One of the most important requirements for ensuring the safe operation of solid fuel heating equipment is the correct organization of the removal of combustion products. In such a way that they come out promptly and completely, without penetrating into the room, and give way to the influx of fresh air necessary for the continuous combustion of the fuel fill. Violation of these rules leads, at best, to inefficient operation of the furnace or boiler. But what’s much worse is the possibility of carbon monoxide poisoning or a fire hazard.

Chimney: calculation of height and cross-section

In this article we will not consider possible options for the construction of chimney pipes - there is a lot of information about this in other publications on our portal. The conversation will focus on the main parameters of the pipe - its cross-section, which ensures the timely removal of combustion products at an optimal speed, and the height, which ensures the creation of the necessary natural draft.

So, the topic of today’s conversation is the chimney: calculation of height and cross-section, justifications and convenient online calculators.

Why are solid fuel devices considered?

It's simple - there are always more problems with them in these matters compared to gas ones. Let's explain why:

- First of all, gas heating appliances are almost always factory-made products. That is, they must have a pipe of a certain cross-section for connection to the chimney. The cross-sectional area of the channel is also specified in the technical documentation of the model. That is, everything is quite simple - it is not allowed to narrow the channel in any of the sections of the upward chimney.

Factory-assembled boilers or stoves always have a pipe for connecting the chimney. That is, there is no longer a problem with the cross-section of the chimney - it should be no less than that specified in the technical documentation.

- The temperature of the gas combustion products leaving the chimney is disproportionately lower than that generated during the combustion of wood or other solid fuel.

- It is also difficult to compare the volumes of gas mixtures formed during the combustion of “blue” and solid fuels. The difference here is quite significant!

But solid fuel heating devices, stoves or boilers, are very often created independently. Or they are “inherited” from the former owners of the house. And here it is never superfluous to check the parameters of the chimney connected to such a device.

However, what concerns the height of the pipe and checking draft can probably be fully attributed to gas heating equipment. The cross section is known, but it wouldn’t hurt to check the rest.

But let's start with the section.

Why does back draft form in the chimney?

This process is influenced by a large number of factors. The main thing is the incorrect design of the chimney at the construction stage. In order not to encounter the problem of insufficient or incorrect traction in the future, it is necessary to correctly calculate in advance:

- chimney cross-section size;

- its location;

- material of manufacture;

- shape;

- pipe height;

- the presence of additional devices that increase traction performance.

The quality of air movement is also affected by the number of people or devices consuming oxygen in the room. The latter include air heaters, irons, stoves, etc.

Regular ventilation of the room is also important for proper operation.

A person can control all this independently, so the presence of reverse draft in the chimney depends only on him. What to do if traction is affected by weather conditions? It is impossible to control them, but it is quite possible to resist them.

How to calculate the cross-sectional area of a chimney?

There are several methods for calculating the optimal cross-section. For example, on the size of the combustion chamber of the hearth or on the area of the furnace blower window. But in this publication, attention will be focused on the methodology, which is based on assessing the volume of flue gases generated during the combustion process.

The combustion of wood and other solid fuels is always accompanied by very significant smoke formation. And the chimney pipe must be able to discharge these volumes outside in a timely manner.

Based on calculations and experiments, experts have long compiled tables from which information can be obtained on specific smoke production for different types of solid fuel. That is, what volume of combustion products is formed when burning, say, one kilogram of firewood, coal, peat, etc.

We will also present such a table (in an abbreviated version). In addition to the specific smoke formation, it shows the calorie content of the fuel (the amount of heat released when burning one kilogram) and the approximate temperature of the combustion products at the exit from the chimney. The first of these characteristics does not particularly interest us at a given moment - it simply gives a general idea of fuel efficiency. But the temperature, yes, will be needed for calculations.

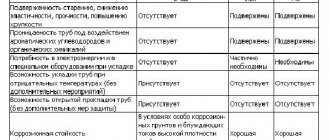

| Fuel type | Specific caloric content of fuel, kcal/kg, average | Specific volume of combustion products released from combustion 1 kg, m³ | Recommended temperature at the chimney outlet, °C |

| Firewood with an average humidity level - 25% | 3300 | 10 | 150 |

| Lump peat (in bulk), air-dried, with an average moisture level of no higher than 30% | 3000 | 10 | 130 |

| Peat - briquettes | 4000 | 11 | 130 |

| Brown coal | 4700 | 12 | 120 |

| Coal | 5200 | 17 | 110 |

| Anthracite | 7000 | 17 | 110 |

| Pellets or wood briquettes | 4800 | 9 | 150 |

As you can see, the volumes are impressive. Even types of fuel that produce minimal smoke are already about 10 cubic meters for every kilogram burned. This means, simply for reasons of physics and geometry, the cross-section of the chimney duct must be able to constantly drain these considerable volumes out.

