We recommend that you read

- Chimney repair

- Stainless steel chimneys

- Boiler chimney

- Steel chimneys

- Chimney height

- Chimney sandwich

- Metal chimneys

- Chimney cable stays

- Chimney masts

- Chimneys for boiler rooms

- How to calculate a chimney

- Typical designs and drawings of chimneys

- Industrial chimneys

- Chimney calculation

- Design of industrial chimneys

The project for organizing work on the demolition or dismantling of a chimney considers the main issues regarding the dismantling of a chimney on the territory of a boiler room.

The project for demolition or dismantling of the chimney is carried out on the basis of the approved Technical Specifications.

The composition and content of the Project for demolition or dismantling work are determined in accordance with the Decree of the Government of the Russian Federation dated February 16, 2008. No. 87.

The following materials are used as initial data when developing this section:

- Technical task;

— Technical report on the inspection of the chimney structure.

— Project documentation has been developed in accordance with the following regulatory documents:

— Decree of the Government of the Russian Federation dated February 16, 2008 No. 87 “On the composition of sections of project documentation and requirements for their content”;

— Federal Law of December 30, 2009 No. 384-FZ “Technical Regulations on the Safety of Buildings and Structures”;

— Federal Law of July 21, 1997 No. 116-FZ “On Industrial Safety of Hazardous Production Facilities”;

— GOST 23407-78 Inventory fencing for construction sites and construction sites. Technical specifications;

— GOST 12.1.004-91 System of occupational safety standards. Fire safety. General requirements;

— GOST 24258-88 Scaffolding means. General technical conditions.

— GOST 12.2.010-75 System of occupational safety standards. Manual pneumatic machines. General safety requirements;

— GOST 12.4.059-89 System of occupational safety standards. Construction. Inventory safety fences. General technical conditions;

— GOST 12.2.013.0-91 System of occupational safety standards. Manual electric machines. General safety requirements and test methods;

— GOST R 12.4.026-2001 System of occupational safety standards. Signal colors, safety signs and signal markings. Purpose and rules of use. General technical requirements and characteristics. Test methods;

— SNiP 1.04.03-85* “Norms for the duration of construction of buildings and structures”;

— SNiP 5.02.02-86 Standards for the need for construction tools;

— SP 12-135-2003 “Labor safety in construction. Industry standard instructions on labor protection";

— SP 12-136-2002 “Labor safety in construction. Solutions for labor protection and industrial safety in construction management projects and work execution projects”;

— SP 48.13330.2011 “Updated edition of SNiP 12-01-2004. Organization of construction";

— SP 49.13330.2010 “SNiP 12-03-2001 Part 1. Occupational safety in construction”;

— SP 2.2.2.1327-03 “Hygienic requirements for the organization of technological processes, production equipment and working tools;

— SP 2.2.1.1312-03 “Hygienic requirements for the design of newly built and reconstructed industrial enterprises”;

— Decree of the Government of the Russian Federation dated April 25, 2012 No. 390 “Fire regulations in the Russian Federation.”

Dismantling stages

Boiler house demolition work can be divided into three main stages.

The preparatory stage is designing the organization of demolition, carrying out measures to disconnect the boiler house building and equipment from communications.

The dismantling stage is the sequential removal of elements of boiler equipment, starting with chimneys. Dismantling and cutting of boilers, metal pipes, control panels, etc. Dismantling of the boiler house building (if necessary).

The final stage is the sorting of scrap, its weighing and evaluation. The site is cleared of construction waste and then removed.

DESCRIPTION AND JUSTIFICATION OF DECISIONS ON SAFE METHODS OF CONDUCTING DEMOLITION (DISMANTING) WORK.

Dismantling work is carried out according to the approved work schedule. Work is performed in one shift during daylight hours.

The dismantling work includes:

— Preparatory work and activities (installation of temporary fences, roads);

- Organization of construction;

— Environmental measures;

— Occupational health and safety measures in construction.

Before the start of demolition and dismantling of the chimney, a set of preparatory measures is carried out in accordance with paragraph 6.9 of SP 48.13330.2011. The territory and workplaces, warehousing, and temporary transport routes are being prepared. Next, the workers, in the process of preparing for dismantling, put up protective fences for the dangerous zones of the dismantled object, install signal lights and warning signs, and also turn off all communications that are connected to the building so that an explosion or flooding does not occur during the demolition process. Next, all premises are vacated. An important part of the preparation is the watering device. During disassembly, a large amount of dust is generated. Before starting work, mark the places for separation of structures in accordance with the element-by-element scheme for their removal, install temporary fastenings of structures, without which collapse may occur. Internal roads provide free access to the structure being dismantled, to the operating area of cranes, and to places where demolition (dismantling) products are stored. The construction of internal roads is completed before the dismantling of the structure begins. Internal roads are looped. At the entrance to the construction site, install points for washing the wheels of trucks and construction vehicles to prevent the removal of soil and dirt from the construction site. Post a sign with the names of the responsible persons on the construction site in a visible place in the work area.

