Current price list from September 15, 2021

Price list for joint sealing kit dated September 15, 2021

To prevent both horizontal and vertical displacement in heating networks, fixed pipeline supports are used.

Pipeline supports are subject to loads of various types. This:

pipeline weight;

linear and volumetric deforming load from high pressure and high temperature of the transported substance;

ground displacement.

To compensate for such loads and transfer their energy to construction supports, as well as to protect elements of pipeline systems with pre-insulated pipes, fixed supports in polyurethane foam insulation are used.

They are:

- with galvanized protection (OC) for above-ground installation:

- with polyethylene sheath (PE) for ductless underground installation.

Supports have the following advantages:

- reliable protection against corrosion;

- reduction of heat loss;

- withstand vibration and temperature changes.

Application

Fixed supports PPU PE are used in the construction of any pipeline. They give strength to the entire line, perceive and absorb loads caused by soil displacement and other forces (for example, temperature deformations). A fixed support for routes and heat supply pipes in a polyethylene shell is used when laying underground communications. The elements are placed evenly along the entire length of the pipe, absorbing linear and vertical loads resulting from the own weight of the pipe, insulation and transported product.

During installation, the fixed support of the heating mains is fixed in a reinforced concrete frame, due to which the heat pipeline is attached at certain points of the heating main into separate sections that, according to the design solution, are independent in terms of temperature deformations. The length of these sections of the heating main is determined by the compensating feature of the expansion joints (including bellows expansion joints) installed between the two nearest fixed supports to absorb the temperature expansion of the pipeline in the insulation.

What are fixed supports used for?

Fixed supports are used to provide strength to above-ground and underground pipelines. Their structure and properties may vary depending on the location.

Aboveground structures are subject to pronounced mechanical stress. Such pipelines are not protected by anything, and if they are unstable, they can quickly become unusable. In order to avoid this, such structures are often placed several centimeters above the ground on special supports.

Such fixed supports take on most of the load acting on the pipeline. Fixed supports can be mounted on concrete or reinforced concrete pedestals, which allow the pipes to pass above the ground.

In addition to increased mechanical load, above-ground structures are subject to significant temperature fluctuations. This is especially pronounced when operating a heating pipeline in severe frost conditions. Therefore, fixed supports above the ground are equipped with additional insulation and eliminate heat transfer.

Underground structures are subject to significant mechanical load in the form of the soil layer under which they are located. Without fixed supports, such heat pipes can bend or shift. In addition, structures experience constant mechanical vibrations.

We recommend reading: How to clean drains using caustic soda?

They are especially pronounced near roads and metro lines. Ground vibrations are transmitted to the pipes, which can interfere with the laminar flow of liquids and also reduce the service life of the structure. Fixed supports with foam protect the pipeline from vibration, pulsation, pressure and movement.

Advantages

By using our products, the durability of heating networks using existing installation methods can be increased by 2.5 - 3 times. Heating networks based on thermally insulated pipes in polyurethane foam insulation are much cheaper to maintain. The polyethylene coating reliably protects the metal from corrosion.

- Ensuring pipeline safety. The support design does not allow the system to deviate from the design constraints.

- Reduction of temperature deformations caused by temperature fluctuations of the transported medium.

- Resistance to mechanical and chemical stress. Preventing pipeline destruction and deformation.

- Easy to install and operate. In this case, competent design is of great importance.

- Reduced capital costs when using a channelless installation method.

