A chimney economizer is a classic heat exchanger that allows you to warm up a certain room in an accelerated mode. This device is located mainly above boilers or sauna stoves. In addition to its heating function, it protects to some extent from radiation spreading from the chimney itself. Due to its properties, the economizer can be effectively used instead of heating radiators.

With this device you can warm up the room faster

Purpose of the economizer

Combustion products, passing through the smoke removal system, heat up the chimney pipes. Part of this thermal energy can be used for additional heating of the room. To do this, a special element is included in the design - an economizer or convector chimney, a heat exchanger of a special design, made from heat-resistant steel and installed in the pipe of a solid fuel stove or heating boiler.

This element allows you to significantly speed up the process of warming up the room, as well as stimulate the supply of heat to neighboring rooms.

The use of an economizer is justified in cases where the furnace is used frequently and is the only source of heating. The efficiency of such a system is much higher, which allows you to save money on fuel volumes.

When is a convector chimney used?

The feasibility of using a convector chimney is determined by the overall design of the heating system. It’s good when a stove, boiler, or fireplace serves as a constantly functioning heating device. A convection chimney is most effective when burning solid fuel.

A chimney economizer significantly increases the efficiency of the entire system, effectively heats adjacent rooms, and prevents harsh infrared radiation from the chimney.

Water economizers are widely used on an industrial scale, using the thermal energy of flue gases to preheat water circulating through heating pipes. At home, it is extremely difficult to achieve effectiveness from such a system.

Convector chimneys are often used in sauna stoves. Some models have a mechanism for closing convection channels to control heating. To quickly heat the steam room, the external air suction passages are blocked, all the thermal energy from the stove and chimney is used to warm it up. When the required temperature is reached, the valve opens again and air circulates through the heat exchanger to adjacent rooms.

Convector chimney device

The design of the economizer implies a modular design, including the connection of sections of steel pipes of different sections:

- The internal module of the device has a cross-section equal to the diameter of the main chimney. Made from sheet steel with a thickness of at least 1 mm.

- The outer pipe serves as the heat exchanger casing. The steel for this element is taken thinner - 0.5 mm. The external module consists of one large diameter pipe, or several small ones, encircling the internal module like flower petals.

Any economizer operates on the principle of continuous circulation of air flows. Cool air enters the lower openings of the device, passes through hot metal pipes, warms up, and enters the room through the upper openings. Next, the warm air gives up its temperature, cools, gradually falls down and again enters the economizer. To increase circulation, a fan is often placed at the bottom of the device.

We recommend that you read: How to hide a gas pipe in the kitchen and not violate regulatory requirements

It is important! The economizer device prevents dangerous carbon monoxide from penetrating into the room, since combustion products remain in a hermetically sealed inner pipe.

For stoves intended for baths, the economizer design often includes an external steel basket with stones that accumulate heat from the chimney pipe.

The standard length of an economizer is 1-1.5 m. The specific value depends on the purpose of the device, potential power and design features. As the length of the economizer increases, the length of the area of contact with the main chimney increases. The heated room warms up faster.

Principle of operation

Pipe economizers are made of high-alloy heat-resistant steel, which has acid-resistant and anti-corrosion properties. Some models are equipped with a top casing made of natural or bush hammered stone, which allows heat to accumulate and be evenly distributed. A chimney equipped with a convector device consists of two parts:

- an internal pipe for removing gases with a steel thickness of no more than a millimeter;

- an external pipe that serves as a kind of heat exchanger casing (with a metal thickness of about 0.5 mm).

This unit will protect the room from harmful carbon monoxide.

The economizer is installed at the base of the chimney. The length of the finished module can vary between 50-100 cm, and the rate of heat transfer depends on this indicator (the larger it is, the faster the building will warm up). Meter-sized systems can be used for heating large buildings, but smaller modifications work well when heating small houses with low ceilings.

The device provides reliable protection of the room from carbon monoxide, which is not able to penetrate into the external pipe of the system. Only air heated by the chimney circulates through it.

