When is pipe replacement required?

Relocating a gas pipe in the kitchen is considered a responsible procedure on which safety depends. Therefore, it should be taken into account that skill and training are required to perform the job. Although hiring specialists will cost a considerable amount, it is still better to spend money to ensure safety. Otherwise, the consequences may be different.

Typically, moving the gas pipe in the kitchen is carried out during a major renovation. But this work may also be required if there are technical deficiencies in the equipment. According to the rules, the gas supply system must be reconstructed after 20 years of operation. Whatever gas procedure is performed, safety rules must be followed.

Transfer instructions

If you need to move equipment, you need to know how to move a gas pipe in the kitchen. The standards for how to transfer the system are determined by the master. But in any case, the owner’s wishes are taken into account. Often the procedure is required due to the inconvenient location of the gas system. The transfer of a gas pipe in the kitchen is carried out by a specialist using the following rules:

- the apartment has a special gas supply valve, which is closed before performing work;

- the gas pipeline is purged to eliminate any remaining gas from it;

- in the area of connection with the gas pipeline, it is necessary to cut off the interfering pipe, and the created hole is sealed by welding;

- a hole is created in the wall and a gas pipe is attached.

It should be taken into account that the gas distribution must have a hole for a flexible bellows hose, which is used to connect gas equipment. Its length can be no more than 2 meters.

How internal gas pipelines are laid

Technological block diagram of the gas pipeline

The laying of internal gas pipelines is carried out from an external reduction gearbox located close to the point of entry of the pipeline into the building. The most common option is one input per section. But in some cases, a separate input is made for each riser. At the entry point there is also a shut-off device with special insulating couplings that allow you to shut off the gas for testing or when leaks are detected.

Before starting direct installation work and introducing the pipeline into the building, the readiness of all elements of the building structure for acceptance of the system is checked. All openings in the walls or ceilings must be made, and the condition of the walls in the apartments on which pipelines leading to gas-using equipment will be installed must be checked. The availability and compliance of all standards of materials and equipment is also checked.

Necessary equipment for connecting the gas system to the stove

Installation of risers is carried out either in staircases or in kitchen areas. It is prohibited to run gas risers through residential premises.

Steps to take when transferring is required

In apartments, gas pipes are usually located in the kitchen. All people use the gas pipeline and the devices connected to it every day. But when the pipe interferes, a transfer is performed.

Before moving the gas pipe in the kitchen, you must:

- draw up an application to the gas service, where you must indicate the reasons for moving the pipe;

- the area where the pipe will be installed must be inspected by a specialist;

- work conditions are assessed;

- the specialist makes a decision on the possibility of moving the pipes.

In some cases, if the owner does not like the dissolution of the system, a new technical plan of the premises is drawn up. This takes into account the location of the equipment.

What is an internal gas pipeline

An internal gas pipeline is the entire system of gas pipes located inside a building. The outer boundary of internal gas ducts is the outer surface of the walls or enclosing structural elements of the building, and their duration is taken into account to consumers - gas-using equipment. Simply put, these are all the gas pipes entering the wall of the building and leading to consumer appliances. Consists of various elements:

Boiler room gas pipeline diagram

- Inputs.

- Risers.

- Apartment wiring.

All elements of the system, except for intra-apartment ones, must be located in non-residential premises (entrances) so that periodic inspection of the pipes is possible. Also, shut-off valves should be located in the entrances, requiring inspections.

Requirements for specialists

Before carrying out work, you must ensure that the specialists have the appropriate qualifications. That’s why it’s so important to look at credentials, certification times, and proof of skills.

When the transfer of the gas pipe in the kitchen is completed, the owner of the premises is given a certificate of the work performed. It includes changes to the gas system.

Generally accepted rules

No matter where the gas pipeline is installed, on the wall, floor, the distance from it to building structures must still ensure the possibility of inspection, control and installation. The system in the kitchen cannot cross ventilation grilles or window openings.

The distance between the pipe and wired broadcasting equipment is established based on safety rules. In residential premises, the height of the equipment and its wiring will be at least 2.2 meters from the floor to the bottom of the pipe. If it has insulation, then the distance to the bottom of the insulation is taken into account.

The gas pipeline is secured using:

These means are also used when it is necessary to secure the pipe to ceilings or columns. With them, the gas pipe in the kitchen will be installed correctly. Installation standards and rules that establish the distance between fasteners are prescribed in special documents.

Communication device

Gas pipes are laid in different ways. The method depends on the task and operating characteristics.

Underground communications are the safest and most common installation method. The laying depth is different: the gas pipeline transmitting wet gas must be placed below the freezing level of the soil, gas pipes moving the dried mixture - from 0.8 m below ground level. The distance of the gas pipeline to a residential building is standardized by SNiP 42-01-2002. The gas pipe can be steel or polyethylene.

- Ground systems - permitted in case of artificial or natural barriers: buildings, water channels, ravines, and so on. Ground-based installations are permitted on the territory of an industrial or large municipal building. According to SNiP, only steel gas pipelines are allowed for overhead communications. The distance to residential facilities is not established. The photo shows an above-ground gas pipeline.

