High-density polyethylene (LDPE or LDPE - abbreviations) is a thermoplastic polymer obtained by polymerization of the hydrocarbon compound "ethylene" (ethene) under the influence of high temperatures (up to 1800), pressure up to 3000 atmospheres and with the participation of oxygen. LDPE is a lightweight, durable, elastic material used in many areas of modern human activity. It can also be called low-density polyethylene (LDPE or LDPE), since it has relatively weak intramolecular bonds and, therefore, a lower density than other types of polymers. The abbreviation LDPE is also used to designate it - the English equivalent of LDPE.

Varieties

High-density polyethylene sheets are produced in various categories depending on the production technique used. The presence of all kinds of impurities is allowed in the raw material, which can be both sediments of related substances and the main participants in the reaction being carried out.

Suspension

Such polyethylene may include chemical stabilizers. During the polymerization of ethylene, they contribute to the formation of a suspension substrate from the granulate. Typically this includes alcohols, oxides of light metals, slightly aggressive acids, as well as certain types of clay.

Mortar

In most cases, it contains residues of catalysts that participate in polymerization under high temperature.

Gas phase

The structure of such polyethylene consists of fragments of essential components, as well as gases. And of all the listed varieties, it has the weakest structure, since it is relatively heterogeneous and contains less wear-resistant areas.

Garbage bags

Large, durable bags are in demand not only for storing and carrying garbage, but most often fall into this category. Garbage bags come in different sizes and are rated based on the volume they can hold. It is calculated in liters. In everyday life, the most popular sizes of garbage bags are 30-60 liters. Huge bags of 160 liters can be used in production. The thickness of trash bags affects their ability to withstand loads. The density of garbage bags is measured in microns. In the article we gave an example of how many kilograms a bag of what density can hold. You can also use these numbers as a guide when choosing garbage bags.

Need some advice?

You want to order packages for the first time, you don’t understand all the intricacies, we are ready to help you! Call (812) 666-18-64

or leave a request and we will call you back.

Distinctive features of LDPE film

Like any other polyethylene product, LDPE film is resistant to environmental influences and provides excellent protection against liquids and water vapor. At the same time, high-density polyethylene gives it special properties:

- Low density ensuring transparency;

- Increased resistance to cuts and physical damage;

- High flexibility, elasticity and extensibility;

- Possibility of easy recycling and subsequent reuse.

In Japan, recycling of LDPE films is routine; only 5% is not recycled and is disposed of. In Russia this figure is negligible. Enterprises that process polymer materials can be counted on one hand. Thus, every year in Moscow only 3% of the plastic film used is sent for recycling. The remainder ends up in landfills. Recycled film is slightly less transparent, but cheaper, which suggests significant benefits from its production and sale.

What is PVD

Literally, the symbol “LDPE” stands for “high-pressure plastic (polyethylene - PE”), but technically it is a low-density thermoplastic with weak intermolecular bonds, made by extrusion under high pressure.

In addition to the common abbreviation LDPE, the abbreviations LDPE, LDPE and LDPE are also used to designate high-pressure plastic.

On a note! Cellophane does not belong to polymeric materials, because... made from wood cellulose.

What can be found in the GOST rules

The standard itself can always be found in the databases of legal portals or downloaded on the same page. To make it easier to navigate all the rules describing HDPE polyethylene in it, you should immediately refer to the contents of this document.

Document structure

- Relevance of the prescribed rules (dates of adoption and amendments),

- Links to additionally necessary legislative acts,

- Explanation of markings with an explanation of the meaning of each position from the 8-digit code,

- A complete description of HDPE of existing brands with standards for all technical indicators for each grade - in relation to the chemical composition and physical and mechanical properties,

- List of permitted additives with their individual properties, separately for gas-phase and suspension types,

- Safety requirements for both the polyethylene composition itself and the rules for working with the finished product,

- Rules for acceptance of finished batches of HDPE with a description of the tests carried out and determination of grades,

- Issues of proper packaging, safe transportation and storage that does not violate the quality of products,

- Guarantees that a polyethylene manufacturer can provide for its product.