This is why we “dance” when calculating.

Chimney prices

chimney

The volume of combustion products released when burning solid fuel for an hour can be determined by the following formula (taking into account the thermal expansion of gases).

Vgch = Vud × Mch × (1 + Td/273))

Vgch is the volume of combustion products formed within an hour.

Vsp is the specific volume of combustion products generated for the selected type of fuel, m³/kg (from the table).

Mtch is the mass of the fuel charge burned within one hour. It is usually found by the ratio of the full fuel load to the time of its complete burnout. For example, 12 kg of firewood is loaded into the stove at once, and it burns out in 3 hours. This means Mtch = 12 / 3 = 4 kg/hour.

Td - gas temperature (℃) at the outlet of the chimney pipe (from the table).

273 — a constant for bringing temperature parameters to the Kelvin scale, used in thermodynamic calculations.

Since the unit of time in our calculation system is a second, it is not difficult to find out the volume obtained per second - the result is simply divided by 3600:

Vgc = Vgch / 3600

To find out the cross-sectional area of a channel that is guaranteed to pass this volume through itself at a certain speed of gas movement, it is necessary to find their ratio

Sc = Vgс / Fд

Sc is the cross-sectional area of the chimney channel, m².

Fd - gas flow speed in the chimney pipe, m/s

A few words about this speed. For heating appliances and household-grade structures, they usually aim to stay in the range from 1.5 to 2.5 m/s. With such a low speed, on the one hand, there is no significant resistance to the flow, and no strong turbulences arise that slow down the movement of gases. Heat losses are minimized, the temperature of gases at the outlet of the pipe is reduced to normal values. At the same time, the speed is sufficiently high to reduce the formation of condensation and the deposition of ash on the inner walls of the channel.

If the cross-section is found (and this is its minimum value), then using known geometric formulas you can find either the diameter for a pipe with a round cross-section, or the side length for a square cross-section, or select the lengths of the sides for a rectangular one.

Below is a calculator that will greatly simplify these calculations. It must indicate the type of fuel, its approximate consumption (more precisely, the mass and burning time of a full load) and the expected flow rate of gases in the chimney. The program will do the rest itself.

The final result is shown in three views:

— minimum diameter for a round section;

— minimum side length for a square section;

- cross-sectional area, according to which you can, for example, select the dimensions of the sides for a rectangular section.

Calculator for calculating the parameters of the chimney pipe cross-section

Go to calculations

Rules for checking chimneys and ventilation ducts

Some homeowners and renters find inspecting and repairing such a simple-looking smoke and vent system to be simple. But that's not true. The ventilation duct must provide air exchange in the amount of eighty percent of the air volume. But nowadays, statistics show that people are replacing elements of old exhaust ducts without taking into account the requirements for ventilation and smoke systems.

Elements that have outlived their useful life are replaced with metal-plastic and steel. What does this mean? The fact that such structures are much less airtight than the old ones. Therefore, the technical condition of the channel becomes unsatisfactory, since normal ventilation is reduced to nothing.

Before you begin the channel checking operation, you need to clearly understand the set of rules that govern this process. Below is a list of what you need to take care of:

- Checking act. It must be drawn up before any inspection that complies with the standards begins. Without signing this document, the company can easily prohibit residence on the premises. It includes all the characteristics of the duct, from length to such specific details as analyzing the air inside for dangerous levels of carbon dioxide.

- Frequency of inspection. It was mentioned above. It is worth recalling here that even in cases where the deadline for the next inspection has not yet come, there is no need to hesitate to call a specialist if there is even the slightest suspicion of a system malfunction. It can be about health and even life, and you shouldn’t forget about it.

- If a malfunction is detected in the ducts, then it is necessary to stop using the ventilation elements until the necessary repair work is completed.

- The end of the work, just like the beginning, should be marked by the signing of an act - this time an act of inspection of the smoke removal system. Again, this document is very important, and without it, unpleasant questions may arise.

What should the audit reveal (or, at best, not reveal at all)? There are several types of faults that will be the first to be noticed. The presence or absence of damage is one of the main factors that can affect the serviceability of the ventilation or smoke removal system

The reason for this is obvious. Equally important will be the identification of contaminants that affect the smooth operation of canals.

