Types of gas pipelines

The distance from the water supply to the gas pipeline in each case is calculated based on measurements of a particular section. Nevertheless, a horizontal space of about 1 meter is maintained before the water supply.

Pipeline in the city

When gas workers place a gas connection too close to a water supply line, then this work does not comply with SNiP (SP) standards. After this, you can go to court and complain about unscrupulous gas workers.

Laying new pipes and sewers requires experience and knowledge.

In order for the installation to be carried out in accordance with SNiP standards, you need to know not only what distance between the gas pipeline and the water supply it is desirable to maintain. It is recommended to at least briefly learn about the types of gas pipelines. There are only three of them:

- low pressure line;

- medium pressure gas pipeline;

- high pressure gas pipeline.

Underground pipeline

Some people who are building a house and intend to carry out communications themselves or are engaged in street construction work often do not know how the water supply pipe from the gas pipe should be correctly located.

For example, the distance from a gas pipeline to a water supply is laid nearby only with the permission of the water utility in accordance with SNiP standards. It is important to note that the gas pipeline must be installed at a distance from the foundation of the house.

It is worth clarifying that gas is supplied to houses, which has thermal conductivity characteristics. The coefficient of such fuel is almost 10,000 kcal/Nm³.

Laying pipes in winter

Main purpose of gas pipelines:

- The low pressure gas pipeline supplies a resource for household needs. These pipes are made for buildings such as high-rise buildings, clinics, office premises, canteens, and educational institutions.

- The medium pressure line is intended for main lines or for boiler room operation. In numbers, the pressure on such gas pipelines is 0.05 kgf/cm² – 3.0 kgf/cm². They are usually not installed in houses.

- According to the normative rule, a high-pressure gas pipeline is installed to supply enterprises and workshops with fuel. The pressure varies from 3.0 kgf/cm² to 6.0 kgf/cm².

Communication distance standards according to SNiP and SP

Products made from stable, strong polymer materials are suitable for laying underground gas pipelines. It is also worth considering that a plastic pipeline is only suitable for transporting low pressure gas, up to 0.05 kgf/cm².

The world of water supply and sanitation

When designing external water supply and sewerage networks, it is preferable to provide for an underground method of placing communications.

In climatic zones with the presence of permafrost soils, water supply, sewer and drainage pipelines should be placed in the zone of temperature influence of heating pipelines.

It is allowed to place flammable and combustible liquids in common channels and pipeline tunnels together with pressure pipelines of water supply (except fire-fighting) and pressure sewerage.

Underground utilities should be placed parallel in a common trench; at the same time, the distances between utilities, as well as from communications to the foundations of buildings and structures, should be taken as minimally acceptable, based on the size and placement of cameras, wells and other devices on these networks, the conditions of installation and repair of networks.

The horizontal (clear) distances from the nearest underground utilities to buildings and structures should be taken no less than those indicated in Table 6.

| Engineering Communication | Horizontal distance (clear), m, from underground utilities to | ||||||||

| foundations of buildings and structures | fencing foundations, gallery supports, pipeline overpasses, contact networks and communications | track axis of 1520 mm gauge railways, but not less than the depth of the trench to the base of the embankment and excavation | tram track axes | ||||||

| 1 Water supply and pressure sewerage | 5 | 3 | 4 | 2,75 | |||||

| 2 Gravity sewerage and drains | 3 | 1,5 | 4 | 2,75 | |||||

| 3 Drains | 3 | 1 | 4 | 2,75 | |||||

| End of table 6 | |||||||||

| Engineering Communication | Horizontal distance (clear), m, from underground utilities to | ||||||||

| roads | foundations of overhead power transmission line supports | ||||||||

| side stone, edge of the roadway, reinforced shoulder strip | the outer edge of the ditch or the bottom of the embankment | up to 1 kV and outdoor lighting | St. 1 to 35 kV | St. 35 kV | |||||

| 1 Water supply and pressure sewerage | 2 | 1 | 1 | 2 | 3 | ||||

| 2 Gravity sewerage and drains | 1,5 | 1 | 1 | 2 | 3 | ||||

| Note It is allowed to provide for the laying of underground utilities, with the exception of fire-fighting water supply and gas pipelines of flammable and toxic gases, within the foundations of supports and overpasses of pipelines, galleries, and contact networks, provided that measures are taken to exclude the possibility of damage to communications in the event of settlement of foundations, as well as damage to foundations in an accident on these communications. | |||||||||

