Modern life presupposes the presence of such a benefit of civilization as centralized heating. However, stoves, fireplaces, boilers and other similar equipment still find their use. At the same time, channels made on the basis of brickwork are becoming less and less common, since they have been replaced by metal structures made of stainless steel, guaranteeing reliability and high performance characteristics. The starting materials for the production of vertical channels are sheet and galvanized steel, chrome-plated products and various metal alloys, which guarantee the final product high resistance to the external environment.

Types of chimney pipes

Before answering the question of which product is best to use for a system that provides removal of fuel combustion products, it is necessary to understand the existing options and their differences. When installing chimneys made of stainless steel yourself, it is assumed to use the following types of products:

- Metal pipe in one layer.

- Corrugated cylindrical product.

- Sandwich pipe.

Single-layer structures used as a chimney are distinguished by their small wall thickness, which ranges from 0.6 to 2 mm. The cost of such products is low, but at the same time their use is somewhat limited due to existing shortcomings.

This type of pipe can be used directly in insulated rooms.

The temperature difference between the air outside and inside a single-layer stainless steel chimney creates conditions that ensure an increase in energy consumption. At the same time, the formation of condensation reduces the performance of the heating system and negatively affects its service life.

As for corrugated pipes, they are often used in the construction of channels for the removal of flue gases that have curved transitions. Such products are not strong enough and have low thermal resistance. Thus, polymer products made of stainless steel are designed for operation at temperatures up to 900 °C. At the same time, it efficiently removes combustion products from furnaces, regardless of the fuel used.

The most effective chimneys are the so-called sandwich systems .

Their design involves the presence of two pipes, one of which is located inside the other. A non-flammable material, for example, mineral wool, is placed between them, providing the required level of thermal insulation. Sandwich pipes can be installed not only outside the room, but also inside it.

Requirements for smoke vents of gas units

Heating boilers that burn natural and liquefied gas are high-efficiency installations with an efficiency of 88% or more. In practice, this means that the temperature of combustion products fluctuates between 70-120 ° C, which contributes to the formation of condensation on the walls of uninsulated flues. Hence the first rule: sections of vertical channels located outside the building or passing through cold attics are subject to mandatory insulation.

Brick caps - even those need to be insulated

The remaining requirements for the installation of chimneys are as follows:

- The cross-sectional dimensions of the channel or shaft are determined by calculation, but should not be less than the diameter of the outlet pipe of the gas boiler.

- When constructing a chimney, it is allowed to use frost-resistant clay bricks, asbestos-cement pipes and other non-combustible materials - steel, heat-resistant concrete, ceramics.

- Porous building materials must not be used.

- In the lower part of the vertical gas duct it is necessary to provide a pocket with an inspection door, which serves as a condensate collector.

- Chimneys for gas boilers are allowed to be installed inside brick walls and laid next to ventilation shafts, separating them with a sealed partition 12 cm thick. When leading to the roof, the chimney and exhaust pipe are made at the same level.

- The head of the flue should not fall into the zone of wind pressure created by the ridge of the roof, a neighboring building or tree. How to determine the required height is shown in the diagram (the minimum is 5 m).

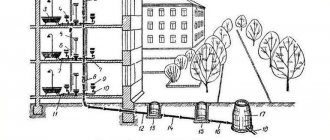

A few words about how to correctly remove combustion products from several heat sources, for example, a boiler, a wood stove and a gas water heater. If the issue is resolved at the construction stage, then the standards require the installation of a separate channel for each piece of equipment. They can be combined into one unit with a ventilation exhaust pipe. In an existing building, gas-using installations can be connected to one chimney, observing the distance between the connections, as prescribed by the diagram:

Properties of stainless steel

The performance characteristics of chimneys directly depend on what grade of material was used in their manufacture. In this regard, when purchasing pipes, you need to pay attention to the markings:

- 409 is a steel suitable for heating devices that operate on solid fuel.

- 430 - used mainly for parts that are practically not exposed to aggressive influences. Typically, the outer part of the casing is made from such steel, since it does not deform in a humid atmosphere.

- 316 is a material containing elements such as nickel and molybdenum, which provides acceptable resistance to thermal and chemical influences. This circumstance allows us to say that such pipes are ideal for a gas boiler.

- 304 is a steel whose characteristics are comparable to grade 316, but with a significant reduction in the amount of alloying additives, which ultimately reduces the cost of the finished product.

