When building a house or during renovation work, as a rule, there is a need to deal with plumbing. But after purchasing structural elements and delivering them to the site, before proceeding with installation, it is necessary to prepare materials. Any experienced plumber will confirm that the most problematic areas of the pipeline include various interfaces and joints. That is why it is necessary to take care of sealant for water supply pipes.

You can seal connections when installing a new water supply using different methods; you just need to take into account the material of the pipes

Application and performance characteristics

Most often, this sealant is used when installing plumbing: it helps to seal joints into which water can get, causing mold to settle there. The product is perfect for sealing seams between the wall and the bathtub, shower stall, sink, toilet, and countertop. High-quality sealants are used when laying or replacing elements of water supply and sewerage systems. When assembling pipes, they will prevent leakage and increase the service life of the unit.

Since most sanitary sealants have antiseptic properties, they are suitable for installing window systems inside and outside buildings, helping to prevent mildew and mold. Also, any of the sealants can be used for other purposes:

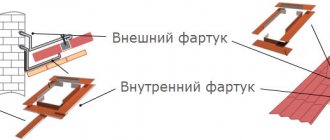

- roofing works;

- strengthening greenhouses;

- sealing joints in masonry;

- installation of vinyl cladding;

- mirror mountings.

A good sealant has the following qualities:

- high level of elasticity, the possibility of application to deformable bases, moving elements and parts of structures;

- resistance to water, steam, condensate, chemicals and UV radiation;

- excellent adhesion to ceramics, concrete, tiles, stone, glass;

- tolerance to temperature changes;

- versatility and low consumption.

What problems does plumbing sealant solve?

Experienced plumbers recommend taking the issue of sealing a bathroom as seriously as possible. The risk of leakage always remains, and only the use of special compounds helps reduce this danger. If there are holes between the wall and the bathtub, mold will likely appear in the room, and a leak in the water supply system can even lead to serious troubles. The most problematic areas are those where inserting fittings or creating branch pipes is required: there the use of sealant is especially necessary.

Using plumbing sealant when connecting water pipes

Sealant for water pipes and plumbing solves the following problems:

- preventing the occurrence of leaks caused by the presence of cracks, cracks or too much water pressure;

- protection against temperature changes arising from the regular supply of hot water;

- maintaining important parts and assemblies intact, extending their service life;

- enhancing the effect of using gaskets.

Composition of sealants

Silicone sealant is produced on the basis of silicon compounds and various polymers, as well as additives:

- fungicides and antiseptics to provide antifungal properties;

- organic extenders to reduce viscosity and better flow into small cracks and holes;

- fillers (quartz and glass dust) to enhance adhesion;

- pigments to give a certain shade.

Sealants with other compositions may include acrylic, polyurethane, organic solvents and other components that provide the product with reliable adhesion and sealing ability.

Release forms

Many sealants are sold in plastic cartridges for a gun with a volume of 290–360 ml. Also on sale are products in tubes of 50–100 ml - regular or equipped with a special piston like a syringe. For large-scale plumbing work, it makes sense to purchase soft packages of sealant of 600 ml or more, for squeezing out which special guns are used.

Choosing a high-temperature sealant for the boiler and heating system of a private house

If the heating boiler is not located in the house, but on the street in a separate extension, then the temperature regime of the pipes connecting the boiler and home radiators is taken into account. This moment is especially critical for the northern regions, where in winter the temperature drops below -30 degrees . In such cases, it is recommended to give preference to thiokol types. In addition, silicone mixtures that contain additives that improve temperature properties are suitable.

Photo 2. High-temperature silicone sealant Moment used for heating boilers. The substance is red-brown in color.

If a crack appears in the boiler, then seal the equipment using a high-temperature compound. To accomplish this task, thiokol and silicone mixtures are used.

is also suitable for this purpose . Anaerobic mixtures have a slightly different mode of action, so they tolerate high temperatures more easily and harden quickly. The main disadvantage is the rather high price, however, the use of anaerobic sealant is fully justified in emergency cases.

Basic requirements for compositions

To choose a truly high-quality sealant, you need to evaluate its compliance with the most important criteria:

- Suitability for a particular material. Some sealants are designed for use on plastic, while others are suitable for metal substrates. There are also universal compositions that are suitable for any plumbing task. The information the user needs is always on the packaging.

- Resistance to adverse effects. A good sealant must withstand the influence of household chemicals, alkalis, ultraviolet radiation, high and low temperatures.

