Repairing or replacing the faucet axle box in a mixer yourself will cost much less than calling a plumber. A breakdown that requires replacement of the axle box crane is usually visually clear. This is water leaking from the faucet tap or from under the faucet handle, as well as difficulties in moving the handle itself.

If there is such a problem, then replacement will be simply necessary. There is no need to understand faucet models and their technical properties, since the choice of plumbing fixtures is large, you just need to know and take into account that they differ in their technical design. And the mechanism for replacing worm and ceramic ones is often similar. And what to do in this case? What parts need to be replaced? Where to start the renovation? You will find the answers to these questions by reading this article.

Crane axle box

The main reason for leakage of ceramic faucet axle boxes

The most common cause of leakage of ceramic tap-boxes of water mixers and the need to repair them is wear of the plastic pressure washer (marked with an arrow in the image), which can be made of polypropylene, caprolon or fluoroplastic.

Pressure washers made of polypropylene and caprolon, unlike fluoroplastic ones, are not sufficiently resistant to elevated temperatures, so more often due to their wear they fail and require repair. The wear of the plastic washers of these products is also increased by the fact that, usually, the hot water tap is used more often.

When the pressure washer wears out significantly or is completely destroyed during operation of the water tap, a gap appears between the ceramic plates and the faucet begins to let water through in the closed position.

The thickness of the new plastic washer from the photo is 1 mm, the inner diameter is 10 mm, the outer diameter is 12 mm. You can buy one if you find the same one, or make it yourself, but there is a method that will significantly increase the life of a ceramic faucet axlebox until the next repair, which is to make a pressure washer from a piece of copper wire.

Preparing for work

Before you begin directly repairing/replacing the mixer, you must turn off the water in the riser. Otherwise, problems with the tap will be aggravated by flooding of the apartment (not only your own, but also the neighbors below). Only after turning off the water can further work begin.

Water supply risers

To carry out repair work, you will need the following:

- some kind of vessel (to collect water);

- rags;

- Adjustable wrench;

- sponge;

- silicone seals;

- cleaning agent;

- screwdrivers;

- wrench;

- fluoroplastic sealing tape;

- rubber gaskets (new);

- pliers.

Fluoroplastic tape

All these tools/materials are quite enough to deal with a leaking plumbing faucet with your own hands.

On a note! If the mixer was purchased recently and you even saved the packaging, then you may find the manufacturer’s instructions and even a repair kit in it. In this case, the work will go much faster.

Repair kit for mixer (AKVAREM)

Repair of ceramic faucet axle box (leakage repair)

Repairing a water faucet with ceramic plates consists of replacing a worn plastic washer:

- For a crane axle box that requires repair, remove the rod clamp.

- Take the valve axle in your left hand, clenched into a loose fist, with the rod on the side of the thumb, and squeeze the body of the product with a ring of the index and thumb.

- Press the valve stem with sufficient force with your thumb or the palm of your right hand, and the entire contents will fall out of the body into your loosely clenched left palm.

- Remove the remnants of the pressure washer if it is really worn out and the reason for the need for repair is in it (this will be immediately visible by its thickness and appearance, and sometimes only scraps of the washer remain).

- Select a copper wire with a diameter of about 1 mm, wrap a ring of wire around the stem of the valve axlebox in the place where the plastic washer was. If necessary, grind it on both sides with fine sandpaper if the assembled ceramic tap-box is difficult to rotate (you need to check by installing the product on the mixer).

- In some faucet axle boxes, a homemade pressure washer made of wire with a diameter of 1 mm can move so far that the rod will slip through it and the tightness will be broken. In this case, you will have to connect the ends of the copper ring by soldering, then grind off the excess solder, or take a wire of a larger diameter and flatten a washer from it to 1 mm. Such a ring will first have to be installed in the body of the valve axle box, and only then the rod must be inserted.

- Before final assembly and installation of the repaired faucet axlebox into the mixer, apply a little waterproof lubricant to the copper ring.

Pressure washers

From left to right: worn plastic washer; ring made of copper wire Ø 1.2 mm; wire ring Ø 1.8 mm.

What to do if the new faucet is dripping?

Sometimes even a faucet that was purchased and installed relatively recently begins to leak. In such situations, the reason, as a rule, is simple to the point of banality - the device has a manufacturing defect, which is difficult to identify during external inspection.

Important information! Cracks and chips inside the structure can hardly be eliminated on your own - even an experienced plumber will not be able to do this. That is why the only correct solution is to return the faucet to the store and ask the seller to replace the defective model.

