Many people think that laying heating pipelines comes down to just quick installation of pipes. In fact, behind such seemingly simple work there is a whole complex of activities hidden. It is based on a lot of preliminary calculations and drawing up a project, which must be approved by the relevant government agencies. But we will not dwell on this issue. Let's say all the documents are already in hand and the installation method has been chosen. What are the features?

Even a small mistake at the installation stage can lead to premature wear of the entire system in the future.

Necessary materials

Choosing pipe material is a very important task. If you do not approach it carefully enough, then in the future this will affect the performance of the pipeline. Most often, metals and polymers are used for their laying. Steel and cast iron perform well. High-quality copper also demonstrates high performance. This is what applies to metals. Among polymer materials, the choice is much wider: many types of polyethylene, polypropylene and so on. Pipes reinforced with fiberglass and aluminum are quite popular.

All of the presented materials have certain features, thanks to which they have become popular. In the domestic market, steel pipes for pipeline installation are most in demand. This is due to the low cost of materials. But it has a number of disadvantages: such pipes are susceptible to corrosion, require painting, and installation is difficult.

As mentioned above, copper pipes are also used in pipelines. This material has a long service life, but is also expensive. Copper pipes are resistant to corrosion, overgrowing of the cross-section, and can withstand high and low temperatures, as well as temperature changes. Such a pipeline will last a very long time, but the costs for it will be corresponding.

Among polymer materials, polypropylene is most often chosen. Such pipes are relatively cheap, yet have high performance characteristics and are durable.

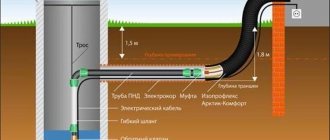

There are two types of pipeline laying for external devices currently in use: open (digging up the ground) and closed (it is also called trenchless. It is implemented by punctures, punching, drilling or sinking. Let's consider them in more detail.

Installation of underfloor heating

Video

The future structure, at a minimum, must be durable, because it will have to withstand pressure from the outside and from the inside. In addition to all this, the blanks in the network must resist corrosive formations.

Based on the above, we can conclude that the following pipes can be used for the floor:

Copper. They are the most expensive. They fully meet all regulatory requirements that arise in the case of hidden installation. Because they do not create oxygen permeability, are not afraid of corrosion, and are highly durable.

Polymer types made of vapor-proof plastic. They tolerate internal and external pressure well and are not at all afraid of the influence of corrosive processes. But they are not very durable. , it plays the role of a protector.

Metal-plastic (composite products consisting of several layers, mainly a combination of polyethylene and aluminum). These pipes are very durable, they have enough hardness, and they are not subject to corrosive formations. With these indicators, this type of pipes for laying heating in the floor compares favorably with a lower price compared to copper analogues

It is worth paying attention to this type of pipe rolling.

The technology for laying heating in the floor is determined based on the type of pipes, their diameter and wall thickness. When working, it is recommended to avoid tapping and other butt fastenings using fittings.

The workpieces are secured to the floor using planks, on which a laying slot is prepared for the required volume of pipes. The most optimal solution is when the pipes are laid directly into the grooves made in the panel ceiling.

Open method of laying pipelines

Basically, the open method of laying pipelines is used in circumstances where the necessary equipment to implement a closed one is not available. Since this option is a compromise, it has a number of disadvantages: the need for large expenses, destruction of the landscape with its subsequent restoration, temporary suspension of the work of enterprises located in the work area, difficulty in moving, and so on.

The open method of laying pipelines and sewers consists of digging trenches of the required depth, followed by strengthening them and placing the pipes themselves. The task consists of several stages.

Stages of work:

- Digging a trench and leveling it;

- Strengthening the trench;

- Pillow filling;

- Pipeline laying;

- Covering pipes;

- Closing the trench;

- Restoration of the landscape of the territory or road surface.

Laying an open pipeline is associated with large costs and a large amount of work. Therefore, the closed method is most often used. It preserves the environment, is more economical, and does not interfere with the life of a populated area.

Closed technologies are widely used within cities, but are also used outside them. This method is used to lay communications under water structures, in nature reserves, as well as under reliefs in areas where it would not be possible to implement an open pipeline. These include swamps, ravines, canyons, and so on.

Factors to consider when calculating installation depth

As a rule, a pipe in the ground is affected by various destructive factors. These include:

- soil pressure;

- corrosion;

- stray currents.

These destructive factors must be taken into account when choosing material for future communication.

In addition to freezing, overheating of the pipeline structure, which can occur during the hot period of the year, is also undesirable. Let's consider the main factors on which the laying depth of a particular pipeline structure directly depends:

- temperature fluctuations in a particular region. Temperature indicators in summer and winter periods of the year;

- soil composition;

- vegetation in a specific area where the pipeline will be laid;

Note! The calculation results for each factor must be recorded with an accuracy of tenths.

- temperature of the working medium that will move along the pipeline line;

- the depth of water in the soil or its complete absence;

- the amount of precipitation falling in a specific region where the communication will be laid.