- 316Ti and 321 are multifunctional steel grades with excellent ductility and resistance to aggressive environments, capable of withstanding temperatures up to 850 °C.

- 310S is a first-class steel that has many positive characteristics, including resistance to temperatures up to 1000 °C.

Connecting a collective smoke duct

With a collective chimney, heating devices must be of the same type.

The need to have one smoker for several households arises if there is a need to save money, space, or there is no way to organize the exhaust gas exhaust system differently. From a technical point of view, this is a completely acceptable option and such structures are effectively operated. In this case, it is necessary to consider two options:

- Connecting heating devices of the same type to the device.

- Connecting fundamentally different heating units to the line, for example, a gas boiler and a brick fireplace.

In the first case, there is no difficulty in including equipment in a common channel, since for such devices it is possible to calculate a smoke channel for one draft value at which all units will operate correctly.

In the second option, it will not be possible to coordinate the devices, since the chimney for the fireplace should occupy 1/10 of the firebox area, and this is too much for the boiler. The result is either excessive or insufficient thrust for one of the devices, which is fraught with negative consequences.

The most correct solution would be to use a two-channel system. Its essence is that the internal space of the pipe is divided into two channels, each of which is designed for its own heating equipment.

How to choose a stainless steel chimney

When purchasing a vertical channel for the removal of combustion products made of stainless steel, you must clearly understand what each type of product is. Let us dwell in some detail on the characteristics of steel units.

Corrugated pipe

From a design point of view, such a product is a spring made of steel wire, onto which a multilayer foil is attached using a special technology. The walls of such a pipe have a thickness from 100 microns to 0.1 mm.

As a result, the corrugation provides the chimney product with unique properties, including the following positive characteristics:

- flexibility of the gas duct, which makes it possible to install in hard-to-reach places with a complex configuration;

- low cost of the product itself and its installation;

- suitability for use when restoring old brick chimneys in case of problems with their tightness;

- the ability to stretch and compress the product;

- installation outside the building due to the presence of insulation.

At the same time, the corrugated pipe is not without the following disadvantages, which are largely determined by the thin walls of the product:

- short service life of the chimney, limited to 10 years, which does not allow its installation inside building structures;

- high aerodynamic resistance arising from corrugated walls, which minimizes the traction force if the vertical channel, for example, of a two-story house, is completely made using such a pipe.

Corrugated products should only be used in short sections or for connecting gas-using devices to the chimney shaft. Due to the fact that the walls of such pipes are small, they should not be installed on stoves and boilers that use solid fuel, the operation of which involves the release of combustion products caused by high temperatures.

Sandwich chimneys

Channels of this type are distinguished by their versatility, operational reliability and high cost compared to other types of similar products. Sandwich systems are suitable for any equipment intended for heating, with the possibility of installing them inside and outside buildings.

If we recognize the high cost of the product as a disadvantage, then the second negative point is the large size of the chimney, which implies the need for adequate space for its installation.

Some owners of private houses independently install standard pipes, insulating them with basalt wool. In this case, questions regarding fire safety remain open.

A correctly installed factory-made sandwich chimney, which contains insulation such as basalt wool, not only ensures fire safety, but also an opportunity to avoid the appearance of dirty streaks. At the same time, choosing products with an outer layer of stainless steel allows you to decorate your home.

Single wall pipe

Compared to a corrugated product, this type of vertical channel is more expensive, which pays off with a longer service life. In addition, single-walled structures with oval shapes became available for sale, which led to improved aerodynamic properties. Such products are supplemented with shaped parts that simplify the laying of pipes in hard-to-reach areas.

A flat oval cylindrical product with a large cross-sectional area allows you to use less space for installing a vertical channel. At the same time, such pipes cannot be used as gas ducts for heat generators with high efficiency, that is, more than 90%. For example, these devices include diesel and gas boilers. Here it is necessary to give preference to chimneys with thermal insulation.

The mentioned heat generators operate in such a way that the exhaust gases have a low temperature, and this in turn leads to the formation of condensation and, as a consequence, to the appearance of black streaks. In this regard, single-circuit channels are suitable for various furnaces whose efficiency does not exceed 60%.

In addition, they can be installed on boilers operating on solid fuel, but condensation in this case cannot be avoided. Units with an efficiency of 70-85% must be equipped with insulated vertical channels.