New faucet

Finally, we note that the faucet in the kitchen or bathroom can start dripping at any moment. To solve this kind of problem, you can go one of two possible ways - to involve a qualified specialist in the work or to try to do everything yourself. However, if you know the exact cause of the leak and how to properly eliminate it, then no difficulties should arise.

Note! To prevent a leak from appearing at the most inopportune moment, regularly carry out preventive measures - change gaskets in a timely manner, check the condition of locking mechanisms. All this will significantly extend the life of the crane!

Making a plastic washer

Sometimes a washer made of copper wire moves apart immediately, but a soldered one only holds when the valve axle is not tightened. And then, when the tap is opened, the loosely tightened faucet box may begin to turn away.

In this case, there is no way to do without a plastic washer. To make it you will need durable material. Polyethylene lids for glass jars are not suitable - they are too soft, the side of the stem will fall into such a washer after heating.

Polypropylene washers can be made from thin-walled plastic containers. At the bottom of such containers there is a triangular icon and under it the letters “PP”, which indicate the material of manufacture - polypropylene. The thickness of the plastic on the lids of round containers in which marinated meat for barbecue is sold is 0.6 mm.

Suitable for making washers are plastic water bottles (0.3 mm thick), detergents (shampoos, gels, conditioners), the material of which is polyethylene terephthalate (PET). Naturally, you will need 2 or 3 of these washers (from plastic containers and bottles) to repair one ceramic faucet axle.

We place the selected piece of plastic (or several pieces folded together) between two wooden blocks and drill several holes with a ∅ 10 mm drill (or another diameter, depending on the diameter of your rod where the washer is installed). The edges turn out quite smooth. It is better not to trim small thickenings along the inner edges.

Next, use scissors to cut out blanks with one hole from a piece of plastic and cut off the excess from the outside to a width of 2 mm. The outer edges of the cut washers can be easily adjusted to size using a fine-grained block or sandpaper.

Features of operation

After installing the crane box, you should not overtighten it, because this will lead to possible faucet leaks. Just tighten it all the way.

To be fair, it is worth noting that often, instead of replacing the valve axlebox, it is enough to replace all the gaskets present on it. To do this, you need to have a little more in-depth plumbing skills, but once you figure it out, you can fix any faucet axle box. Masterprof has developed a special universal set of gaskets in its product range. It contains gaskets for all types of crane axle boxes, which allows you to repair any product.

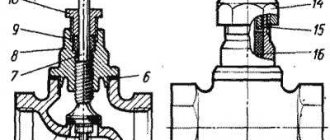

Crane axle box device with ceramic plates

The ceramic faucet for a water mixer consists of the following components:

- The valve stem with a plastic pressure washer and sealing rings.

- Ceramic crane axle housing.

- Sealing gasket (pressed against the valve seat).

- Fixed ceramic plate.

- Movable ceramic plate.

- Rod lock.

As you can see in the image, in a ceramic faucet, only the plates that shut off and open the water are actually ceramic.

If any components of the ceramic faucet are coated with salts from hard tap water, including the sealing gasket (number 3 in the photo), place them in a citric acid solution for a while to remove the deposits.

How to replace the faucet in a faucet?

To replace the crane axle box, you need to do the following:

- The risers with cold and hot water must be closed. After which you need to make sure that water is really not flowing; to check this, you need to fully open both taps.

- After which you need to take some flat tool, a screwdriver or a knife may be suitable for this, and use it to remove the plastic colored plug. It needs to be pryed up and then removed.

- Under the plug there is a screw that needs to be unscrewed. If the axlebox is imported, then the plastic lock cannot be located on it, which must also be removed.

- After this, you need to remove the handle. At this stage, difficulties may arise in the form of nitrous on the splines, then they need to be soaked or resort to the help of pullers specially designed for this.

- After the flywheel is removed, access to the valve axle is open; it must be unscrewed using an adjustable wrench. If the axlebox has a lock nut, then you must first release it, and only then begin to unscrew the axlebox.

Installation of a new crane axlebox is done in the reverse order. When replacing the crane axle box, you can change the direction of its rotation. To do this, you need to unscrew the locking screw that is screwed into the axlebox rod. Next, you need to screw this screw in from the reverse side, which will allow the axle box to turn in the other direction.

Some tips from practice

- Do not close the ceramic valve axle with rotation limiters by a quarter or half turn with great force, and, moreover, do not try, using such efforts, to loosen the handwheel 1 (handle) of the valve on the splines during dismantling. The result can be disastrous: due to damage to the limiters, a completely closed repaired faucet will allow water to flow through, and if the handwheel is slightly turned towards opening, the flow will stop completely. You will have to either partially open the valve after each closing to eliminate any leakage, or replace the valve axle.