A person allowed to liquidate an object must:

— Obtain permission from the technical customer to liquidate the facility;

— Obtain from the technical customer documents certifying the disconnection of communications;

— Issue an order for the organization that determines the procedure for carrying out work at the construction site every shift;

— Appoint those responsible for the execution of work, fire safety and electrical safety;

The corresponding orders must be issued by subcontractors involved in the work. Upon completion of the preparatory work, you can begin the actual dismantling of the structure.

Before dismantling begins, an inspection of the technical condition of the facility’s structures is carried out in order to establish:

- danger of collapse of structures;

-safe dismantling work.

The construction site area, including work areas, workplaces, driveways, aisles, storage areas, must be kept clean and tidy in accordance with clause 6.2.6 SP 48.13330, clause 6.1.6 SP 49.13330.

At the entrance to the construction site, it is necessary to install information boards in accordance with paragraph 6.2.8 of SP 48.13330.

The construction organization dismantling the facility must obtain from the technical customer a document certifying the disconnection of electricity, gas pipelines, steam pipelines, water pipes, air ducts, as well as all communication systems, automated and remote control of technological equipment. This document must contain a conclusion on permission to carry out work, characteristics of networks and their design. Disconnection of utility networks is carried out by the organization in charge of these networks, with the execution of the relevant documents.

The temporary power supply scheme for the period of dismantling the structure must be independent of the existing electrical wiring diagram of the facility.

First of all, work is carried out that does not require fire cutting in accordance with GOST 12.3.036.

Work with fire cutting should be started only after the technical customer has checked the completion of work to prepare the equipment for dismantling. Lifting of dismantled equipment or its components is carried out only after removing all fastening elements, disconnecting process pipelines and removing instrumentation. Before dismantling equipment installed on reinforced concrete foundations, it is necessary to lift (separate) it above the foundation using jacks or wedges (SNiP 5.02.02). The weight of the lifted equipment or part thereof must correspond to the parameters of the truck crane and its rigging equipment. During dismantling work, it is necessary to constantly monitor the stability of the remaining non-dismantled elements.

Fire cutting work is carried out only after the area has been cleaned and cleared of flammable and explosive substances within a radius of at least 10 m and in the presence of the necessary ventilation.

The dismantling of the structure is carried out in such a way that the removal of some elements does not cause the collapse of others. If doubts arise about the stability of structures, dismantling work is stopped and continues only after appropriate measures have been taken to strengthen the structures and permission has been obtained from the person in charge of the work at the site.

When carrying out dismantling work, comply with the requirements of SP 49.13330.2012, Rules for labor protection when working at height. Order of the Ministry of Labor dated March 28, 2014. No. 155n”; PPR in the Russian Federation No. 390 dated April 25, 2012. “Fire safety rules in the Russian Federation.”

Persons who are specially trained, have passed a knowledge test, have a certificate for the right to perform dismantling work, have passed a medical examination and have undergone on-the-job training and special training are allowed to carry out dismantling work. briefing All workers must be provided with special clothing, special shoes and other personal protective equipment.

In the work area it is necessary to have sets of fire extinguishing equipment at the rate of 1 set per 200 m2 of area. All work on dismantling and dismantling structures should be carried out in the presence and under the direct supervision of responsible engineers in accordance with safety requirements.

Persons at least 18 years of age who have passed a medical examination, are trained in the rules of using the tool, safety precautions and have an electrical safety group of at least II are allowed to work with electrified tools, for connecting and disconnecting electrical points with a group of at least III. All electric tools are subject to accounting and registration in a special journal. Each electrified tool must have a registration number. Monitoring the serviceability and timely repair of electrified tools is assigned to the department of the chief mechanic of the construction organization. Before issuing an electrified tool, it is necessary to check its serviceability (no short circuit to the body, insulation of the supply wires and handles, condition of the working part of the tool) and its operation at idle speed.

Before starting work, workers must:

— present to the manager a certificate confirming knowledge of safe work methods;

— receive an assignment from a foreman or manager and undergo on-the-job training on the specifics of the work being performed;

— wear special clothing, safety shoes, a helmet and personal protective equipment of the established type;

After receiving the task:

— prepare the necessary materials and check their compliance with safety requirements;

— check the workplace and approaches to it for compliance with safety requirements;

select technological equipment, tools, protective equipment necessary when performing work, and check their compliance with safety requirements.

A worker should not begin work if the following safety requirements are violated:

- malfunctions of technological equipment, protective equipment for workers and tools specified in the manufacturer’s instructions for their operation, in which their use is not allowed;

— untimely carrying out of regular tests (technical inspection) of technological equipment, tools and devices;

— insufficient lighting or clutter of work places and approaches to them;

— the presence of unprotected openings and openings in the covering, as well as unprotected differences in height along the perimeter of the building covering.

