Repairing the riser of the drainage system is greatly simplified if a compensation sewer coupling has been installed in advance. This is a simple fitting that solves several operational issues. Its main purpose is to compensate for temperature expansion of plastic pipes.

However, this device allows you to solve other problems that arise during the operation or repair of the internal part of the sewer system. Most users do not install this element when assembling a riser in a private house, and in multi-apartment buildings, expansion joints are not used to save money. As a result, difficulties arise during the operation or repair of pipelines.

Specifications

To understand the capabilities of the compensating part, you need to understand its technical characteristics. They depend on the material from which the device is made. Options:

- density - approximately 0.92 g/cm;

- wall thickness - at least 4.5 mm;

- maximum temperature – up to 95 degrees Celsius;

- color - white, gray;

Construction and plumbing stores sell products with a diameter of 20 to 110 mm. The service life declared by the manufacturer is 50 years.

When calculating the diameter of the compensator, it is necessary to determine the maximum compression and expansion of the pipe when heated. For example, we can consider a pipe with a diameter of 90 mm. Its maximum expansion is 4.2 cm, compression is 2.1 cm. The diameter is calculated depending on the maximum magnification, which is equal to ΔL/2 = 21 mm.

Type four: fighting fire

As you know, in the event of a fire, any internal engineering networks of a building, including sewerage, can spread the flame: fire couplings are designed specifically to stop the fire.

Description

How is a fire protection coupling for sewerage constructed?

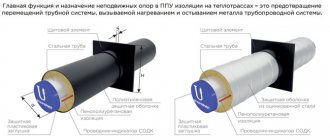

1 - tie lock, 2 - detachable galvanized body, 3 - petals for fastening, 4 - thermally expanding liner.

How it works?

The liner in the coupling consists of a mixture of graphite and rubber or other materials that significantly increase in volume when heated and do not support combustion. The critical temperature of the coupling is 170 - 200C. A coupling installed in front of the internal fire barrier or directly in it, when the liner increases in volume, completely blocks the gap and creates a flame barrier for up to three hours.

Installation

Fire-proof couplings for sewerage are mounted directly on plastic pipes inside the partition, on one side of it or on both sides.

The coupling is placed only on a plastic pipe. The thermal liner is triggered after its walls burn out or melt and blocks the passage in the wall. For obvious reasons, this scheme will not work with a cast iron pipe.

For installation you need:

- Disconnect the split housing;

- Place the coupling on the pipe and tighten it with a snap tie;

- Secure the body to the petals.

How to select and install a compensator for polypropylene pipes

For heating systems in an apartment or house, polypropylene pipes with a diameter of 20 or 25 mm are usually used.

It is considered irrational to use pipes of larger diameter, especially if a boiler with a circulation pump is installed. Therefore, most often the simplest and most reliable circuits and devices are chosen for installation. Despite the reliability of the bellows expansion joint, its installation is very difficult for small-diameter pipes. It is much easier to use a U-shaped junction or loop for this. But Kozlov’s compensator became a real find today. It is easy to install, and according to its characteristics it is perfect for hidden installation, because its outer diameter is not much larger than the diameter of the heating pipes.

U-shaped expansion joints are most often installed on horizontal sections. The loop compensator has proven itself to be excellent for vertical installation. It is the loop type that is most often used when installing water pipes.

The Kozlov compensator can be installed regardless of position; it is equally convenient for both horizontal and vertical installation.

Type one: for connection

Description

The most common coupling for sewer pipes consists of two counter-directional sockets. The narrowing between them allows the shaped part to be positioned symmetrically relative to both pipes: neither of them can be inserted beyond the narrow section.

When installing a new sewer system, if possible, it is assembled without couplings, using socket pipes and fittings. The fact is that the bell directed against the flow of sewage practically does not create resistance to the flow and, what is much more important, does not catch the garbage it transports. The socket, directed in the direction of flow of the drains, often collects rags, hair and various deposits.

Here is the approximate price of shaped PVC parts of the most popular sizes:

Installation

The main area of application of couplings is repair and insertion of additional bends

.

As a rule, they are used with another shaped part - a compensating pipe

(a short socket pipe with an elongated socket).

The photo shows a compensating pipe in the sewer drain of my house.

For example, when inserting into a straight section of a sewer drain (horizontal section of a sewer) without socket joints, the installation instructions look like this:

- A section of pipe is cut out;

The most convenient way to cut plastic and cast iron sewers is with a grinder. To mark the cutting line, wrap the pipe in a sheet of paper and trace it with a pencil or marker along one edge of the sheet.