Useful applications

At the end of the document, you will find as many as 5 appendices that describe not only the physical and mechanical properties of polyethylene, but also provide recommendations for its production and further use:

- The first appendix gives markings for the first and second grades of each base brand.

- The second will help you choose the appropriate (and permitted) additive formula for the manufacture of products for various purposes:

- for those in contact with food,

- intended for children,

- for the production of packaging,

- pipelines and fittings,

- medical devices and even prosthetic products.

- The next page (Appendix No. 3) provides instructions for the use of polyethylene of each of the brands described - both a complete description of the scope of application and processing methods.

- The fourth sheet will be necessary for those who need to color low-density polyethylene in any color: here is a table matching the color and the substance that will color HDPE products.

- The latest appendix describes all the physical and mechanical characteristics of the grades, from melting points to a list of dielectric properties.

IMPORTANT! GOST is not only instructions for action for manufacturers, but also useful information for consumers. Knowing the standards, you can choose products that fully meet your needs and safety regulations.

What is the difference between PVD and HDPE

Being made from the same polymer, high- and low-density polyethylene differ significantly in their performance characteristics. The differences are based on different manufacturing technologies, which initially affect the density of the material.

- LDPE is a low-density PE, characterized by high strength properties mainly due to the flexibility and elasticity of the material.

- HDPE is a high-density PE that has higher strength indicators in relation to chemical and radiation background, but lower plasticity indices, increasing the likelihood of pipe rupture under the influence of water hammer or sub-zero temperatures.

In addition, LDPE is more resistant to ultraviolet radiation than high-density PE, which is prone to cracks when exposed to direct sunlight.

The following types of polymers occupy a somewhat intermediate position between LDPE and HDPE products:

- MDP (medium pressure polyethylene), obtained by mixing LDPE and HDPE masses and accumulating the qualities of both materials.

- LDL (Linear Low Density Polyethylene) or LLDPE (Linear High Density Polyethylene). It has a rigid structure inherent in HDPE, but is resistant to cracks, just like elastic LDPE.

- PVDF (Polyvinylidene fluoride) is a fluorine-containing polymer. Characterized by a wider range of operating temperatures, strength and wear resistance.

Areas of application

The presence of foreign components, including catalysts, determines the widespread use of HDPE for industrial purposes, where strength and strength are considered more important criteria than toxicity and environmental friendliness. Only a small part of the finished product is used to satisfy household needs.

The scope of use of the material directly depends on the method of processing polyethylene. In accordance with GOST, the following areas are distinguished: extrusion, injection molding, as well as blowing and rotational molding.

Extrusion

This method involves producing polyethylene from polymer raw materials by pressing the finished material through a molding cone - the hole of the extruder. The method makes it possible to produce packaging bags, conveyor and bubble belts for packaging goods, as well as electrical wires and meshes of various types (household, agricultural and construction). The material is widely in demand for the production of pressure sewer pipes, drainage and gas pipes of various diameters. HDPE retains its characteristics when exposed to temperatures from -60 to +100 degrees.

Injection molding

This method of processing polymer raw materials involves injecting a melt under high pressure into a mold with its subsequent cooling. This method produces fittings, kitchen accessories, as well as furniture fittings, plastic lids, container boxes and some types of plumbing fixtures.

Blowing

During processing, heated plastic is injected under pressure into a special cavity shaped like the product that is planned to be manufactured. The technology makes it possible to obtain tanks, tubs, cisterns, barrels and all kinds of cosmetic bottles.

Rotational molding

This method of manufacturing polymer products appeared relatively recently in our country. It allows us to produce a wide variety of products according to customer drawings. Rotomolding is used to create children's play complexes, mobile dry closets, garbage containers, traffic cones and many other products. This area of using HDPE is considered one of the most promising.

From high-strength polyethylene you can obtain the thinnest film, the thickness of which is comparable to tissue paper and does not exceed 7 microns. It can be a good alternative to heat-resistant paper, for example, parchment - unlike the latter, HDPE has good water resistance and exceptional aroma and vapor barrier characteristics.