- Internal networks - the location inside buildings and the distance between the walls and the pipeline is determined by the installation of consumer objects - boilers, kitchen equipment, and so on. Laying gas pipes in grooves is not allowed: access to any section of the pipe must be free. Steel and copper products are used to organize internal networks.

In summer cottages, the construction of a ground-based option is commonplace. The reason is the cost-effectiveness of such a solution.

Allowable distances

SNiP 42-01-2002 determines the distance between the house and the gas pipe based on the gas pressure. The higher this parameter, the greater the potential danger the gas pipeline poses.

- A distance of 2 m is maintained between the foundation of an inhabited house and the low-pressure gas pipeline.

- Between gas pipes with an average parameter value and the building - 4 m.

- For the high pressure system the distance is set at 7 m.

SNiP does not regulate the distance between the house and the above-ground structure. However, it establishes a security zone around the onshore gas pipeline - 2 m on each side. The zone must be allocated. Accordingly, when building a house, compliance with this boundary should be taken into account.

Building rules regulate the placement of the gas pipe relative to the window and door opening - at least 0.5 m, as well as the distance to the roof - at least 0.2 m.

SNiP recommendations for gas pipelines are based on fire safety requirements and sanitary standards, so compliance with them is mandatory.

Safety

Typically, the gas pipeline system in an apartment is approved by room planning documents. Options for moving and decorating a gas pipe in the kitchen can be suggested by a master, and the owner will choose the most suitable type of work. They are usually fixed to the walls. But if you use any changes, move or cut the pipe, then you should take into account safety standards.

During repairs, when work is being done on the system wiring, there is a possibility of an accident. Therefore, if moving the pipe is associated only with improving the appearance of the room, then it is better not to implement this idea. It can be used in case of technical malfunctions.

If a decision has been made to make changes to the gas supply system, then the work should be carried out at a time when there are not many people in the room. If the activity is carried out by specialized companies, the owner of the premises can familiarize himself with certificates confirming the skills of the employees. In this case, it is safe to carry out work.

All activities related to cutting, moving, and fastening pipes must be carried out with the provision of a certificate of work done. And only then can you be sure that nothing threatens yourself and your loved ones.

General standards

In order for the kitchen to be a safe place, you need to familiarize yourself with generally accepted rules. They allow you to properly operate the gas system. If everything is properly equipped, the room is safe.

The slabs are installed in rooms whose height is 2.2 meters and above. When the ceiling is sloping, then for the equipment you need to choose that area of the kitchen that corresponds to the standard. The room should have a window with a window, which will allow repair work to be carried out without the use of artificial lighting. This will allow you to ventilate the kitchen. Having ventilation will be a great advantage.

There should be at least 1 meter between the slab and the opposite wall. If the ceilings and walls are made of materials that are prone to burning, then they must be treated with plaster. The stoves can be used in kitchens separated from the hallway by a wall or door.

The pipes must be routed in such a way that there is more than 7 cm between the wall and the slab. There may be a branch to the slab, but only at the level of the connecting fitting. The disconnecting device is mounted above 1.5 meters from the floor, and 20 cm from the side of the stove. A special flexible hose is used to install the equipment. It must be changed, taking into account the advice in the equipment passport.

Masking pipes

It is possible to hide communications if the gas pipe was moved. The rules and requirements must be observed. It is easier to hide the system when making repairs or replacing furniture. There are several proven methods for this. The simplest method is to cover it with furniture. Thanks to pencil cases, you can hide the riser in the kitchen. Communications will not be visible, and besides, free access will be provided to them.

Another good solution is to install a decorative pipe box. This design is inexpensive compared to buying furniture. This method is great for those people who can make such things. To make the box, wooden blocks and a metal profile are used. Decorative panels are fixed on it.

If the room does not allow the installation of bulky structures to hide communications, you can apply decor to the pipes. This will allow you to perfectly decorate them so that the kitchen is always cozy. You can use bright magnets. The painting with unusual patterns looks beautiful.

Regular painting of pipes is suitable so that they match the design of the room. Heat-resistant paint is perfect. A common method of covering pipes is to use drywall. Only any method must ensure the safety of the premises.

How to choose a gas meter

So, if you only have a two-burner gas stove, then a G-1.6 meter will be sufficient. A gas stove consumes approximately 1 m3 per hour. If you also have a gas water heater, then it is better to use a meter marked G-2.5. If there are other gas appliances, then the passport of any gas equipment must indicate the gas consumption per hour. Thus, you can calculate what your planned total gas consumption is and then select a gas meter of the required marking.

But in addition to the estimated throughput of the gas meter, it is necessary to take into account such parameters as:

- Direction of gas flow in the meter

- Overall and connection dimensions

- Availability of temperature reading correction (thermal correction)

According to the direction of gas flow, the meters are left-handed (gas flows from the left) and right-handed (gas flows from the right). When choosing a meter, take into account the relative position of the gas pipe and the devices that you are going to connect.