Detected violations of safety requirements must be eliminated on their own, and if it is impossible to do this, they must immediately report them to the foreman or work manager. If an emergency condition of structures is detected, workers must be immediately removed from the dangerous area, the dangerous area must be fenced off with the installation of warning signs or guards. Work can begin upon written instructions from the chief engineer and the issuance of a work permit indicating measures to guarantee safe working conditions.

When performing work, it is necessary to take measures to prevent exposure of workers to the following hazardous and harmful production factors related to the nature of the work:

— location of the workplace near a height difference of 1.3 m or more;

— increased air pollution in the working area;

— increased temperature of equipment surfaces, materials and air in the working area;

— sharp edges, burrs and roughness on the surfaces of equipment and materials.

Upon completion of work you must:

- clear the workplace of debris and waste construction materials;

- clean the tools, containers and materials used in the process of performing the task and put them in the designated place;

- inform the foreman or work manager about all problems that arose during work.

After finishing work or a shift, it is prohibited to leave materials, tools or equipment in order to avoid an accident. Bulky devices must be securely fastened.

When performing hot work, comply with the requirements of PPR in the Russian Federation No. 390 dated April 25, 2012. “Fire safety rules in the Russian Federation.”

If a fire occurs in the workplace, it is necessary to extinguish it using fire extinguishers, dry sand, and covering the hot spots with asbestos or tarpaulin.

In case of accidents that occur as a result of an accident, the worker performs all operations to evacuate victims, provide first aid, and deliver (if necessary) to a medical facility under the guidance of a foreman (foreman).

To carry out all types of hot work, the facility manager is required to issue a work permit.

The permit must indicate the location, technological sequence, production methods, specific fire-fighting measures, responsible persons and its validity period.

At the facility, a person must be identified who is responsible for the safety and readiness of primary fire extinguishing equipment.

Fire extinguishers must always be kept in good condition, periodically inspected, tested and promptly recharged.

The use of primary fire extinguishing agents for household and other needs not related to firefighting is not permitted.

Dismantling a brick pipe

Brickwork is reliable and durable, but in a number of situations disassembly and demolition of the pipe is required. Depending on its size and diameter, various dismantling techniques are used:

- Manual disassembly using rotary hammers, hammers and sledgehammers. Work at height is carried out by specialists who have access to this type of activity. Even home chimneys should be disassembled very carefully.

- Industrial mountaineering - manual disassembly in a row, starting from the top. The detached parts of the structure are dumped inside the trunk so as not to damage nearby structures or buildings. The dust content of the site during the dismantling process is minimal, as is the noise. Most often, industrial climbing is ordered for dismantling boiler pipes and chimneys at enterprises.

- A directed explosion is carried out only after obtaining permission from the relevant authorities.

- Robotic demolition using special equipment. A vertical lift is attached to the pipe and moves along the scaffolding. Disassembly begins from the top using remote-controlled robotic arms.

- Felling in a specific direction. It is not often used for brick structures, since the masonry is destroyed when it falls and the bricks can scatter far.

You cannot dismantle brick pipes yourself. Only specialists analyze the condition of the chimney before disassembling and take into account all the safety nuances. When demolishing high-rise buildings, a dismantling project must be developed and approved. Engineers calculate the possible consequences and choose the optimal disassembly method.

LIST OF MEASURES FOR RECLAMATION AND IMPROVEMENT OF THE LAND (IF NECESSARY).

In the process of dismantling the chimney, measures should be taken to prevent contamination of the construction site with waste, the entry of harmful and hazardous substances into surface and ground waters and the soil, and air pollution. The need to replant and cut down trees and shrubs is agreed upon with the relevant forestry authorities. Work should be carried out to ensure maximum preservation of green spaces. Green spaces that are not subject to felling at the construction site must be fenced off. The trunks of free-standing trees are protected from damage by sheathing them with lumber at least 2 meters high. Products of demolition, dismantling of buildings and structures, construction waste must be removed in a timely manner; Littering and littering the construction site with garbage is prohibited. The “burial” of precast concrete and other elements is strictly prohibited. The burning of combustible waste and construction waste on a site within urban areas is prohibited. Products from dismantling objects, including construction waste, must be transported down through chutes or containers (boxes) using lifting cranes. The lower end of the chute must be no higher than 1 m above the ground or completely fit into the bunker in accordance with paragraph 4.2.8 of SP 49.13330. Disposing of garbage without gutters or from a height of 3 m or more from the zero level is not permitted.

When dismantling buildings, structures, equipment and pipelines, the following measures are provided to preserve the existing soil and vegetation layer:

— It is not allowed to use machines and mechanisms in a faulty condition;

— Refueling is not allowed. Washing and repairing vehicles on a construction site;

— The operation of machines and mechanisms during their temporary downtime is not allowed.