Double-walled sandwich chimneys

This type of product is the most expensive, but at the same time more reliable and versatile in use. A double-walled channel can be laid both inside and outside the house. This design is suitable for any type of stove and boiler. The only minor drawback of such a channel is that, due to the insulation, the pipe has larger dimensions than its predecessor, discussed above. However, professionals recommend assembling precisely this type of chimney.

Correct installation of the factory pipe will allow you not to worry about the occurrence of leaks, thanks to which the stainless steel will retain its beautiful appearance for a long time.

Calculation methods and rules

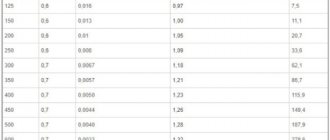

The calculation rules have their own tolerances; you need to know them before calculating the diameter of the pipe. There are several calculation methods, they depend on who and for what conditions they will be fulfilled:

- High-precision, used in the production of boilers and carried out by the design departments of equipment manufacturers.

- Approximate calculations performed by non-specialists based on graphs, diagrams and tables.

- Automatic, obtained on the basis of online calculation.

Accurate calculations are understood as those in which many factors are taken into account: the temperature of the flue gases at the outlet of the boiler and from the pipe, the speed of movement of gases in the furnace and in sections of the smoke exhaust system, the loss of gas pressure along the movement in the gas-air tract. Most of these parameters were obtained experimentally by manufacturers of boiler equipment and depend on the brand of the boiler, so this type of calculation is practically not available to users.

With regard to the indicative method, before calculating the diameter of the chimney, the volume characteristics of the combustion chamber are taken into account. To determine the geometric parameters of pipes, there are various tables and graphs. For example, with a firebox with dimensions of 500x400 mm, a round pipe from 180 to 190 mm will be required.

The third method is based on the use of special online calculators. They take into account almost all important parameters, so they produce very accurate results. In order to use them, the operator will need to know a lot of starting data.

Exact method

Accurate calculations are based on a rather labor-intensive mathematical base. To do this, you will need to know the fundamental geometric characteristics of the pipe, heat generator and fuel used. For this calculation, you can use the following method for determining the diameter of a round pipe for a wood-burning stove.

Calculation input parameters:

- Gas T readings at the boiler outlet t – 151 C.

- The average speed of flue gases is 2.0 m/s.

- The estimated length of the pipe, which is standard for stoves, is 5 m.

- Mass of burned wood B= 10.0 kg/hour.

Based on these data, the volume of exhaust gases is first calculated:

V=[B*V*(1+t/272)]/3600 m3/sec

Where V is the volume of air masses that are necessary for complete combustion of fuel - 10 m3/kg.

V=10*10*1.55/3600=0.043 m3/sec

d=√4*V/3.14*2=0.166 mm

Swedish method

Chimney calculations are often performed using this method, although it is more accurate when calculating smoke exhaust systems for fireplaces with open fireboxes.

Swedish method

According to this method, the size of the combustion chamber and its gas volume are used for calculation. For example, for a fireplace with a portal, the height is 8 masonry heights and 3 masonry widths, which corresponds to the size F = 75.0 x 58.0 cm = 4350 cm2. The ratio F/f = 7.6% is calculated and it is determined from the graph that a rectangular chimney of this size cannot work; it is possible to use a structure with a circular cross-section, but its length must be at least 17 meters, which is not really high. In this case, it is better to make the choice from the opposite direction, according to the minimum required diameter section. It is easy to find by the height of the building, for example, for a 2-story house, the height from the fireplace to the chimney cap is 11 m.

F/f ratio = 8.4%. f = Fх 0.085 = 370.0 cm2

D= √4 x 370 / 3.14 = 21.7 cm.

Advantages and disadvantages

Stainless steel chimney pipes meet the requirements for the safety and reliability of the channels used to remove combustion products, which allows us to talk about the following advantages:

- the surface of the chimneys retains in the form of precipitation a small amount of products of the chemical reaction of oxidation of the substance;

- unlike ceramic systems, the chimneys in question do not require a special foundation for their installation;

- high resistance to acid attack as a result of fuel combustion;

- due to the modular type of chimneys, their installation is simplified as much as possible;

- sandwich systems virtually eliminate the possibility of a fire;

- high level of tightness.

Regarding the disadvantages of stainless steel-based chimney systems, the following can be said:

- the use of structures where single-wall pipes are used as vertical channels can cause fires due to strong heating of the walls of the product, so it is advisable to insulate them;

- Sandwich systems are more reliable, but even here there is a drawback such as deformation of the weld due to temperature changes, when the metal periodically contracts and expands, which reduces the tightness of the welded joints.