The horizontal (clear) distances between adjacent underground utilities when they are placed in parallel should be taken no less than those indicated in Table 7, SP 18.13330.2011.

| Table 7 | ||||||||||||

| Engineering Communication | Horizontal distance (clear), m, between | |||||||||||

| running water | sewerage | drainage or gutters | gas pipelines for flammable gases | |||||||||

| low pressure up to 0.005 MPa | average pressure St. 0.005 to 0.3 MPa | high pressure St. 0.3 to 0.6 MPa | ||||||||||

| 1 Water supply | 1,5 | (See note 1) | 1,5 | 1 | 1 | 1,5 | ||||||

| 2 Sewerage | (See note 1) | 0,4 | 0,4 | 1 | 1,5 | 2 | ||||||

| 3 Drainage and wastewater | 1,5 | 0,4 | 0,4 | 1 | 1,5 | 2 | ||||||

| * According to requirements []. Notes 1 The distances from the sewerage system to the drinking water supply should be: to the water supply system made of reinforced concrete and asbestos-cement pipes laid in clay soils - 5 m, in coarse and sandy soils - 10 m; to a water supply system made of cast iron pipes with a diameter of up to 200 mm - 1.5 m, with a diameter of more than 200 mm - 3 m; to the water supply system made of plastic pipes - 1.5 m. The distance between the sewerage and industrial water supply pipelines, regardless of the material and diameter of the pipes, as well as the nomenclature and characteristics of the soil, must be at least 1.5 m. 2 When two and more than gas pipelines of flammable gases, the clear distances between them should be for pipes with a diameter of: up to 300 mm - 0.4 m; more than 300 mm - 0.5 m. 3 The table shows the distances to steel gas pipelines. The placement of underground gas pipelines made of non-metallic pipes should be provided in accordance with the set of rules for the design of internal and external gas supply devices. | ||||||||||||

| End of table 7 | ||||||||||||

| Engineering Communication | Horizontal distance (clear), m, between | |||||||||||

| gas pipelines and flammable gases | power cables of all voltages | communication cables | heat pipes | canals, tunnels | ||||||||

| high pressure St. 0.6 to 1.2 MPa | outer wall of a channel, tunnel | ductless laying shell | ||||||||||

| 1 Water supply | 2 | 0,5* | 0,5 | 1,5 | 1,5 | 1,5 | ||||||

| 2 Sewerage | 5 | 0,5* | 0,5 | 1 | 1 | 1 | ||||||

| 3 Drainage and wastewater | 5 | 0,5* | 0,5 | 1 | 1 | 1 | ||||||

When crossing utility lines, the vertical (clear) distances must be no less than:

a) between pipelines or electrical cables, communication cables and railway and tram tracks, counting from the base of the rail, or highways, counting from the top of the coating to the top of the pipe (or its case) or electrical cable - based on the strength of the network, but not less than 0 .6 m;

b) between pipelines and electrical cables placed in canals or tunnels and railways, the vertical distance, counting from the top of the canals or tunnels to the bottom of the railway rails, is 1 m, to the bottom of the ditch or other drainage structures or the base of the railway earthen embankment canvas - 0.5 m;

c) between pipelines and power cables with voltage up to 35 kV and communication cables - 0.5 m;

d) between power cables with a voltage of 110-220 kV and pipelines - 1 m;

e) in the conditions of reconstruction of enterprises, subject to compliance with the requirements (Rules for the construction of electrical installations PUE), the distance between cables of all voltages and pipelines can be reduced to 0.25 m

f) between pipelines for various purposes (with the exception of sewer pipelines crossing water pipelines and pipelines for toxic and foul-smelling liquids) - 0.2 m;

g) pipelines transporting drinking water should be placed 0.4 m higher than sewer or pipelines transporting toxic and foul-smelling liquids;

h) it is allowed to place steel pipelines enclosed in cases transporting drinking water below sewer pipes, while the distance from the walls of the sewer pipes to the edge of the case must be at least 5 m in each direction in clay soils and 10 m in coarse and sandy soils , and sewer pipelines should be made of cast iron pipes;

i) utility and drinking water supply inlets with a pipe diameter of up to 150 mm may be provided below sewer lines without installing a casing, if the distance between the walls of intersecting pipes is 0.5 m;

j) when laying ductless pipelines for water heat pipelines of an open heating or hot water supply system, the distance from these pipelines to the sewer pipelines located below and above should be taken as 0.4 m.

