Modern toilets come in a variety of designs and from a wide range of materials. The products also differ in the shape of the bowls and methods of connection to the sewer system. Since the installation of any type of plumbing by hired specialists requires significant financial resources for the budget of the average family, many users practice connecting the toilet to the sewer independently, taking into account the simplicity of the work performed.

To install a toilet, no special tools are required, and the connection to the sewer pipeline itself is carried out using numerous varieties of shaped plumbing products. In this case, it is important to choose the right design of the device - the connection technology and the types of parts used depend on this.

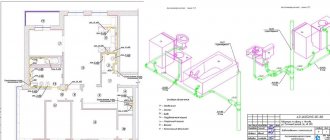

Toilet installation steps

General rules for installing a toilet

To properly connect any toilet to the sewer system, you should follow a few simple recommendations:

- The diameter of the pipes from the toilet outlet to the waste outlet should not change either upward or downward.

- The jointly connected toilet and sewer outlets must be located at right angles to the vertical riser pipe or its horizontal section.

- All horizontal pipe sections must be laid with a slope. For pipelines measuring 110 mm, its standard value is 20 mm.

- When laying sewer pipelines, direct 90-degree turns should be avoided; they are usually implemented by sequentially joining two 45-degree shaped elements.

- Fastening of plastic polyvinyl chloride (PVC) pipelines to supporting surfaces is carried out in increments of no more than 10 values of their outer diameters.

- To clear the system from blockages, inspection hatches must be present or tees must be installed at a distance of no more than 10 m from each other.

Release forms

Classifications of sanitary devices

Progress does not stand still - manufacturers systematically bring new varieties to the market.

They can be classified into several groups based on criteria. Depending on the location of fixation, it is customary to distinguish the following categories:

- Floor-standing.

- Hanging.

Manufacturers also make allowances for the age of their customers and offer:

- Sanitary products for adults.

- Children's options.

The bowl in the equipment may differ in shape:

- Funnel-shaped.

- Rounded.

- Design form (in cases where custom production is acceptable).

The drainage system has differences, and manufacturers have gone as far as possible in this matter. The following options are available:

- Single-mode. When you press the button, the tank is completely emptied.

- Dual mode. You can pour out all the water or only part of it.

- Contactless. Flushing is carried out automatically. This is the most expensive option.

A common question is the availability of side release devices. The reasonableness of such a question occurs only if you have to deal with very small dimensions of the bathroom. The ingenuity of our people is truly limitless, and the side release is proof of this. The thing is that if you place the toilet on its side, you can easily free up the space needed to install a washing machine.

So, such varieties have not yet gone on official sale today, but if you wish, you can literally do everything with your own hands. To ensure lateral descent, adapters can be used. On horizontal sections, you should make a 90-degree turn out of two 45 degrees, although some recommend 90 degrees at once, just to ensure a slope.

Release options

Structurally, all toilets differ from each other in how they connect to the sewer pipeline; for this purpose, their neck is installed in different directions relative to the bowl. Thanks to this, plumbing fixtures can always be rationally connected to the drain, regardless of its spatial location.

Vertical

Since in this type of design the outlet pipe is located at the base of the bowl, a sewer outlet placed in the floor is used to connect it. This type of connection was previously often used in Soviet Khrushchev buildings and is now popular in Western Europe and the USA. Since the waste pipe must be hidden in a relatively narrow floor slab, which is both the floor and ceiling of the lower apartment, such an inclusion is practically not used in modern multi-storey buildings.

The situation is different with private houses and dachas, where plumbing fixtures on the lower floors are much more often connected to a drain with an outlet in the floor. In apartment buildings, this connection scheme is sometimes used on the first floors, where the riser goes into the basement.

Main types and typical dimensional parameters of corrugations

Straight

Plumbing fixtures with horizontal outlets are used in restrooms where saving space is important. With this placement, the sewer outlet comes out horizontally from the wall, and the bowl outlet is connected to it using an elastic cuff.