- Long service life. The product must last for at least 5 years when it comes to sealing pipes, and up to 3–5 years when sealing seams between a wall and a bathtub or other plumbing fixtures.

- Elasticity. The sealant must not crack from vibration or temperature changes, which cause expansion and contraction of materials. If elasticity is poor, the seam will quickly deteriorate.

- Polymerization time. If your bathroom renovation is urgent, you need to choose the fastest-drying compounds.

A few recommendations

You should know that it is difficult to determine exactly how many windings will be needed. Therefore, here you will have to act empirically. It’s even better to practice in advance and do test runs of water. If there is not enough tow, then leaks are inevitable, and if there is too much, then when tightening, you can simply break the thread and damage the pipe.

Brass and bronze pipes require special care when working, as they are quite “delicate” when tightened.

It is also better to refuse to use oil paint, since if you need to dismantle the system, you will have to carry out all the work using high temperatures, otherwise the connections will not separate.

In general, everyone determines how to seal water supply pipes for themselves, focusing on their preferences and financial capabilities.

Liquid sealants are used to seal cracks in the heating system . This substance is sold at any hardware store and costs little.

However, the product is used only to eliminate small cracks; it is useless to seal large holes.

Types of sealants

There is a whole range of materials on the market for sealants that are used in plumbing work. Some have been used for decades, but are considered ineffective, others have appeared in stores recently, but have a longer service life.

Linen sealant

Wrapping threads and joints with linen thread is the oldest method of sealing, but it is also the cheapest and most short-lived. The principle of operation of the thread is as follows: after contact with moisture, flax swells and seals cracks and leaky joints. Conventional fibers cannot be used when working with thin-walled materials: after they swell and increase in size, there is a risk of pipeline rupture in the joint area. Also, do not use flax thread where the water supply system pipes are under high pressure: strong water pressure will still lead to leakage.

Under the influence of moisture, flax fibers are weakened and destroyed in a fairly short period of time; the joint will have to be maintained regularly. Constant dampness will cause metal parts to rust and deteriorate. To reduce the disadvantages of natural flax, manufacturers began to produce an improved modification of the thread, where the fibers are impregnated with paint and varnish compounds. However, after some time, even such material begins to rot and become unusable, and the tightness of the joints is broken.

FUM tape

Fluoroplastic material sealant, or FUM, is a polymer tape wound on a reel, which is widely used in plumbing work. It is made of fluoroplastic-4, which is not subject to rotting. Winding pipe joints with such a device provides more reliable protection against leaks than when using flax thread. Main properties of FUM tape:

- tolerance to chemicals, ultraviolet radiation, temperature changes within –70...+300 degrees;

- preventing metal corrosion;

- elimination of friction of elements against each other due to smoothness;

- durability of service;

- small thickness;

- excellent plasticity;

- no toxicity.

FUM tape also has disadvantages. It is not suitable for sealing large diameter holes. Reversing the nut or fitting after applying the tape is unacceptable: it will immediately deteriorate. In connections subject to vibration, complete sealing cannot be achieved, as well as in those where temperature changes occur too frequently.

Plumbing thread

This material is prepared on the basis of artificial fibers and is impregnated with special compounds and antiseptics. The thread does not suffer from rotting, protects the metal from rusting, allows you to reliably seal pipe joints, while it does not break due to reverse movement and allows for the possibility of dismantling the system. Reliable sealing is achieved even when the connections are not fully tightened. The cost of such a thread is high, so it is less often used in plumbing work.

Using a special thread to seal threaded connections

Liquid sealants

Sealants in the form of a suspension are used independently or in combination with FUM tape, flax or plumbing thread. It is better not to use them in pipelines that operate under pressure without additional thread sealing. Some products shrink greatly when they dry, as indicated in the instructions.

Anaerobic sealant for plumbing

Sealants from this group harden in an airless environment, and in the presence of air they retain their fluidity. After complete polymerization, they do not change volume, reliably protecting joints and seams from leaks, while having high elasticity and minimal consumption. Excess product that has come out can be easily removed manually. Other advantages of anaerobic compounds:

- high level of adhesion to plastic and metal;

- Can be used for any plumbing work;

- tolerance to aggressive environments, lack of interaction with surfaces due to chemical inertness.

The price of such sealants is quite high, but the quality is high and the consumption is minimal.