— It is not allowed to use substances and building materials without quality certificates during the work process;

— Lighting fires and burning any materials or waste in them is not allowed.

Protection of lands from the impact of the object is ensured by:

— allocation of special places at the work site intended for the placement of temporary household and storage facilities, sites for storing building materials;

— storage of solid waste should be carried out in sealed containers installed on a hard surface, and, as it accumulates, transported to a solid waste landfill;

— during the execution of work, cutting down trees and shrubs and backfilling the root collars of trunks of growing trees and shrubs not provided for in the design documentation is not allowed;

— orderly storage and transportation of soil and bulk materials is ensured at the construction site.

Vegetable soil is removed from the work area, stored in a specially designated place and stored until the dismantling work is completed. After the dismantling work is completed, suitable soils are used to backfill pits and trenches, and the soil and vegetation layer is restored. Contaminated soil unsuitable for backfilling is transported to a solid waste landfill.

- Reviews

- Add a review

No reviews.

Add a review

When it's harder to break than to build

Comparing existing technologies for dismantling industrial chimneys, it is worth noting that the methods of directional blasting and felling using cables, although less expensive, can be used when there is enough free space around and there is absolute confidence that the surrounding buildings and communications will not damaged. It is almost impossible to do this in conditions of dense buildings and the layout of production facilities. The only effective method remains tiered dismantling by industrial climbers.

| Along with this service you can order:

|

High-altitude work associated with the dismantling of massive structures always poses a particular danger, both for the performers and for surrounding objects. Therefore, the dismantling of the boiler room chimney is carried out according to a special project developed by our engineers and agreed upon in the relevant instructions.

Painstaking work of installers

Brick pipes are the most common, and their disassembly is the most difficult. The fact is that over time, various cracks and deformations appear in such a structure, which, when removing the bandage rings, can cause unpredictable destruction with the separation of massive large pieces. To minimize the likelihood of such a phenomenon, our specialists use proven technology for dismantling a brick chimney:

— the initial inspection is carried out with special care to identify weak points and existing cracks in the pipe; — safe places for securing and securing workers are equipped; — the sequence of dismantling individual elements is determined and the direction of their discharge is established (inside or outside the pipe), means of protecting adjacent buildings and communications are prepared; — separation of bricks and blocks is carried out using manual or electromechanical tools, minimizing the impact on damaged masonry.

Dismantling a metal chimney is carried out using a different technology, since its division into small pieces is impractical. Our specialists cut it into sections (if it is welded) or disassemble it at the connecting joints. The separated parts of the pipe are removed using lifting equipment.

Our work experience allows us to make optimal decisions in any, even non-standard situations. Thanks to this, we are able to dismantle industrial chimneys in the shortest possible time, without taking up space on the industrial site and without limiting the functionality of the current production process. You can order a project and a team of our specialists on the website or by calling the numbers listed here. You will also be pleasantly surprised by our affordable prices and the ability to perform work at any facility in the Moscow region.

Order

Services

Estimate documentation

The local estimate for the chimney is drawn up according to the “Methodology for determining the cost of construction products on the territory of the Russian Federation” - MDS 81 - 35.2004, put into effect on 03/09/2004...

more detailsChimney demolition

Before the start of demolition and dismantling of the chimney, a set of preparatory measures is carried out in accordance with paragraph 6.9 of SP 48.13330.2011.

The preparation of the territory and workplaces, warehousing, temporary tran… read moreOOS development

The purpose of developing the environmental protection section is to determine the impact of an existing or newly built boiler house, as well as after technical re-equipment, on environmental pollution, as well as to develop measures for ...

moreChimney installation

We provide quick and high-quality installation of boiler room chimneys of any type and height.

All work is carried out under the control of engineering and technical personnel, the work project and is accompanied by a warranty for a period... moreManufacturing

Chimneys are manufactured and installed according to individual projects, which include measures to ensure safe and durable operation.

We manufacture chimneys of various types: one... more detailsLight barrier

The light barrier is designed to warn aircraft of danger at night or in poor visibility.

Signal lights are installed on pipes on one or several tiers in height depending on the height of the building... moreAerodynamic calculation

Aerodynamic calculation determines the throughput of the structure at a minimum value.

The throughput must have such an indicator that will allow hot gases and other substances to freely pass through the chimney and escape into the atmosphere... moreStrength calculation

Optimal stability and strength are calculated taking into account several factors.

divided into two categories: -external (seismic activity, soil stability, amount and intensity of precipitation, wind rose); -operational (weight of the structure, number… more detailsDevelopment of QOL

KZh - working documentation for the manufacture of monolithic reinforced concrete structures at the construction site.

In the KZH section, all reinforcement components of reinforced concrete structures are studied in detail, dimensional drawings of the formwork, specifications of materials are provided... moreThermal insulation of chimney

Poor quality insulation or its complete absence leads to premature destruction of the gas outlet trunk.