In this case, the sewerage inlet is located at a certain height, and the toilet can be moved close to the wall, increasing the area of the room. This type of connection is used in modern models with plastic risers, in which the input tee can be easily raised to any distance from the floor, as well as in installation versions.

Oblique

A universal outlet with an angle to the horizontal plane of 140 - 145 degrees, widely used in both old and modern plumbing equipment. Convenient when connecting toilets to tees located at the screed level. The advantages of this connection option compared to the horizontal one are the absence of stagnation and non-criticality to the alignment of the connected pipes.

Installation tool

Nuances of the work

If you have to carry out work in the bathroom of an old house where cast iron pipes are installed, then the device must be connected in the following way. The outlet is inserted into the hole in the sewerage system. The remaining gap should be filled with cement mortar, this must be done in such a way that the composition does not get into the riser. You can use a cuff that fits over the outlet, which is immersed in the opening of the sewer pipe. The surface must first be cleaned of cement, dirt and foreign objects. Unevenness can be eliminated using sealant.

Materials and tools

Before connecting the toilet to the sewer system in an apartment or private house, prepare the following tools and materials:

- Corrugations, cuffs, eccentrics, pipes, shaped parts through which the toilet outlet is connected to the sewer.

- Fasteners for screwing the base to the floor. Typically the set consists of a pair of dowels with hex screws included in the package.

- Flexible hose for supplying cold water to the tank.

- Adjustable or regular wrenches for fixing the liner and bowl to the screed.

- Tape measure and pencil for marking cut pipes and mounting holes on the flooring.

- A hacksaw or grinder with a disc for metal or concrete for cutting hard PVC pipes to size, sandpaper for removing burrs from their edges.

- A hammer drill with drills matching the size of the mounting dowels for ceramic tiles and concrete for drilling holes for attaching the bowl to the floor.

- The sealant that most plumbers use to seal flexible rubber pipes to prevent leakage is completely useless in this application. It may be needed to coat the bottom of the bowl in order to give it a stable position in case of an uneven floor. Also, under the bottom you can place scraps of the substrate for laminate, linoleum, rubber and other waterproof elastic materials cut along its perimeter.

Dimensional parameters of standard horizontal bends and their connection through cuffs

Installation cost

If it is necessary to replace or properly install a toilet, the first thing that interests us is how much it costs to install a toilet. The cost of installing a toilet by an experienced craftsman in the capital is at least 1,500 rubles. This does not include the cost of consumables - screws, corrugations, lubricants and the cost of dismantling if necessary.

You will have to buy them in any case, but if we have all the necessary tools for installing and connecting the toilet to the sewer, then the cost of all work is reduced by exactly the cost of ordering a qualified technician. You can perform many toilet installation operations for free, if, of course, you do this yourself.

Connecting toilets to the sewer system

To connect the toilet to the sewer, first of all, the joint location of its outlet and the drain hole is taken into account - the type of shaped elements used, corrugated pipes and transition couplings depends on this. Often, plumbing fixtures are connected to an outdated cast iron riser; to carry out this operation, special adapters of various types are purchased.

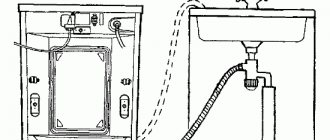

With horizontal outlet

The main advantage of direct outlet is the ability to install the toilet close to a false wall, if a PVC pipe with a socket and a rubber sealing ring comes out horizontally from it; it has an internal diameter of 110 mm for connecting the socketless opposite end of a similar pipe. The outlets of most standard toilets have an outer circumference in the range of 100 - 102 mm; in order to join them with a 110 mm socket, you will need an elastic adapter-cuff, the first end of which is put on the outlet of the device, and the second is lowered into the waste pipe. Connecting a toilet with direct outlet to the sewer using a cuff is the main method of installing plumbing with this design of pipes.

Another joining option is to use a section of a drain pipe, one of the sides of which has a standard outer diameter of 110 mm and is inserted into a drain socket with similar dimensions, and the second is equipped with an internal cuff that can be easily put on the toilet outlet (a similar system is used when installing wall-hung modifications with installation ). Often the inlet drain hole in the wall and the toilet outlet do not coincide; in this case, eccentrics are used to align them, which are sold in a wide range in the retail chain.