If you are installing a new gas meter to replace the old one or you already have a gas pipeline installed, then you need to know the center distance (A) and thread diameter (F) of the connecting pipes. If the discrepancy in thread diameter can be easily compensated by selecting adapters, then if the interaxial distance does not match, you will have to move the gas pipe or, more likely, buy another meter.

You also need to take into account the distance (E) from the axis of the connecting pipe to the rear wall of the meter because the gas pipe runs at a certain distance from the wall and the meter may not fit in size.

Overall dimensions of the meter

Meters with automatic temperature correction (thermal correction) are initially more expensive than similar meters without thermal correction, but in the future they allow you to save on gas costs. The thing is that meters without thermal correction are designed for gas metering under normal conditions - with an ambient temperature of +20 ° C and a pressure of 760 mm Hg. Art. If the gas is colder, for example in winter, then its density increases, and in summer, on the contrary, it decreases. An increase in gas density leads to the fact that the consumer receives more gas and pays less according to the meter. Therefore, for those who have a gas meter located outside, the temperature coefficient is used in the calculation. In the middle zone for the summer months it is 0.96 - 0.98, and in winter it is about 1.15, and on average for the year it is about 1.1. The coefficient is applied monthly, without taking into account the actual temperature of the supplied gas. The volume of gas payable for a month is calculated as the product of the volume of gas on the meter for a given month and the corresponding temperature coefficient. To avoid disagreements when paying for gas, it is better to install a meter with a thermal corrector, which will automatically determine gas consumption in accordance with its actual temperature. This is especially true for those who consume increased volumes of gas, for example, for heating a cottage and heating water.

For those who have a meter in their apartment, the use of a thermal corrector is also relevant and allows you to save money. After all, in fact, the temperature in the kitchen is higher than +20°C, especially when the gas stove is on, so the density of the gas is lower than normal. Consequently, the thermal corrector will “slow down” the meter.

Reasons for moving the gas pipe in the kitchen

To move a gas pipe, contact the Gorgaz authorities or special authorized organizations. When filling out an application, service representatives are always interested in the reasons for the change in communications.

Among the main reasons when it may be necessary to change the pipe layout are:

- replacement of old equipment;

- major renovations in the kitchen and the owner’s desire to change the placement of the stove, boiler, gas meter;

- moving the pipe under the tabletop;

- correcting design errors in new buildings;

- purchasing new kitchen equipment with modern built-in equipment.

Regardless of the reason, all of the above actions require approval from the city gas service.

Important! In a Khrushchev or other apartment, altering gas pipes without the appropriate permit is prohibited and faces administrative liability in the form of a fine.

To avoid such a situation, you should immediately contact specialized organizations, whose employees will help you draw up a transfer project and issue permission for its implementation.

Technical features of the work

A decision on whether a specific gas pipe can be moved can only be made by the gas service of the city (district) under whose authority the apartment is located. Even minimal trimming of any element of the gas pipeline requires permission from the relevant department.

Features of gas pipeline placement

Since any work related to gas communications falls into the high-risk category, only specialized specialists with appropriate qualifications have the right to perform them. The specialist must have a valid license and certificate.

Documentation procedure

Since independently moving a gas pipe in an apartment or on a site is punishable by a fine, the very first step if you want to make changes is to obtain the appropriate permission.

Step-by-step process for approving a transfer project:

- Collection of the necessary package of documents (passport, title documents for the apartment, redevelopment plan).

- Visit to the gas service office at your place of registration and submit an application. The application indicates the address and describes the details of the request itself.

- Departure of a specialist to inspect the facility. This is one of the most important points, since based on the results of the inspection it will be clear whether the implementation of the planned project is possible. Plans are often changed because the desired changes do not meet security requirements.

- Approval of the final transfer scheme, drawing up an estimate. It is impossible to give an exact price, since it is individual for each application and depends on the volume and complexity of the work.

- If the service’s decision is positive, the applicant pays for the service and discusses the time for the work with the specialist.

Project approval takes on average 5 working days. The process may be delayed due to the submission of an incomplete package of documents, or if it is necessary to make changes to the scheme. If the transfer violates the standards, the gas service refuses to change the location of the outlet pipes.

SNIP requirements

The placement of gas pipes is carried out in strict accordance with certain standards and requirements. To shorten the approval period, it is better to familiarize yourself with these points in advance by studying the current version of the SNiP document 2.04.08-87.

Options for proper pipe transfer

Among the most important norms and rules for installing gas equipment, which must be observed in residential premises, it is worth noting:

- Accessibility to any element of the gas supply system.

- The minimum ceiling height for installing a gas stove is 2.2 meters. It is also necessary to have a window or an opening flap on the ventilation duct.

- The permissible number of burners depends on the volume of the kitchen (two for 8 m³, three for 12 m³ and four for 15 m³). If, in addition to the stove, you plan to install a boiler, you should add another 6 m³ to the calculated volume.

- It is prohibited to install the equipment in the bathroom, basement, or near a window.

- It is recommended to install the equipment near a wall made or finished of non-combustible material. The distance from the stove to the wall is 7 cm, from the capacitive boiler - 10 cm.

- The passage in front of the stove is at least 1 meter.

Important! Do not remove the stopcock. Moving it also requires permission and approval of the project.

