Choosing the optimal chimney for a gas boiler is not an easy, but completely achievable task. After all, you want it to be an extremely simple design to install and operate, and also with high efficiency. The coaxial type meets all the requirements, the installation of which can become a bit of a “snag”. Do you agree?

We will help you understand quite complex issues. We provide site visitors with extensive information about the rules for constructing a coaxial chimney, about the selection and arrangement of the optimal option. Here you will find valuable tips on decorating sections of canals laid inside houses.

The article we have proposed describes in detail the standards for installing a coaxial chimney. Useful diagrams for its proper assembly and installation are provided. The information is confirmed and supplemented by photo collections and video tutorials.

General information

The coaxial type smoke exhaust duct has a simple design. It consists of two pipes. They are inserted into each other. Thanks to this design, two circuits are formed.

Regardless of the material used in manufacturing, coaxial smoke exhaust ducts are installed during the construction of houses or after installation of the boiler unit. Any of the mounted options is manufactured in production shops.

To ensure effective smoke removal, you need to know not only general information, that is, a coaxial chimney - that it is a structure of 2 pipes located inside each other. It is also necessary to understand how such smoke exhaust ducts function and where they are installed.

Two-pipe system for smoke removal Source torange.biz

Coaxial pipe device

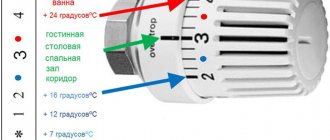

A coaxial chimney is a pipe that consists of two compartments. Two pipes of different diameters are located one inside the other. They are taken outside. There are jumpers inside the structure. They do not allow the pipes to come into contact with each other. It turns out that the design of the coaxial pipe consists of two channels, each of which is designed to perform a specific function:

- a pipe that has a small diameter is designed to remove combustion products from the combustion chamber;

- the thicker pipe provides oxygen supply to the boiler.

This means that combustion products leave the boiler, and oxygen enters the combustion chamber. In this case, the gases do not mix with each other. Most often, coaxial pipes are installed in a horizontal position. It is very rare to find a coaxial pipe that is installed vertically.

Principle of operation

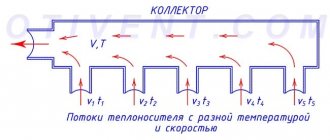

In private buildings, a coaxial chimney is installed in order to remove smoke through one system and supply the air required for combustion of fuel in the boiler from the street. Such processes provide two channels in the design.

Street air enters the boiler through the space between the two chimney pipes. Through an internal channel, combustion products are removed from the unit outside the building. Therefore, the street air is heated before entering the firebox. This increases the boiler gearbox.

Due to the movement of initially cold air, the coaxial pipe has its own cooling system. Therefore, the surface of the structure heats up less. This is the main reason why it is less fire hazardous than a single-channel chimney.

On a note! Coaxial smoke exhaust ducts can be installed in wooden houses when performing a smaller volume of work, the purpose of which is to protect buildings from fire. Manufacturers produce this type of chimney additionally with a heat-insulating layer of basalt wool. Therefore, the designs differ not in two, but in three channels - for smoke, street air and heat insulation.

Part of a coaxial system without insulation Source ooopipe.ru

Advantages

So, what are the advantages of a coaxial chimney system?

The advantages of the innovative device are:

- long service life - life expectancy more than 50 years;

- resistance to wear – the system resists the destructive influence of climatic, mechanical, biological, thermal factors;

- practicality - the structure does not pass through the roof, so there is no need to violate its integrity;

- safety - the risk of fire in the area of contact of certain flammable surfaces with the smoke exhaust system is reduced, since the internal pipe is perfectly cooled by the external one;

- environmental friendliness - the smoke exhaust promotes complete combustion of fuel, so the number of unburned particles emitted into the air is significantly reduced;

- efficiency - there is no need to organize additional ventilation, since substances harmful to the human body do not enter the home;

- compactness - the chimney has optimal dimensions, resulting in space saving;

- extremely wide range - choosing the right sample for a particular system is not difficult;

- efficiency - increasing the efficiency due to warming the incoming cold air mass on a heated pipe;

- easy installation - no special skills or knowledge required.

The advantages are impressive. Is not it? Let's move on to the disadvantages.

Boilers for the use of coaxial chimneys

Coaxial type smoke exhaust ducts are mounted on condenser and turbine boiler units. Such chimneys are installed on equipment with closed chambers where fuel is burned. In this case, smoke removal from boiler units can be carried out by force or naturally. Gas boilers meet these conditions.