Intersections of pipelines with railway and tram tracks, as well as with roads, should, as a rule, be provided at an angle of 90°. In some cases, with appropriate justification, it is possible to reduce the intersection angle to 45°.

The article was written on the basis of SP 18.13330.2011, section 6.

Pipeline options

For those who already know what distance between the water supply and gas is recommended to be maintained, the next step to think about is how to properly establish communication with or without support. It all depends on the situation. Options for installing pipelines:

- underground;

- aboveground;

- interior.

Pipe installation

If you need to choose a budget installation method, then the above-ground option is considered the cheapest. It is also advisable to choose products made from high-strength metal.

There are some nuances:

- The open method is suitable for summer cottages and areas around private houses. Pipes are laid above ground when it is impossible to establish gas communications internally. Obstacles can include: reservoirs, ravine, well.

- The internal method involves installation indoors. It is necessary to specifically calculate with gas workers, taking into account SNiP (SP) standards, how many meters between the low-pressure gas pipeline and the water supply it is desirable to observe. The distance according to the classical principle is 1 meter, but in each case the numbers differ. To carry out this communication in the house, you need to use products made of copper or steel.

- When the gasket is closed, a parameter such as gas humidity is taken into account. If wet gas will flow through the pipes, then the pipe is placed at a level where the soil freezes. Structures with dry gas are laid from 80 cm into the ground.

Water supply network at the dacha

How to choose pipes for a water floor

Choosing which pipe to make a warm floor is not difficult, since you can use:

- copper tubes;

- metal-plastic products;

- polypropylene pipes;

- cross-linked polyethylene products.

It is considered optimal to choose a pipe for a heated floor made of copper, since this metal has the highest degree of heat conductivity. Products made from it are durable, but they have a high cost, which is inaccessible to many consumers.

In addition, pipeline installation requires the use of professional equipment, which leads to significant financial costs.

Laying underfloor heating pipes made of metal-plastic will cost much less than copper. Their first inner layer is a polyethylene tube, followed by an adhesive composition, thanks to which an aluminum pipe is attached, which is necessary to ensure the rigidity and thermal conductivity of the system. The last layer is a polyethylene tube that protects the pipeline from possible mechanical damage.

Information for designers

Based on the construction rules of SNiP (SP), it must be taken into account that it is impossible for everyone to calculate the same distance from the gas pipeline to the water pipes.

Valves

The following points should be extracted from the document:

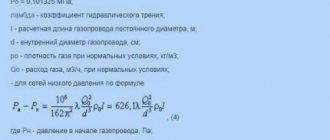

- The vertical distance between a low, medium or high pressure gas pipeline when crossing water pipes should be 20 centimeters.

- The horizontal distance of the gas pipeline with the “low pressure” characteristic should be 1 meter in clear distance to the water supply.

- It is advisable to distance the horizontal gap between the pipe with medium pressure by 1.5 meters in the light.

- If the gas is under high pressure, then the distance from the gas pipeline must be designed at least 2 meters.

- The distance from the pressure sewer to the gas pipe can be the same as to the water supply - about 1 meter.

Water

Recommendations for calculations

In order to reduce the hydraulic resistance of the system and increase the efficiency of its operation, experts recommend adhering to the relationship between the diameter of the pipe for a warm water floor and the length of the circuit:

- 16 mm - maximum pipe length for a warm water floor (for 1 circuit) within 60-70 m;

- 20 mm – up to 80-90 m;

- 25 mm – up to 100-120 m.

The greater the distance between the pipes of the water heated floor, or the step in each circuit, the larger the diameter of the pipes is selected.