Requirements for internal gas pipelines

Installation of internal gas pipelines must comply with certain requirements. Installation at your own discretion or based on the principle of ease of installation is strictly prohibited. The most important issues include:

Requirements for a gas pipeline

- Pipelines are introduced directly; laying a gas pipeline through other premises is prohibited.

- It is prohibited to cross air ducts that disrupt the operation of the building’s air-technical components.

- The maximum permitted pressure is 3 kPa.

- In places where pipelines cross corridors, installation is carried out at a height of at least 2.2 m, but not less than 10 cm from the top of the pipe to the ceiling.

- Gas pipelines must be firmly attached to the walls using clamps, hooks or brackets.

- Free sagging of the pipeline due to its own elasticity is prohibited.

- It is not allowed to use one lowering device for several devices; each of them must have its own.

The kitchen area must correspond to the number of burners on the stove:

- for 2 burners you will need 8 m2;

- for 3 burners - 12 m2;

- 4 burners will require at least 15 m2.

Requirements for the room in which the consumption device is located:

Gas inlet

- well lit;

- it must have a ventilation duct. Special ventilation units can be used;

- the window unit must be equipped with a window (transom).

The installation and use of internal gas pipelines must be carried out in compliance with all safety requirements stipulated by SNiP and GOST. Any violations are subject to criminal or administrative prosecution, depending on the severity of the violations detected.

Main stages of work

Independent intervention in the pipeline is strictly prohibited, even if we are talking about a flexible line with which household gas appliances are connected. The process of moving any gas pipe in an apartment is carried out in several stages, each of which must be carried out exclusively by an employee of the gas company.

Preparatory activities

After the project has been agreed upon, it is already known which sections of the pipeline will be changed, what the specialist will cut, where to add and where to move. The visit of a specialist or team is agreed upon in advance, but most often the work is carried out within a week after the permit is issued.

Proper preparation is the key to quality work

Before the technician’s visit, the room should be prepared. To ensure high-quality work, unimpeded access to gas communications must be ensured. It is also worth taking care of furniture and equipment that could be damaged by workers during dismantling/installation or welding work.

Craftsmen, as a rule, come with their own consumables, but this is discussed when setting the date for the transfer. More often than not, the customer may be required to independently purchase flexible hoses, water heaters and other materials. The customer selects and purchases the equipment to be installed independently.

Installation work

The actual process of transferring a gas pipe is a set of standard sequential actions:

- Shut off the gas supply and blow through the pipes with air to remove residual methane.

- Dismantling the section of pipe of interest and closing the junction with the riser using welding or a plug.

- Using a drill, prepare a hole in the place where the pipe is being transferred. It will be used to attach a new element.

- A new piece of pipe is welded to the hole on one side, and a shut-off valve is installed on the other.

- To seal the joint, tow is used.

- Connecting gas equipment.

- Restoring gas supply, checking the quality of connections, absence of leaks.

Master's work

Upon completion of installation, the specialist must provide the customer with a certificate of completion of work.

Laying gas pipelines

General instructions

6.1.

The standards of this section apply to the design of gas pipelines and gas equipment located inside buildings and structures for various purposes. The possibility of installing gas equipment and laying gas pipelines in specific buildings should be determined in accordance with the building codes and regulations for the design of the relevant buildings. 6.2. Gas pipelines laid inside buildings and structures

, as during construction, should be made of steel pipes that meet the requirements of Section. 11. To connect mobile units, portable gas burners, gas appliances, instrumentation and automation devices, it is allowed to provide rubber and rubber-fabric hoses. When choosing hoses, one should take into account their resistance to the transported gas at a given pressure and temperature.

6.3. Pipe connections should usually be made by welding. Detachable (threaded and flanged) connections may be provided only in places where shut-off valves, gas appliances, instrumentation, pressure regulators and other equipment are installed. The installation of detachable connections of gas pipelines should be provided in places accessible for inspection and repair.

6.4. The laying of gas pipelines inside buildings and structures should, as a rule, be open. It is allowed to provide for the hidden installation of gas pipelines (except for LPG gas pipelines and gas pipelines inside residential buildings and public buildings of a non-industrial nature) in the grooves of the walls, covered with easily removable shields that have holes for ventilation.

6.5. In the production premises of industrial enterprises, including boiler houses, buildings of consumer service enterprises for industrial purposes and public catering, as well as laboratories, it is allowed to lay gas supply pipelines to individual units and gas appliances in the floors of a monolithic structure, followed by sealing the pipes with cement mortar. In this case, it is necessary to provide for painting the pipes with oil or nitro-enamel waterproof paints. At the points where the gas pipeline enters and exits the floor, cases should be provided, the ends of which should protrude above the floor by at least 3 cm.

6.6. In the production premises of industrial enterprises, it is allowed to lay gas pipelines in the floor in channels covered with sand and covered with slabs. The design of the ducts must exclude the possibility of gas spreading under the floor. Laying gas pipelines in channels is not allowed in places where, due to production conditions, substances causing corrosion of pipes may enter the channels.