Silicone compounds

Such sealants are the most popular when carrying out plumbing work. They can be used to seal any seams and joints, grooves and cracks in the bathroom and kitchen. Due to their tolerance to high temperatures, the products are even suitable for repairing heating systems, and their elasticity prevents them from cracking and crumbling on deformable substrates.

Depending on the composition, sealants based on rubber silicone are of two types: acidic and neutral. The former contain acids that can cause corrosion and are therefore not suitable for metal products. Neutral sealants are based on amines and do not react with metals or delicate materials, therefore they are used everywhere. To enhance the sealing effect, silicone products are often used in conjunction with reinforcing meshes.

Terms of use

The nose of the tube is placed at 45° to the surface so that it is convenient to apply and does not block the view. The gap is filled to its entire width and depth, since sealing materials do not expand during polymerization.

Recommended application parameters:

- depth – 2 – 12 mm;

- width – 6 – 30 mm.

Large gaps are applied several times. After applying the first layer, wait until it dries, then repeat the treatment a second and third time until it is filled. To shape the seam, you have 10-15 minutes after application , then a film forms on the sealant.

On the surfaces of plastic panels, lining, there are cracks and chips, which are treated with a silicone compound of a suitable color or use acrylic and then paint. The non-shrink strip resists moisture and household chemicals.

For cold water

Plumbing is often made from plastic pipes; they are joined together by welding or threaded fittings. In the second case, be sure to use a sealant to prevent liquid leakage. You can take acrylic mixtures that effectively insulate cold water pipes.

For hot water

In this case, silicone varieties are often used. Keep in mind that not all sealants belong to the heat-resistant category, so choose according to the manufacturer’s information on the packaging.

Heated elements also include sewer pipes , which are connected into a socket through rubber gaskets. When hot water is drained, the joints may become depressurized, so they are also sealed with silicone.

Under pressure

based on sodium silicates are especially durable After hardening, such pastes gain high strength. They are used when joining water and other pipes operating under pressure. If the pipeline supplies hot water, for example, from a boiler to the point of disassembly, such compositions will additionally withstand high temperatures.

Do-it-yourself sealing of connections

Silicone compounds can be applied even without sufficient experience and knowledge - the process is simple, but is carried out strictly according to technology.

Preparation of the treated surface

From the bases on which the sealant will be applied, it is necessary to remove any dirt, dust, oil stains, and remnants of old compounds (mastic, grout). After mechanical cleaning of surfaces, degrease them with alcohol, acetone or special solutions.

If you are going to seal the gap between the bathtub and the tiles with plumbing sealant, you need to pour water into it before starting work. When the bathtub is filled and under load, the outer parts are always slightly deformed, and the sealing seam will immediately take the desired position.

Sealing

Most sealants in tubes and cartridges are excellent for installation in a mounting gun. The tool helps to apply products more accurately, faster, and in strictly required quantities. Procedure for working with plumbing sealant:

- Remove the plug from the tube tip.

- Cut the tip of the nozzle at a 45 degree angle.

- Place the tube in the gun.

- Slowly and carefully press the trigger to apply the sealant.

In order for the seam to be of good quality, the line of sealant must be continuous. It is recommended to start from any angle. After completion of the sealing, it is necessary to correctly form the seams, which will distribute the composition and increase the reliability of operation.

Creating a seam

If the sealing seam is small, you can give it the desired shape using your finger. You need to put on gloves and carefully smooth out the sealant, moving the excess and directing it to where the layer came out thinner. If the seam area is large, smoothing is done with a narrow spatula, having previously moistened it with soapy water.

Finishing

To complete the sealing, you need to remove the excess compound that has come out beyond the seam using a wet cloth. The initial setting time of the sealant is short, so you must act quickly, otherwise the entire seam may be damaged when removing excess. After a few days, you need to carefully examine the sealant layer. If defects, voids, or cracks appear on it, they must be repaired.

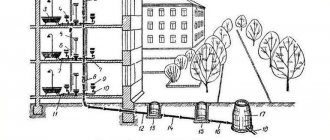

Preparatory work before refilling batteries and pipes

First, choose the best sealant that will suit your system. Before purchasing, pay attention to the consumption of the active substance. For every 60 liters of coolant water in the pipes, about 1 liter of sealant is required, however, these figures may vary depending on the type of sealant. To determine the volume of coolant, multiply the cross-sectional area by the total length of the pipe. And also add to this indicator the volume of radiators and boiler (this information is indicated in the installation passport).