Characteristics

The thermal insulation characteristics of fixed supports in polyurethane foam must correspond to the parameters shown in table No. 3.

| Index | Characteristic |

| Density*, kg/m3, not less | 60 |

| Compressive strength at 10% deformation in the radial direction, MPa, not less | 0,3 |

| Water absorption when boiling for 90 minutes, % by volume, no more | 10 |

| Shear strength in the axial direction, MPa, no less, at temperature (for pipes with PE sheath): | |

| (23 ± 2) °С | 0,12 |

| (140 ± 2) °С** | 0,08 |

| Thermal conductivity at an average temperature of 50 °C, W/m°C, no more | 0,033 |

| Shear strength in tangential direction, MPa, not less, at temperature** | |

| (23 ± 2) °С | 0,2 |

| (140 ± 2) °С | 0,13 |

| Radial creep of thermal insulation at a test temperature of 140 °C, mm, no more, for**: | |

| 100 h | 2,5 |

| 1000 h | 4,6 |

| * Density of the middle layer of insulation. **Determined at the customer's request. | |

"TABLE 3" Characteristics of polyurethane foam for fixed supports

To carry out calculations, the thermal conductivity value of polyurethane insulation in a PE shell is taken to be 0.033 W/m•°C and is determined using the “pipe” method set out in Appendix D to GOST 30732-2006. PUF must have a closed, homogeneous, fine-cell structure in cross-section. The presence of cavities (voids) the size of which exceeds 1/3 of the thickness of the thermal insulation layer is not allowed. A waterproofing coating can be applied to the ends of the heat-insulating layer.

On supports, the diameter of which is up to 426 mm inclusive, under the cover layer of polyurethane foam insulation, two indicator-conductors are installed, made of soft copper with a cross-section of 1.5 mm2, which are used to organize operational monitoring of the parameters of the protective shell and heat-insulating coating. The conductors are placed in the same section plane, parallel to the longitudinal axis of the pipe. They are laid through centering supports or other channels 20 (±2) mm from the surface and must have a certain pre-tension. When using supports with a diameter equal to or exceeding 530 mm, three conductor indicators are installed.

To control the quality of the laying of conductors, the electrical resistance between them and the steel pipe of the support is measured. The device must show at least 100 MΩ when applying a voltage of at least 500 V.

Table: dimensions of PPU PE supports.

| Outer diameter of steel pipe | Pipe diameter according to PE shell | Length, L | Sheet metal dimensions | P* max, t | Weight, kg | |||