6.7. Channels intended for laying gas pipelines, as a rule, should not intersect with other channels. If it is necessary to cross channels, provision should be made for the installation of sealing bridges and the laying of gas pipelines in cases made of steel pipes. The ends of the cases must be extended beyond the jumpers by 30 cm in both directions.

6.8. When laid together with other pipelines on common supports, gas pipelines should be placed above them at a distance that ensures ease of inspection and repair.

6.9. The laying of gas pipelines in transit through industrial premises where gas is not used is allowed for low and medium pressure gas pipelines, provided that no fittings are installed on the gas pipeline and unhindered 24-hour access to these premises is provided for personnel servicing the gas pipeline.

6.10. It is not allowed to provide for the laying of gas pipelines in premises classified as explosion and fire hazard categories A and B; in explosive zones of all premises; in basements; in warehouse buildings of explosive and flammable materials; in the premises of substations and distribution devices; through ventilation chambers, shafts and channels; elevator shafts; waste disposal rooms; chimneys; through rooms where the gas pipeline may be subject to corrosion, as well as in places of possible exposure to aggressive substances and in places where gas pipelines may be washed by hot combustion products or come into contact with heated or molten metal.

6.11. For internal gas pipelines experiencing temperature effects, it is necessary to provide for the possibility of compensating for temperature deformations.

6.12. For gas pipelines transporting wet gas and laid in rooms where the air temperature may be below 3 °C, thermal insulation made of non-combustible materials should be provided.

6.13. Shut-off devices on gas pipelines in production premises of industrial and agricultural enterprises, industrial consumer service enterprises should be provided with:

- at the gas pipeline entrance indoors

- on branches to each unit

- in front of burners and igniters

- on purge pipelines, at places where they are connected to gas pipelines.

If there is a gas meter or gas control unit inside the room, located at a distance of no more than 10 m from the gas pipeline entry point, the shut-off device at the input is considered to be a valve or tap in front of the gas pipeline or meter. Installation of fittings on gas pipelines laid in channels, in concrete floors or in wall grooves is not allowed.

*Sections, paragraphs, tables, formulas to which changes have been made are marked in these building codes and regulations with an asterisk.

6.14.* The need to meter gas consumption and the choice of metering system at gas supply facilities must be determined in accordance with the instructions of the “Rules for the use of gas in the national economy” approved by the Ministry of Gas Industry and the “General Provisions on the Procedure for Accounting and Control of Fuel, Electrical and Heat Energy Consumption for Industrial , transport, agricultural and public utility enterprises and organizations” approved by the State Committee for Science and Technology, the State Planning Committee of the USSR, and the State Standard. According to the decision of the executive authorities of the constituent entities of the Russian Federation on the procedure for recording gas consumption by consumers and regulating gas prices in gasified residential buildings, as well as during gasification of greenhouses, bathhouses and other household buildings, it must be possible to record the gas consumption of each subscriber by installing it on the gas pipeline (in apartment, individual house) gas consumption meter - meter.

6.15. Gas flow metering devices should be placed in gas distribution centers or gasified premises. It is allowed to place gas flow metering devices in other rooms of at least II degree of fire resistance that have exhaust ventilation. No more than two gas meters can be installed in parallel on one gas pipeline.

6.16. Laying gas pipelines

in residential buildings should be provided for non-residential premises.

In existing and reconstructed residential buildings, it is allowed to provide for the transit laying of low-pressure gas pipelines

through living rooms if no other installation is possible. Transit gas pipelines within residential premises should not have threaded connections or fittings. It is not allowed to provide gas pipeline risers in living rooms and sanitary facilities.

6.17.* The installation of shut-off devices on gas pipelines laid in residential buildings and public buildings (with the exception of public catering establishments and consumer service enterprises of an industrial nature) should be provided for:

- to disconnect risers serving more than five floors

- in front of the meters (if a disconnecting device at the input cannot be used to turn off the meter)

- in front of each gas appliance, stove or installation

- on branches to heating stoves or appliances in accordance with the requirements of clause 6.46.

On gas supply pipelines to cooking boilers, restaurant stoves, heating stoves and other similar equipment, it is necessary to install two shut-off devices in series: one to turn off the device (equipment) as a whole, the other to turn off the burners. On gas supply pipelines to gas appliances that have a shut-off device in front of the burners in their design (gas stoves, water heaters, stove burners, etc.), it is necessary to install one shut-off device. The need to install devices for disconnecting risers (entrances) of 5-story or less residential buildings is decided by the design organization depending on local specific conditions, including the number of floors of buildings and the number of apartments to be disconnected in the event of emergency and other work. Devices provided for disconnecting risers (entrances) should be installed, whenever possible, outside the building.

6.18. The distance from gas pipelines laid openly and in the floor indoors to building structures, process equipment and pipelines for other purposes should be taken from the condition of ensuring the possibility of installation, inspection and repair of gas pipelines and fittings installed on them, while gas pipelines should not cross ventilation grilles, window and doorways. In industrial premises, it is allowed to cross light openings filled with glass blocks, as well as lay a gas pipeline along the sashes of non-opening windows.