- The ends are cleaned of burrs;

- The outer chamfer is removed

from them ; - A coupling is put on the lower pipe;

- The compensating pipe is pulled all the way onto the top one;

- The socket of a straight or oblique tee is put on the smooth end of the compensator;

- Then the compensator, together with the tee, is moved down the pipe until it aligns with the coupling socket;

- The molding is fixed with clamps or clips under each socket to avoid uncoupling of the connections.

Advantages of using PVC fittings

PVC fittings for sewerage have many advantages that distinguish them from other materials:

- light weight. This advantage is considered one of the main ones, since the low weight of shaped elements made of polyvinyl chloride ensures high-speed installation of the sewer structure without special costs. Installation of PVC products can be done alone. The low weight of these devices makes them easy to transport;

- long service life. The shelf life of such products, as a rule, is at least 30 years (in some cases more);

- high level of resistance to destructive corrosive influences;

- resistance to aggressive chemical compounds;

- high coefficient of moisture resistance;

- smooth inner walls. Thanks to the perfectly smooth inner walls, products made of polyvinyl chloride are not prone to overgrowing due to the accumulation of salt deposits;

- ease of installation. Labor costs when installing a sewer system using PVC connecting fittings are reduced to a minimum. A sewer structure of this kind is mounted like a construction set (the edge of the first pipe is put on the end of the second).

- the ability to mount a structure of almost any configuration.

Polyvinyl chloride products are popular and easy to assemble and, in addition, have high performance characteristics. Reliability and long service life are the two main guarantees inherent in products made from this material.

PVC pipe products are easy to assemble, as they have sockets, and rubber seals ensure tightness

Advantages of expansion pipe

The plumbing expansion fitting has many advantages. Thus, the part allows you to repair the drainage system without disassembling the entire network. This saves a lot of money, effort and time on maintaining the system’s functionality.

In addition, modern expansion pipes compare favorably with:

- Affordable cost (the price of a high-quality pipe rarely rises above $4);

- Long service life (can last up to 50 years);

- High technical characteristics (the pipes remain effective at temperatures up to +96°C and work well in conditions of negative temperatures);

- High elasticity of elements and connections (which allows you to compensate for linear expansion, water hammer, strong pressure).

The expansion pipe has a long service life and low price

Sewage pipes are made from modern material that is resistant to aggressive environments. They have a smooth inner surface, which minimizes the risk of pipeline blockage. In addition, thanks to the material used, plumbing pipes have a low noise level and do not require additional painting or pre-installation preparation.

Compensation pipe 110 is quickly and easily installed in the pipeline.

If you have the necessary tools, you can embed it yourself with minimal time. The product kit includes a double-leaf sealing ring, which ensures high reliability and tightness of the connection.

Compensators for polypropylene pipes: bellows, U-shaped, Kozlov compensator

Unlike metal pipes, the range of expansion joints for polypropylene pipes is not so large. This is mainly due to the fact that polypropylene is used for water supply and heating systems with low temperature indicators

But this in no way reduces the importance of installing compensators. The second point is the features of installation work

For metal fittings, welding, soldering, threaded connections, and flanges are used. But for polypropylene, only soldering. And therefore for this type of pipes the following are used:

- Bellows devices;

- U-shaped inserts;

- Loop type inserts;

- Kozlov compensator.

Compensator and its types

By definition, a compensator is a device for compensating linear extensions of a pipe system. Each material has individual linear expansion indicators, so an expansion joint is not needed for every pipe line. The relevance of the element increases if there is a sewer system hidden in the screed or wall. In appearance, the element is a corrugated pipe equipped with connecting flanges on both sides.

A plastic sewer compensator is indicated for repairing/replacing a PVC pipe riser without dismantling the entire system. Representing a piece of a curved shape, the compensator has the same cross-section as the elements of the main line and is inserted by cutting out the piece and fusing the compensator with a blowtorch.

Often, the installation of an element is required to renovate a bathroom or toilet room, when differences in floor level require raising or lowering the cross on the riser to arrange the angle of drainage into the sewer.

Conclusion

When purchasing couplings, make sure that there are no cracks on their surface. Check the ends especially carefully. In the event of a chip, it will be impossible to achieve the tightness of the installed sewer system without replacing the damaged part.

You can learn more about sewer systems from the video in this article.