For proper installation of a pipeline structure in the soil, it is necessary to take into account each of the above factors. Today, thanks to the development of technology, their definition is not difficult.

Pipes laid underground sometimes require additional protection or insulation

Horizontal directional drilling

Closed pipeline laying is a high-tech process implemented through the use of drilling complexes. The section is devoted to a description of horizontal directional drilling (for more details: “Advantages of laying pipes using the HDD method - how the work is performed”). This is the best option for laying pipes in a closed way.

Horizontal directional drilling process:

- Drilling a pilot well. At this stage, navigation equipment is used to give it direction.

- Expansion of the well to the required size.

- Pipe laying.

A pilot well is also called an experimental well. Drilling it is the most important step in laying closed pipes. For this purpose, a drill head with an integrated emitter is used. It is attached to a flexible drive rod. Thanks to this, workers will be able to control the drilling process. In such a system there is a hole into which a special solution is supplied, which cools the installation, reduces friction and protects the well from destruction.

There is a transmitter in the drill head. It sends signals to the locator, and that’s how it is controlled. The primary responsibility lies with the operator. It adjusts the position of the head, controlling the entire drilling process. Its task is to prevent deviation in the well from the design trajectory. Horizontal directional drilling is a complex process with a high level of automation. To implement this method, precise planning and modern equipment are required.

Video

In this video, a specialist will share his knowledge and tell you how to install a home heating system with your own hands:

Today, water supply is produced using modern materials.

Metal-plastic pipelines have become a very popular option for using these products for cold and hot water supply, as well as heating. However, it is worth knowing that when installing metal-plastic pipes with your own hands, it will be appropriate to additionally install gearboxes. This type of pipe does not like pressure drops in the system; reducers equalize this pressure.

Water pipe routing diagram.

Directional puncture

The directional puncture method involves the use of pneumatic punches for drilling wells. They then tighten pipes whose diameter does not exceed 400 mm. The pneumatic punch has a cylindrical body. It contains the firing pin and the air distribution system. Compressed air is released onto the body, and then blows are applied, so it moves.

The key feature of the puncture method is the speed of its implementation due to the speed of the punch. In addition, they compact from each other to a small extent. The benefits are greatest when several pipelines are laid nearby or close to infrastructure.

Specifics of work when chipping walls

Answers to questions when making grooves in finished buildings are listed below:

- Various pipelines and cables can be laid in the walls, but only those that do not require constant maintenance.

- Elements installed in the groove should be no more than 30% of the thickness of the structure that does not have reinforcement.

- In block-type houses, all communications in the walls are installed at a depth equal to the location of the internal metal frame (reinforcement) in the panel.

You need to know that in accordance with building codes and regulations, in order to avoid dire consequences, it is strictly forbidden to cut load-bearing walls and ceiling slabs in multi-apartment panel buildings. At the same time, the stability of the building sharply decreases.

Basic rules for safe work when making furrows for laying communication networks with your own hands:

- Disconnect all electrical wires walled up in the walls. You can forget about them forever.

- Study all the diagrams of pipelines laid in buildings. In the absence of such drawings, it is necessary to turn off all communications in order to avoid bitter consequences in the event of possible collisions of a sharp and destructive tool with pipes, thereby avoiding additional costs for unplanned repairs both for yourself and your neighbors.

- To reduce the cost of building materials for finishing work, after organizing the laying of pipes, it is recommended to make recesses corresponding to the size of the masked element.

- It is necessary to strictly follow the rules of labor protection instructions when performing construction work. Use special personal protective equipment (PPE) - eye goggles, respiratory respirators, since the process of crushing brick and concrete is accompanied by a large release of fine dust and the formation of cutting stone fragments.

How to mask pipes in a wall is described below.

Recesses in the wall for water and coolant supply pipes

In this case, it is especially important to maintain the stability of buildings and structures, since such pipes, unlike cables, take up much more space in the wall

Necessary tools for creating pipe grooves:

- Grinder or angle grinder. For deep grooves, a machine with more power is used.

- Hammer.

Procedure for step-by-step gating:

- First of all, using a dark chalk-colored writing object, a pencil, draw a pipeline laying diagram on the wall.

- Deeply cut furrows along the lines of the applied markings using a grinder.

- To remove materials from the future groove, it is necessary to transversely cut the space between the furrows made along the drawn lines with a grinder.

- Using a hammer drill, crush the wall material, brick, concrete, etc., between the cuts made.

For high-quality gouging of stone material, it is recommended to use a special tool for such work - a wall chaser. Such a professional device makes quality gating due to the following features:

- Two working diamond blades are provided.

- The gap between the installed disks is adjusted.

- The design of the device provides for connection to a dust collector of a special vacuum cleaner.

The cost of such a professional tool as a wall chaser is high. Therefore, to reduce the cost of work when gating, experts recommend the usual universal devices: a hammer drill and an angle grinder. If it is not possible to purchase a regular tool, it can be rented from service departments

At the same time, it is important not to damage the rented equipment and avoid overheating and sudden collisions, which can quickly disable the rented equipment.