6.19. The minimum clear distances between a gas pipeline laid along the wall of a building and communication and wired broadcasting structures should be taken in accordance with the “Safety Rules for Work on Cable Communication and Wired Broadcasting Lines” approved by the USSR Ministry of Communications in the prescribed manner.

6.20. The distances between gas pipelines and electrical utilities located indoors, at points of convergence and intersection, should be taken in accordance with the PUE.

6.21. The laying of gas pipelines in places where people pass should be provided at a height of at least 2.2 m from the floor to the bottom of the gas pipeline, and if there is thermal insulation - to the bottom of the insulation.

6.22.* Fastening of openly laid gas pipelines to walls, columns and ceilings inside buildings, frames of boilers and other production units should be provided using brackets, clamps, hooks or hangers, etc. at a distance that allows for inspection and repair of the gas pipeline and the fittings installed on it. The distance between the support fastenings of gas pipelines should be determined in accordance with the requirements of SNiP 2.04.12-86.

6.23. The laying of gas pipelines transporting wet gas (except for the vapor phase of low-pressure LPG) should be provided with a slope of at least 3 ‰. If there is a gas meter, the slope of the gas pipeline should be provided from the meter.

6.24. Vertical gas pipelines at intersections of building structures should be laid in cases. The space between the gas pipeline and the case must be sealed with tarred tow, rubber bushings or other elastic material. The end of the casing must protrude above the floor by at least 3 cm, and its diameter must be taken from the condition that the annular gap between the gas pipeline and the casing is at least 5 mm for gas pipelines with a nominal diameter of no more than 32 mm and at least 10 mm for gas pipelines of larger diameter.

6.25. Internal gas pipelines, including those laid in channels, should be painted. For painting, waterproof paints and varnishes should be used.

6.26. Gas appliances and gas burners should be connected to gas pipelines, as a rule, with a rigid connection. Connection to the gas pipeline of gas appliances, laboratory burners, as well as portable and mobile gas-burning devices and units installed in the workshops of industrial enterprises may be provided after the shut-off valve with rubber-fabric hoses. Rubber-fabric hoses for connecting household gas appliances and laboratory burners should not have butt joints.

6.27. On gas pipelines of industrial (including boiler houses), agricultural enterprises, consumer service enterprises of a production nature, purge pipelines should be provided from the sections of the gas pipeline most remote from the point of entry, as well as from branches to each unit before the last shut-off device along the gas flow. It is allowed to combine purge pipelines from gas pipelines with the same gas pressure, with the exception of purge pipelines for gases with a density greater than that of air. The diameter of the purge pipeline should be at least 20 mm. After the shut-off device, a fitting with a tap for sampling should be provided on the purge pipeline, if a fitting for connecting an igniter cannot be used for this purpose. In some cases (for example, for cutting and welding stations, small industrial furnaces) with a supply gas pipeline with a diameter of no more than 32 mm, it is allowed to install a shut-off device with a blind fitting instead of purge pipelines.

6.28. The distance from the end sections of the purge pipelines to the intake ventilation devices must be at least 3 m. If the building is located outside the lightning protection zone, the terminals of the purge pipelines should be grounded.

Free advertisements in the industry. Great plan: sell something you don't need.

The product range of the manufacturer Gruen Pumpen includes barrel pumps for chemical acids, alkalis, solutions and reagents.

Application of flexible hose

Flexible hoses are used exclusively for connecting a gas stove. Its use as a pipeline element is prohibited.

The market offers a large number of types of this product. For the gas system, 3 types are used:

- Rubber-fabric is the cheapest option with a short service life (on average 5 years), characterized by an insufficient level of rigidity and a low permissible temperature. At the same time, it provides good electrical insulation, flexibility and is available in a wide range.

- Rubber with metal braid - the optimal combination of quality, price and service life. The hose is made of vulcanized rubber, reinforced with textile thread and externally trimmed with metal braid. It is reliable and easy to install.

- Bellows - most often used for installing gas equipment. The higher price is justified by a service life of about 30 years, reliable protection against mechanical damage, electrical insulation and resistance to chemicals.

Using a flexible hose to connect devices

When choosing, you should consult with specialists who will install the equipment.

Installation of a gas boiler in combined kitchens

In modern construction, the arrangement of studio apartments or layouts in which the living room and kitchen are combined into one large space is actively practiced. Of course, such a solution has a lot of advantages - for example, it opens up a large portion of free space, which is perfect for implementing all kinds of design ideas.

The problem is that gas services regard such layouts as residential, so the installation of any gas equipment in them is prohibited. In studios this problem cannot be solved, but when combining a living room with a kitchen, options are possible.

So, it is quite possible to call the room “kitchen-dining room” during the paperwork process. Thanks to this name, the combined room will not be considered residential, so you can safely install a gas boiler in it. Another option is the installation of a sliding partition between the rooms or a complete re-issuance of all certification papers.

Options for hidden gas pipe placement in the kitchen

The easiest way to hide gas communications is during the repair or replacement of a kitchen unit. When masking pipes, it is also important to adhere to the above rules and requirements.