There are several reasons that have a particularly strong impact on the integrity and functionality of the chimney. more detailsKM development

The company's experienced specialists are ready to develop design documentation for the CM stage (metal structures) in the shortest possible time.

We can develop both stage P (project), necessary for passing the examination, and stage P (working). more detailsKMD development

KMD design is carried out on the basis of KM calculations and represents the development of detail drawings of the designed metal structures.

This set of construction documentation is necessary for the manufacture of metal structures, t... more details

Reasons for dismantling chimneys

Leaving a pipe (especially a brick one) just like that, in the middle of the white sky, is quite dangerous and costly. Seasonal temperature changes have an extremely negative impact on brickwork, gradually causing cracks and, as a result, destroying it. During operation, there is regularly hot air inside the chimney, which eliminates temperature changes, but it is not economically feasible to warm up an unused structure.

Old chimney

As a result, it is much easier to dismantle a chimney pipe one-time than to maintain the pipes in a safe condition, spending financial resources on a monthly basis.

As for metal pipes, their dismantling is required in cases where replacement occurs - dismantling the old one and immediately installing a new pipe. Or when the operation of the boiler room stops forever. Naturally, in this case it is dangerous to leave a metal mast, especially since boiler houses use pipes with a minimum wall thickness - over time they can rot at the base.

Kunstkamera

Zhukovsky's blow in the chimneys

The boiler reached operating mode, that is, hot gases flowed through the pipe at the calculated flow rate, then the burner suddenly went out - the fan stopped, the gas continued to move by inertia, and accordingly left behind a vacuum zone.

The boiler was started in violation of the operating schedule, without pre-heating... more detailsPoor quality chimneys

Photo 1. Thermal insulation in the form of soft mineral wool mats with a density of 25 kg/m3 instead of 120 kg/m3 according to the project.

Photo 2. Absence of a condensate trap at the bottom of the vertical gas outlet of the boiler. Photo 3. Foreign objects on the diaphragm of the explosive... more detailsSmoke Leaning Tower of Pisa

Comments on the project The shape of the load-bearing lattice tower does not meet the requirements of SP 43.13330.2012 “Structures of industrial enterprises.

Updated version of SNiP 2.09.03-85.” The use of this design solution (rigid struts in the form of a system of volumetric trusses) is… more details30 meters, Du-500, Du-400, ...

1. The adopted design solutions of the “KM” section do not comply with the requirements of SP 43.13330.2012 “Structures of industrial enterprises.

Updated edition of SNiP 2.09.03-85”: – the shape of the load-bearing exhaust lattice tower does not meet the requirements of paragraphs. 9.4.8, 9.4.11; ... more detailsDestruction of load-bearing belts...

The only reason that can cause tensile stresses in the wall located along the generatrix of the cylindrical surface is water.

When water turns into ice, it increases its volume by 9.05%. Ruptures of seamless pipes, as they look in the photo, are typical for damage caused by ... more details

Methods

There are several ways to disassemble a boiler pipe. Why pipes? They are more complex than the room as a whole, because the room is usually no higher than one floor, and the pipe, as we noted above, is a rather tall structure made of different materials. Let's take a closer look at each of the methods.

Industrial mountaineering method

A dismantling method in which the chimney is disassembled by workers manually, and the process proceeds from top to bottom. The process is very labor-intensive and time-consuming, but it is also the safest way. In addition, there is no unnecessary bureaucracy with the issuance of permits. Also, manual disassembly does not harm structures located near the boiler room.

Using specialized equipment

Otherwise, this method is called “Pipe Rolling”. It is used when demolishing a pipe made of metal in several segments, but can also be used when dismantling brick or reinforced concrete structures. It is rare that the base of a chimney is cut, thereby causing it to fall.

Directed explosion

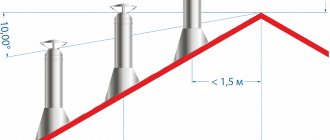

Perhaps one of the most difficult methods in terms of obtaining various permits from government services. In addition, for the use of this method there are a number of conditions, for example, the radius of fall of the chimney and fragments during the explosion must be a distance greater than at least one and a half times the height of the chimney.

Robot manipulators

Demolition takes place with the participation of special sliding scaffolds; such robotic manipulators work remotely. The pipe is dismantled from the top, going down to the base. The method is quite expensive, since it requires maintenance personnel to operate.

Methods for dismantling a brick pipe

Demolition of a brick pipe is carried out in the following ways:

- Dismantling by hand using rotary hammers, hammers and sledgehammers. Since all work is carried out at height and the workers are on the chimney, high-quality organization of the entire process is necessary.

- Industrial alpinism. The building is dismantled manually using the row method. Starts from the top. Materials are dumped into the shaft. No permits are required. Demolition using this method will be inexpensive compared to using special equipment. The risks of damage to neighboring structures by brick fragments, dustiness of the site, and the presence of noise typical of machinery and explosions are eliminated. It is most often used in enterprises and boiler houses.

