Date: April 8, 2014 During normal operation of pipelines, the direction of water flow is assumed to be in one direction.

To prevent the formation of backflow, check valves are used that have a one-way flow capacity and operate automatically.

Check valves are used when several pumps operate when combined into one network.

When the pressure in one line decreases, excess water pressure forms a reverse flow in it, which can cause damage to the pump and fittings.

The check valve automatically cuts off the emergency section from the reverse flow.

When choosing a check valve, its main technical characteristics are taken into account:

- Bore diameter DN (nominal diameter). A number of conditional passages are prescribed in GOST 28338-89;

- Pressure PN (nominal pressure) is the maximum excess pressure at which long-term and safe operation is guaranteed. A number of nominal pressures are prescribed in GOST 26349-84.

- In addition to domestic standards, international ISO, North American ANSI, and German DIN are used.

What is a check valve for?

A check valve is a type of shut-off valve, the purpose of which is to protect the water supply system from interruptions, changing water flow parameters, as well as from liquid leaks.

Shut-off valves protect not only the water, but also the sewer system. Interruptions in the operation of pumps or when they are turned off without a reverse device lead to emergency situations.

The design of the product is represented by a body, a cover, a seat, a valve, a rod, and a flywheel.

During the working process, the fitting mechanism prevents the water channel from moving in the other direction, protecting the pipeline and plumbing from water hammer, so it is recommended to install it on:

- water supply system;

- sewer main;

- heating system;

- pipes near water meters;

- plumbing fixtures;

- branching pipes in front of the water heater.

The valve is also installed before the operation of submersible pumps at the dacha in the well. In this case, the mounting location of the device is a certain section of the pipe. The mounting location is located in front of the equipment or behind the ratchet.

Installation diagram of a check valve in a private house Source geoburstroy-ug.ru

If the water supply system uses a vibration pump, then the device is installed before the pipe receiver.

Valves are installed horizontally or vertically.

The cost of valves in rubles ranges from 460 to 5400. The price depends on the material of manufacture, diameter and model.

Important! If there is a need to install a check valve for water for the water supply system of a country house, then before the cold season it is recommended to install a tee at the lower point of the pipes, attach a valve to it and drain the water so that the system does not defrost and the return device does not fail.

Scheme of water supply for a house with a storage tank

The presented scheme can be easily integrated into existing piping, both in water supply with one central pipeline and with several. Its compactness is due to the use of free space above the tank, in which the pumping station is suspended on brackets.

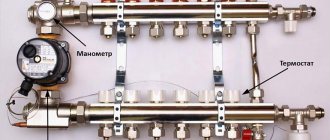

Figure 1 shows a water supply diagram for a private house with two central pipelines consisting of:

- 1 - tank 500 liters;

- 2 - pump;

- 3 — receiver (membrane tank);

- 4 - pressure switch;

- 5 — bronze five-point adapter;

- 6, 17 — pressure gauge;

- 7 — hose with reinforcing braid;

- 8 - check valve;

- 9 — float valve;

- 10 - American with external thread;

- 11 — American with internal thread;

- 12 - bronze transition from the container to the external thread;

- 13, 14 — MRN (male thread coupling);

- 15 — МРВ (internal thread coupling);

- 16 - bronze transition from external thread to internal thread;

- 18 — flow meter;

- 19 — mesh filter;

- 20 - 26 shut-off valves.

The suction discharge and distribution line is made of polypropylene pipeline and transitions with diameters of 32 mm (suction) and 20 mm.

Main characteristics and operating principle

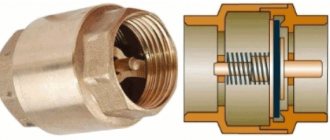

The check valve consists of a body with a limiter, intake and output zones, and a locking (spring) mechanism on the limiter.

The body is made of steel (high temperature), cast iron, brass, bronze and dense plastic or plastic.

Technical indicators of the valve element are characterized by nominal diameter (DN), pressure (PN), operating temperatures and a number of other quality characteristics:

- type of connection;

- diameter of the landing part;

- meeting the requirements for the tightness class.