| Type-1 | Type-2 | H, mm | S, mm | Type-1 | Type-2 | |||

| 33 mm | 110 | — | 2000 | 255 | 16 | 2,3 | 15,71 | — |

| 42 mm | 110 | — | 2000 | 255 | 16 | 3,3 | 16,94 | — |

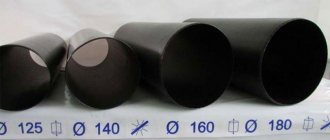

| 48 mm | 125 | — | 2000 | 255 | 16 | 5,3 | 20,28 | — |

| 57 mm | 125 | 140 | 2000 | 255 | 16 | 7,5 | 25,16 | 26,26 |

| 76 mm | 140 | 160 | 2000 | 275 | 16 | 9,5 | 30,37 | 31,55 |

| 89 mm | 160 | 180 | 2000 | 295 | 16 | 12,5 | 34,80 | 36,30 |

| 108 mm | 180 | 200 | 2000 | 315 | 20 | 20,5 | 48,02 | 49,58 |

| 133 mm | 225 | 250 | 2000 | 340 | 20 | 26,5 | 61,57 | 63,95 |

| 159 mm | 250 | 280 | 2000 | 400 | 25 | 36,0 | 81,98 | 85,06 |

| 219 mm | 315 | 355 | 2000 | 460 | 25 | 50,0 | 127,17 | 131,98 |

| 273 mm | 400 | 450 | 2000 | 550 | 30 | 75,0 | 204,28 | 212,86 |

| 325 mm | 450 | 500 | 2000 | 650 | 40 | 90,0 | 275,87 | 284,51 |

| 426 mm | 560 | 630 | 2000 | 750 | 40 | 120,0 | 352,72 | 366,82 |

| 530 mm | 710 | 710 | 2000 | 900 | 50 | 150,0 | 552,64 | 552,64 |

| 630 mm | 800 | 800 | 2000 | 1000 | 50 | 205,0 | 653,30 | 653,30 |

| 720 mm | 900 | 900 | 2000 | 1100 | 50 | 235,0 | 772,81 | 772,81 |

| 820 mm | 1000 | 1100 | 2000 | 1300 | 50 | 310 | 1025,85 | 1060,14 |

| 920 mm | 1100 | 1200 | 2000 | 1300 | 60 | 430 | 1192,58 | 1232,39 |

| 1020 mm | 1200 | 1200 | 2000 | 1400 | 60 | 470 | 1365,41 | 1365,41 |

| 1220 mm | 1425 | 1425 | 2000 | 1600 | 60 | 500 | 1843,19 | 1843,19 |

Transportation

Insulated supports can be transported by rail, water and road transport. Transportation is carried out in compliance with the requirements of the manufacturer, as well as the requirements of GOST 30732-2006 and SP 41-105-2002.

The minimum temperature at which loading and unloading operations are allowed is:

- -18°C for products in a protective shell made of polyethylene;

- -50°С for products with a protective shell made of galvanized steel.

For loading and unloading ENO, traverses and soft slings in the form of towels with a width of 50 to 200 mm are used. The use of cables, chains, ropes and other rigging equipment that can cause damage to the protective shell and polyurethane foam layer is prohibited. It is prohibited to unload and store by dropping, rolling or dragging supports, or allowing them to collide.

The cargo area (body) of the vehicle performing transportation must be equipped with devices that prevent unauthorized movement of shaped elements during movement.

Pre-insulated PPU pipes

Polyurethane foam (PPU) is a lightweight but very durable material designed for heat and waterproofing.

Thanks to its closed-porous structure, consisting of cells filled with gas, PU foam has the lowest thermal conductivity of the medium of all known thermal insulation materials. The material has excellent mechanical properties. Even when exposed to extreme temperatures, it demonstrates dimensional stability and high dimensional accuracy. Polyurethane foam does not delaminate, does not crack and has high wear resistance. The durability of the material is about 25-30 years.

PPU belongs to materials with flammability class G1-G4. The material burns only in the presence of a direct flame. If there is no flame, it goes out and does not smolder.

Resistant to acids, alkalis and solvents. It is also environmentally safe, indestructible and indestructible by fungi, i.e. resistant to rotting and microorganisms.

Rigid polyurethane foam is one of the most widely used materials in construction.

- Unlimited layer thickness

- Reduced flammability

- The material is not afraid of moisture, i.e. no additional layers of vapor barrier required

- Resistance to mechanical loads

- Heat and frost resistance in the temperature range from -60°С to +100°С

- High acoustic insulation

- Light weight and no load on building structures

- High adhesion

- Monolithic seamless surface of the insulating layer

- Maintainability

- Possibility of use for both new and renovation of old buildings

- Ease of transportation and storage

- Chemical resistance to weakly acidic sediments and industrial hydrocarbons

- Operation for at least 25-30 years

Storage

It is necessary to store shaped elements in accordance with the recommendations of the manufacturer, as well as in compliance with the standards of GOST 30732-2006 and SP 41-105-2002. To place products, you should choose flat horizontal areas, free from stones and other objects that could damage the protective shell and thermal insulation layer.

Shaped products with a smaller diameter can be stacked on larger products. If products are to be stored in open areas for longer than two weeks, it is necessary to provide protection from direct sunlight by installing a canopy or using opaque roll covers. It is also desirable to protect the ends of the shaped elements from moisture or contamination. Storage and installation of supports in places where there is a risk of flooding with water is prohibited.

Pipe insulation with polyurethane foam

TechImpEx LLC produces pipe insulation with polyurethane foam. Such pipelines maintain the initial temperature of the coolant, regardless of the length of the section, and their surface is protected from the effects of aggressive environments and corrosion. In the company's catalog you will find a wide range of pipes for various applications. You can purchase PPU pipe insulation from us at an affordable price.