This type of chimney is also one of the best smoke removal options for convectors and units using pallets. If the smoke exhaust duct is made of stainless steel, then it is allowed to be connected to boiler equipment that is equipped with an atmospheric burner.

Two-channel smoke removal systems are suitable for almost all modern models of gas boilers. Coaxial-type channels are installed when installing double- and single-circuit units. Such boilers can have any operating principle. Coaxial systems are even installed regardless of the design of the combustion chambers.

Wall-mounted gas boiler with a connected coaxial channel Source baltgazservice.ru

Important! Experts take into account the parameters that the unit manufacturers indicate in the equipment documentation to determine whether a coaxial pipe is suitable for a gas boiler.

Boiler models with two pipes are produced. One of them is needed to remove smoke, and the other is used to supply air to the combustion chamber. It is not advisable to connect two-channel smoke removal systems to such units.

Manufacturer

So, which manufacturer should you choose?

The reputation of the following manufacturers is as pure as a child’s tear:

- "Baksi" is a company that creates first-class quality structures;

- Burderus is a company that produces extremely reliable devices;

- “Herman” is an organization that creates high-quality chimneys;

- “Vailat is a manufacturer that delights its fans with durable products;

- "Navien" is a company that produces wear-resistant products;

- "Viesman" is an organization that creates chimneys that have a long lifespan;

- “Proserm” is a company that cares not only about its income, but also about the quality of its products;

- Daewoo is a company that produces products that resist the negative effects of environmental factors;

- Ariston is a company that creates products that have no competitors.

Thus, the choice is yours!

Types of coaxial chimneys

When experts select a coaxial smoke exhaust duct for a specific gas unit, they take into account that for some models only chimneys that are manufactured by the same manufacturer as the boiler itself are suitable. After all, such equipment has non-standard diameters.

When choosing, the material used in the production of pipes of the two-channel system is also taken into account. In the manufacture of structures, manufacturers often use aluminum alloys, plastics and stainless steel. Basically, the first and third options are found in private homes.

Plastic and metal channel for smoke removal Source ventilyaziya.ru

Plastic chimneys

To make such channels, manufacturers use special heat-resistant plastic. It can withstand temperatures of a maximum of 205°C. Channels made of this plastic are intended for condensing-type gas boilers. These chimneys are different:

- affordable price;

- low weight;

- easy installation.

A plastic coaxial chimney for a gas boiler has disadvantages. One such disadvantage is the short service life. These pipes are connected to units operating exclusively in low-temperature smoke exhaust mode.

See also: Catalog of companies that specialize in autonomous gasification of country houses and related work

Stainless steel chimneys

Coaxial type smoke exhaust pipes, made of stainless steel, can withstand temperatures of a maximum of 550°C. They are products that are resistant to acids. Manufacturers produce them with or without insulation.

Stainless steel coaxial chimneys without thermal insulation material are often additionally insulated to reduce the volume of condensate. The advantage of such smoke exhaust ducts is their long service life.

Stainless steel coaxial type channel Source aliimg.com

A vertical coaxial chimney for a gas boiler is created from factory-insulated pipes. Due to the presence of heat-insulating material in the design, the aerodynamics of the smoke exhaust channel improves. This system is connected to boilers from which combustion products are removed forcibly or naturally.

Flaws

So, what are the negative aspects of the devices?

Coaxial chimneys have the following disadvantages:

- cost – the price of innovative devices is 40% higher compared to separate devices;

- condensation formation - concentric placement of pipes with hot and cold air promotes the formation of condensation, which is why there is a need for insulation or moisture removal.

- high cost of repairs - if one or another part in the structure fails, a significant investment will be required to carry out the repair.

High price. A stingy person pays twice. Condensate. Special elements available on the market solve this problem. Expensive repair work. A careful attitude is the way out of the situation. And no matter how you look at it: the innovative device deserves attention.

Having considered the pros and cons of coaxial chimneys, it’s time to move on to their types.

Installation standards

Professionals always install chimneys in accordance with the rules. When the installation is carried out for a boiler with a closed chamber where fuel burns, then they are guided by SNiP 42-01-2002. If you do not follow the established rules, the gas service will not allow you to operate the system.

During installation, be sure to maintain the distance from the coaxial chimney to the window, door, and even a nearby building. Each of the values should never exceed the values indicated in the standards.