How to check and adjust the draft in the chimney of a gas boiler

Draft is a decrease in pressure in the place where fuel combustion occurs. The pressure decrease occurs due to the removal of combustion products through the smoke channel. Speaking within the framework of this article, draft forces fresh air into the combustion chamber, where there is a reduced pressure that occurs due to the fact that gas combustion products are discharged outside.

The presence of draft indicates that the chimney is designed and installed correctly, and the equipment is working properly. The lack of draft may be a direct or indirect confirmation of the need for preventive maintenance or repair of equipment and the chimney system.

The speed of air flow in the chimney can be measured with a special device - an anemometer

The following methods are used to check the draft level:

- visual inspection - there should be no smoke in the room where the heating equipment is located;

- using improvised means, for example, a sheet of paper. It is brought to the inspection hole. If there is traction, then the sheet will deviate towards the hole;

- measurement with a special device - an anemometer. It is used to control air speed.

To control traction, it is better to use the latter method, since only it will show the exact value. When measuring natural draft, the flue gas velocity should be in the range of 6–10 m/s. The value is taken from SP 41–104–2000 “Design of autonomous heat supply sources.”

If it is necessary to reduce the draft level, then this will require reassembling the chimney based on a chimney of a larger cross-section. To increase traction, it is recommended to check the quality of the installation joints and mechanically clean the smoke channel using a steel cable with a brush attachment.

If this does not help, then the only way out is to replace the chimney with a preliminary calculation of the chimney cross-section. In this case, it is desirable to reduce the number of rotating elements to a minimum or remove them altogether.

Why does the boiler blow out and how to fix it

The main reason why the burner in a boiler blows out is the backdraft effect that occurs due to problems with the chimney.

Before starting any measures, you should check the height of the chimney above the ridge level and the presence of an installed deflector, which reduces the penetration of wind flows into the chimney. If the pipe installation is not carried out according to the rules, then after the steps described below, you will need to extend the pipe and install a deflector.

Sometimes, in order to increase draft, you need to clear the chimney of soot

In order to solve the problem with the boiler blowing out, you will need to do the following:

- First of all, you need to check the draft level in the pipe. It is better to use an anemometer. If you cannot find it, then with the boiler running you need to lean the paper against the outlet of the chimney. If the sheet is attracted to the chimney, then there should be no problems with draft.

- If you find that the blowing occurs due to a loss of natural draft, you will need to check the chimney joints. A thermal imager is used for this. If the pipe allows air to pass through, the device will show a strong temperature difference between the main pipe and the junction of the two modules.

- If the chimney is assembled correctly, then it is necessary to clean the smoke channel using a cable with a nozzle. The diameter of the nozzle is selected to match the cross-section of the chimney pipe. To remove soot, tar and other combustion products, an inspection hole is used at the bottom of the chimney.

- After completing these simple steps, you will need to check the traction level again. If natural draft has not improved, then it is necessary to carry out work to correct the height of the chimney and install a deflector. During installation, heat-resistant sealant and crimp clamps are used.

In cases where the work described above does not produce results, you should contact the gas service to check the gas equipment. Perhaps the problems with blowing are associated with hypersensitive automation.

Installation Rules

When carrying out independent installation of a chimney, where stainless steel is used as the manufacturing material, it is necessary to take into account the following technical standards:

- the height of the pipe installed on a flat roof or in close proximity to the ridge (1.5 m or less) is 0.5 m or more;

- if the chimney is located at a distance of 1.5 to 3 m from the ridge, then the height parameters of the horizontal fin and the smoke exhaust channel must be correlated;

- it is important that the floors of the building are located with pipe joints at different levels;

- smoke exhaust channels can have no more than 3 turns, and the diameter of the cylindrical product should not be less than the corresponding size of the outlet pipe;

- if the vertical channel is more than 3 m away from the ridge, then the pipe along its edge and the line that is 10 degrees from the horizon formed by the ridge strip must be the same level;

- it is necessary that the wall thickness of the smoke removal channels differ depending on the equipment used: solid fuel boilers - 1 mm, liquid fuel heating devices - 0.8 mm, gas heat generators - from 0.5 to 0.6 mm;

- the passage for the sandwich pipe should form a gap of 13 cm, and in the overlap area - 20 cm;

- The minimum height limitation of a stainless steel chimney pipe is 5 m, and the length of the horizontal section is 1 m.