Situations often arise when a device with a horizontal outlet is connected to a drain near the floor surface; in this case, a corrugated pipe, a fan pipe or a rigid system of two joined short PVC pipes with a slope angle of about 45 degrees is used.

Typical dimensions of toilet vertical outlets and their connection to the drain

With vertical

Water in plumbing fixtures with a vertical outlet falls freely downwards, so there are no increased requirements for sealing the connection. To connect, it is enough to use one adapter sleeve, placed with one end inside the sewer pipe and the other on the outer surface of the toilet outlet.

During installation, the adapter collar is inserted into the sewer outlet, after which the toilet is placed with the outlet inside the adapter - this makes it more convenient to track the accuracy of its location. If it is necessary to move the plumbing fixture slightly, an eccentric is placed in the sewer hole, and then installed in the intended location.

Dimensions of toilets with inclined outlet and their connection through corrugation

With oblique release

Plumbing fixtures with an inclined outlet are purchased more often than others. This is due to the design of standard risers, in which a tee is placed above the floor at the same level as its plane, and above it there is a pipeline. Typically, the distance between the outlet and the inlet sewer socket is greater than with other connection methods, so the most popular connection option is the use of corrugation. A flexible corrugated pipe is inserted into the drain socket, and the other end is connected to the toilet outlet; the connection method is not critical to the distance and alignment between the pipes.

It should be noted that the typical outer size of a corrugation with flexible cuffs for insertion into a waste pipe is 110 mm - this is not entirely practical for connecting it to the socket of a PVC pipe with a similar inner diameter due to the possible low sealing of the joint. Therefore, it is optimal to insert a regular corrugation into a cut PVC pipe having an internal size of less than 110 mm (about 105 mm) for the thickness of its walls.

If a toilet with an oblique outlet is installed, experienced plumbers will connect it to reduce hydraulic resistance using one or two corner fittings with slopes of 45 or 90 degrees. Typically, one of the elements is inserted into the sewer socket, and the second is connected through an o-ring to the bowl outlet (an o-ring seal is not needed to cut a drain pipe at the outlet). Using corner shaped elements complete with other parts, it is convenient to connect the bowl when placing the drain on the side.

Connection of plumbing fixtures using PVC corner fittings

To the cast iron sewer

The difference between a cast iron pipe and a plastic one is its higher internal diameter and trapezoidal shape (from 118 to 123 mm) without built-in O-rings. This feature makes it difficult to connect polymer PVC pipes to a cast iron sewer and can be easily eliminated with a special adapter collar, which is placed inside the cast iron pipe.

At the end of most corrugated pipes there is a cuff made of a series of flexible rings, the outer diameter of which (the usual range is 110 - 120 mm) is not capable of or can partially overlap the cast iron socket. They can also be used to connect to cast iron pipelines, either with or without a collar.

Connection to a cast iron drain using intermediate collars

Dismantling old elements

Before connecting the toilet to the sewer pipe, the installation site should be cleared of elements of the previous structures. The procedure is carried out using a hammer, screwdriver and pry bar.

In most cases, the outlet of old products is built into a cast iron structure (“elbow”), which requires breaking the pipe with a hammer. When performing this procedure, be sure to wear safety glasses. Otherwise, sharp ceramic shards will get into your eyes, causing injury.

After the old plumbing fixture is dismantled, you need to knock on all sides of the cast iron pipe, then begin to remove the cement layer and other deposits from the walls.

To remove small parts, a screwdriver and a hammer are enough, but for large elements you will need to use a pry bar. When tapping with a hammer, it is important not to overdo it, because... strong impacts will lead to the splitting of the cast iron socket.

In this case, you will need to break the floor to get to the sewer riser. Then you will need to connect the new outlet to the riser.

When the main deposits have been removed, you can begin the final stage of cleaning the pipeline. To do this, you need to coat them with a special chemical for cleaning the toilet, and then scrape off the residue using a wire brush.