Standard values of installation distances for the smoke exhaust duct from a gas boiler Source teploknam.ru

Thus, SNiP says that the head of the chimney must be at least 2000 mm relative to the ground. When the channel is mounted in a brick wall, it is necessary to create an opening in it with a diameter of 10 mm larger than the same pipe size. At the same time, for a wooden enclosing structure the standard is already 50 mm.

SNiP also states that the horizontal distance from the chimney to the window and door must be at least 500 mm. At the same time, the minimum standard to the window opening above the pipe is already 1000 mm. At the same time, the distance to windows and doors of other structures must be at least 1500 mm.

Important! It is allowed to connect more than one unit to a double-circuit smoke exhaust system, but only if all models have forced or exclusively natural draft. The maximum length of a coaxial chimney for a gas boiler must be 3000 mm. Moreover, for turbine units, from which smoke is removed forcibly, the value of this standard is a maximum of 5000 mm.

Standard lengths of smoke exhaust pipes for De Dietrich PLUS MSL units Source duim24.ru

Features for installation in a private home

If you thought about a chimney at the construction stage of a building, the best choice would be to install a vertical brick shaft, inside of which a steel or asbestos pipe can be located. At the same time, it is important that the gas water heater and the heating system have different shafts for removing smoke.

If the building has already been built, the most suitable chimney option is an insulated steel pipe. It can either be attached to one of the external walls, or installed inside the building through its ceilings and roof.

Other nuances of installing a chimney in a house are the following:

- The material and design of the chimney, as well as the installation location, must comply with current regulations.

- The chimney must be easily accessible so that, if necessary, possible problems can be quickly eliminated.

- When installing a chimney vertically in a house, it is important to prevent a significant deviation of the pipe - it should not deviate more than 1 meter throughout the entire structure.

- The end of the chimney pipe should protrude at least 40-50 cm above the roof.

Basic installation options

Factory chimneys are supplied with detailed installation instructions. Effective operation of double-circuit pipes is ensured only if all specified recommendations are fully observed.

Horizontal installation

This installation option is carried out taking into account the characteristics of a private home. First, you always select a place where the smoke exhaust system will go outside. It is taken into account that the height of the pipe will be at least 1000 mm if the gas boiler is mounted on the floor. This value is measured from the unit's nozzle to the street opening in the wall.

Important! The pipe must not go directly to the street. When a wall-mounted boiler is mounted, then the distance from its nozzle to the hole in the wall can be reduced to 500 mm. In this case, the maximum number of rotary bends should be 2 pieces.

Conventional diagram of horizontal installation Source legkovmeste.ru

When horizontal installation of a coaxial chimney is carried out, never forget about the maximum length of the pipe. This standard depends on the model of the boiler unit and is from 3000 to 5000 m.

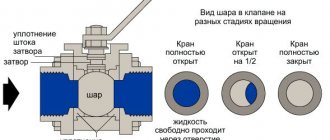

If it is necessary to lengthen the channel, couplings are used. They must have heat-resistant rubber seals. During installation, it is prohibited to use any sealants or sealing materials based on silicone.

Vertical installation

When a vertical coaxial chimney is connected, its maximum length can be 7000 mm. This value allows the use of double-circuit pipes in two-story buildings.

When a building is built from aerated concrete blocks, the system is laid inside the building. The reason for this is the inability of such walls to withstand heavy loads. For brick houses, the location of the smoke exhaust does not matter. However, it is always additionally insulated.

Installation features

The horizontal type of chimney is quite easy to install, and it also takes up much less space. To obtain the highest quality work, you must follow a number of requirements:

- The outer pipe should be 2 meters from the ground.

- Distance from the pipe to doors, windows, ventilation ducts, etc. vertically and horizontally should be at least 0.5 meters.

- If there is a window above the ventilation hole, the distance to its lower area should be at least a meter.

- There must be a free space of at least 1.5 meters under the coaxial pipe. There should be no obstacles, pillars, walls or fences at this distance.

- If there is no receiver for collecting condensate, then the pipe must be placed with a slope towards the ground. Its angle should be from 3° to 12°.

- It is prohibited to lead the channel into any space other than the street.

- If gas pipes and chimney parts pass nearby, a distance of 20 cm should be maintained between them.

The chimney pipe can be placed under a canopy or balcony. The closer the chimney opening is located to the balcony, the longer the length of the outer part of the pipe should be. There is an opinion that with a horizontal installation scheme, the length of the chimney should not be more than 3 meters. This is not always true. Some types of equipment are 4-5 meters long.