- If threaded connections cannot be unscrewed or handwheels cannot be removed from the stems of faucet axle boxes requiring repair, place cotton wool or a cloth moistened with 70% vinegar essence2 on the problem areas for about an hour3, sometimes adding essence drop by drop. Vinegar penetrates into hard-to-reach places and softens rust and deposits from tap water. The procedure may need to be repeated. Protect the decorative coating of the faucet from contact with vinegar essence, as it may not be resistant to acids.

- Dip the handwheels and decorative trims, covered with a coating of salts from hard water, into a solution of citric acid (2 heaped teaspoons per glass of water), and they will return to their original state. If you have an expensive faucet and you are not sure that citric acid will not harm it, try it first in an inconspicuous place. Observe how the reaction proceeds: hissing, the release of bubbles. If the process stops and the plaque is not completely cleared, replace the solution with a new one or add more citric acid to the same solution4.

1So I ruined the faucet axle box on the kitchen mixer, the handwheels of which are very difficult to remove from the stems; when installed, they snap back into place only with the help of a fixing screw. Exactly the same handwheels in the bathroom can be removed and installed on the slots without difficulty.

2I usually use undiluted 70% vinegar essence, less often slightly diluted with water. Vinegar works where WD-40 fails.

3It is impossible to accurately predict the time a threaded connection will be ready for unscrewing; it can range from half an hour to several hours, depending on the initial state.

4I add citric acid to the same solution, having first removed the parts to be cleaned from it, and after the added acid has dissolved, I immerse them back. When cleaning the rods and bodies of repaired ceramic valve axle boxes from plaque, I do not remove the rubber sealing rings from them.

conclusions

When faced with valve mixer leaks, you should first inspect the faucet axle box. As a rule, the reason is the failure of one of the elements of the unit. If the whole point is that one of the gaskets is worn out, they change it. More serious damage can be resolved by replacing the entire part. Ceramic valve heads are considered more reliable in this regard: leaks on them occur much less frequently than on rubber ones.

Sources:

- https://trubarik.ru/fitingi/remont-kran-buksy-svoimi-rukami-s-keramicheskimi-plastinami-i-chervyachnoj

- https://seti.guru/kran-buksa-dlya-smesitelya

- https://masterprof.net/academy/poleznoe/kran-buksa-kak-vybrat-ustroystvo-zamena-svoimi-rukami/

- https://lucheeotoplenie.ru/remont-otopleniya/remont-kran-buksy-s-keramicheskimi-plastinami.html

- https://fugar-kamin.ru/truby/remont-kran-buksy-svoimi-rukami-instrukciya-s-foto-i-video.html

- 1

Advantages and disadvantages

Like any complex structure, a ceramic crane axle box has a number of distinctive performance properties. They appear during the installation process - for the device to function correctly, you only need to screw the block into the mixer body.

The positive aspects include the following:

- Low effort to open (close) the tap.

- Small overall dimensions, which help to reduce the housing of plumbing fixtures.

- Reliability. Subject to the operating conditions, a ceramic crane axle box can last for decades.

But besides this, you should take into account the disadvantages:

- High cost relative to classic locking devices. Exceptions are cheap models, in which the quality of the materials used is significantly reduced.

- Water requirements. In the presence of solid particles, rapid wear of the ceramic plates will occur, which is caused by an abrasive reaction - damage to the surface, as a result of which the tightness of the device will deteriorate.

All this must be taken into account when choosing a specific ceramic faucet model. But sooner or later, even this reliable device can fail.

What you need to pay attention to when choosing a valve head

If you use faucets at home made in Russia or even in the USSR, then their rotating mechanism is equipped with a connecting part that has a square shape. Until now, this connection option is considered the most successful and reliable. It practically eliminates the possibility of erasing the edges and turning the flywheel. Devices manufactured abroad are more susceptible to this.

Crane axlebox options Source gilevasvetlana.ru

Such devices use a splined valve mount. There are many small grooves on the stem. When cut, it resembles an asterisk. The splines can wear out over time, and the product has to be completely replaced.

Selection rules

What should you first of all pay attention to when buying a crane axle box? The ideal option would be to take the old part with you and ask the seller to find you the same one.

If for some reason the seller is unable to help you, pay attention to:

- Length of the body and stem (the difference can be significant);

- Thread pitch (sometimes different);

- Rod head for the flywheel (square or star-shaped).

As for the manufacturer, good crane axle boxes are produced by German, Italian and Russian manufacturers.