As you might expect, a drain clogged with debris and overgrown with mold does little or no harm to the homeowner. Finally, the third most important factor is the presence of sufficient traction. Without this, the entire meaning of ventilation is meaningless.

To determine these values, the height of the outlet pipe is set. It is also determined whether there are objects that block the free exit of smoke (or the entrance of fresh air). These can be either natural (trees) or artificial (buildings) objects. An important step is to take a sample for carbon dioxide content.

During the inspection, specialists use powerful lighting devices, cameras and video cameras, thanks to which they can detect even the most subtle violations in the condition of the output channel

It is very important to ensure that people arriving for inspection are equipped with similar tools

Chimney pipe height.

Here we can do without complex calculations.

Yes, of course, there are rather cumbersome formulas that can be used to calculate the optimal height of the chimney with great accuracy. But they become really relevant when designing boiler houses or other industrial installations, where they operate with completely different power levels, volumes of fuel consumed, pipe heights and diameters. Moreover, these formulas also include an environmental component regarding the emission of combustion products to a certain height.

There is no point in presenting these formulas here. Practice shows, and this, by the way, is also stipulated in building codes, that for any of the theoretically possible solid fuel devices or structures in a private house, a chimney pipe (with natural draft) with a height of at least five meters will be sufficient. You can still find recommendations to focus on the figure of six meters.

This refers specifically to the height difference between the outlet of the appliance (for stoves it is often considered from the grate) to the upper edge of the pipe, without taking into account the attached umbrella, weather vane or deflector. This is important for those chimneys that have horizontal or inclined sections. Let us repeat - not the total length of the pipe used, but only the difference in heights.

The height of the chimney is precisely the difference in height between its inlet and outlet, and not the total length of the pipe, which may have horizontal or inclined sections. By the way, you should always strive to minimize the number and length of such sections.

So, the minimum length is clear - five meters. Less is impossible! What about more? Of course, it is possible, and sometimes even necessary, since additional factors may intervene due to the specifics of the building (commonly the height of the house) and the location of the pipe head relative to the roof or neighboring objects.

This is due to both fire safety rules and the fact that the pipe head should not fall into the so-called wind pressure zone. If these rules are neglected, the chimney will become extremely dependent on the presence, direction and speed of the wind, and in some cases the natural draft through it may disappear altogether or change to the opposite (“capsize”).

These rules are not so complicated, and taking them into account it is already possible to accurately determine the height of the chimney pipe.

Chimney pipe prices

chimney pipe

Basic rules for the location of chimneys relative to the roof elements of the building

- First of all, no matter what roof the chimney passes through, the edge of the pipe cannot be closer than 500 mm from the roof (pitched or flat - it doesn’t matter).

- On roofs of complex configuration, or on a roof adjacent to a wall or other object (say, the edge of the roof of another building, an extension, etc.), the wind support zone is determined by a line drawn at an angle of 45 degrees. The chimney edge must be at least 500 mm above this conditional line (in the top figure there is a left fragment)..

- The same rule, by the way, also applies when there is a tall third-party object next to the house - a building or even a tree. The figure below shows how the graphical plotting is done in this case.

Tall trees near the house can also create a zone of dense wind pressure.

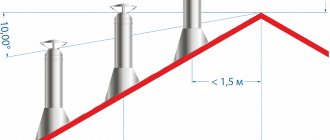

- On a pitched roof, the height of the section of pipe protruding above the roof depends on the distance from the ridge (left fragment of the upper diagram).

— A pipe located at a distance of up to 1500 mm from the ridge must, with its edge, rise above it by at least 500 mm.

— At a distance of 1500 to 3000 mm, the upper edge of the pipe should not be lower than the level of the ridge.

— If the distance to the ridge is more than 3000 mm, the minimum permissible position of the pipe edge is determined by a line passing through the top of the ridge, drawn at an angle of -10 degrees from the horizontal.

To reduce the dependence of draft on wind, special caps, deflectors, and wind vanes are used. In some cases, the use of a spark arrester is also required - this is especially true for solid fuel devices.

All that remains is to sit down with a drawing of your house (existing or planned), determine the location of the pipe and then finally settle on some height - from 5 meters or more.

Step-by-step installation of a gas boiler chimney

Installation of the chimney

Installation of the chimney system is as follows:

- The passage of the pipe through the ceiling and roof is accurately marked - this process must be monitored repeatedly so as not to make mistakes.

