Options for installing a chimney pipe for a gas boiler

Attached - the pipe is mounted through a blank wall outwards, horizontally to the ground. The pipe is covered to avoid possible freezing in winter.

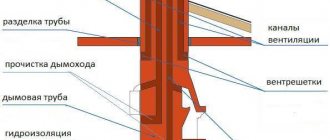

The internal chimney is located inside the house and passes through the ceilings and roof. In this option, the structure is insulated with special fireproof materials.

IMPORTANT! Combustion products have a high temperature, so the fire inspectorate pays special attention to the design and materials that are used as exhaust pipes.

Experienced craftsmen advise installing oval (or round) pipes, although this limits the choice during installation.

This is due to the fact that in an oval-section pipe the exhaust gas does not encounter obstacles, which causes uneven heating of the exhaust gas, which in turn creates good draft. In a design with a square cross-section, reverse vortices are formed in the corners, which interfere with traction.

Frequent errors and problems during installation

The most common mistake is the lack of insulation of a single-layer pipe. Inside the house, this can lead to fire of flammable structures and objects and burns to people. In the open air, the lack of insulation causes many very unpleasant consequences:

- flammable gases cool very quickly, draft decreases, combustion products or even carbon monoxide can enter the room and cause poisoning of people. During frosts, reverse draft may even occur - an extremely dangerous phenomenon;

- A very large amount of condensate settles on the walls, which leads to rapid failure of the pipe.

You cannot install a flue without a deflector or at least a cap - snow and rain should not get into the head and channel.

It is necessary to provide access to the required amount of air to the boiler - there must be a special window in the boiler room that is constantly open.

The chimney must be straight. If absolutely necessary, inclined and horizontal sections with a length of no more than 1000 mm each and the total length of their projections onto the horizontal no more than 2000 mm are allowed. The tilt angle is no more than 30° from the vertical (45° is allowed).

The length of the chimney increases by the sum of the lengths of the horizontal projections.

If the chimney passes in the same place with ventilation ducts, then it must be higher than the other ducts, the ventilation ducts must be covered with a cap located below the head of the gas duct. This protects against possible combustion products entering the room.

Gas boiler design

Open burner. This is a boiler installed on a special foundation, with an open firebox. In this option, pipes made of brick or ceramics are best suited since the main task of the chimney is to provide good draft.

IMPORTANT! A brick chimney is heavy and difficult to install. In addition, it is hygroscopic.

Closed burner (turbocharged boiler). With this option, a coaxial chimney or a system of sandwich pipes and fittings is best suited

Expert advice

Is it possible to reduce the diameter of the chimney of a solid fuel boiler?

One of the most common questions that readers ask about installing a chimney is the question of reducing the diameter. The diameter cannot be reduced! This parameter is calculated by designers based on the power of the boiler, and changing it will lead to many negative consequences, the most harmless of which is a decrease in the power of the boiler, and the most serious is poisoning of the residents of the house with combustion products. They don't joke with fire! – in this matter, you must rely on the instructions for the boiler.

Increasing the diameter is also undesirable. If the diameter of the outlet pipe is non-standard, use a slightly larger diameter pipe in the standardized size range. Too large a diameter also leads to reduced traction.

Chimney pipe size

The most correct thing would be to choose the optimal ratio between the diameter and the length of the chimney to ensure normal draft.

- long pipe - heat leaves the firebox

- thick pipe - a lot of space, exhaust gas cools quickly, and backdraft is reduced

- narrow and high - the laws of physics come into play, creating resistance in the pipe, reducing traction

IMPORTANT! The description for a gas boiler always indicates the width of the chimney pipe, since the efficiency of the chimney depends on the power of the boiler.

Traction force

It is known that the intensity of the removal and discharge of heated smoke and gas into the external environment is directly influenced by draft

. This is a key characteristic of the chimney system, demonstrating its efficiency. The traction force is affected by the cross-section of the chimney, diameter and height:

- the narrower the upper part, the sooner the gas and smoke mass comes out;

- Minimizing inclined or horizontal parts and branches helps to speed up draft, that is, creating as vertical a chimney as possible.

Determination of effectiveness

The reason for the low efficiency is incorrect assembly of the system, poor connection of components. In most cases, these errors are noticeable at the time of assembly, so they can be easily eliminated. Otherwise, to eliminate the shortcomings, you have to dismantle and reassemble the chimney.

A sign of high efficiency is a noticeable hum in the pipes that accompanies the operation of the boiler. The rate of smoke removal is regulated using a damper that partially blocks the chimney.

Fire brick chimney shaft

This design is popular because the main advantages are low cost, good material strength and heat resistance. In addition, such a chimney is not difficult to repair.

IMPORTANT! A so-called deflector is always installed on the pipe. This is a lid, a cap that prevents precipitation from entering the mouth of the pipe.

Among the disadvantages, the most important are the hygroscopicity of the brick, the heaviness of the structure itself (this means that it will be necessary to install an additional foundation), and the complexity of installation.