18055 0 6

This article is devoted to shaped parts for connecting socketless sewer pipes - sewer couplings. In it I want to mention several little-known varieties of this style and talk about methods for installing couplings in various conditions.

Why do you need a compensator?

Compensation pipes can be used in pipelines of internal non-pressure sewer networks in administrative, residential and industrial buildings. In addition, such parts are used in the construction of water conduits and drains. Their effectiveness is especially noted if internal sewerage is located in the floors and foundations of buildings.

It is a low cylinder with a bell-shaped device. The main purpose of such a part is the maintenance and repair of the internal sewer system. If a section malfunctions, the pipe cuts into the pipeline to replace it.

In addition, the sewer pipe is needed for:

- Connections of individual elements of the internal sewerage system;

- Compensation for construction tolerances (often during mass construction, floor heights at sites may differ by several hundred millimeters);

- Protection of the pipeline from deformation and destruction due to linear (thermal) expansion.

In addition, such an element greatly simplifies installation work. Thus, the pipe is most often installed in the lower parts of the risers - in utility and technical rooms. This makes it possible to ensure the necessary slope of the pipeline for better drainage of wastewater and simplification of the internal components of the system located in the basements of buildings.

Device classification

Modern compensators for sewerage are classified according to the material of manufacture, design, purpose, location and method of installation, and cross-section. Thus, polypropylene and polyvinyl chloride expansion joints are considered the most popular. They are ideal for repairing PVC pipelines.

To connect a pipeline consisting of different pipes, as a rule, a special compensator is used - a reduction.

Reduction is also used to connect pipes with different sections. A sewer coupling is used to connect pipeline sections on a level area. When repairing a pipeline, a full bore coupling is used.

According to their purpose and installation location, compensators are divided into several types:

- Universal;

- Loop;

- Coils;

- Bellows axial;

- Flanged;

- Shear;

- Rotary.

The compensation pipe may vary in diameter

Such compensators are especially convenient to use when installing rotating sections and compensating for construction tolerances. Thanks to such parts, you can easily stabilize the pressure in the pipeline, extinguishing the turbulence of liquids. The main feature of these expansion joints is that they can be installed on flexible sections of the pipeline. In this case, the parts can be mounted using welding, flanges, or a coupling. The choice of connection is selected depending on the type of pipeline.

The procedure for inserting into the sewer

In order to install a compensator, you must first select the right part. Thus, a reliable sewer compensator must meet the requirements of the pipeline. The most popular models are parts with a cross-section of 50 and 110 mm in the inner circle. In this case, the wall thickness of such a part must be at least 3.2 mm. The total length of the bell is usually 280 mm.

Before installing the expansion pipe, you should watch the training video

Installing a sewer pipe is quite simple:

- First, the damaged section of the pipeline is cut out (for example, using a hacksaw), or the pipe is cut in the place where it is planned to install the pipe.

- The edges of the cut pipe are processed with emery cloth or a file.

- Then a bend is pulled onto the pipe to compensate, and the underside of the riser is treated with sealant.

- A compensator is inserted into the pipe socket and the riser is secured.

After repair, experts advise putting the system into operation after 4-6 hours. At the same time, craftsmen recommend making pipe cuts with tools with small teeth. Clean and dry areas of the riser should be sealed with silicone.

The compensation pipe is an important part that is used in the maintenance of pipelines transporting fecal waste and water waste inside residential and administrative buildings, and industrial complexes. The sewer pipe 110 has high technical characteristics and service life. This is a simple device that can be easily installed in a pipeline.

Sewer expansion coupling: what is it for, how to install, types for pipes

Repairing the riser of the drainage system is greatly simplified if a compensation sewer coupling has been installed in advance. This is a simple fitting that solves several operational issues. Its main purpose is to compensate for temperature expansion of plastic pipes.

However, this device allows you to solve other problems that arise during the operation or repair of the internal part of the sewer system. Most users do not install this element when assembling a riser in a private house, and in multi-apartment buildings, expansion joints are not used to save money. As a result, difficulties arise during the operation or repair of pipelines.

Varieties

There are several types of expansion couplings. The most common is a straight model with one bell and an internal element. There are also designs with flange connections, which are used on lines with a diameter of 63 to 110 mm. However, these parts are only suitable for cast iron pipelines equipped with flanged connections. On lines made of polymer materials, parts with bell-shaped elements are used. It is noteworthy that for welded pipelines the use of expansion joints of this type becomes useless, since the principle of their operation is based on the sliding of the socket along the pipe. In such cases, flanged or corrugated fittings are needed.