Finish cleaning with a rag. The first 5-6 cm of the cast iron socket must be completely smooth from the inside, because the absence of leaks in the future and the tightness of the joint depend on this. The entire procedure must be carried out wearing protective gloves.

Installation errors

Connecting the toilet to the drainage system with your own hands, if you follow the instructions, is not a very difficult operation. The following most common mistakes should be avoided during work:

- The plumbing fixture is purchased in accordance with the placement of the sewer inlet pipe - if it is located near the floor, choose a model with an oblique outlet, if placed at a higher level - with a straight outlet. If you do the opposite and connect a bowl with an oblique outlet to pipes at a high altitude, there will be disturbances in the operation of the drain - its slowdown, incomplete emptying of the bowl, excessive water consumption.

- Too large a distance from the device to the sewer riser will lead to increased water consumption when drained into the sewer.

- Using a large number of right angles or a sharp bend in the corrugation will cause slow drainage, incomplete cleaning of the bowl after pressing the button and, accordingly, excessive water consumption.

- Placing the bowl on an uneven floor without a backing will cause it to become loose over time and, in extreme cases, cause damage. Often the manufacturer supplies fasteners that are not very reliable; in many cases it makes sense to replace them with dowels and screws of greater length and diameter.

Varieties of cuffs and fan pipes

- Connecting the toilet to a horizontal pipe after other plumbing fixtures will lead to slower flow and incomplete drainage; large volumes of water will be needed to clean the bowl.

- Installing a toilet in separate units, in which the bowl is first screwed to the floor and then the tank is placed, can lead to errors in its spatial arrangement. With a fairly high probability, in the future it will not be possible to properly connect the connecting elements (corrugation, cuffs, shaped elements); the tank may rest against the back wall or, conversely, be located too far from it.

- When choosing a popular corrugation among consumers, one should distinguish between the areas of use of its two main varieties: the first, with a cuff in the form of several 110 mm plastic rings, is designed for placement inside a cut PVC pipe. The second model with smooth outer walls of 110 mm is designed for installation in an extended socket of PVC pipes, which has an internal rubber sealing ring.

Installation of a toilet using drain pipes (white)

When choosing a toilet, pay attention to the location of the inlet pipe of the sewer pipe - if it is placed in the wall at a certain height from the floor, choose a model with a horizontal outlet; if the drain is located at the bottom, it is better to use a device with an oblique outlet. The preferred connection methods also depend on the design of the outlet: in straight horizontal and vertical ones, cuffs are used, in inclined ones, corrugations or corner shaped elements are used.

For reference

If you need to replace or install a new device, you should be careful, as an error may be made. Direct production is typical for the products of many foreign and Russian manufacturers, including Cersanit, Duravit, etc. Companies often offer for sale products whose service life can reach 30 years.

Variety of species

Classification of vertical type models is carried out in several directions.

Material

Stainless steel, bronze, glass and many other materials are used for production. Although all such models are expensive. The most popular designs include:

- Earthenware toilets. Ceramic material is inexpensive. But the porous surface gets dirty quickly and is difficult to clean. The situation can be corrected by covering the device with glaze.

- Porcelain models are more expensive. But it keeps the surface clean perfectly.

Advantages and disadvantages of a toilet with a vertical outlet to the floor

Each type of release has its positive and negative sides. Bottom flush toilets are gaining popularity due to significant advantages. Let's consider the main advantages.

The choice of a suitable model in a particular case is based on the options for the release of the drainage system, which should dock with the sewer without any problems

Pros of vertical release:

- Allows you to save space;

- The high water level ensures hygienic drainage;

- Plaque from the walls of the toilet bowl is washed off better;

- Good drainage is also ensured by the built-in siphon;

- No splashes during rinsing;

- High quality and reliable tank.

This type has no particular disadvantages. Among the disadvantages, it is worth noting the need for a special hole in the floor. It must be cut into the tile during installation. Another disadvantage is the small selection. You need to work hard to find the right option.