To install a coaxial chimney with your own hands, you need to stock up on the necessary materials. The list of tools may vary depending on the situation, but most often the following devices are required:

- the pipes themselves;

- adapter connecting the chimney and boiler;

- tee, elbow;

- crimp clamps for effective fixation of parts.

Most often, all installation equipment is supplied with the chimney. To route a pipe through a roof, wall or ceiling, use fire-resistant gaskets. They are required to protect materials located near the chimney from ignition and overheating.

Installation and operation

Installation and correct connection of the system to the boiler is a simple process. To install a horizontal chimney, you need to follow the step-by-step instructions:

- First, you need to place the gas boiler in its place, and mark the center of the intended pipe outlet on the outside wall of the building.

- Now the boiler should be temporarily removed and using a hammer drill and a cutting bit, drill a hole in the load-bearing wall. Its diameter should be 20 mm larger than the size of the outer pipe.

- An adapter must be connected to the boiler outlet hole. When connecting, use a sealing gasket. Then, using self-tapping screws or self-tapping screws, attach the adapter flange to the surface of the boiler.

- The pipe must be connected to the external pipe of the adapter. To create a reliable fixation, do not use any sealants.

- Be sure to check the tightness of the connections and the fixation of the fasteners. If everything is done correctly, the pipe is inserted into the hole in the wall.

- Now the boiler can be returned to its original place and mounted on the wall. The chimney must be installed with a slope of 3-5 degrees towards the street. It should be fixed in the wall with small stones.

- Holes between the outer casing and the wall must be sealed with polyurethane sealant.

High-quality ventilation

Although waste substances exit through a sealed channel, and air enters from the outside, care must be taken to ensure good ventilation of the room in which the boiler is located. This will allow you to maintain ideal humidity levels in the room, which will have a positive effect on the operation of the equipment and extend its service life.

No matter how high-quality the system is, it may fail after some time. If a minor breakdown occurs in the boiler room, with good ventilation, carbon monoxide will escape naturally. In this case, the risk of gas poisoning is significantly reduced.

A coaxial chimney is a reliable, efficient and easy-to-install equipment. In order for the system to work efficiently, it is necessary to comply with the installation requirements and follow the operating instructions.

Important points for installing double-circuit smoke exhaust

To ensure that smoke is removed effectively, certain standards must be observed during installation. So, when connecting a gas boiler to a coaxial chimney exiting through the wall, then a slope of 3° must be made. At the same time, strictly follow the manufacturer's recommendations.

When connecting the chimney to the boiler, use a special adapter. In this case, it is prohibited to use pipes that are made at the installation site using improvised means.

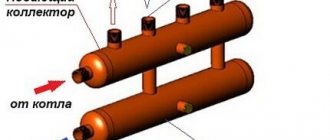

Important! After the outlet pipe of the boiler, a tee with a condenser collector is most often installed and only then the coaxial pipe is raised to a height of 500 to 1000 mm. Before starting the system, be sure to first check the traction.

If it is necessary to extend the chimney, the pipes are collected using condensate. Their installation is carried out according to the “mother-father” principle. At the same time, the number of turns of the double-circuit pipe is reduced as much as possible so as not to worsen traction. To secure the chimney, special clamps are used.

Signs of icing in an air duct

Indicators of ice formation at the end of a coaxial pipe include:

- the “Flame break” error appears on the boiler display or on its dashboard;

- condensation forms on the surface of the air duct;

- The boiler lights up and goes out after a short time.

Condensation on the surface of the duct.

These signs will help determine the cause of the malfunction of the heating equipment, if the visibility of the coaxial structure is poor (the pipe goes to the external, solid, side wall of the building, etc.).

Pros and cons of double-circuit chimneys

All coaxial chimneys for wall-mounted gas boilers or floor-mounted units are more expensive than conventional stainless steel smoke exhaust ducts. In this case, it often becomes necessary to lengthen double-circuit pipes. In this case, their price increases. In addition, you still need to attract professionals to properly assemble and install the smoke removal system.

Despite the higher cost, all chimneys are of the coaxial type:

- quickly assembled and installed;

- create good traction if installed by professionals;

- do not clutter the façade of the house;

- take outside air rather than the environment from the room, which reduces the ventilation requirements of the boiler room.

