During renovation and construction work, we use increasingly modern materials. These include, in particular, PVC pipes. Of course, such pipes are much more durable than metal ones. They have a huge number of advantages. But these advantages appear only when the correct installation is done. This is the issue we will touch on today. And, in particular, the subject of our article will be glue and adhesive compositions used when installing PVC pipes. We will talk about the types of such compositions and the rules for their selection depending on specific circumstances.

Review of properties and methods of fastening PVC pipes

Products made from unplasticized polyvinyl chloride are characterized by rigidity and high strength. Hollow materials with a round cross-section are also distinguished by their tightness, with a service life of over 50 years (reaches a century-long figure). For installation of communications, glue for polypropylene pipes is often used.

Brief technical description

PVC pipes are inert to corrosion, most chemicals and biological activity. Such properties are in demand in the construction of water supply and sewerage systems. Other characteristics are also useful here, such as:

- mechanical resistance to water hammer and pressure up to 1.6 MPa;

- maintaining quality at temperatures from -15 to +66 degrees Celsius (CPVC up to +100 degrees);

- resistance to environmental conditions (ultraviolet radiation, changes in humidity, temperature within acceptable limits);

- the smoothness of the walls determines low hydraulic resistance, absence of plaque and build-up from salts and fats (it is easy to clean the outside);

- safety for humans, animals and plants.

Plastic water supply in a residential area Source sakh.com

It is also worth noting the affordable prices and easy installation. The latter implies easy cutting, elasticity and a method of fastening individual elements. Here it is enough to have a set of inexpensive fittings and glue for PVC sewer or water pipes.

Product installation

The assembly of communication lines is carried out in three ways: using sockets, bolts or using related parts. In the first case, pipes for sewer systems are used. On one side they are made with a thickening, the inner diameter coincides with the outer diameter of the main part. That is, channels or corners with tees are simply inserted into each other. To ensure the tightness of the connections, the walls are additionally coated with glue for plastic pipes.

In the case of ventilation systems, gluing is not necessary; you can limit yourself to sealing agents. Another relevant connection here is a flange connection. The technique is applicable to large-diameter pipes (entry into the building, installation of valves, valves, taps).

Flange connection of polymer channels Source techfabinternational.com

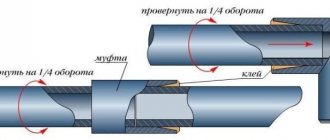

The second technique applies to plumbing products of relatively small diameter. Fittings are additionally used here. These include connectors (at different angles), tees, adapters with different end diameters. Here, for installation, you may need not only glue, but a special iron for working with polymer pipes and a bevel remover. Due to the strong and tight connection (subject to the rules), the method is otherwise called chemical welding.

Advantages of using “cold welding”

The links are connected to each other either mechanically, or by welding or using special glue. The welding method is the most popular, but it requires a special machine, which is very expensive, or you can call a specialist, which also costs money. The adhesive connection method is less common, but very effective. The “cold welding method” is often used. The seams are reliable and durable, in no way inferior to other joining methods.

There is only one disadvantage of this method: the composition is intended for gluing PVC pipes of cold water supply only; it can dissolve or simply lose its adhesive properties when exposed to high temperatures.

Advantages of joining using an adhesive composition:

- the pipeline remains smooth from the inside, there is no roughness or various damage, which helps to avoid blockages in the future;

- no risk of leakage;

- components adhere at the molecular level;

- the seams are absolutely sealed and may leak if exposed to hot temperatures;

- there is practically no labor and cash costs, gluing takes place in five minutes;

- no additional tools are needed for work;

- a fairly simple method that can be performed by a non-professional;

- there is no need to buy a welding machine.

Types of glue for PVC pipes

Not only polymer products differ from each other. For pipe installation, products with different properties and rules of use are also used. Let's consider how to glue a sewer plastic pipe or water pipe.

Operating principle

The adhesive composition contains a chemically active solvent. It reacts with the polymer base of the products, due to which the polyvinyl chloride softens. Such walls polymerize among themselves during the process of rapid hardening, forming a monolithic connection.

Connection of elements in section Source aquatherm.com.au

See also: Catalog of companies that specialize in water supply, sewerage and related work

Here it is necessary to note the heterogeneous composition of adhesives. To avoid making a mistake with your choice, you can refer to the manufacturer’s recommendations for a specific type of pipe. As a rule, the differences come down to three options: for PVC or chlorinated polyvinyl chloride, polypropylene.

Review of materials for gluing PVC

The classification of adhesives is carried out along with the purpose regarding the composition of the products and their strength. Here, soft bases include water-pressure and corrugated samples. Another option is solid. These can be fittings or siphons.

The second criterion for choosing adhesive for PVC pipes and fittings is the operating temperature conditions during installation. So, there are options for hot fusion and cold welding. The first materials belong to the group of flammable and combustible materials that are unsafe for the skin.

The installation technology here involves the use of a soldering iron and welding equipment for round polymer products. Using the first, the end parts of the pipes are heated to +260 degrees Celsius.

For cold welding, universal or specialized compounds can be used.

Tool for working with polymers Source poolplanet.ru

The first are designed to work with all polymer products (for example, linoleum), the second only for PVC and its modifications. This technique is more suitable for socket type connections. Here it is especially important to ensure the cleanliness of the contacting walls so that adhesion is uniform and the result is durable and airtight.