Pipe insulation with polyurethane foam

This type of plastic is used as an insulating material due to a set of unique characteristics:

- one of the lowest thermal conductivity coefficients;

- excellent adhesive properties;

- long service life in conditions of high humidity, high and low temperatures;

- excellent sound absorption;

- low moisture absorption.

| Prices for foam insulation services | ||

| PPU pipes | Price for PPU-PE insulation service including VAT/m | Price for insulation service PPU-Ots with VAT/mRUB |

| Type 1 (Central region, Northwestern) | ||

| 57/125 | 350 rub. | 400 rub. |

| 76/140 | 385 rub. | 435 rub. |

| 89/160 | 425 rub. | 475 rub. |

| 108/180 | 500 rub. | 550 rub. |

| 133/200 | 650 rub. | 700 rub. |

| 133/225 | 700 rub. | 750 rub. |

| 159/250 | 800 rub. | 850 rub. |

| 219/315 | 1300 rub. | 1300 rub. |

| 273/400 | 1800 rub. | 1850 rub. |

| 325/450 | 2000 rub. | 2000 rub. |

| 426/560 | 3000 rub. | 3000 rub. |

| 530/630 | 3500 rub. | 3500 rub. |

| 530/710 | 4500 rub. | 4500 rub. |

| Type 2 (regions of the Far North) | ||

| 57/140 | 450 rub. | 500 rub. |

| 76/160 | 480 rub. | 530 rub. |

| 89/180 | 580 rub. | 630 rub. |

| 108/200 | 680 rub. | 730 rub. |

| 133/250 | 650 rub. | 700 rub. |

| 159/280 | 800 rub. | 850 rub. |

| 219/355 | 1500 rub. | 1500 rub. |

| 273/450 | 2400 rub. | 2450 rub. |

| 325/500 | 2600 rub. | 2600 rub. |

| 426/630 | 3900 rub. | 3900 rub. |

| Type of thermal insulation | Thermal conductivity coefficient, W/(m K) | Density, kg/m3 | Operating temperature range, °C | Porosity | Service life, years |

| PPU hard | 0,019-0,040 | 60-160 | -150…+145 | closed | 30 |

| Expanded polystyrene | 0,043-0,064 | 15-35 | -80…+80 | open | 15 |

| Mineral wool | 0,052-0,058 | 55-150 | -40…+120 | open | 5 |

| Expanded clay | 0,120-0,180 | 200-250 | open | 15 | |

| Cork board | 0,050-0,060 | 220-240 | -30…+90 | closed | 3 |

| Foam concrete | 0,154-0,160 | 250-400 | -30…+120 | open | 10 |

Delivery of goods is carried out by freight transport. The cost is 6-7 thousand rubles. in St. Petersburg. In the region and other regions, the cost is calculated individually.

The unique thermal insulation properties of polyurethane foam are explained by the fine-cell gas-filled structure of the material. Insulated polymer cells are filled with air or carbon dioxide. They form an insurmountable barrier to moisture.

The advantages of rigid polyurethane foam insulation: flexibility, strength and lightness. These products are used for the construction of heating plants and hot water supply systems. Pipeline systems made of polyurethane foam with a shell of polyethylene or galvanized sheet have a long service life and can be laid without ducts.

If damaged, the insulating layer must be restored. Carrying out repair work does not require high costs and effort. The PPU insulation is based on a half-cylinder shell with locking connections. The size of these shells depends on the outer diameter of the pipe. This type of PPU pipe insulation is also used to prevent heat loss at pipeline joints. A special tape is used to secure the shells. If the installation technology is followed, the replaced section is not inferior in terms of the characteristics of polyurethane foam pipe insulation applied industrially.

TechImpEx LLC guarantees high quality of all types of products. The modern technologies used for insulating polyurethane foam pipes increase the service life of the material to 30 years or more.

Ask a Question

Ask a Question

*required fields are marked