Important! The calculation can be done by direct measurement - for this, all the water is drained from the pipes and the volume is measured using containers of a known size. This method is more labor-intensive, but more reliable.

The process of setting up for pouring

Complete the process of setting up the system for pouring:

- Remove air from the heating system , as premature solidification will lead to the formation of unwanted clots in the system.

- If the system has filters , then dismantle them so as not to damage the system.

- Open all heating system valves so that the sealant penetrates every work area.

- Install an automatic pump on the first radiator . Turn it on for 1-2 hours to warm the pipe and remove remaining air (optimal pressure level is 1 bar ).

Pouring procedure

After that, start filling:

- Prepare a large container for preparing the solution.

- Pour the required amount of water into it.

- Add sealant and mix the solution.

- Immediately introduce the solution into the heating system using a pump to minimize contact of the sealant with air.

- Start the heating system in normal mode (optimal water temperature - at least 50 degrees ).

- You need to run the sealant with the coolant for at least 4 days , and on the 5th day it is recommended to carry out control measures to check whether the sealing is effective or not.

Popular manufacturers

To buy a truly high-quality sealing compound for plumbing work, you should give preference to those produced by well-known brands.

Makroflex

Finnish sealants of this brand are widely used by craftsmen. They are distinguished by high quality, excellent technical characteristics, environmentally friendly composition, and long service life. For working with plumbing, Makroflex NX-108 is well suited, which is useful for professional and household use.

"Moment"

In the Moment catalog you can find several products based on silicone or polymers that are suitable for working with heating and sewer pipes, and for sealing joints in the bathroom. The sealants “Silicone Universal” and “Silicone Neutral” from “Moment” have good indicators of moisture resistance, elasticity, and durability.

"Econ"

Econ products stand out for their low price and decent quality. The brand's sealants are easy to use and can be applied manually or using mounting guns. These compositions are more designed for domestic use.

Tytan

The company's product range includes polyurethane and silicone sealants for plumbing work, as well as products based on acrylic and bitumen. All products have high strength characteristics, excellent elasticity, and after drying the seams can be painted.

Ceresit

The company produces a whole line of sealants with high adhesion to metal, plastic, and other plumbing materials. The products are distinguished by their versatility, good insulating ability, and contain antiseptic components.

To avoid problems with the operation of pipes and plumbing equipment, it is better to immediately purchase a reliable sealant and apply it in accordance with the manufacturer’s instructions. In this case, the effect of complete sealing of joints and seams will be ensured, and there will be no need for repairs.

What to do with cast iron pipes?

In old houses there are still old pipes made of cast iron. Since this system has already served for a long time, leaks are quite possible. There are several ways to deal with them:

- Each subsequent element is nested within the previous one. The joint itself must be minted using a heel. For those who do not know what it is, it can be explained that it is a natural fiber that is first thoroughly impregnated with mineral oil. To do this kind of work you will need a tool such as a hammer, which looks like a large screwdriver. It helps to drive the heel tightly into the fastening places, after which they wind it several times along the top.

Cast iron pipe connections

After this procedure, the seams are additionally treated with a solution based on PVA glue, as it allows you to create a more plastic consistency.

- Another option for sealing cast iron pipes is the use of hot sulfur. All fastenings are shed with it. But here it is immediately worth noting that this substance is very harmful to health, so it should be used very carefully. Although recently no one uses this method anymore.

If you still decide to use sulfur, you should remember that if it catches fire, it should under no circumstances be extinguished with water, since the chemical reaction will cause the release of sulfuric acid.

But again, thanks to progress, modern water pipes already have rubber cuffs that help create the necessary sealing. You can simply use additional silicone sealant at the end of installation, but it should be selected so that it is suitable for the material from which the system elements are made. As for its drying, usually such sealing dries quite quickly, but experts recommend not touching the product for 48 hours and only after this time can you be sure that the sealant has dried.

Manual removal of anaerobic fixative

If it is necessary to separate joints treated with sealant in pipes, then the strength of the sealant and the time when it was applied are taken into account.

If the composition has not yet begun to polymerize, it can be easily removed. If the sealant has hardened, then you will need a wrench and a hair dryer.

Carry out actions in the following sequence:

- Turn on the hair dryer and direct the air to the site of the knot.

- Expect melting or destruction of the retainer.

- Remove the remaining product with a rag.

- Disassemble the connection with a key.