The most popular methods of hidden pipe placement:

- shelter with furniture - pipes are hidden under the furniture, while providing easy access;

- installation of a decorative box made of wood or metal profile;

- applying decor to the pipes, if the kitchen area allows (bright magnets, painting);

- regular painting of pipes to match the color of the overall style of the room;

- plasterboard structures.

Masking communications

Regardless of the chosen method of disguise, the main rule is to ensure safety.

Requirements for premises and rules for installing gas equipment in a residential building

1. In the room where gas-using equipment is installed, it is allowed to use window openings as easily removable enclosing structures, the glazing of which must be at least 0.8 m2 - with a glass thickness of 3 mm, 1 m2 - with a glass thickness of 4 mm, 1.5 m2 - with a glass thickness of 5 mm .

When installing equipment with a power of more than 60 kW or placing equipment in the basement or ground floor of a building, regardless of its power, window openings must have a glazing area of 0.03 m2 per 1 m3 of room volume and structures enclosing them from adjacent rooms.

Safety measures and checking the integrity of the gas pipeline

Working with gas distribution is always risky. Therefore, you should not perform it yourself, and it is also better to take care that there are no people in the room during the period of such actions.

How to hide communications in the kitchen

It is important to familiarize yourself with the documents confirming the qualifications of the workers who will carry out the transfer of gas pipes. After completing the work and checking the integrity of the gas pipeline, the owner of the apartment has the right to demand a certificate of completion from the master. This is the only way to be sure of personal safety.

Checking the entire system for leaks and general performance

The final stage of transferring gas pipes is extremely important - checking the overall performance and tightness of the system. Everything must be carried out in accordance with the design, all fittings are tightened, properly sealed, etc. Before turning on the gas equipment, the gas pipeline system is checked for leaks.

The tightness of gas pipe connections is checked using a soap solution

Testing is carried out in the traditional old-fashioned way using a simple soap solution, which is prepared on the basis of water and any soap. You need to beat up a certain amount of foam and apply it with a sponge or brush to new gas pipeline connections, as well as to possible leaks. Bubbles that appear at the joints of the units after gas is supplied to the system (the valve is opened) indicate poor quality of the seal . In this case, the work on sealing the joints will have to be redone.

The tightness of the gas system can be checked using a portable gas analyzer or gas leak detector, which determines the concentration of gas in the air. Representatives of the gas service should have similar devices.

There are special devices for monitoring gas leaks

Hands off!

First, about the prohibitions. Yes, dear reader, I have no doubt that you are full of enthusiasm and are eager to carry out the transfer of the gas pipe in the kitchen yourself. However, please take the restrictions I have listed as seriously as possible:

- You cannot move the gas riser in the kitchen. All you can do is change where the tap attaches to it or the length of that tap;

Relocation of the riser requires mandatory calculation and approval. Usually it is refused.

- You cannot use polyethylene or plastic pipes indoors . SNiP 2.04.08-87 in paragraph 4.85 directly states that polyethylene is prohibited for laying in residential buildings, and in paragraph 6.2 it states what materials should be used;

Excerpt from SNiP: gas pipelines made of steel pipes should be installed inside buildings and structures. To connect gas appliances, it is permissible to use rubber or rubber-fabric hoses (read: reinforced gas hoses). However, it is still recommended to use hard eyeliners.

- Do not close general plug valves, ball valves and valves on gas supply inlets and risers . If at the time you turn off the gas, someone is cooking food, the fire will go out, and after starting it will continue to flow into the kitchen. The result of such a development of events is usually described in TV reports by random witnesses: there is no one among the residents to tell about it;

Captain Obviousness suggests: for any work related to disconnecting the riser and carried out by gas service specialists, it is necessary that the residents of all apartments be at home. When launched, all residents are notified about it personally.

The gas taps in the entrance must not be touched. Categorically.

- Finally, the main thing: PB (safety rules) 12-368-00 prohibit any gas-hazardous work carried out by persons who have not undergone instructions and exams on safe work methods .

Simply put: only a representative of Gorgaz or a licensed gas equipment servicing company should connect any gas appliances.

What will happen

If you are incredibly lucky and, without the necessary knowledge and practical experience, prevent a gas leak, your amateurishness will be revealed during the first scheduled inspection of gas equipment by representatives of the gas service.

The consequences are unpredictable: they can either turn a blind eye to the work you have done or draw up a report on an administrative offense that endangered the life and health of people.

Worst case scenario... Comrades, I won’t spoil your mood. Everyone knows what a gas explosion in a residential building is.

Rules for installing a gas stove in an apartment or private house

Gasification of a private house with liquefied petroleum gas (LPG) or, if there is a nearby main pipe, connecting the house to natural gas solves several problems at once: it provides gas for a hob in the kitchen, a heating boiler or a water heater for a hot water supply system.

But in order to make the use of gas useful and safe for yourself, your family and home, you must comply with a number of requirements when installing gas equipment, as well as the rules for its operation.

It is the conditions for the correct installation of the stove, heating boiler and other equipment that will be discussed in the article:

Just shhh

My further recommendations are somewhat akin to the “bad advice” of Grigory Oster: I am going to talk about what, strictly speaking, should not be done. However, alas, we live in a real and far from perfect world.