The diameters of the products correspond to the size range of pipes (for PVC products this is 50, 75, 110, 160 mm, etc.). Most often, a compensator is found on a sewer riser, so fittings with a diameter of 110 or 160 mm are in maximum demand. However, sometimes they are installed on sunbeds whose length is too long. This allows you to replace individual line components without complete disassembly.

It is recommended to select an expansion joint made of the same material as the rest of the pipeline. Otherwise, size mismatch or other problems may occur. The wall thickness of different types of sewer systems differs, so the outer and inner diameters of the elements may not match. In addition, the difference in physical properties creates significant problems in the operation of the system. An exception may be the area where two lines made of different materials are connected, but in these places other fittings are usually used.

Feature of PVC sewer fittings

Today, pipes for sewer systems are made from modern polymer materials, such as polyethylene (PE) and polyvinyl chloride (PVC). Shaped parts of sewer pipes are also made from these materials. Sewage pipelines made of polyvinyl chloride are considered the most popular, as they have many advantages over others (especially when compared with old cast-iron sewer structures).

Note! The use of PVC fittings allows you to quickly and easily install sewer systems, since this does not require welding equipment or other specialized tools.

We can confidently note the fact that the use of connecting elements made of this material increases not only the operational properties of the installed system, but also increases its “shelf life” as a whole.

Such connecting parts are most popular when installing sewer structures in apartments and private houses. PVC fittings have a long-term temperature resistance of no more than 80 °C. In addition, they can withstand short-term exposure to temperatures up to 95 °C. Pipes and fittings made of this material can transport not only wastewater, but also chemicals. Chemicals transported through such pipelines have a certain pH range (from 2 to 12).

Fittings for PVC pipes are common parts on the market and are available in a fairly wide range.

How to choose a siphon for a sink

When deciding which sink siphon model to choose, you need to take into account a combination of several factors

Be sure to take into account:

- price. It does not determine the quality of operation of the device, although it reflects the length of its service life;

- aesthetics. In a washbasin without a pedestal, the chrome details will be visible and create a certain impression. If there is a pedestal, they will be hidden, their aesthetic perfection will not be visible;

- neck diameter;

- presence of overflow;

- will a washing machine or dishwasher be connected, which will require an additional drain;

- what is the horizontal distance between the neck and the sewer outlet;

- is the release included?

- location relative to the sewer outlet. If the displacement exceeds 2-4 cm, it is advisable to install a corrugated siphon or a bottle siphon with a flexible pipe;

- the siphon inlet tube should not have a diameter larger than that of the entrance to the sewer. It's better that they match. If the diameter of the inlet tube is smaller, you will need an adapter.

The choice of siphon depends on the design features of the sink or sink and the need to connect household appliances to the drain system

Type two: for repair

Description

Yes, yes, yes, I remember very well what is written just above: the coupling is also used mainly for repairs. The so-called repair coupling differs from it only in the absence of a narrowing between the sockets: it has the same internal diameter along its entire length. This feature makes it possible to freely move the coupling along a smooth pipe or... correctly, butt-joined smooth pipes.

Accordingly, this type of fitting is used to eliminate defects in smooth, permanent sections of the pipeline.

Installation

- A cut is made on the pipe near the defect;

- The ends of the pipe move relative to each other. If necessary, the pipe is freed from nearby fasteners;

- The cuts are deburred and chamfered;

- The coupling is put on one of the pipes;

- The pipes are centered;

- The coupling is moved to the end of the second pipe and secured with a clamp.

Peculiarities

Modern manufacturers are able to offer a wide range of similar products, but the difficulty may lie in choosing the right device model

Qualitative and technical indicators should be given great attention, as well as the operating range of its operation. It is the flanged rubber expansion joints that are entrusted with the task of neutralizing the resulting stress, which will appear periodically in different sections of the highway as a consequence of temperature surges

This type of product is characterized by the presence of such primary indicators as flexibility and extensibility, which can guarantee a high level of tightness of the entire system. The main types of compensators will look like this:

- bellows;

- lens;

- stuffing box;

- pipe

Also worthy of attention are special designs - vibration compensators, which will also fall into the category of bellows equipment. Similar elements are used in many everyday areas of activity, which include the gas, oil, manufacturing and food industries. The universal type of equipment can be either coupling or flange. It is precisely these designs that are usually used for high-quality compensation of any temperature changes for a wide variety of purposes. Thus, it becomes possible:

- protection of sensitive system elements;

- isolation of vibration loads;

- alignment of missing axle alignment;

- preventing rapid destruction of the line due to frequent temperature fluctuations.