The diameter is: 15, 20, 25, 32, 40, 50, 60, 80, 400 mm.

Check Valve Working Process Source nehomesdeaf.org

Connecting the device to the water supply is possible in the following ways:

- welding (welding);

- coupling (thread);

- flanged (o-rings);

- wafer (fixed with seals at the end of the pipe).

The valve's tightness is ensured by surfaces with a seal. The necessary sealant is always provided by seals made of rubber, plastic, and steel overlays.

The operating principle of the check valve is simple:

- the water that moves through the valve presses the spring that holds the device closed;

- high water pressure begins to compress the spring, opens the valve, and the liquid circulates freely in the required direction.

When the direction of the water channel changes or a drop in pressure occurs, the spring mechanism of the device closes the valve. This prevents water from moving in the opposite direction.

Types, advantages and disadvantages

Regardless of the mounting location, internal structure and material of the locking element, the following main types of valves are distinguished:

- Coupling on a spring.

The body is represented by two cylindrical parts connected to each other by a special thread. The locking mechanism itself is made of several parts: a rod (metal, plastic), a spool plate (2 parts - upper, lower), a sealant gasket (between the discs).

Sleeve check valve Source met-all.org

When connected, the body parts are sealed with hermetic gaskets. When the lock opens, the spring weakens, so with good pressure the water bed circulates easily. When the pressure decreases, the spring presses the spool plate against the seat, and the passage of water is blocked. Used for pipes with small diameters.

- Rotary paddle.

It is represented by a spring-loaded plate shaped like a petal. It works thanks to a rotating disk, the axis of which is located above the passage opening. At normal pressure, water circulates, the petal moves to the side, opening the channel. When pressure drops, a spring-loaded plate closes the hole.

- Ball.

The bolt element has the shape of a ball. The valve moves due to the force of compression and expansion of the spring. When the liquid pressure decreases, the ball lowers and closes the passage opening. The product is practical to use, has a removable cover, so it is convenient to carry out technical work without dismantling.

- Lifting.

Used on horizontal pipes due to the vertical axial installation. Recommended for large diameter pipes. Has a removable cover. The locking element is represented by a spool. When there is sufficient water pressure, the spool rises, allowing water to circulate. At low pressure it drops onto the seat and the flow is blocked. The device is indispensable at high temperature and hydraulic conditions.

Check lift valve Source shop.sodeco-valves.com

See also: Catalog of companies that specialize in water supply and sewerage.

- Wafer.

Ideal for polypropylene pipes. Located between two adjacent seals. Used when operating pumps. Protects against water hammer. There are also disc valves, the locking part of which is a pressure disk, as well as flanged valves, equipped with tight gaskets.

The advantages of installing all types of reverse devices are:

- Stabilization of the water supply system.

- Reducing the cost of electrical networks when heating water with a boiler.

- Reducing the risk of air masses entering the system.

- Providing water when the pump is turned off.

The disadvantage of locking products is the need for periodic maintenance.

Important! The non-return valve is lightweight and long, has reliability, tightness and ease of installation.

Check valve for water

The mechanism works by circulating water in one direction. It ensures stability in the operation of the water supply system, maintains the required pressure and protects the system from possible accidents. Most often, lift-type valves are used for water pipes in order to subsequently change the spring.

View of installed valves near meters. Source market.sakh.com

The water check valve is of modest size. Its greatest domestic use is recommended in the following cases:

- Water system pipes . When supplying hot and cold water through different pipes, the valve equalizes the difference in pressure of each flow to normal levels.

- Water heater . When filling the tank with water, a shut-off element at the entrance prevents the heated liquid from circulating in the other direction.

- Individual heating. The shutter equalizes the pressure in the floor, radiators, and boiler.

- Metering device . Protects the meter from emergency hydraulic shocks, normalizes the operation of turbine indicators.

- Autonomous system . Prevents water from flowing into the well if the submersible pump is turned off.