So, the process of making grooves in the wall for laying pipes is not particularly complicated. But beginners in the construction and repair business should practice and gain experience, for example, on non-permanent country houses.

Punching method

The punching method is intended for laying metal pipes of large diameter (from 800 mm). And one of its main features is the absence of the need to dig a trench. This method is used for pipelines no longer than 80 meters. The essence of the method is that hydraulic jacks press a steel case with a knife at the end into the ground. It pours into the pipes, then they must be cleaned manually.

This method is widely used when laying pipelines under various structures, highways and rails. It is also involved in the construction of water, oil and gas pipelines, and the installation of sewers. In addition to the fact that large diameter pipes can be used in this way, there are other advantages: relatively low costs and speed of work.

Features of polymer products

As you know even from a school physics course, when substances are heated, they begin to increase in volume. This is directly related to plastic products, and the high temperature also makes them plastic.

When installing pipelines for cold water, you can not take into account the expansion coefficient (for more details: “Preliminary calculation of the thermal expansion of polypropylene pipes”). At the same time, when arranging the heating structure, this nuance must be taken into account.

It is this circumstance that raises doubts among many home craftsmen as to whether it is possible to wall up polypropylene pipes into the wall, which will begin to lengthen and expand when the hot pipeline is started.

This raises a logical question as to whether the finishing materials in which the elements of the engineering system are embedded will be damaged.

Experts assure that metal pipe products that expand slightly can simply be embedded in a layer of material, but in order to hide polypropylene pipes in the wall, you have to fully adhere to the technology of installation work (more details: “Types, properties, installation of propylene pipes with your own hands”) . Otherwise, the finishing of the room will become covered with cracks, and the tile covering will most likely fall off.

Auger drilling

There is a way to lay pipelines using special equipment - auger drilling machines. In this case, drilling goes into the receiving pit from the working pit. This means there is no need to go to the surface. This method is suitable for laying closed pipelines up to one hundred meters from steel, concrete or polymer pipes (100 - 1700 mm in diameter). It is highly accurate, the maximum deviation will not exceed 30 mm. The pipeline itself will be smooth, without sagging. This method is often used when installing gravity sewers, when laying pipes under railway tracks or in the communications area of houses.

Options for decorative masking of pipes

If you want to hide heating pipes without undertaking major repairs, then this can be done using decorative interior design techniques.

Wall panels

Decorative removable panels are made from various materials. It can be glass, plastic, metal, wood, fabric or leather on a rigid frame. You can order such panels according to your own sizes, or you can purchase standard ones.

Advantage of using removable panels:

- communications remain accessible, but are not visible;

- the panel can be changed with a change in interior or mood;

- They are easy to care for.

Note! Metal panels or screens have an attractive appearance and do not lead to heat loss.

Interior decor

You can hide heating pipes by using them as a piece of furniture. For decoration, natural materials, artificial flowers, and curtains are used.

Options:

- Natural motives. The design of pipes to resemble a tree trunk, vine, or reed looks impressive. To do this, the pipe is lined with matting, wrapped with hemp or similar material of natural color and texture. Then they decorate with flowers, birds, ceramic dishes, etc.

- Stylization as a support or canopy for shelves, decorative interior elements of the corresponding style.

- In rooms decorated with tiles, pipes are masked with covers with pebbles, shells, and elements stylized in a marine style.

Note! Materials should be selected taking into account their heat resistance and naturalness. The use of decorative elements made of synthetics can provoke the release of harmful substances when they are heated.

Installation of internal pipelines

SNiP 3.05.01-85 regulates the installation of internal pipelines. The document also applies to water supply systems, climate control equipment, heating, drains and similar communications.

Basic operating principles

If you plan to implement a pipeline with a diameter of no more than 50 mm, then steel pipes are used. In other cases, cast iron is more suitable. The water supply should be located at a distance of one and a half meters from other communications. If it passes through the wall of a building, it must be protected from possible precipitation. Main water pipelines in buildings with large human traffic are carried out in the basements; in industrial facilities they are placed on the technical floor or in the attic.

Installation requirements

When laying pipes in the wall, it is recommended to use shock-absorbing materials. For example, energyflex, polyurethane foam. These materials will serve as a gap between the wall and the pipe; accordingly, there will be no pressure on the concrete when the pipe expands.

The fewer connections, the better. Connections are the most vulnerable part of polypropylene systems, least protected from leaks and having low pressure resistance.

Pipes must be selected in accordance with the conditions of further operation.

Based on wall thickness, all PPR pipes are divided into categories from PN10 to PN25.

- PN10 pipes are thin-walled, designed for cold water supply or for heated floors and other low-temperature, low-pressure systems.

- PN16 and PN20 are used for water supply with pressure up to 1.5 MPa and heating systems with pressure not exceeding 0.8 MPa.

- PN25 is reinforced with a layer of fiberglass or aluminum, which increases strength and temperature range. Accordingly, the products can be used in central heating systems at pressures up to 1.5 MPa, and in cold water supply up to 2.5 MPa.