Double-circuit pipe from the boiler for simultaneous removal of smoke and air flow Source tm24.by

However, there are other disadvantages of using double-circuit smoke exhaust pipes. Their installation must be coordinated with the gas service, which will definitely advise you to take measures for the correct disposal of condensate. After all, according to sanitary rules, highly toxic liquid should not fall on the ground, but this requirement does not apply to private houses.

Advice! To avoid serious installation errors and ensure efficient operation of double-circuit chimneys, it is better to entrust the installation work to specialists. Professionals will organize the correct condensate drainage, taking into account the features of the smoke removal system and boiler unit.

Condensate should not drain into the boiler Source mystroy24.ru

Remedies

You can find out how to solve this problem or how to melt ice in a chimney in this section:

- You can partially cope with this problem and reduce the amount of ice by removing the plug located on the top of the device;

- Change the angle of inclination of the coaxial system (if it is vertical or horizontal and located at a right angle). This will allow the condensate that forms to drain and not freeze inside the pipes.

To prevent icing, you can use special anti-ice products.

Insulated systems are less susceptible to icing

Although the instructions make it possible to partially solve the problem by removing the plug, ultimately, after the situation improves, it will be necessary to fix it to its original position, since its constant absence can lead to other malfunctions.

Tip: the fastest way to remove ice is with a special anti-ice spray,

the price of which depends on the chosen volume and manufacturer.

Briefly about the main thing

The dual-circuit smoke removal system structurally consists of 2 pipes. Removes smoke through an internal channel. In this case, the space between the two pipes is used to supply air to the firebox. Such systems are connected to gas boilers. Manufacturers produce them from stainless steel and plastic.

Vertical and horizontal installation of coaxial chimneys is possible. Their maximum height can be 7000 mm. In this case, the greatest length relative to the ground is 5000 mm. These standards depend on the specific model of the installed boiler unit. Condensate is not allowed to enter the boiler. For this purpose, condenser collectors are installed. At the same time, in country houses it is allowed to lay a chimney sloping towards the street.

Ratings 0

Classification

So, what types of devices are there? There is the following classification of structures.

1.) Location. There are such devices:

- internal - laid in mines;

- external - located on the inside of the facade in order to avoid deteriorating the appearance of the building.

2.) Insulation. There are such devices:

- insulated - used in regions where low temperatures prevail for a long time;

- not insulated - used in areas where high temperatures reign for a long time.

3.) Output type. It depends on the location of the boiler in the room and the path along which the chimney is laid. There are structures with the following conclusion:

- vertical;

- horizontal.

4.) Amount of equipment. Options available:

- individual - intended to serve one boiler and do not differ in the presence of branches;

- collective – systems where individual branches are connected to a common channel.

As you can see, the choice is good and rich.

Disadvantages when using the device

The disadvantage of a coaxial geyser is its energy dependence. If there is a power outage, there will be no hot water. You will need to use an electric generator or a reliable uninterruptible power supply. Other negative aspects of these devices:

- A coaxial gas unit is almost twice as expensive as an atmospheric one. But when comparing the purchase and installation in a complex, a coaxial chimney will cost much less than making it out of brick or installing an insulated sandwich.

- Fan noise is heard on some speaker models.

- It is better to entrust cleaning of the device to a specialist. Modern equipment has a complex structure, so trying to find the malfunction and fix it yourself is not recommended.

To install this type of unit, permission from the organization supplying natural gas is required. You should also notify neighbors that a chimney exhaust will be installed on the facade of the house.

When a chimney is not needed: chimneyless speakers

Nowadays, due to the spread of turbocharged speakers, it is precisely such devices that are called chimneyless, since they do not require a special chimney, and their coaxial chimney is discharged through the wall. However, there are also columns that discharge combustion products into the room in which they are installed. As a rule, these are low-power models with low performance. An example of such a dispenser is Neva 3001, whose power is 9 kW and productivity is only 2.6 liters per minute.

To install such a speaker, good ventilation of the room is very important, but even in this case there is a danger of carbon monoxide poisoning, because it has no odor and affects a person when he is not even aware of the mortal danger. That is why the chimneyless column loses to the turbocharged one and has recently been practically not used.

One of the options for solving the issue of hot water supply is to install a gas water heater. One of the important aspects of installing a gas water heater, on which ensuring high-quality draft and removal of combustion products, and, accordingly, efficient operation of the equipment depends, is the selection of a suitable chimney and its correct installation. Read an overview of the characteristics of a galvanized steel chimney on this page.

Gas chimney in the photo.