- Next, holes are made according to the markings for the passage of the pipe.

- Install an adapter for the transition, which is connected to the pipe located on the boiler.

- Then a tee with a compartment for collecting moisture is attached and secured with a special bracket.

- The next section of the chimney is joined. If necessary, an element called a “knee” is used.

- If the pipe will pass through the ceiling, a special passage pipe must be included in the chimney kit. The pipe passes through a metal sheet in which there is a hole slightly larger than the diameter of the pipe. The sheet is attached to the ceiling.

- For reliability, the joints of two pipe sections are fixed with clamps and tightened with bolts.

- The chimney is fixed to the wall with special brackets in increments of approximately two meters.

- The design is completed by a cone-shaped tip.

- The last step is to insulate the chimney pipe from flammable materials at the transitions.

It is impossible not to highlight the nuances of choosing and installing a chimney, depending on its location. It can be installed outside and fixed to the wall (wall-mounted), or run inside the building.

Internal chimney

If heat must emanate from the chimney to all the rooms where it will pass, there is no need to choose a pipe with internal thermal insulation; it is insulated only from the outside. It should be taken into account that when the chimney passes inside the house, the risk of combustion products entering the rooms increases, and the fire hazard also increases.

Therefore, it is very important to perfectly fit the individual parts and secure them securely with clamps. Installation will require a larger number of different additional elements, since the pipe will pass through at least one floor and roof. We should not forget that if in the future it is necessary to carry out repair work on such a chimney, this will become quite a problematic task.

Comparison of external and internal chimney layouts

External chimney

- The external version of the chimney requires correctly calculated thermal insulation.

- The advantage is the safety of this heating element.

- Installing an external chimney is much simpler than an internal one.

- If repairs are necessary, they can also be easily carried out under any existing conditions.

Checking the planned pipe for the amount of natural draft

In fact, we have already determined the main parameters of the chimney - the sufficient cross-section of its channel and height. But for devices with natural draft, it is never a bad idea to check the strength of this very draft. So that it does not happen that the constructed chimney suddenly refuses to perform its main functions.

Draft is essentially the difference in pressure between hot gases in the pipe and the outside air. It is this difference that stimulates the movement of gas flow through the chimney channel.

It is believed that for normal operation of a chimney with natural draft, this difference must be at least 4 pascals for each meter of pipe height (0.408 mm of water column or 0.03 mm of mercury). That is, for a five-meter pipe (our minimum), the thrust should be at least 20 Pa. This ensures both normal gas removal and the necessary air flow for continuous combustion of the fuel.

How to calculate this thrust. Naturally, it largely depends on the densities of gases, which, in turn, are closely related to temperature. You can verify this by looking at the formula with which we will work:

Δ P = Htr × g × Patm × (1 / TV – 1 / Tds) / 287.1

Δ P - natural draft in the pipe, Pa.

Htr —chimney height, m.

g —gravitational acceleration (9.8 m/s²);

Patm - atmospheric pressure. A value of 750 mmHg is considered normal. However, the area for which the calculation is carried out may have its own specifics. We must understand correctly that sea level is considered the norm. And with increasing altitude, this rate begins to decrease. And quite significantly. So when making calculations you will need to be guided by the norm for your region of residence.

Atmospheric pressure is usually measured in millimeters of mercury. However, to calculate in the SI system it is necessary to convert it to pascals. This is not difficult if you know that 1 mm Hg. Art. = 133.3 Pa.

TV - outside air temperature. Moreover, reduced to the Kelvin scale, that is, C° + 273.

Tds is the average temperature of gases in the chimney. Defined as the arithmetic average of the input and output indicators, followed by conversion to the Kelvin scale.

287,1 — gas constant of air. It would be more correct to select this value for the specific chemical composition of the exhaust gases. But in our case, the error will not be significant, greatly affecting the final result.

A few important notes on inlet and outlet temperatures.

You should always strive for its optimal values. Statistics show that most fires occur with sauna stoves, into which there is practically no heat removal; the heat in the steam room builds up in a short time, and the chimney usually heats up to dangerous temperatures. Therefore, you need to be able to control the temperatures in the pipe using available means - gate valves, valves, additional heat recovery devices (for example, water heating tanks).

In household and heating stoves this is easier, but control is still necessary. In boilers, where the very essence of the work is the constant transfer of heat to the circulating coolant, these issues are not so pressing.