Operational features of gas pipelines made of different materials

Gas pipelines with high pressure are mounted from pipes that have large dimensions. In cases where it is necessary to make a structure of increased strength, seamless steel pipes are used. The joining of such pipes is carried out using welding equipment. Welding such products is a rather labor-intensive process.

The most suitable material for pipes through which gas will be transported is copper. This is due to the fact that copper has several performance advantages over its steel counterparts. Let's consider the main advantages of pipelines made of this material:

- small weight;

- easy installation;

- corrosion resistance.

However, copper gas pipelines are used quite rarely, as they are expensive.

If pipes with thin walls are used when laying gas transmission lines, it is recommended to take into account their high thermal conductivity coefficient. Due to their high thermal conductivity, such products tend to become covered with condensation.

Helpful information! To ensure anti-corrosion properties, it is recommended to coat the surface of steel pipelines with oil paint (in several layers).

When laying gas networks underground, the use of polymer pipes is permitted

When laying gas transmission lines underground, as a rule, pipes made of modern polymer materials are used. The most popular polymers used for these purposes are polypropylene (PP) and polyethylene (PE). Let's consider the main advantages of such polymers:

- high coefficient of flexibility;

- corrosion resistance;

- ease of installation;

- democratic price.

Pipes made of polymer materials are ideal for underground installation, as they feel comfortable under such conditions. It is very important to remember that plastic pipelines are used only for organizing lines with low pressure levels. Polymer pipes have appropriate markings that determine their operational affiliation. For example, polyethylene pipes used for gasification of private buildings are produced black and have a yellow marking.

The distribution of the gas transport structure inside the house is carried out using special flexible hoses. Such hoses are made from a special material - vulcanized rubber, and are also distinguished by the fact that they have reinforcement. In most cases, they are used to connect gas stoves to geysers.

Such hoses have operational limitations that are worth paying attention to:

- they do not apply if the room temperature exceeds +45 °C;

- It is prohibited to use rubber hoses in areas that are located in seismically active areas (more than 6 points);

- they are not used in high-pressure communications.

Galvanized pipe for gas boiler

At the moment, on the gas equipment market, a round galvanized pipe is the most optimal design, as it is very stable and can easily withstand mechanical loads.

“Sandwich” type structure - one tube is inserted into another, basalt wool is used as a gasket.

SNiP restrictions when laying a gas pipeline

As mentioned above, SNiP 42-01-2002 describes all the necessary restrictions on the installation of gas pipeline structures. The distance between a residential building and communications is determined by the gas pressure: the higher this indicator in the pipe, the farther it must be located from the house.

Let's consider the main provisions that are described in SNiP:

- the distance between the foundation of a residential building and the low-pressure gas transmission communication is 2 meters;

- the distance between the foundation of a private house and the medium-pressure pipe is 4 meters;

- high-pressure gas pipelines should be located at a distance of 7 meters from a residential building;

- in accordance with SNiP, the distance of the pipeline that transports gas to a window or door opening must be at least 50 cm;

- the distance from the pipe to the roof of the house should be at least 20 cm.

Items prescribed by building codes and regulations must be complied with without fail, as they take into account fire safety and plumbing standards.

Coaxial pipe for gas boiler

This option was introduced recently, but it is already very popular.

In structure, these are two pipes that are inserted into one another.

The main advantage is that additional ventilation in the house is not required, since the air enters the pipe from the street, and not from the room.

Thanks to their non-standard design, coaxial chimneys for gas boilers perform 2 tasks simultaneously - the inner pipe removes exhaust gas, and cold air flows back through the outer pipe.

Types of gas pipelines

Depending on the pressure under which gas moves through the pipes, gas pipelines are classified into three main types:

- low pressure lines;

- medium pressure lines;

- high pressure lines.

Low pressure line. The pressure indicator in such communications reaches 0.05 kgf/cm². Such pressure in gas pipeline structures is typical for economic systems that supply gas to ordinary consumers. Such networks are installed for residential and administrative buildings, which include: multi-storey residential buildings, educational institutions, offices, hospitals, etc.

Note! For household needs, as a rule, gas is used, which has a high thermal conductivity coefficient (about 10,000 kcal/Nm³).

Pipelines with average pressure indicators. In such pipelines, gas is transported under pressure from 0.05 kgf/cm² to 3.0 kgf/cm². Such lines are in most cases used as main lines, and are also installed in the main city boiler houses.

High pressure gas pipelines. The pressure indicator in such pipelines can vary from 3.0 kgf/cm² to 6.0 kgf/cm². Such lines are installed to supply gas to various production enterprises.

Networks transporting gas to end consumers are low pressure lines

There are situations in which the pressure in a gas pipeline structure may exceed the established limits. In some cases it reaches 12.0 kgf/cm² (highest pressure line). Organizing a system with such pressure indicators requires separate calculations. All gas pipelines are classified not only by pressure, but also depending on the material from which they are made.

Ceramic pipe for boiler

Complex design - a fragile ceramic tube is covered with heat-insulating material and inserted into a solid expanded clay block.

The inner tube is smooth, round in cross-section with a smooth surface, which is optimal for good traction.