Optimal chimney diameter parameters

A complete calculation of a chimney is quite difficult for a non-specialist to perform. To do this, it is better to use the advice of heating engineers on choosing the optimal indicator:

- With a maximum thermal power of the heating device of up to 3.0 kW, pipes with a diameter of 140 mm will be sufficient.

- If the boiler has a power of up to 4.5 kW, the optimal dimensions of the chimney are no less than 140 mm.

- When using a high-power boiler device of 7.5 kW, the diameter of the chimney pipe must be at least 150 mm.

A user who knows the thermal power of the boiler can make an approximate calculation of the chimney using the optimal values and coordinate it with the indicator of the boiler outlet pipe. You can also refer to the manufacturer's instructions, which regulate the installation diagram with all the parameters of the smoke ventilation system. In cases where the heating capacity is unknown, calculations are made based on the hourly consumption of fuel burned by the installation, or this indicator can be determined from the passport for the heat generator.

An equally important indicator for accurate calculation of the geometric parameters of the chimney is the temperature of the flue gases at the entrance to the pipe part. This parameter is related to the type and quality of the fuel burned and the efficiency of the boiler heating surfaces. For properly configured equipment it should be within 150-200 C.

For fireplaces, the indicator of the optimal speed of gas movement through the smoke exhaust system is also important; usually this indicator is taken to be 2 m/s with an indicator of natural stove draft of 4 Pa per 1 m of chimney.

Calculation of installation parameters

Installation of a vertical channel must comply with certain standards, which are regulated by technical supervision documents:

- In order to ensure acceptable draft, the minimum permissible height of the chimney in terms of plan is 5 m.

- The limit on the length of horizontal sections is 1 m.

- In those buildings where there is no heating, and on the street, it is impossible to install chimneys that do not have thermal insulation.

- Vertical channels along the cut line must be higher than the roof in accordance with the following conditions:

- flat roof – from 500 mm;

- the presence of extensions to the main building - not lower than the upper level of the highest point of the house, including the attached part;

- more than 300 cm from the pipe to the ridge - not below the line drawn from the upper line of intersection of two slopes down at an angle of 10 degrees to the horizon;

- pitched roofing of a building with a pipe located at a distance of less than 150 cm from the ridge - from 500 mm;

- the distance of the cylindrical product from the horizontal rib located at the junction of the slopes at the top point of the roof is 150-300 cm level with the ridge or higher.

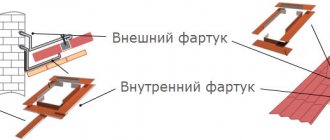

- Installation of a spark arrestor is mandatory, provided that the roof consists of flammable materials.

- Stainless steel pipes for the vertical channel at the joints must be at a distance of at least 700 mm from the floor, ceiling and wall, and they are not allowed to be present in the immediate depth of the side structures and where the floors pass.

- Regardless of the roofing material, there must be a gap of at least 130 mm between the pipe and the ceiling.

- If a single-wall product is used, this gap should be from 1000 mm. As for sandwich systems, even with their large thickness, this kind of gap should be 200 mm.

- It is important that the connection of pipes on inclined and horizontal sections corresponds to the principle of installation “by smoke”, when cylindrical products coming from the boiler are inserted into subsequent ones, which avoids obstructing the movement of combustion products along the gas outlet channel.

- Connecting pipes in sections running vertically is the “condensate” installation principle. In this case, each subsequent product is inserted into the one below, excluding dripping moisture from entering the insulation.

- The chimney can be installed in such a way that there will be turns, but no more than three.

- At any pipe junction, their diameter cannot be less than the standard outlet pipe of the heating device.

The flue gas exhaust duct can be installed in such a way that it will pass through one or another number of rooms in the house. In this case, it is necessary to use sandwich pipes with insulation. But you can also close the structure using brickwork.

Today, chimneys equipped with double-layer insulation have become widespread. This made it possible to install pipes outside buildings by fastening them using brackets or metal profiles. The advantages of this scheme are undoubted, since its use eliminates the need for thermally insulated passages through the floors and roof.

Which chimney is considered reliable and safe?

Reliability and safety are the most important qualities of a chimney. If the chimney system does not meet these requirements, it is strictly forbidden to use it. And it doesn’t matter what material it’s made of. Here we can draw an analogy with construction: a house without a foundation will not stand, no matter how beautiful it is. Likewise, an unreliable chimney will not last long.