- Directed explosion. A permit is required for this event. We need an accurate calculation of the trajectory of the chimney's fall, a platform with dimensions corresponding to the height of the pipe. Before the explosion, personnel are evacuated and the technological process is suspended. Preparation takes a long time and is more expensive than other demolition methods.

- Robotic dismantling. The pipe begins to disassemble from the top, gradually reaching the very bottom. It is required to install a mast vertical lift, which is used to secure the sliding scaffolding. They contain people and equipment - robotic manipulators controlled remotely.

- Classic felling using special equipment. Refers to an inexpensive method.

Precautions and common problems

Before demolishing brick pipes, the chimney must be inspected to prevent accidents. Dismantling technology is determined only after this. The safety of personnel must be considered first. Incorrect determination of demolition methods and lack of pipe inspection can lead to the following problems:

- If areas affected by erosion and cracks are not detected, the trunk may collapse from vibration. To prevent this problem, you need to carry out preliminary inspections of the chimney, which will show you to disassemble it in large parts or choose less dangerous methods.

- Deviations of structures from established directions due to incorrect calculations or work performed by non-professionals.

- During the demolition of a massive chimney of a boiler room or another industrial building, the fall of the trunk creates a significant shock wave, which can cause glass to crack on neighboring buildings. Therefore, seismic risks must be taken into account: carry out preparatory work, secure weak structures, and bring them into compliance with safety regulations.

- During the demolition of a chimney, there is a risk that the trunk will break or sag, and this can lead to the destruction of the entire pipe and accidents, to prevent which reinforcement with metal reinforcement is carried out.

Stages of work

Carrying out such a responsible event requires preliminary preparation, which includes:

- Contacting the customer to exchange information.

- Departure for the purpose of inspecting the territory, taking measurements of the trunk, studying nearby buildings, underground and overhead communications.

- Determining the location and area over which chimney fragments can fly.

- Study and analysis of the information received.

- Conducting negotiations, choosing a dismantling method, reaching agreement on price and timing.

- Signing the contract, paying the advance.

- Establishing the boundaries of the territory where the work will be carried out and fencing it.

- Carrying out demolition using the chosen method.

- Organizing the removal of a broken chimney.

- Signing acts, paying bills.

The demolition of such pipes is carried out quite often, since brick has been one of the main materials for their construction for a century. A long service life leads to the fact that chimneys become unusable, become unsafe, wear out, and require replacement. The choice of technology is influenced by their design.

Dismantling methods

Dismantling of chimneys is carried out in different ways, depending on the material from which the pipe is made, its functionality, the free space around where it is planned to collapse the structure and other conditions.

Chimney pipes can be demolished using the following methods:

- Industrial mountaineering;

- Directional explosion;

- Rolls using special equipment;

- Using robotic manipulators.

Industrial alpinism

The use of the industrial mountaineering method means that the building is dismantled manually, provided that it is brick or reinforced concrete. Dismantling the chimney starts from the top, gradually moving down. This method eliminates the paperwork involved in obtaining a blast permit. Its cost is much lower than when using special equipment. The risk of damage to nearby buildings and structures by fragments of brick or reinforced concrete, as if this happened in an explosion, is eliminated.

When using the method of industrial mountaineering, dustiness of the site is eliminated, and there is no noise, which is mandatory when using construction equipment or an explosion. It is possible to work in confined spaces.

Dismantling a brick structure can be done in two ways - disassembling outward and disassembling inward.

In the first method, working scaffolding for industrial climbers is arranged inside the pipe. The pipe itself, using special hand tools, is disassembled in rows or in blocks that are thrown down. In this case, a safe zone must be provided around the pipe, equal to 0.3-0.5 of the height of the chimney pipe. There are few advantages in this method and they lie in the fact that a small area for work is required and in the method itself, which does not require complex equipment and devices.

The time frame for dismantling structures up to 35-40 m high can range from 10 to 20 working days. The cost of such work is extremely high.

Dismantling brick chimneys by disassembling them inside takes more time, and accordingly, its price will be higher.

For this method, it is necessary to arrange a mobile station around the working site, and make protective screens from the mesh below, protecting people and machines from accidental falling of fragments.

The main obstacle to the rapid dismantling of a chimney pipe with the help of industrial climbers can be the emergency condition of the pipe, which entails a loss of time.

Pipe felling

Dismantling a metal chimney can be carried out using special construction equipment. Iron pipes consist of several segments that are welded or bolted together. The method consists of sequentially disconnecting the links and felling them using a construction crane or hoist. Gas welding equipment is used for welding joints.

If space allows, the metal structure can be dumped entirely. To do this, the pipe is cut at the base, while temporary fastenings are installed.

After this, using guy ropes and construction equipment, they are laid on the ground.