Replacing a vertical drain with a different design

If the area of the room allows you to move the structure to the side by 20 cm, then it is realistic to install any other device with a different type of descent instead of a vertical device. The connection is made through a corrugation.

- The old model of plumbing is being dismantled.

- The new design is placed at an accessible distance from the sewer pipe so that there is enough corrugation and the connection is not cumbersome.

- The end of the toilet pipe is treated with sealant.

- A corrugation is placed on the joint.

- The other end of the corrugated pipe is fixed in the sewer pipe. The slope of the pipe should be towards the sewer. There should not be even slight bends on the surface. Otherwise, it is a pre-arranged place for garbage collection.

Right choice

Having decided on the release form, you need to consider a few more important points:

Toilet material

Traditionally, ceramic appliances are installed in houses and apartments. However, you should know that ceramics come in different varieties. Two varieties have gained the most popularity:

- Faience: attractive at its affordable price, but has a porous structure. When the glaze coating wears off, the material begins to absorb water (the product becomes less durable), dirt and unpleasant odors.

- Porcelain: this material is somewhat more expensive than earthenware, but it is not characterized by porosity.

Note that the difference in price is not significant, so it is better to choose the porcelain model.

Porcelain floor-standing toilet

If you are interested in a very budget option, pay attention to acrylic toilets. Just be prepared for the fact that they quickly lose their attractive appearance and are short-lived. Those who want to add some zest to the interior will certainly like a copper toilet

And if you need a vandal-proof device (usually installed in public toilets), then the best would be a stainless steel toilet

Those who want to add some zest to the interior will certainly like a copper toilet. And if you need a vandal-proof device (usually installed in public toilets), then the best would be a stainless steel toilet.

Bowl shape

For a long time, the most common were toilets with a sloping back wall and a drain hole placed forward. But this form has a drawback: after each session, the bowl has to be cleaned with a brush.

Today, a new type of toilet is becoming fashionable - funnel-shaped, in which the drain is located almost in the center. Feces go directly into the water, so the bowl does not get dirty. But at the same time, they can splash the user, which, of course, no one likes. This problem is less noticeable for owners of toilets with an anti-splash system.

First of all, such toilets are taller than their regular counterparts, that is, the distance from the rim to the surface of the water in the siphon is increased. In addition, they have a special collar around the drain hole, which is designed to extinguish “gurgles”.

Diagram of a funnel-shaped toilet with horizontal outlet

Toilet bowls are produced that have a platform instead of a sloping wall. Most users consider this form to be outdated and impractical, mainly because the device may splash its owner when the water is released. But if you take a closer look at such toilets, you will discover a significant advantage: waste falls into a small puddle of water (the platform has a concave shape).

Therefore, the porcelain remains clean; at the same time, no splashes or “gurgles” annoy the user.

Design

For most users, a toilet design is familiar, in which the bowl and tank are made in the form of two autonomous elements. This design has its benefits: if chips or cracks appear, only the damaged part will need to be replaced.

Autonomous toilet and cistern

But there is also a drawback: due to wear of the sealing gaskets or fasteners, water may leak out from under the tank. If you don’t want to deal with such troubles, purchase monoblocks in which the tank and bowl are made as a single piece.

Type of plum

There are two options. The classic one is direct drainage, when water simply runs down the shortest path from the inlet of the bowl into the siphon.

A circular drain is considered more advanced, in which streams of water first rush into the channels under the rim and then flow down, washing the entire surface of the bowl.

Types of toilet flush

When choosing a toilet with a circular flush, you should take into account its important feature: if the water contains a large amount of dirt, hardness salts and other impurities, the narrow channels under the rim will quickly become clogged.

Drain mechanism

Regular drainage is no longer quoted. The most popular have become toilets with two buttons: with one, the entire tank is emptied, with the other, only half. If you have a water meter, such a system will help save a lot of money. Economical toilets may have one button, but it has a design feature: when pressed again, the drain valve closes.

Thus, the user has the opportunity to pour as much water into the toilet as he sees fit.