When calculating how many pipes a warm water floor will require, you need to decide on the number of circuits. There is a rule according to which the area heated by the circuit should not exceed 20 square meters. If the room area is larger, several circuits should be organized.

Installation restrictions

It is important to take into account the fact that high pressure in pipes is dangerous. They must be placed both from residential buildings and from the water supply at a safe distance.

Table of distance from buildings and structures according to SNiP

It is worth knowing the main prohibitions of SNiP:

- According to building codes, the gas pipe must be fenced with two parallel lines located from it. The distance to the lines is calculated differently depending on the pressure.

- The fundamental part of the building must be located at a certain distance from the gas pipeline with a low pressure indicator - 2 meters.

- Facade walls should be 4 meters away from medium pressure gas communications.

- Gas pipelines with high pressure gas must be located at a safe distance from the house - 7 meters.

- The distance from the pipe supplying gas through a window or doorway should be 50 cm.

- The distance from the pipe to the roof should be about 20 cm.

Pipe joining

These points must be observed without fail when laying a gas pipeline, since the above standards guarantee fire safety and sanitary standards.

Where can I find official information?

SNiP 3.05.01-85 entitled “INTERNAL SANITARY SYSTEMS” (incomplete name of the document) regulates in detail the laying of water supply pipes, including heating ones, as well as the relative position of the radiator, floor, and underwater pipes. You only need to pay attention to a few points, since this document is a universal paper for different types of plumbing fixtures, as the name suggests.

Radiator installation diagram

The “HEATING” section begins with paragraph 3.18 and ends with number 3.33. The most significant points are 3.20 and 3.22. This is where the relationship of the radiator with respect to all elements of the room, as well as the distance between adjacent pipes, is described.

Distance from wall

Water supply location

In areas where communications are installed, you should adhere to the norms of perpendicular and parallel distances between pipes carrying gas and water. Also, knowledge of SNiP rules will help to correctly install water supply and gas into the house, while saving on digging trenches for laying communications.

High pressure gas pipeline

The gas pipe must not be installed with pipes carrying flammable liquids or near electrical cables.

Heating of non-residential premises (greenhouse)

In non-residential spaces, the rules for installing pipes are less strict.

Practical benefits rather than safety are taken into account here. Polypropylene and metal pipes are laid according to strict regulations only if they conduct gas, which is used to heat the greenhouse. Water radiators and polypropylene pipes are not subject to strict regulations unless it is a commercial site.

The optimal distance between heating pipes in a greenhouse is a gap of 120 mm, where there are no trays with plants.

Such passes help to evenly warm the soil without drying it out. Parallel laying is the most effective. With it, the greenhouse will produce the most fruit, since the trays are heated evenly.

Choosing a heating system as a guarantee of comfort

Despite the growing popularity of such designs, most residents of private houses are in no hurry to abandon traditional radiators. Meanwhile, the operation of a heated floor system has undeniable advantages. To evaluate them, you need to understand the features of both heating methods.

Radiators are installed locally. That is, their location most often becomes the coldest places in the house. And the installation of a warm water floor is carried out over a larger area of the room. Specification for connecting a radiator A distinctive feature of a radiator heating system is the air flows that rise upward.

Since their installation height above the floor is about 12 cm, the lower part of the room remains cold, and at head level the air temperature becomes too high. Using an alternative heating method, residents of houses receive the desired effect, in which their feet remain warm and their heads remain cool. The disadvantage of radiators is that the coolant temperature is too high, reaching 80°C. An alternative heating option requires water heated to 40-45°C, which significantly saves energy consumption.

Of course, alternative heating is not without its drawbacks. But there are very few of them, and they are as follows:

- energy dependence associated with the need to pump coolant through long pipes; a narrow range of applications that does not allow the use of this method for heating steps and flights of stairs. Installation of a radiator

Installation of radiator heating requires careful calculation.

The efficiency of such heating depends on many factors, one of which is the height of the radiators above the floor level. It is also necessary to take into account that radiators are installed in such a way that a certain distance remains between the window sill and the radiator, as well as between the wall and the heating device. Therefore, it is very important to choose the right size of radiators, otherwise they will have to be replaced.