It is noteworthy that worn-out PVP items do not decompose under the influence of external natural factors. That is why the issue of their recycling is especially relevant - such a solution can be not only economically profitable and environmentally friendly. In recent years, polyethylene processing has become one of the most promising areas of industry. Recyclable materials are widely in demand in the manufacture of plastic containers, dishes and other products that do not require high quality products.

What is the difference between LDPE and HDPE polyethylene, you can find out from the video below.

Where can I order the production of LDPE packaging?

For more than 15 years, we have been producing and selling wholesale high-quality LDPE bags at a competitive price. We use modern equipment and produce large batches of products on time.

Today TornadoLogo is one of the leaders in its field. We are trusted by Russian Post, Rosneft, PJSC Sberbank, Rostelecom. The quality of our projects meets the stated standards. If we identify a manufacturing defect, we will redo the order or return the money.

You can buy packages of standard and original shapes with corporate symbols. We will prepare a layout for you and make a sample for free. The company has a flexible system of discounts for large customers. Regular customers are provided with installment plans.

Our products are available throughout the country. When ordering from 30,000 rub. We deliver finished products free of charge throughout Moscow and within 10 km from the Moscow Ring Road.

TornadoLogo managers will tell you in detail about our services and calculate the exact cost of the work. Call us at +7 (495) 966-03-82 or order an online calculation.

Characteristics

Polyethylene sheets are produced in strict accordance with regulatory documents that indicate how this material is manufactured, transported and stored. At the moment, the most used types are sheets made from high-density polyethylene (HDPE) and low-pressure polyethylene (HDPE). Separate standards have been developed for these types, GOST 16338-85 for HDPE and 16337-77 for LDPE.

Low-density polyethylene sheets have the following characteristics:

- very high density - more than 0.941 g/cm³;

- excellent frost resistance;

- moisture resistance;

- tolerates contact with oily and fatty liquids well;

- environmentally friendly.

High pressure polyethylene sheets have the following basic properties:

- flexibility and plasticity;

- density 0.900–0.939 g/cm³;

- melting point – +103–+110 degrees Celsius;

- withstands low temperatures of about minus 120°C.

The standards indicate all the parameters for both groups; after studying them, you can familiarize yourself with everything in detail. Both materials do not emit harmful substances and are absolutely harmless to the human body in direct contact with them.

And also when using it, no precautions are required. You can also find a less common one - high molecular weight polyethylene

This type of material has increased resistance to mechanical stress, rigidity, reliability and wear resistance. It is able to resist impacts even at minus 200°C, begins to melt at +150°C, and the density is 0.95 g/cm³.

Advantages and disadvantages

Due to their physical characteristics, high-pressure PE pipes have a number of advantages:

- They are strong, durable and durable. LDPE pipes can withstand the pressure created in the circuit by the movement of the carrier, even when pressure lines are installed. A slight displacement of the soil when laying underground communications will also not harm the pipeline.

- The lightness of the material facilitates transportation and installation work and does not create additional load on the structure.

- Thermal and chemical resistance expands the scope of use of LDPE pipes.

- LDPE pipes are not subject to corrosion processes.

- The high index of flexibility and elasticity of the material ensures resistance to sub-zero temperatures, which prevents rupture of the line even when the media freezes.

- Elasticity prevents damage to the pipeline as a result of water hammer.

- The low thermal conductivity index minimizes heat losses when transporting hot media and prevents the formation of condensation on the outer part of the pipe.

- LDPE pipes are environmentally friendly for human health, so they can be used without restrictions to supply drinking water.

An undoubted advantage is the low cost with a fairly wide range of models.

Unfortunately, nothing is perfect in the world. Similarly, LDPE pipes have some disadvantages that should be taken into account when designing pipelines:

- Insufficient resistance to ultraviolet radiation will require the installation of an additional protective casing when laying the pipeline in open areas.

- Susceptibility to high temperatures (and at a carrier temperature above 80⁰C the material is prone to softening) limits the use of LDPE pipes in the field of hot water supply and heating. A prerequisite is the presence of an automatic thermostat that controls the heating of the liquid.

