts that press the oil seal. After drops of water appear under the oil seal, you can press the bolts.

Water supply heating installation services

LLC DESIGN PRESTIGE 8(495)744-67-74

In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our heating page > resant.ru/otoplenie-doma < you can view and get acquainted with examples of our work. But to be more precise, it is better to check with an engineer about the cost of work and equipment.

To contact us, use the contact number of DESIGN PRESTIGE LLC 8(495) 744-67-74 , which you can call around the clock.

Heating from DESIGN PRESTIGE LLC Type: water here > /otoplenie-dachi.html

note

Our company DESIGN PRESTIGE LLC is part of the non-profit organization ANO INTERREGIONAL BOARD OF FORENSIC EXPERTS. We also provide independent construction technical expertise services.

Heating cost calculation

The cost of repairing heating systems

Cost of installation of water supply

Similar services:

- Welding metal heating pipes When installing heating pipes, you often have to connect them by welding. Of course, in some cases a threaded connection may be suitable, however...

- Pipeline welding The method of electric arc welding of pipelines is often used in the installation or manufacture of technological lines. They are produced on direct or alternating current. Economical,…

- Welding gas pipes Welding gas pipes requires real professionalism, which is quite dangerous. You need to work quickly and efficiently. Before starting the connection, the edges of the pipes are processed:...

- Welding profile pipes The main method of welding profile pipes is the usual butt joint of the ends. It is performed using the arc or gas method, but due to its simplicity and…

- Welding galvanized pipes Special technology for welding galvanized pipes allows you to connect them without disturbing the zinc coating. Flux is applied to the joint area, which provides...

- Welding pipes using manual arc welding When welding pipes using manual arc welding, professionals advise making a triple seam - it will be more reliable than a single one. It is most convenient for a welder to work...

- When welding a fixed pipe When welding a rigidly fixed pipe, a different technique is used: the first seam is made from the bottom up to half the diameter of the pipe, and then lowered...

- Welding of steel pipes The welding of steel pipes remains the most popular - both in production and in everyday life. The qualifications of the welder play a significant role here...

- Burner repair consists of: • Cleaning the fuel filter. • Cleaning the burner from soot. • If necessary, replace the nozzle. • Cleaning the heater from soot •…

- Features and types of welding of steel pipes One of the most popular types of work on the market is welding of steel pipes. This work can be carried out not only in large…

- Pipe welding The success of such a complex connection largely depends on the correct choice of pipe welding method, which is chosen for a particular type of metal. IN…

- Features of manual arc welding It is performed in several passes, after each it is necessary to remove the slag. Each subsequent seam is made overlapping the previous one. This method allows you to achieve...

- Welding vertical pipes In some cases, welding is very difficult. For example, it is difficult to weld pipes that are in a vertical position. This kind of welding...

- Automatic pipe welding and preparation for welding Modern welding technologies have made great strides forward. One of the areas is automatic pipe welding. With the use of automatic welding, it became possible to eliminate…

- Welding vertical pipes The second and third seams are performed with slow movements. The beginning and end of the seam are shifted by 3 centimeters. The last seam is made straight and...

- Heating repair at the dacha Repair of the boiler room, boiler equipment Installation and replacement of heating radiators Installation and repair of heating systems Repair of heating pipes at the dacha We will…

- Welding process You should start welding heating pipes with tacks. This is the technology of butt connection. They are part of the seam. To perform them, electrodes are used...

- Repair and adjustment of automation systems Modern boiler houses are equipped with automated systems with varying degrees of complexity, designed to ensure the normal functioning of the boiler without the constant presence of a person. Boiler room…

- Repair and maintenance of boiler rooms This boiler room needs repair! There is nothing to serve here. The concepts of boiler room repair and maintenance have subtle but significant differences for the uninitiated:…

- Welding of components and parts After this stage, having ensured that the joints are aligned correctly, the seam is welded. Before the first pass, use electrodes of a smaller diameter, for example...

Repair or replacement of shut-off valves - the advantages of our company

For each individual case, our specialists try to find an individual approach in order to complete the work as quickly as possible. Our staff consists of qualified and experienced employees who know their business, so repairing shut-off valves will not be difficult for them. We are always ready to come to your aid, so if you have any questions, you can contact our managers who will answer your questions 24/7. Entrust the servicing of your system's shut-off valves to experienced specialists. Contact a reliable engineering equipment service company. GLOBAL-ENGINEERING LLC . The result of our work is always the same - high efficiency and uninterrupted operation of the equipment .

To request a service, contact our specialist.

See also:

Heat exchanger repairRepair of pipelines for various purposesWelding work |