This type of product can significantly increase the service life of the products used and the pipeline itself. In this way, it was possible to almost completely avoid the occurrence of serious emergencies on the line, which could completely or partially destroy the existing main line. The material used is not afraid of numerous jumps, since it belongs to the category of high-quality raw materials, which are characterized as incredibly reliable and durable.

Areas of use

Compensators are necessary to protect the pipeline PP. They can be used not only in water supply, but also in sewerage or heating. Moreover, they can be used to compensate for linear expansion in both residential and administrative buildings, in production, etc. Often these devices are installed in the middle of the pipeline, between its fixed sections (supports, for example, dividing the main line).

This installation method is popular in the construction industry due to its ease and simplicity. And due to its low weight, no special tools or equipment are needed for installation.

Note! Compensators can be used not only for horizontal, but also for vertical sections

Variety three: cuffs

Description

Yes, yes, the coupling can be made not only of plastic or cast iron, but also of rubber.

Strictly speaking, a rubber coupling for sewerage is not a completely accurate name. Under this name, cuffs are usually sold that allow you to connect parts of different sizes or made of different materials.

Here are some examples of such products used in sewer installation:

- Sealing collars for joining a smooth pipe with a cast iron socket;

- Cuffs are adapters from PVC to polyethylene pipe (they differ slightly in outer diameter but have the same nominal diameter);

- Connecting cuffs for connecting the tank shelf and the toilet flare, used in old-style domestic compacts.

Installation

The sealing collars are inserted into the socket, after which a pipe of smaller diameter is pressed into them with some force. The connecting ones (in particular, the same cuff between the tank shelf and the toilet) are a little more difficult to install:

A few nuances:

- Before installing a cuff of any type, the parts to be connected (primarily the inner surface of the socket) are cleaned of any contamination

; - If the surface of the socket is uneven, the sealing collar is seated on silicone sealant

;

Before applying the sealant, the socket must be not only clean, but also completely dry.

- A leak in the connecting collar, if it is not caused by cracks in the rubber, can be eliminated by applying a tie wire clamp.

Types of compensators

Essentially, the compensator is a fitting. Namely, an element that serves to level out linear extensions of the sewer network during its operation.

Manufacturing materials

For the production of sewerage pipes, manufacturers traditionally use:

- metal: steel and cast iron;

- molded reinforced concrete;

- asbestos cement;

- ceramics.

Just a few years ago, plumbers preferred to work with metal pipes. However, this material has several disadvantages:

- he is very heavy;

- installation of a metal pipeline is complex and time-consuming;

- Steel sewers rust, and cast iron sewers quickly become overgrown with sediment.

Therefore, with the beginning of the production of polymer pipes, builders are increasingly giving preference to them. There are three types of plastic products, including sewer expansion joints:

- polypropylene products;

- polyethylene analogues;

- polyvinyl chloride expansion joints.

Scope of application, cross-section and design features

All materials used for sewerage installations have their own linear deformation parameters. Therefore, the plastic expansion joint is not suitable for all pipelines. The effectiveness and demand for this fitting increases if the drainage network is walled up in floors or walls.

The compensator is mounted on a sewer pipe at the bottom of the risers, located in technical, utility, and basement rooms. It gives the desired slope to horizontal sections when unifying drainage branches made of different materials.

The fitting allows you to compensate for deformations and failure of the network due to its linear temperature contraction/expansion.

Compensators are often used to repair internal sewer systems. They make it possible to replace failed sections of the pipeline without completely dismantling it.

Often, installing a fitting is necessary when renovating a bathroom or restroom. In this case, it is used if differences in height of the floor require raising or lowering the crosspiece of the riser to create an optimal angle for the discharge of sewage into it.

The expansion pipe made of polyethylene and polypropylene is a straight section of pipe. On one side it is equipped with a 110 mm connecting socket. It contains an o-ring seal made of rubber.

Polyvinyl chloride products can be corrugated, which improves their compensation characteristics. There are also products with a curved configuration; they are designed for installation or repair of rotating sections of sewer networks.

Special couplings

Fire protection

Another element without which the sewer system should not be operated is fire couplings that prevent the spread of open flames through pipelines.

This device is a metal cylinder with a special liner. The latter consists of a special non-flammable material that swells under the influence of elevated ambient temperatures.

An activated fire suppression coupling for sewerage seals the pipeline, preventing further spread of fire.