The chimney system is, first of all, a utility network and its selection and installation should be carried out exclusively by professionals. The same as with heating devices. Of course, a choice can be made based on its spectacular appearance and “reasonable” price, but the result of such a choice can be a fire or carbon monoxide poisoning.

The main thing when buying a steel chimney is the quality of the materials. Be sure to ask the seller for system test certificates, and also ask what fireproof clearances need to be made from flammable materials.

It is important to know! A reputable manufacturer will have test certificates for the chimney system and will inform the buyer of installation requirements and minimum clearances for flammable materials.

According to SP 7.13130.2013 Heating, ventilation and air conditioning clause 5.27 , the dimensions of the grooves and offsets for heat-generating devices and factory-made smoke ducts should be taken in accordance with the technical documentation of the manufacturer.

Simply put, your chimney manufacturer should guarantee your safety. If the cuts are not indicated, the manufacturer is confused about the values, which means that certification was not carried out and there were simply no tests. And, accordingly, no one guarantees your safety.

SP (set of rules) is a kind of law for builders. This document specifies and recommends standards for construction, design, production of building products and their operation. In other words, the joint venture is a kind of analogue of the administrative and criminal codes in construction.

If the equipment does not comply with the SP, it can be fully considered questionable, and therefore potentially dangerous to life and health.

Cost of sandwich systems

The price of such structures depends on many factors, including the selected type of system model, the area for its placement and components.

Before purchasing a sandwich chimney, you should take the required measurements at the installation site and make appropriate markings. The cost of the purchased system depends on the accuracy of such work, so it is necessary to approach this process as responsibly as possible.

When choosing a chimney, the material from which it is made is not the main criterion for evaluating the product. It is important to take into account the technical characteristics of sandwich systems: a high-quality chimney means good draft, ease of use, safety, etc.

The average cost of one pipe ranges from 1,500 to 3,000 rubles. The specific price depends on the following parameters:

- internal section of the product;

- thickness and material of the thermal insulation layer;

- degree of strength of stainless steel pipes;

- presence or absence of coating on system elements;

- module length.

The sandwich system consists not only of straight modules, so you will need to select other components: tees, elbows, adapters and corners. Such elements have a high price, for example, the cost of one product can reach 4,000 rubles.

Why do you need to know the diameter?

Beginners do not understand the importance of the chimney cross-section for a stove and why it is so important to correctly calculate not only the internal size, but also the height of the pipe. When developing an individual project for an autonomous heating system for a residential or industrial premises, the level of traction and performance of the unit depends on the accuracy of the data.

Inexperienced builders can make a pipe with a large or insufficient cross-section. In any such option, the operation of the heating device is disrupted, and you are simply throwing money away. For optimal operation of the home heating system, it is important to carry out an accurate calculation and familiarize yourself with the recommendations of regulatory documents.

Important! Fire safety at home, work productivity, comfortable temperature - the solution to all these issues depends on the correct determination of the size and length of the chimney.

Manufacturing of large diameter stainless steel flues.

Features of the operating conditions of large-diameter industrial gas ducts in aspiration systems place increased demands on materials, manufacturing and installation technologies. Otherwise, normal and efficient operation of the system will not be ensured.

The main requirements are the strength of the gas ducts and the long service life of the entire industrial aspiration system. Exposure to high temperatures should not have a deforming effect on the material of the walls and connections, and the condensate and acids contained in the gas flow should not lead to their corrosion.

The material for the manufacture of gas ducts that best meets all requirements is stainless steel. Due to the high cost of stainless steel, it is possible to manufacture gas ducts from other types of steel, after preliminary calculation of durability under specific operating conditions. In some cases, modern composite materials can be used for the manufacture of industrial gas ducts.

The basis for the production of gas ducts is stainless steel sheet with high heat resistance characteristics. In combination with the correct technological process, it ensures long periods of uninterrupted operation of large-diameter gas ducts.

Highly qualified engineers and an experienced team of production workers are involved in the production of gas ducts. Modern equipment and a streamlined technological process allow us to produce high-quality products in a short time. Each stage of production is subject to control by quality control specialists with appropriate qualifications.

The technology for the production of large-diameter stainless gas ducts at an industrial site consists of the following stages:

- Marking of steel sheets of the flue body and connection elements.

- Cutting steel sheets of the flue body and connection elements.

- Bending steel sheets of the flue body and cutting out connection elements.

- Welding steel sheets of the flue body and connection elements

- Fastening the thermal insulation and cover layer.

- Mandatory quality control of gas ducts.