For saunas and baths, equipment modifications are equipped with special external baskets in which stones are placed to accumulate heat. In some cases, the design of economizers is somewhat simplified, leaving holes for air intake at the edges of the system. This allows for faster heating and removal of excess heat generated on the surface of the chimney.

In this video you will learn how to make an economizer with your own hands:

Device advantages and disadvantages

The economizer has a number of advantages:

- Simplicity of design. The device does not have complex components or mechanisms that can fail.

- Ease of installation. To install an economizer, you simply need to connect the device on both sides to the smoke exhaust system.

- Economical. The economizer increases the efficiency of the heating system, since heat does not go directly into the pipe.

- Fire safety. The external elements of the economizer will not warm up more than the main chimney pipe. However, it is imperative to maintain the distance from walls and flammable objects recommended by regulations.

- Long service life, provided that the device is made of quality materials.

- Low cost.

Note! Some economizer models are additionally equipped with a device for shutting off the smoke exhaust duct, which allows you to regulate the heat transfer of the system.

Despite the obvious benefits of the economizer, there are some disadvantages of the device:

- Minor complication of the heating system design.

- Increasing the dimensions of the chimney.

- Complicating the chimney cleaning procedure due to the appearance of two additional joints.

How to increase the efficiency of a sauna stove

There are situations when a solid fuel sauna stove cannot sufficiently heat the room. In this case, it is necessary to increase the efficiency. In this article we will talk about ways to increase efficiency.

What is furnace efficiency

Each furnace has its own parameters, but they are all united by efficiency. The combustion process of fuel in a furnace is accompanied by the release of heat. Efficiency means how much heat remains in the stove after complete combustion of the fuel.

But if the efficiency of the furnace is not enough, methods are used to increase it.

Convector or economizer

Convectors come in three types: water, electric or gas.

Convector chimneys are successfully used for the accelerated rate of heating of adjacent rooms, which is carried out by selecting heat flows from gases escaping through the smoke. They also protect against infrared radiation that comes from the chimney. They are easy to install and simple to operate.

The convector is mounted in two ways:

By connecting the pipe to the general chimney.

Installation of your own smoke removal system. This method will allow you to heat two rooms at the same time. You can install a convector in one room and install a chimney in another. This method is especially relevant for those who have a bathhouse with a relaxation room.

The process of operation of a convector involves the transfer of heat by convection currents. This is a constant circulation of air flows from bottom to top, which is due to the fact that cold air is heavier than hot air.

We recommend the Fehringer economizer

It is designed to quickly warm up the steam room. There are four 60 mm pipes installed in the chimney, and spiral swirlers are placed in each of them. They prevent the free release of heat to the street. Heat is transferred to convection channels and directly to the steam room.

Economizer mesh for stones on the chimney

The economizer mesh is placed on the chimney pipe. Stones are placed in the space between the chimney pipe and the mesh.

This is one of the important elements of the steam room, since it allows you to remove the hard infrared radiation emanating from the hot metal of the chimney pipe, which burns the human body.

Thanks to the economizer grid, you will get softer and more pleasant steam. It allows you to significantly increase the heat capacity of the stove and protect the chimney. It removes heat from the thermally loaded section of the chimney much more efficiently, which prolongs its life by more than 50%. The convenience of this economizer is that you do not need to remove the pipe to install it.

We recommend using the Ermak economizer.

We hope our recommendations will be useful to you when arranging a bathhouse. We wish you success and easy steam!

Source

How to make an economizer with your own hands

Making the device yourself is not at all difficult.

Required:

- Several sheets of metal of suitable thickness.

- File.

- Metal scissors.

- Welding machine.

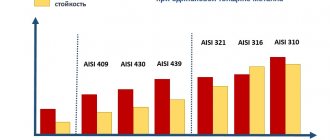

Stainless food steel is suitable for the manufacture of a convector chimney. This material is resistant to aggressive influences, can easily withstand high temperatures, and has a long service life.

Note! Galvanized steel is often used, although it is better to use it in domestic heating systems where the temperature does not exceed 200°C, because when this threshold is exceeded, galvanizing releases toxic compounds.