Another selection criterion is the setting time of the materials. Thus, instant adhesive for polypropylene can be classified as a means for cold welding. To form compounds here, 4 minutes at room temperature or one at +40 degrees Celsius is enough. Hot gluing compounds dry in 30 minutes and harden in 2.5 hours. It takes a day to complete the polymerization process.

Step-by-step procedure for gluing elements

Before you start gluing polypropylene, study the instructions. As a rule, recommendations and procedures, as well as compliance with proportions for two-component formulations, are indicated by the manufacturer directly on the packaging. However, there is a general principle of action:

- The surface must be cleaned and degreased, for example, with a solvent for polypropylene;

- The glue is applied in a thin layer to all surfaces that require subsequent gluing. This action is relevant unless otherwise specified by the manufacturer;

- Fixing the parts should take at least three minutes.

After treatment, you should not move or disturb the parts in any way for a couple of hours until they are completely dry.

The glue is applied in a thin layer to all surfaces that require subsequent gluing.

How to properly glue polypropylene pipes together

The question is not only how to fasten polypropylene, but also how to do it. The work is specific and requires certain tools:

- Device for cutting plastic pipes;

- Sandpaper;

- Glue gun;

- Directly the glue itself;

- Brush with natural bristles.

How to do:

- First you need to cut the pipes to the appropriate size.

- Using sandpaper, clean the cut areas, removing roughness and burrs.

- Make notes.

- Degrease the surface.

- Apply glue. If the sealant for propylene is packaged in a tube, it is applied using a glue gun. In the jar, glue is applied with a brush.

- Then connect the parts after maintaining the specified time.

- Remove excess substance using a regular napkin.

The quality of gluing is checked after 24 hours. Craftsmen additionally install rubber or wire clamps. In plumbing structures, after this time it is already possible to run water under pressure for testing. It is not uncommon for subsequent defects to appear in the work. This may be caused by a slow pace of work, uneven gluing, or distortions in the process. It is important to follow the manufacturer's direct timing instructions.

The quality of gluing is checked after 24 hours.

Methods and means for repairing PVC pipelines

During pipeline operation or installation work, it is impossible to completely eliminate the possibility of leaks. In this case, you need to find a solution for urgent repair of products or restoration of tightness in connecting nodes. Let's consider which adhesive or sealant for polypropylene is suitable for such purposes.

Leakage in the hub connection with the fitting Source tumentoday.ru

Causes and consequences of leaks

Identifying root causes is often helpful in finding problems and solutions. More often this is a depressurization of the connecting seam. To prevent or minimize the risks of “gaps” appearing, you need to monitor:

- temperature conditions during the soldering process;

- degree of reliability of fixation of nut fasteners or crimp fittings;

- correct preparation of elements for soldering, welding or other connections (cut angle, evenness of edges, cleanliness of walls);

- the applicability of the adhesive for a specific section of the pipeline;

- admissibility of the use of sealing and sealing materials.

It is not difficult to identify problems in polymer pipelines in a timely manner. In places of depressurization, condensation (dew), leaks appear, or the pressure in the system changes downwards. Without urgent intervention, the situation may turn out to be an emergency. This applies not only to the water supply or sewerage system itself, but to neighboring premises, apartments, houses, furniture and interior items, household appliances, and electrical wiring.

Consequences of failure to detect a leak in a timely manner Source ytimg.com

Review of methods and materials for pipeline repair or restoration

The action algorithm includes three stages: turning off the water, troubleshooting, testing the system for serviceability. Only after this can you return to full operation of communications.

To stop the transportation of liquid, it is not always necessary to turn off the central riser in a particular house. Today, plumbers are trying to create separate circuits or bypasses by integrating shut-off valves or tap fittings into the system. This way, it will be possible to de-energize only part of the pipeline and continue to use the rest as before.

Before carrying out restoration measures, you need to decide how to seal the plastic water pipe. Here are the main criteria for choosing funds:

- efficiency;

- performance;

- ease of use.

More often, connections of polymer products are made with the creation of conditions for polymerization. In this case, it is impossible to disassemble the monolithic assembly and create it back. Therefore, it is necessary to cut out part of the contour and insert a new one using a similar technology (which was used previously).

Replacing a damaged section of a pipeline Source homify.com

Characteristics

- Model P-70 Primer

- Plastic UPVC / CPVC

- Application softening before gluing

- The environment is aggressive

- Color transparent

- Shelf life, g 3

- Available packaging, l 0.946 / 0.473

Synonyms: pipe glue, UPVC pipe glue, PVC pipe glue, PVC-U pipe glue, CPVC pipe glue, PVC-C pipe glue, CPVC pipe glue

Professional adhesive for UPVC, PVC, PVC-U, CPVC, PVC-C, CPVC pipes from Weld-On, you can buy and ask any questions you are interested in from our managers by making a request by email or by calling the office on +7 ( 351) 777-94-98

2394 views

Working with a cast iron radiator when leaking

It happens that the heating battery leaks - the threaded joint has deteriorated, or a leak has appeared in the section. Repairs will require epoxy glue and a bandage. The material is impregnated with glue and applied to the hole area. After setting, you can paint this area with the main color. This measure is considered temporary, and after turning off the heating it is better to replace the radiator.

Cold welding of batteries is also used. The special product is kneaded in your hands and applied to the injury site. It quickly melts, sets and allows the “patch” to exist until the heating is turned off.

You should not try to glue radiators if there is a strong leak that has led to an emergency. It is better to immediately call a team of specialists who will stop the leak and replace the radiator with a new one.