Directional explosion

Dismantling of boiler room chimneys can be done using a directed explosion. However, prior to carrying out such an operation, permission must be obtained from the relevant authorities. In addition to the permit, it is necessary to accurately calculate the trajectory of the pipe’s fall and prepare a site of the required dimensions corresponding to the height of the chimney pipe.

Before blowing up a chimney pipe, it is necessary to take all measures to evacuate the enterprise personnel and suspend the technological process. Despite the speed of the whole process, preparation for it takes a lot of time and this pleasure costs more than all other methods of dismantling a chimney.

Robotic manipulators

Dismantling of a reinforced concrete chimney, as well as a brick one, can be done using robotic manipulators that dismantle the pipe from above, gradually reaching the very bottom.

This requires the installation of a vertical mast lift, with the help of which sliding scaffolding is installed. On the scaffolding there are people and the equipment itself in the form of robotic manipulators. The robots are controlled using remote control.

Dismantling reinforced concrete chimneys is the most labor-intensive due to the fact that during installation, high-strength material was used, which is several times superior to the grades of ordinary concrete.

The most inexpensive method of dismantling industrial chimneys is rolling, especially if it is made of brick.

Technology

The manufacture of chimneys most often occurs from materials such as metal, brick, reinforced concrete. Depending on the material, each structure must be dismantled using different methods.

Dismantling a metal pipe

To demolish a metal chimney, you will need the help of a crane. Special brackets are welded on top, and the lift hook is attached to them. If the entire pipe is dismantled, then the bolts and metal braces that hold the chimney are cut off at the base, then using a lift it is lowered onto a special platform or next to the boiler room. If the pipe is high enough, then in addition to a crane, you will need an aerial platform. The whole process will take place in several stages.

Then they release it onto the platform, weld the eyelet to the resulting top edge again, attach the hook, cut it according to the mark, lower it and place it on the platform. Thus, the entire pipe is dismantled.

Dismantling a brick pipe

To disassemble this type of pipe, a roller or explosive is used. The detonation method is considered very dangerous, so it is necessary to ensure the safety of people through evacuation. It is also necessary to correctly calculate the explosives and determine where to place the charge. The method is very fast, but at the same time complex and expensive. In addition, quite a lot of fragments fly from the bricks. Rolling up a brick chimney takes a lot of time, but is much cheaper and not so difficult. Felling is carried out in several ways.

Breaking out pieces of pipe or an entire sector

With this method, special scaffolding is installed outside at a certain distance, after which the bricks are hollowed out with a tool, thereby reducing the strength of the surface. After all these manipulations, the level is divided into parts.

Using special supports

With this option, bricks are knocked out and supports made of durable material are installed. Next, the part that is supported by supports is demolished by heavy equipment.

Rolling with removal of dangerous parts of the pipe

The pipe is disassembled in parts, starting from the very top. Masonry debris is dumped from the inside or outside.

To speed up the dismantling of a brick chimney closer to the base, heavy equipment is used.

Dismantling a reinforced concrete gas pipe

For disassembly, they use the method of blasting or cutting sectors with diamond equipment. Detonation is carried out in the same way as for a brick pipe. Sector cutting is carried out in two ways.

Circumferential cutting

Method using a lift: the chimney is divided into sections, two grooves are cut out at the top of the section exactly opposite each other, a cable passes through them, which is attached to the lift, then a sector is cut off, lifted and placed on the platform, the next sector is cut in the same way.

Slitting

The chimney is cut from the top into small pieces, cutting out either rectangles or triangles. The cut pieces are discharged inward or outward.

Dismantling process

If it is necessary to dismantle a chimney in a boiler room, demolish a window sill block in a house or a fence, then it will be necessary to prepare in advance for such work. In some cases, such measures can free up more space in the room and improve the layout.

According to the law, chimneys or exits to balconies and loggias must be dismantled by specialists after preliminary calculations of the load-bearing capacity of the structure. It is also recommended to call specialists to draw up a project. After this, all documentation is agreed upon with utility services and the redevelopment process is determined.

To demolish such structures, the impact method is usually used, which can only be achieved with power tools.

It is important to first secure the area and determine the thickness of the walls or chimney. The choice of equipment and its power depends on this

If the wall is on concrete masonry, then it is necessary to use a diamond tool, with which you can achieve cutting accuracy. This equipment is also used when it is necessary to carefully dismantle and ensure precise cutting.

The need to dismantle a chimney in a boiler room may arise in cases where the structure itself is in disrepair or the repurposing of the enterprise in whose building this pipe is located is required. Therefore, even those chimneys that are in good technical condition and can last for several decades are often subject to demolition.

All work is carried out with the help of industrial climbers, which allows us to achieve the following advantages:

- low noise level;

- no dust.

If the pipe is in poor condition, then preference is given to the method of directed explosion or felling. But industrial mountaineering is the cheapest and most practical way to demolish such structures.