Polyethylene grades

Basic grades of polyethylene come in 2 types depending on the type of device that produces them (autoclave or tubular reactor) and 3 grades (highest, first and second). If LDPE is produced in granular form, then all its particles must be of the same shape and size. The size limits for LDPE particles are normally from 0.2 to 0.5 cm. Also, small deviations from the norm are allowed in each batch (i.e. the presence of particles larger than the base value), but it should be noted that their percentage should not exceed limits established by GOST.

In total, GOST establishes 8 basic grades of LDPE for autoclaves and 21 grades for tubular radiators. The digital code embedded in the name of each brand makes it easy to determine what product we are talking about (for LDPE, the first digit is always 1, it indicates the presence of high pressure in the system), on what equipment the LDPE was produced (the second and third digits in the name of the brand, numbers from 01 to 49 are assigned to LDPE produced in an autoclave, numbers from 50 to 99 are assigned to LDPE from tubular reactors), how the averaging of the polymer compound took place (0-cold mixing, 1- during melt), what density is the substance (there are 6 classes in total), and also an indicator of PVD fluidity (number separated by a dash).

At the moment, domestic polyethylene producers are located in Angarsk, Tomsk and Kazan. In the countries of the near CIS, LDPE is produced in Belarus (Novopolotsk). The most famous foreign manufacturers of LDPE: TVK, Vordian, Polimeri Europa, NOVA Chemicals, Basell, etc.

Along with the classic forms of LDPE, in recent years the production of a similar modification, linear polyethylene (LLDPE or LLDPE), has begun to gain momentum. Its structure is the same linear as that of low-density polyethylenes, but has a larger number of branches.

LLDPE is a much more promising substance than classic LDPE, since it has several times greater strength, despite the fact that the thickness of the resulting films is much lower. In addition, LLDPE, unlike other polyethylenes, can be used for packaging hot food products due to its larger operating temperature range. It also does not crack and has a shiny surface.

Now the price is almost one and a half times lower than the price of LLDPE, but the hour is not far off when LLDPE will catch up with its “closest relatives” in class.

Every year LLDPE becomes cheaper to produce, which means that potentially in the near future it could squeeze LDPE and HDPE out of the leading positions in the polymer market.

Classification

The use of various stabilizers, additives and plasticizers in production allows us to expand the range of products by changing the physical properties of polymers:

- increasing density and strength (relevant for cross-linked polyethylene);

- adding plasticity (foamed polyethylene);

- improved adhesion to paints;

- reduction in flammability, etc.

In the Russian industrial segment, high-density polyethylene is produced in 2 types:

- PVD-108, characterized by increased strength and rigidity;

- PVD-158, characterized by a particularly smooth texture. As a rule, thin-walled pipes are produced from it.

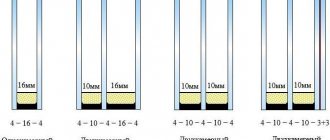

According to the type of structure, LDPE pipes are:

- single-layer;

- two-layer. These, for example, are flexible corrugated models, in which the corrugated outer layer is combined with a smooth inner one;

- three-layer, additionally reinforced with synthetic thread;

- combined, i.e. consisting of several types of polymer (for example, high-density polyethylene and low-density polyethylene).

The size range also differs. LDPE pipes are produced in a wide range of diameters (from 6 to 2200 mm) and lengths (from 2 meters to multi-meter coils (coils) cut to the required size).

Peculiarities

Granulation is the final stage of any technological stage in the production of ethylene polymers. The vast majority of all polyethylenes are produced in the form of granules, that is, durable particles of certain dimensions.

The granulation technique helps solve three problems at once:

- finishing of polymers - removing residual additives and chemical solvents, improving the mechanical characteristics of the material, degassing, as well as homogenization;

- giving the product the performance characteristics necessary for more rational use of polyethylene in the creation of plastic products;

- creation of materials with all kinds of additives that can change the parameters of chemical stability, density, optical, and dielectric properties of polyethylenes.

Polyethylene in the form of granules has significant advantages compared to flake and powder.