Check valves vary in size. Experts note the size in inches, where 1 inch equals 2.5 cm. The following devices are most in demand:

- 1 inch (high water flow, suitable for all pipes);

- 1/2 inch (weak water permeability);

- 3/4 inch (good for small diameter pipes).

Install the valve device on the water pipe in the most suitable coupling version (with two threaded transitions). Sometimes flange and wafer mounts are used. The choice depends on the diameter of the pipes.

Brass valve Source serviceyard.net

Choice: built-in or external?

Depending on the installation location, there are remote and built-in ejectors. There is no big difference in the design features of these devices, but the location of the ejector still affects in some way both the installation of the pumping station and its operation.

So, built-in ejectors are usually placed inside the pump housing or in close proximity to it. As a result, the ejector takes up minimal space and does not have to be installed separately; it is enough to carry out the usual installation of the pumping station or the pump itself.

In addition, the ejector located in the housing is reliably protected from contamination. Vacuum and reverse water intake are carried out directly in the pump housing. There is no need to install additional filters to protect the ejector from clogging with sludge particles or sand.

A remote ejector for a pumping station is more difficult to install than an internal model, but this option creates a much less noise effect

However, it should be remembered that this model demonstrates maximum efficiency at shallow depths, up to 10 meters. Pumps with a built-in ejector are designed for such relatively shallow sources; their advantage is that they provide excellent incoming water pressure.

As a result, these characteristics are sufficient to use water not only for domestic needs, but also for irrigation or other economic operations. Another problem is the increased noise level, since the vibration of the operating pump is added to the sound effect of water passing through the ejector.

If you decide to install a pump with a built-in ejector, you will have to take special care of sound insulation. It is recommended to install pumps or pumping stations with a built-in ejector outside the house, for example, in a separate building or in a well caisson.

The electric motor for a pump with an ejector must be more powerful than for a similar model without an ejector.

An external or external ejector is installed at a certain distance from the pump, and this distance can be quite significant: 20-40 meters, some experts even consider 50 meters acceptable. Thus, a remote ejector can be placed directly in a water source, for example, in a well.

The external ejector does not so much increase the pump’s performance as it is designed to increase the depth of water intake from the source, which can reach 20-45 m

Of course, the noise from the operation of an ejector installed deep underground will no longer disturb the residents of the house. However, this type of device must be connected to the system using a recirculation pipe through which the water will return to the ejector.

The greater the installation depth of the device, the longer the pipe will have to be lowered into the well or well.

It is better to provide for the presence of another pipe in the well at the design stage of the device. Connecting a remote ejector also involves installing a separate storage tank from which water will be drawn for recirculation.

Such a tank allows you to reduce the load on the surface pump, saving some energy. It is worth noting that the operating efficiency of the external ejector is somewhat lower than that of models built into the pump, however, the ability to significantly increase the intake depth makes one come to terms with this drawback.

When using an external ejector, there is no need to place the pumping station directly near the water source. It can be installed in the basement of a residential building. The distance to the source can vary within 20-40 meters; this will not affect the performance of the pumping equipment.

Device for pump and pumping station

The check valve is not only suitable for water, but also for the pump. The reverse device is in demand in everyday life, as it allows liquids to flow into the house without delay, and is suitable for all types of pumps (deep, self-priming, submersible, surface) and pumping stations.

Use of a valve in combination with a pump. Source lobster-farm.ru

Pressure regulation, increased pressure and protection from emergency situations are the advantages of such a valve. The petal type is most often used. In this case, the diameter of the locking mechanism must correspond to the diameter of the pipe. This tightness of the connection is reliable and efficient during operation.

A check valve for a pump is indispensable in situations where the pumping system fails due to jumping pressure (decrease) in the water bed. Installing the product allows you to mix hot and cold water, prevent damage to the pumping system, eliminate the risk of pressure loss, and also block the outflow of liquid.

The body of the product is often made of brass or stainless steel. In the middle of it there is a spring-loaded plastic or metal plate with a rubber seal.