Gas connection price in Russian regions

The costs of gasifying a site are largely related to its location. The largest amount for connecting to the gas network will have to be paid to homeowners in the Moscow region - 400,000-700,000 rubles. (most expensive within the boundaries of Moscow).

For owners of country cottages in the Leningrad region, gas installation will cost less than in the capital region - around 300,000 rubles.

If the applicant wishes to install a gas pipeline under rivers, highways, etc. – it’s possible. But the use of horizontal directional drilling will increase the cost of gasification of households

Gasification is the cheapest in the European regions of the Russian Federation, where the installation of a gas pipeline on a site can be carried out for 70,000-120,000 rubles. And in the Nizhny Novgorod region, connecting a home gas network to a natural gas main costs approximately 150,000-200,000 rubles.

In the regions of eastern Russia, the gas pipeline network is poorly developed, since there are significantly fewer industrial centers there than in the western regions. For example, in the Novosibirsk region, the costs of private homeowners for gasification will be at least 200,000 rubles.

The most difficult situation with gas pipelines is in the regions of the Far East, where there are very few gas pipelines. Local owners of plots, even if they belong to the first category of applicants, will spend an average of 200,000-250,000 rubles. for gas supply to your cottage.

Stainless steel chimney for gas boiler

More reliable than brick. Resistant to corrosion and various weather conditions, very durable. Another plus is that the assembly is made from several segments, which means it’s easy to replace a damaged area.

IMPORTANT! Ventilation shafts are not used as openings for pipes. This is strictly prohibited.

Gas pipeline security zone

The security zone of a gas pipeline communication is the space that is located between the pipe and two conventional lines located parallel to the sides of it. The distance from the axis of the pipeline to these lines can be different, since it depends on the pressure inside the communication.

The security zone for areas with low pressure is at least 2 meters on each side of the pipe

Let's look at examples of security zones for various gas pipelines:

- for communications that are laid in an open way, the security zone will be 2 m on each side of the pipe;

- for lines that consist of polyethylene pipes with special copper wires marking the route, it is 3 m from the communication (on the wire side) and 2 m on the other side;

- along gas transmission lines that are laid in permafrost soil conditions, the security zone is 10 m on each side of the communication. This indicator remains the same regardless of what material the track is made of;

- for points that regulate gas in the pipeline, the conditional, closed line of the security zone is 10 m from their boundaries. For private gas control points, the security zone is not regulated;

- the security zone for gas pipelines laid under water is 100 m;

- for communications laid in forest belts and in areas with trees and shrubs, the security zone is 3 m (in the case of underground laying of the route). And for communications installed above the ground, the distance from the tree to the pipe must be no less than the height of this tree;

- for private purposes, as a rule, pipes with a cross-sectional index of at least 80 mm are used. For such a pipeline, the security zone will be 2 m on each side.

Stages of installing a chimney for a gas boiler (step-by-step instructions)

A chimney for a gas boiler in a private house is installed in three main stages:

Preparation

First, determine the location of the future chimney (a blank wall for an external chimney or a place where it is convenient to break through the ceilings and roof for an internal chimney).

Then they decide on the issue of protection - if the pipe will pass inside the house, thermal protection is necessary; the external chimney is closed to avoid freezing in cold weather.

Installation of coaxial pipe

If there is not enough space (a narrow street or a window is too close), the pipe is installed parallel to the ground, but if there are no such problems, then the chimney is installed vertically, along the wall.

IMPORTANT! In any case, the maximum length cannot exceed two and a half meters.

Chimney installation

The chimney installation scheme depends on the type of structure and the selected material. This is a technically complex process, strictly regulated by SNiP.

One part of the pipe is inserted into the other in such a way that it does not interfere with the exit of gas from the chimney.

Connecting and checking traction

Connection to the gas pipeline can only be carried out by a specialist. To do this, apply to the local gas service (waiting period 30 days)

IMPORTANT! Installation of a chimney for a gas boiler is carried out in accordance with SNiP (building regulations) and basic fire safety requirements.

Any equipment that operates on a hazardous energy carrier, such as gas, must be installed in compliance with all rules.

First of all, they carry out all engineering and technical calculations, draw up documentation, and then obtain permission from the gas service. And only after that they implement the project - on their own or with the involvement of specialists.

Maintenance and cleaning

The chimney must be periodically cleaned of soot. Better 2 times a year. It can be cleaned mechanically and chemically. The choice is yours. After cleaning, be sure to check the traction.

In winter, sometimes condensation or precipitation freezes in the upper part of the pipe - it is necessary to ensure that the channel is not blocked - this reduces draft and creates a danger of poisoning residents with combustion products.

Photo of the correct installation of chimneys for a gas boiler in a private house

Principle of operation

The operating principle of any chimney is based on a simple law of physics - warm air and vapors are always lighter and tend to rise, while cold air is heavier and, accordingly, settles below.

Due to the difference in temperature between the street (outside the pipe) and hot gases (inside the system), draft appears. Thanks to it, combustion products do not disperse throughout the room, but escape into the atmosphere.