Linen thread

In this way, tightness was achieved for the joints of products with threaded joints since ancient times.

Filament is cheap and widely available. The disadvantages of linen thread for joints include the following:

- difficulty of use. If you do not have sufficient skills, winding the thread around the thread will be done incorrectly - the thread may unwind and the tightness will be broken.

- lyophilicity. Linen quickly becomes saturated with water and swells sharply. Weak pipes at the joints may rupture, and metal joints may rust. Linen thread is suitable for pipes made from the most durable substances.

- low temperature resistance. Linen is destroyed at high temperatures and is not suitable for heating devices that are exposed to heat.

Types of thread locks

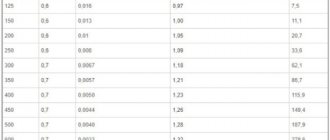

According to their strength characteristics, anaerobic compounds are of the following types:

- easy sealing - used for processing connections that are subject to moderate loads, but can be disassembled (withstand a breaking force of 3-10 Nm);

- medium sealing. Used for units that are subsequently separated by heating or a key (withstand a breaking force of 25 Nm);

- strong sealing - it is difficult to separate such connections; they are mainly used to create a unit for a long period of action; the sealant can withstand a breaking force of 50 Nm.

The latest type of threaded materials for fixation has the highest resistance to temperature changes and shocks; these sealants are best suited for repairing pneumatic products and high-pressure devices.

In terms of ductility, airless threaded materials for fixation are as follows:

- gel-like and liquid;

- difficult-to-flow (thick) and medium-flow.

For small gaps, liquid-type materials with a viscosity of less than 20 mPa are suitable, otherwise they will not fit into the gap. If the distance exceeds half a millimeter, then any composition, including the thickest one, will do.

For threaded joints, various compositions are used, with different characteristics, types, and ingredients.

Airless retainer

This thread sealant for connections is the most modern and popular in our time.

The anaerobic composition is used by both amateurs and professionals and is available in tubes of various volumes. Outdoors, airless sealants remain in a liquid state, and they can easily process any thread on connections.

When the nut is tightened, the compound will harden. Polymerization takes 3-4 hours, then it can be used. Disconnection of the unit is possible after heating.

Selection conditions

To select a high-quality thread locker, you should listen to the recommendations of specialists. When purchasing a sealant, it is necessary to take into account the width of the gap, the specificity of the thread, and the composition of the pipe.

The retainer must be used in a specific case, which is indicated in the instructions. In cases where the assembly is expected to be frequently disconnected, you should not purchase heavy-duty sealant. It will be very difficult to dissolve it.

If you need to make an urgent repair, a sealant with the shortest curing time is suitable.

It is recommended to use thread materials from a popular brand that is easy to rely on, rather than using a low-quality sealant to save money.

Non-hardening fixative

This sealant is applied to the threads and the nuts are tightened.

As a result, the seam is sealed and prevents the movement of fluid. The paste-like threaded connection material does not harden and the nuts can be unscrewed at any time. The non-hardening sealant completely fills all gaps and seams, and the pipes do not stick together.

It cannot be used for pipes under pressure, as the liquid will wash away the sealant and cause a leak.

Manual

Before using the sealant, the contacting surfaces must be prepared.

They are cleaned of debris and grease is removed with acetone or isopropyl alcohol. Before applying some fixatives, you need to treat the knot in advance with an activator (supplied) with a brush.

When the preliminary surface treatment is completed, the parts must be completely dry, then the entire surface of the thread is evenly covered with a thick ring of sealant.

If the gap is wide, the nuts, the fitting, and the thread itself are treated with a fixative.

The components are connected, excess sealant is wiped off with a dry cloth. If necessary, excess fixative is collected and applied to another unit. The joint should stand until the joint parts finally set (the hardening time is indicated by the manufacturer).

When making a seam and using the product in the future, it is very important to adhere to the specified temperature regime.

PTFE sealing tape

It is inexpensive and easier to use than thread.

The FUM tape is wound onto the thread and the fitting is screwed on, this is very reliable. The tape does not crumble, does not stick, if necessary, it can be easily removed after unwinding the connection. The product can be used in pipes for drinking water and any other.

The disadvantage of the tape is that it is not very tight - vibrations or mechanical stress loosen the joint. Over time, the pipe may leak; it is necessary to tighten the nuts in a timely manner.

Do not wind FUM tape in pipes under high pressure.