The check valve for the pump has a mechanism in the form of a cone or ball with a spring of minimal rigidity. The unit is installed before or after the pump. Cast iron or plastic connections are secured using a special adapter.

For a deep-well pump, it is also recommended to install a primary filter. For a surface pumping station, the fittings are attached to the suction pipe of the pressure blower, immediately behind the ratchet.

Plastic model in section. Source heat.guru

General information and areas of application

Purpose

The pipeline system provides for constant movement of the medium in strictly one direction. When the pressure decreases, backflow may occur, which can cause damage and damage technical equipment.

A check valve is a pipeline shut-off device that does not allow the flow of the working medium to pass in the opposite direction.

In the event of an emergency, it acts as a fuse to protect the pipeline or equipment from critical changes or hydraulic shocks. Operation occurs automatically due to the energy of the water flow, which classifies the device as a direct-acting valve.

Areas of application

1. Centralized water supply.

2. Autonomous water supply.

3. Sewer line.

4. Autonomous heating.

5. Industrial networks:

- water pipes;

- drains;

- oil and gas pipelines;

- transportation of chemicals;

- other engineering networks.

Problems to be solved:

- preventing cold water from entering a hot pipe;

- system pressure stabilization;

- protection of pumping equipment when the pump stops;

- protection of equipment from water hammer;

- leakage prevention;

- preservation of pipe filling.

Advantages

The manufactured products have a carefully thought-out design with high efficiency.

Advantages:

- stable operation under sudden pressure changes;

- minimum flow closure time due to the small stroke of the shut-off device;

- automatic action when the flow or system parameters change;

- small weight and size values;

- versatility;

- simplicity of design;

- ease of maintenance;

- good throughput;

- the use of different technologies for fastening to pipes.

Return valve for sewerage

To prevent the flow of waste from being disrupted and circulating in the opposite direction, experts recommend installing a check valve on the sewer pipe. Such a valve will become an indispensable assistant in everyday life for all types of premises, as well as in production, since at the right time it will close the hole in the outlet sewer pipe.

Sewage return valve. Source orgtorg.org

Expert advice on product selection

It is better to choose a check valve for a sewer, water supply or heating system in a specialized store rather than in the market. What matters is quality, reliability, tightness, and long service life.

Installed valve on a pipe. Source osn.by

You should inquire about the guarantee of trouble-free operation of the product from the manufacturer. Quality products will always have it.

A disc valve with a coupling fastening is suitable for metal-plastic pipes, and a rotary type of product is suitable for the heating system. It is necessary to select a water valve in accordance with the parameters of the installed system, the contamination of the flowing medium, the method of fastening and the required size.

The placement of the device must take into account the direction of flow. There must be special requirements for tightness so that there is no leakage of liquid when the valve is closed.

A valve with a large diameter may knock during operation. If the product has an inappropriate or too large diameter, a rattling sound will periodically appear when installed near the pump.

The valve body must be protected from mechanical damage in the form of stretching, bending, scratches and compression. The paint-and-varnish coating of the housing protects the device from corrosion.

The flanges must be parallel to each other during installation. The connecting bolts must be installed from the flange side crosswise, diagonally.

The factory arrow on the body must coincide with the direction of water flow, according to the technological diagram.

Valves for water Source chastnyjdom.ru

If you install a strainer in front of the valve, this will extend its service life.

Important! It is better to leave the choice of product to a specialist.

Electrical part

The station motor is powered directly from the electric meter through a circuit breaker.

To protect the pump, quickly de-energize the engine in cases of unstable power supply or rotor overload, it is advisable to select a machine 10% more than the rated power. For the station motor used in the example, the rated power is 0.77 kW, taking into account the requirements, you need to use a 3.85 A circuit breaker ((770 W + 77 W) / 220 V), but the closest parameter is 5 A. You can use a circuit breaker with differential control.

As practice shows, conventional circuit breakers with similar current parameters cope with their functions quite well.