This part must be installed on every plastic pipe in the building and fixed to the main wall or ceiling. Their installation is not difficult and can be done at any stage of construction work.

Advice! Fire suppression couplings for sewerage are an effective means of preventing the spread of fire throughout a residential building. When building a country house or renovating an apartment, you should not neglect the installation of this element. Small savings now can lead to huge fire damage in the future.

When purchasing a product for fire protection, you should make sure that the product meets accepted standards and has the appropriate certificate issued by regulatory authorities. Otherwise, its effectiveness will be zero.

Repair coupling

Special elements used in the sewer installation process include a repair coupling. It is slightly longer than standard connecting parts and is used to replace damaged sections of the pipeline, as well as insert additional fittings.

The procedure for using special accessories is as follows:

- the pipe is cut in the right place (or the damaged area is cut out);

- a special repair element is put on the lower end (its outer cut must be pushed until it is level with the end of the pipe);

- a coupling with an elongated socket is put on the upper end in the same way;

- the required shaped part (or an undamaged section of pipeline) is inserted;

- then the coupling with the extended socket is moved down, and the repair one is moved up, as a result of which all the parts are connected together.

The inserted pipe section (during repairs) should be treated accordingly. To do this, the ends are chamfered, after which they are treated with technical lubricant. This guarantees a complete absence of leaks after repairs.

In particularly difficult cases, maximum efficiency can be achieved by pumping silicone sealant into the ends of the couplings. After it hardens, there can be no talk of any leakage.

Local treatment plants (VOC or AC)

During normal operation, autonomous sewerage installations are capable of producing fairly clean water. It cannot be used as drinking water or for watering the garden, but as a technical one it is very possible. The basis of cleansing is the work of aerobic bacteria (they live in the presence of oxygen). The waste they process turns into sludge, settles to the bottom of a special tank, from where it is then pumped out. Pumping frequency is 1-4 times a year, depending on the intensity of use.

In general, an autonomous wastewater treatment plant is a good thing, but it has certain operational features that you must know before deciding what is better for the sewage system of a private house - a septic tank or an AC.

This is roughly what installations for an autonomous sewer system in a private house look like. This is AU Topas

At the outlet, the ACs have water purified by 90-95%. With this quality, it can be poured onto the ground, however, for this you must have laboratory tests on hand. Therefore, many still prefer to use an intermediate settling well from which the water is then used for technical purposes. The second option is to divert the wastewater to filter devices. This, of course, is reinsurance, but in emergency situations it saves.

What is used to clean wastewater?

Waste is processed by anaerobic bacteria (they live only in the presence of air). To provide them with air in the VOC, aerators are constantly running. In addition, during cleaning, the contents are pumped from one compartment to another using built-in pumps. So without electricity, these installations are inoperable.

Inside the AU is also divided into chambers (this is Topas)

If the electricity is turned off, bacteria can survive without air for no more than 4 hours, after which they die, and the wastewater ceases to be processed. To start the system, it needs to be populated with new bacteria, and reaching a working state is possible only after 2-3 weeks. All this time, the wastewater will flow, at best, semi-purified. This is where a sump well or filter unit comes in handy. It will improve the situation at least a little.

Features of operation

Since the volume of autonomous treatment plants is small, they need constant feeding: bacteria need nutrients for normal life. Therefore, this type of device is suitable for private homes of permanent residence - regular receipts are needed. In principle, preservation for a certain period is possible, but the procedure is not pleasant, and it will take a long time to return to the installation mode.

Bacteria that process waste in automatic wastewater treatment plants are also sensitive to active chemicals. Since the chamber volumes are smaller, the release of detergents or disinfectants can significantly damage the recycling process. Moreover, cleaning and antibiotic treatment can negatively affect.

Station after operation 3-6 months

VOCs are much smaller in size than septic tanks. They are calculated depending on daily water consumption, but there is such an indicator as salvo discharge. This is the amount of waste that an autonomous sewer installation can accept at one time. If this value is exceeded, untreated wastewater flows into other chambers, which significantly reduces the degree of purification. So, in this situation, you have to decide which plumbing fixtures and household appliances work at the same time. And if the bathtub is drained, no other devices should work for some time.

Briefly: advantages and disadvantages

Autonomous sewerage treatment plants are certainly convenient; with them, sewerage for a private home is implemented quickly - installation takes 10-12 hours. Pumping out excess sludge is necessary several times a year (1-4 times depending on the intensity of use, but maybe less or more often). The amount of sludge pumped out is very small (5-10 buckets depending on the model) and maintenance can be carried out independently, although the procedure is not the most pleasant. But they are doing this, since the visit of a specialist is not cheap at all.