- Reducing the volume by half (the density of bulk polyethylene in powder and granular forms is 0.20-0.25 g/cubic cm and 0.5-0.6 g/cubic cm, respectively). This allows you to significantly reduce the costs of warehousing, moving and packaging the product.

- High flowability - the use of granules does not create any problems during packaging and transportation. Plastic granules do not stick to the walls of the equipment, do not collect in the units of transport mechanisms, are not electrified and do not form “dead zones” that cause instability of production processes and stoppage of technological equipment.

- Minimizing loss of presentation - polyethylene granules are poured out of containers and loading mechanisms in full.

- Low susceptibility to photoaging and destruction. Reducing dust generation during production to zero and, as a result, improving working conditions.

After drying and all tests for compliance with product quality requirements, granulated polyethylene is packaged in 25 kg bags and marked. In accordance with GOSTs, granules from a batch must have the same geometry and size in all directions ranging from 2–5 mm, and be equally colored. Each batch may contain granules measuring 5–8 mm and 1–2 mm in a volume not exceeding 0.25% and 0.5%, respectively. Elements with pronounced defects (foreign inclusions and rough surfaces due to polymer destruction) are rejected.

Selection of package sizes

The sizes of plastic bags, like the sizes of paper bags, depend on their type. The smallest packaging and T-shirts, large dense bags are used for garbage, clothes, shoes, car tires.

T-shirt package sizes:

- 28x50,

- 30x60,

- 30x55,

- 30x57,

Standard sizes of bags with cut-out handle – dimensions:

- 38x50+3,

- 45x50+4,

- 55x55+4,

- 58x58+4 and so on.

The packaging dimensions are indicated on the website; it is worth remembering that the total size of the package is indicated, and not its usable area. The length is measured from the beginning of the handle to the bottom, the width from edge to edge. In this case, the part of the package where the folds are located is marked in a special way. The folds on the bags are side folds. Their size is indicated after the “+” sign.

Bags with a cut-out handle usually have a bottom fold that increases their volume. For stores, packages are chosen based on the dimensions of the products sold. It is worth remembering that the buyer, when thinking about which package to choose, will first of all pay attention to dense packages. A durable package is a symbol of reliability for the buyer; with it, he is sure that he will deliver his purchase safe and sound.

Basic methods of connecting and installing LDPE pipes

Currently, there are several technologies for connecting LDPE pipes and fittings:

Docking using compression fittings.

The pipeline connection is carried out using special clamping and sealing rings. This method is easy to implement and does not require special equipment, but is not recommended for pressure systems and pipelines laid in hard-to-reach places. Used primarily for pipes with a diameter of up to 65 mm.

The compression assembly diagram is shown in the photo below:

Direct welding.

The technology involves the use of a special welding machine (soldering iron) with nozzles, with the help of which the outermost part of the elements to be connected is melted. The result is a strong, tight and durable joint.

Connection using electric welding fittings.

The fitting parts are equipped with a special spiral, which, when heated by a special welding unit, fuses the fitting and pipe into a single whole. This connection is considered the most durable.

Advertising packages

Packages with the company logo and contact information are used as advertising. Since to produce such bags you need to make a cliche, the first order costs a little more.

- HDPE packages

Production technology

There are 2 ways to produce LDPE:

- in autoclaves by stirring;

- in tubular reactors.

How is polyethylene obtained ? The feedstock is ethene gas. LDPE is produced by radical polymerization. It consists of initiation, increase and circuit termination. Technologies used: formation in bulk or in suspension. An initiator is supplied to the purified ethene, and a new compound is obtained. Next, the substance is compressed. Residues of ethylene in the granules are disposed of by throttling in a receiver under low pressure. The resulting raw materials are of the highest, first and second grade.

Categories and purpose

There are two large categories of garbage bags - industrial and household.

Parameters of household packages:

- Volume – 20-80 liters;

- Average load capacity - 6-7 kg.

- Usually made translucent or transparent, the density is insignificant.

Features of industrial bags:

- No tendency to stretch, dense structure;

- Load capacity – on average 50 kg or more;

- Volume – about 80-100 liters or more.

Industrial packages can be used, among other things, when organizing cargo transportation. They will protect against UV rays, pollution, and moisture.