Some craftsmen make simplified economizer designs, using sections of metal profiles instead of external steel pipes, or even welding thick iron strips along the chimney pipe. The efficiency of such structures is usually lower, and the appearance is not so aesthetic.

We recommend that you read: How to make a stepladder (ladder) from a profile pipe

After installation, it is recommended to cover a do-it-yourself economizer with heat-resistant black paint. This will not only improve the appearance of the product, but also increase thermal conductivity, and also provide additional anti-corrosion protection.

Installation standards and rules

Installation and operation are carried out with mandatory compliance with the requirements specified in the current regulatory documents:

- SNiP 41-01-2003, which describes the operating standards of heating, ventilation and air conditioning systems.

- SNiP 23-01-99, regulating issues of construction climatology.

- SNiP 42-01-2002, which prescribes the principles of operation of gas distribution systems.

- Code of fire safety rules in the Russian Federation.

- Other documentation on the operation and installation of convector-type chimneys.

Drawings and calculations

In order for the device to fit into the overall scheme of the heating system, the manufacturing procedure must be preceded by a stage of careful and accurate measurements.

When drawing up a diagram, the following points must be taken into account:

- The diameter of the internal pipe of the economizer must exactly match the cross-section of the main chimney.

- The length of the external modules should be slightly less than the length of the internal pipe.

- If the external module is made of several small tubes, it is worth calculating their number in advance so that they encircle the entire circumference of the internal module.

- For the external module, which represents one large-diameter pipe, we provide additional elements - truncated cones with holes made in them.

- The diameter of the outer pipe (if such an economizer design is chosen) is selected so that the gap between it and the inner pipe is several centimeters.

Installation features and main errors

In order for the device to fully perform its functions, ensuring maximum flow of thermal energy into the room, some important nuances should be taken into account during installation.

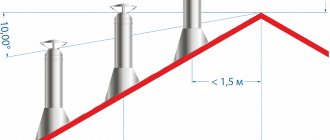

Firstly, the economizer is installed in the lower part of the chimney strictly vertically.

Note! The economizer is mounted only on a metal chimney; it cannot be installed on pipes of a ceramic system.

Most factory-produced convector pipes are equipped with special additional modules, which make it possible to adjust the length of the device if necessary. If such a part is not included in the kit, the pipe can be extended using a simple corrugated stainless steel pipe.

We recommend that you read: Rules for calculating and installing a truss from a profile pipe

Secondly, special attention should be paid to the connection of the economizer to the main chimney. The joints must be completely sealed to eliminate the possibility of hazardous combustion products entering the room.

The convector chimney is extremely simple to install and operate; its installation procedure does not require much effort. And yet, some problems may arise as a result of an incorrect choice of the length of the product or its diameter.

The most common mistakes:

- Incorrect choice of device height relative to floor level.

- Poor tightness at the junction of the convector pipe and the main chimney.

- Failure to comply with the vertical position of the device relative to the walls of the heated room.

Equipment Features

When deciding on the modification of the device, it is necessary to take into account the fact that economizers equipped with two pipes are capable of heating only one room. If there is a need to heat an adjacent room, attention is paid to options with four pipes.

The structure is brought into the required room through a passage previously made in the wall. The arrangement of the latter is carried out taking into account the material of the wall. If there are easily flammable elements, the exhaust pipe must be covered with a heat-insulating casing made of basalt fiber.

The converter device is usually equipped with half-meter pipes. If necessary, they are increased to the required length. If difficulties arise when installing a pipe on a straight part of the wall, it is permissible to use stainless steel corrugations, the edges of which are framed with decorative nozzles.

In this case, pipes for suctioning cold air are located below at a distance of twenty centimeters from the floor. The economizer is attached to the chimney using heat-resistant sealant.

Operating rules

In order for the convector to work correctly and not lose efficiency, you should periodically carry out preventive inspections of the structural elements. This procedure will not require much labor and will boil down to cleaning the inner pipe from soot accumulations and updating the sealing materials.

Cleaning the economizer pipe must be carried out simultaneously with cleaning the entire chimney. This can be done using traditional methods: using a hard brush, special chemicals, or using folk recipes.