So, what to do if you still really can’t wait to move the gas stove or shorten the gas pipe outlet?

Theory

No, no, mon ami, don’t rush to pick up the keys and hacksaw. First, a little tedious, but necessary to familiarize yourself with the regulatory requirements.

Yes, yes, I know it's ugly. Let's not rush.

The standards for gas pipes in the kitchen are set out in the document I have already mentioned - SNiP 2.04.08-87.

- Gas distribution in a residential building should be carried out mainly by welding. Threaded and other detachable connections are permissible only at connections to shut-off valves, gas meters and consumer devices;

From a practical point of view, this means for us that the internal gas pipeline in the apartment cannot be assembled from pieces. It’s really not worth climbing to a gas pipeline with welding without being able to completely turn it off. One more nuance: this paragraph of SNiP does not completely prohibit the use of dismountable connections, but only recommends refraining from them.

- All detachable connections must be made in places accessible for inspection and repair. There is no need to hide them in non-dismountable kitchen furniture;

- The gas pipe must be laid, as a rule, openly;

- If there are several gas consumers, shut-off valves must be installed in front of each of them;

- In places where people pass (for example, above a door or in a hallway), the gas pipe must pass at a height of at least 220 centimeters. What the instructions are related to - I think there is no need to explain;

- It is recommended to paint steel internal gas pipelines to protect against corrosion. At the same time, the decor of the gas pipe in the kitchen or hallway must be waterproof.

The paint must protect the gas pipeline from contact with water.

Practice

After the tap

First and foremost: in the vast majority of cases, there is no need to saw or cut anything. To move the slab, it is enough to extend the line between it and the shut-off valve. To hide an untidy steel liner, you can simply build a cabinet around it (of course, collapsible or with wide-opening doors).

How can you connect a stove or other gas appliance without violating the requirements of SNiP?

Corrugated stainless pipe. In this case, the key requirements will be met:

- The supply to the device will be rigid (a corrugated stainless pipe clearly has nothing to do with flexible hoses);

- The wiring will be done with a steel pipe. Who will say that stainless steel is not steel?

Corrugated stainless steel on the connection to the stove.

When corrugated stainless pipe had not yet appeared on the Russian market, I successfully transferred gas stoves with an oxygen or acetylene hose on steel or brass fittings. An aluminum clamp for a screwdriver was used to secure the hose to the fitting.

To transfer the slab, an oxygen hose with fittings was used.

Stainless steel connections are mounted on compression fittings: the pipe is inserted into the fitting with a loosened union nut, after which it is tightened and compresses the pipe with a silicone seal.

The threads on the connections of the fittings with the stove pipe and the tap are wound with FUM tape.

When starting up, all detachable connections must be checked for gas leaks: soap foam is applied to each of them with a shaving brush. If it bubbles, the connection needs to be rechecked.

Checking the connection with soap foam.

Do not check connections with a lit match. It's not a matter of safety: for a gas to explode, it needs to be mixed with air in sufficient concentration. The fact is that in low concentrations, with minor leaks, it simply will not ignite.

Replacing the faucet

Soviet-style gas plug valves are not particularly easy to use and require regular maintenance. In particular, the plug must be generously lubricated. The lubricant fills the grooves, preventing gas leaks, and reduces the force required to turn the plug.

Is it possible to change the faucet yourself?

Let's just say: I don't recommend doing this. But while working as a plumber, he changed gas taps, without turning off the riser. The fact is that the excess gas pressure in the pipes of a residential building is minimal:

| Consumer | Excess pressure (kgf/cm2) |

| Industrial enterprises | 6 |

| Industrial consumer service enterprises | 3 |

| Residential buildings | 0,03 |

| Public buildings | 0,05 |

It is easy to plug a gas pipe in a residential building with your finger.

If so, the rate of gas flow from the pipe will be minimal, and the pressure will not interfere with installing a new valve instead of the old one.

The replacement algorithm looks like this:

Replacement of gas tap.

All work is carried out only with the circuit breakers in the electrical panel turned off and the windows wide open. Violation of this simple and clear rule can lead to a gas explosion.

What should I replace the gas tap with? On a modern cork. Its purpose specifically for gas is indicated by the yellow markings on the handle.

Installation of apartment wiring

Apartment wiring consists of two parts:

VDGO breeding scheme

- Distribution gas pipeline.

- Lowering to consumption devices.

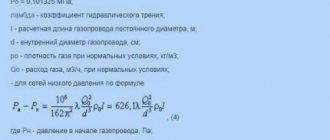

Gas distribution pipelines are located with a slight slope (0.001) if wet gas is transported. The slopes to the devices are made vertical. At the ends of the drops, taps and pipes are installed to connect gas-using equipment.

Steel pipes are used for installation. All pipe connections are made by welding; threaded connections are allowed only at the points of connection of consumer devices or shut-off valves.

An important and responsible component of the system are control devices that lower the gas pressure to the standard value in gasified buildings. They come in cabinet design (SHRP), or in the form of GRU - gas distribution devices, which are open enclosed installations.