This is what it looks like on the site

These home treatment plants have some disadvantages: the high cost of the equipment, dependence on the availability of electricity and the need to monitor the condition of the equipment.

Advantages and disadvantages of bottle-type siphons

Before you start looking for suitable equipment, you should decide what type will be installed. There are four types of siphons, of which the most common is bottle siphons. The name is given because in the area of the water seal the structure takes the shape of a bottle. The bottle type is most widespread, although it has the most complex device compared to others. Preference is given to this type because of its undoubted advantages:

- compact, easy to install in tight spaces;

- ease of installation is combined with ease of disassembly. Therefore, cleaning the structure is not difficult; it does not require much time.;

- objects accidentally slipped inside will not be lost, but will sink to the bottom of the flask;

- only it allows integration with the overflow and inlet for the washing machine.

A bottle-type siphon is the most common model of such products.

A variation of the bottle-type design can be considered a hidden type of siphon. The glass is built into the wall, only a horizontal tube comes out. This is an expensive device and is used occasionally.

Varieties

There are several types of expansion couplings. The most common is a straight model with one bell and an internal element. There are also designs with flange connections, which are used on lines with a diameter of 63 to 110 mm. However, these parts are only suitable for cast iron pipelines equipped with flanged connections. On lines made of polymer materials, parts with bell-shaped elements are used. It is noteworthy that for welded pipelines the use of expansion joints of this type becomes useless, since the principle of their operation is based on the sliding of the socket along the pipe. In such cases, flanged or corrugated fittings are needed.

The diameters of the products correspond to the size range of pipes (for PVC products this is 50, 75, 110, 160 mm, etc.). Most often, a compensator is found on a sewer riser, so fittings with a diameter of 110 or 160 mm are in maximum demand. However, sometimes they are installed on sunbeds whose length is too long. This allows you to replace individual line components without complete disassembly.

It is recommended to select an expansion joint made of the same material as the rest of the pipeline. Otherwise, size mismatch or other problems may occur. The wall thickness of different types of sewer systems differs, so the outer and inner diameters of the elements may not match. In addition, the difference in physical properties creates significant problems in the operation of the system. An exception may be the area where two lines made of different materials are connected, but in these places other fittings are usually used.

What it is

Compensators for sewer pipes are fittings designed to change the length of a network section within small limits. Most often they are used on lines assembled from PVC. This material shows the highest coefficient of thermal expansion. When draining hot water, the length of the pipes increases, and when cooling, it decreases. The compensator takes on these changes, keeping the connections and elements of the riser intact. This is the main, but not the only task that the coupling solves. It also has other useful features:

- it allows you to change the position of the tee relative to the vertical and horizontal parts of the system. During repairs, the floor level often changes (laying tiles, pouring leveling screed, etc.), which is why the height of the toilet, bathtub, shower cabin and other types of plumbing fixtures changes. To connect to the system, you have to change the installation height of the tee, which is easy to do if you have a compensator;

- Replacing parts of the riser is a difficult task, especially in apartment buildings. With a clutch, the procedure is reduced to a few minutes;

- The transition from one pipeline diameter to another is simplified.

As a rule, a PVC D 110 sewer compensator is installed on the vertical part of the apartment part of the system, which requires a riser of the same diameter. The coupling is a straight piece of pipe, one part of which is a socket with a rubber seal, and the other is a connecting element for installation inside the socket. In essence, this is a shortened section of straight pipe, but its connecting element has greater depth, continuing all the way to the very beginning of the narrow (inner) part. This allows you to absorb excess length when heating, or give up some of it when very cool.

Sometimes a sewer compensator is confused with a walk-through or repair coupling. The difference between this fitting and the compensator is in the design of the connecting element - the first has two sockets on both sides, the second is equipped with only one extension. This is a fundamental point, since the repair coupling can slide along the riser, shifting to any distance (until it hits the socket or tee). The compensator has a stationary position and is installed with the socket facing up. It is capable of moving upward only to the depth of the socket.

How to lay sewer pipes - a step-by-step guide with examples

Waste water and human waste are first transported to mains located outside the building, and then end up in storage tanks or septic tanks.

To do this, you can use pipe products made from different raw materials. More recently, cast iron pipelines were used to create an external sewer line in one's own home. Today, everything has changed, and the external laying of sewerage pipes is made from polymer pipe products.