Features of the method:

- the bricks are dismantled piece by piece, and the material is dumped inside the pipe, which makes it possible not to use the space near it from the outside;

- The dismantling period may take several weeks depending on the size of the structure;

- special techniques and tools are used.

Removing partitions and walls

Depending on the purpose of the structures, dismantling methods are determined. If this is a partition between rooms, then all the work can be done independently using a regular hammer drill or hammer. If the foundation is load-bearing, then this involves the use of supports that will prevent the structure from collapsing. You need to start dismantling from the door, gradually knocking out the bricks with a hammer. During work, debris must be removed periodically.

Dismantling a brick pipe by climbers

If industrial climbers need to be used to demolish chimneys, they will dismantle manually using technical tools:

- Hammer.

- Dry cutter.

- Jackhammer.

Dismantling begins with the top masonry of chimneys, so that its elements are either thrown into the pipe opening or down, where there is a specially fenced plot of land allocated for these purposes. If there is a possibility that fragments of chimneys may fall outside, then additional measures are introduced - a mesh, and warning signs are placed that will help protect human lives.

Advantages of working with specialists in this category of chimneys:

- No harm to the environment.

- There is no need to use large, expensive equipment.

- No extraneous noise.

- The package of documents for carrying out work is significantly reduced.

- All work is carried out strictly in compliance with important safety measures.

Technologies we use

One of the activities of Technoleader SPb is pipe dismantling. The work is carried out by professionals after approval of the project. We use methods of felling the entire structure using special equipment, manual dismantling for small chimneys and industrial climbing for high-rise chimneys.

Entire chimney shaft

Demolition of a chimney using a felling is allowed only after determining the fall sector, protecting nearby objects and marking the territory. Complete dismantling using the felling method takes place in 4 stages:

- Carrying out accurate measurements of the trunk, surrounding area, and marking it. Protecting objects located nearby so that fragments do not fly into them. The calculation of the fall sector is 60⁰ with a radius of 1.5 times the height of the demolished structure.

- Installation of temporary supports made of timber, metal or hydraulic cylinders, depending on the condition and dimensions of the pipe. Cutting the base with a hydro-pneumo-electric chipper or a diamond tool.

- Controlled removal of temporary supports for controlled fall of the structure.

- Removal of construction waste. Removing protective coatings and marking the territory. Dismantling the base of dismantled pipes.

- Our company transports waste waste by road to special landfills. After dismantling, a clean area remains on which new structures can be erected.

Industrial alpinism

A reinforced concrete or brick pipe is disassembled manually, starting from the top. The industrial mountaineering method eliminates the need to fill out paperwork for blasting or demolishing a structure. The cost of work is lower, but the speed is much lower than in the method using special equipment.

Dismantling by industrial mountaineering is carried out in 2 ways:

- Disassembly to the outside. Climber workers are inside the chimney. Using special tools, they remove layers of the structure in rows or blocks and throw it outside. In this case, it is necessary to fence the territory to 0.3 - 0.5 height parameters.

- Dismantling the pipe inside. The opposite method to the first option.

According to safety standards, special protective mesh screens are built around the base of the pipe. They are designed to save people in case of an accidental fall and protect cars and buildings from fragments.

Advantages of industrial mountaineering:

When performing high-altitude dismantling, much attention is paid to the safety of the work performed. Therefore, all employees of Razvitie LLC, who perform work at height, constantly confirm their category in mountaineering

This is the key to timely and safe work. 2. Demolition of a chimney by explosion The most important factor when demolishing a chimney by explosion is the availability of free areas for the demolished structure to fall. Current regulations require that the radius of the sector in the direction of the expected fall be at least one and a half times the height of the pipe, and the sector on the opposite side of the pipe - at least 15 m. If the demolition of a pipe takes several minutes, then the preparatory work can take several days or even weeks.

Dismantling with the help of a directed explosion is carried out in the following technological sequence: A project for the demolition of the pipe is developed (the charge to be placed is calculated, the fall pattern of the dismantled pipe is calculated, etc.); The construction site is prepared and equipped; Holes are drilled manually or mechanized; The complete demolition of the structure is carried out by detonating the charge and subsequent removal of waste.

This dismantling method requires highly qualified specialists, as well as accurate calculation of the fall of the dismantled pipe.

Remaining recycled material

Dismantled metal pipes that are unsuitable for further use can, in part, offset the cost of the work. Typically these are steel structures with a wall thickness of up to 10 mm, which after disassembly can be handed over to scrap metal collection points. But it happens that after dismantling the pipes are in good condition - this is commercial metal. Such pipes can be used for other purposes, for example, placed under the road, for drainage, or for the manufacture of non-critical containers.

Good used chimney after dismantling

The destruction of a brick chimney, especially by felling, is accompanied by the presence at the site of the collapse of an abundance of building material - scrap bricks. Part of the brick remains intact and suitable for use in arranging your own site.