The 900 ÷ 600 ℃ (input and output) mode, found on some sauna stoves, is extremely dangerous in all respects, and should not even be considered! Reasonable limits (and even then their upper limit) are 600 ÷ 400 degrees for household brick and metal stoves. Usually they try to maintain it in the range of 400 ÷ 200 ℃. For gas equipment, the lower limit can fall below 100 degrees.

If all the initial values for substitution into the formula are known, you can proceed to the calculation. To do this, we again suggest using the capabilities of a special online calculator.

Calculator for calculating the natural draft of a chimney.

Go to calculations

If the resulting pressure difference falls within the norm (more than 4 Pa per meter of pipe height), then the test can be called successful.

The main parameters of the chimney have been obtained - you can proceed to the selection of materials and detailed design.

This video will tell you about many other subtleties of independent chimney design:

What is the reason for the chimney not working properly?

There are a lot of factors that can disrupt the draft in a chimney, but the worst thing is if it’s all due to an error that was made at the design stage (for example, the height of the pipe was incorrectly calculated or its cross-section was selected incorrectly). In most of these cases, an increase in chimney draft can only be achieved by rebuilding the chimney. In general, even the slightest deviation from the standards and regulations relating to design and installation can lead to improper functioning of the chimney.

One of the simplest and most easily resolved causes of poor draft is contamination of the chimney with soot and various debris. In this case, increasing the chimney draft is quite simple - clean the chimney by contacting a professional chimney sweep, or do it yourself.

Initial data.

The purpose of this work is to provide a computational justification for design decisions taken when designing a metal chimney.

A spatial cylindrical shell was previously adopted, pinched at the base. The result of this calculation will be a check of the overall strength and stability of the structure for compliance with design standards.

The calculation was performed using the SCAD software package version 11.3.1.1.

The software package used makes it possible to implement strength and deformation calculations using the finite element method on a finite element model.

Frequency and rules for professional chimney inspection

In apartment buildings, officials responsible for the maintenance of common property are responsible for checking, cleaning and repairing canals. The legality of their activities must be confirmed by a license. In the private residential sector, the owner carries out inspection and maintenance independently or with the involvement of specialists on a contractual basis.

Professional inspection and cleaning is required under the following conditions:

- when commissioning a gasified building, connecting and accepting new equipment;

- during repairs and re-equipment of canals;

- in the absence of traction;

- regularly as you use the system.

Periodic and initial inspection of the chimney is organized. The latter is carried out upon acceptance of new channels, after major repairs, or reconstruction of the system. This procedure is entrusted to specialized organizations with the involvement of a representative of the homeowner; the result is declared in the initial inspection report.

The following are subject to inspection:

- executive and technical documentation;

- compliance of the assembled elements with the project;

- completeness and quality of masonry and assembly;

- channel cross-section - it must correspond to the gas equipment passport;

- availability of cleaning devices and points of their implementation;

- specifics of thermal insulation and pipe laying area;

- the presence and dimensions of fire protection concessions and cuts;

- presence of traction, absence of blockages;

- the integrity of the head and the correctness of its placement relative to the roof.

Periodic inspection is carried out at least 3 times a year:

- at least a week before the start of the heating season;

- in the middle of this period;

- within a week after its completion.

You need to check the chimney 3 times a year.

Brick chimneys are inspected once a quarter, pottery, asbestos-cement and concrete chimneys are inspected annually, heating and cooking stoves are inspected three times a year in accordance with the cyclical nature of the heating season. In winter, monthly, and in the northern regions - 2 times a month, the heads are inspected to prevent them from freezing and, as a result, blockage.

During these regular activities, the isolation of the channels and the density of their walls, the absence of soot accumulation and blockages, the presence of draft, the condition of fireproof cuttings and thermal insulation are clarified. The results are recorded in a journal entry or in the form of a separate act. If smoke exhaust systems are not suitable for use, consumers are notified of the need to turn off gas appliances until repair work is completed.

How does the damper affect the operation of the heating system?

A damper (damper) is often installed to prevent the formation of backdraft in the chimney and to minimize the risk of fire in the house. Its installation can be carried out directly into the chimney pipe, or into the stove door (or the stove itself). The damper is responsible for the mechanical adjustment of the chimney draft - by closing it, the area is transverse. The cross-section of the pipe decreases, which causes the draft to weaken, and when the damper is open, the cross-section increases and the draft increases.

After all the fuel has burned out in the stove or fireplace, it is recommended to close the damper to reduce heat loss. The device will cool down more slowly, and the room will remain warm for a long time.