The reason was the fragility of cast iron compared to plastic, and in addition, products made from this alloy are heavy and require special equipment for installation.

A special case

Despite the popularity of plastics (primarily polyvinyl chloride and polypropylene), cast iron drainage is still used in many older homes. Accordingly, it periodically needs repairs.

Repair couplings for cast iron differ markedly from plastic products of the same functionality. The fact is that cutting a cast iron pipe and spreading its ends apart is a non-trivial task even for a bench hanged in the basement, not to mention risers.

The coupling for cast iron is a wide split clamp with a rubber gasket. For installation, it is disassembled, put on the damaged area and tightened with bolts. However, much more often a connecting coupling and a compensating pipe are used to repair damaged areas.

The only difference between cast iron and plastic sewers in terms of their installation is the method of sealing socket joints. It works like this:

- Pipes and fittings are installed in the working position and fixed with clamps;

- A heel (a hemp strand impregnated with bitumen) or, which is much better, a graphite gland, is placed in the socket with the sealing of each turn by embossing;

- The outside of the bell is sealed with cement or a cement-sand mixture prepared in a 1:1 ratio.

Insertion method

Installation of the coupling during the initial assembly of the system does not raise any questions. The only condition will be to place the socket towards the flow (on the riser it is directed upwards, on the deck chair it is directed away from the riser). This is an important point, since the reverse position of the connecting element creates the risk of permanent blockage.

Let's consider how to install a compensator on a sewer system if it has already been assembled and put into operation. Procedure:

- In the place where the fitting is installed, a section of pipe is cut out with a grinder. Its size should be 10 cm less than the full length of the compensator. Usually they cut only in one place, the second end is removed from the tee. This is the best variant;

- the edge of the cut pipeline is cleaned of burrs and treated with sandpaper;

- The coupling socket is placed on the free end of the pipe and shifted upward so that the lower part can be inserted into the tee socket. Move the fitting down all the way, connecting its internal element to the tee.

Some sources recommend applying silicone sealant to the internal surfaces of the bells before installation. If the expansion joint is too tight, you can apply a little liquid soap or shampoo to the pipe - the work will go much easier. Before installation begins, it is necessary to notify neighbors about the time and nature of the work so that they do not use the sewer. Otherwise, all the drains will end up on the floor and you will have to do a general cleaning of the premises.

Features of the sidebar

Before repairing the sewer system in an apartment, you need to warn your neighbors in the riser so that they do not use plumbing fixtures. After this, collect all the necessary tools and materials (compensator, sealant, hacksaw, file, and in the case of welding techniques, a soldering machine). Then the water supply is turned off and the technical area is cleared of unnecessary items.

Inserting a fitting made of polymers is also possible for a non-professional if you proceed sequentially:

- The part of the pipe to which the sewer pipe will be connected is trimmed. The cut is processed with a file or coarse sandpaper to remove burrs.

- The upper part of the pipe is coated with silicone.

- The compensator is put on all the way.

- The lower part of the riser is covered with sealant.

- The device is secured with the plant into the socket of the pipeline, where the presence of a rubber seal is checked.

- The system is connected and the riser is secured.

Reliable fastening of the pipe is carried out by rigidly fixing it to the wall with a detachable clamp on a stud. The fastener is placed on the pipe above the compensation device, close to it.

Connection by soldering

To increase the strength of the connection of polymer pipe sections with thick walls, a welded tapping technique is used.

For a high-quality connection, you will need a welding machine for soldering polypropylene. The process goes like this:

- The end of the compensation device entering the plastic pipe is carefully cleaned of burrs and irregularities.

- The soldering machine is connected to the mains and heated to a temperature of approximately 260 degrees. When the device is ready for welding, its indicator will go off.

- The prepared end of the pipe and the end of the compensator are put on the nozzles of the welding machine, suitable in cross-section. When they soften, they are combined.

The plastic parts are combined so tightly that their molecules penetrate each other's layers. This is called the diffusion method. During hardening, both parts must be firmly fixed. Do not rotate or move them, otherwise the seam will lose its tightness.

Nuances of installation work

To install the compensator correctly on the sewer pipe, you should take into account certain installation nuances:

- pipes are cut using a fine-toothed hacksaw, so there will be fewer burrs on the cuts;

- grinding and sealing are carried out only after cleaning and drying the parts;

- All formed cavities are sealed with silicone sealant.