Types of pipe cutters by drive type

Pipe cutters for steel pipes are divided into four types according to the type of drive:

- Manual.

This is the simplest pipe cutter design, the operator does not need any special skills to cut steel pipes with a manual pipe cutter. They are easily attached to the cutting area; the operator makes several turns around the pipe and a fragment with a clear cut is obtained. Pros. Easy to use, low price, ideal for one-time local repair work. Minuses. Cutting requires significant physical effort from the operator and is not suitable for intensive work. - Electrical.

Suitable for heavy-duty work, cutting pipes of almost any diameter. A current source of 220/380W is required for operation. Pros. They calmly cope with heavy loads, cut pipes without burrs, and can simultaneously cut a chamfer while cutting. Minuses. Higher cost compared to manual ones. - Pneumatic.

Pipe cutters with pneumatic drive are professional equipment. Pros. They calmly cope with heavy loads, cut pipes without burrs, can simultaneously chamfer for welding, and cut pipes of any diameter and with any wall thickness. Minuses. Higher cost compared to manual pipe cutters, large dimensions and heavy weight; operation requires an expensive compressor. - Hydraulic.

They work on the principle of liquid pressure and require a pump to operate. Pumping through the pump, the liquid acts on the piston and sets the pipe cutter into action. Tools of this class are more powerful than manual ones, but they are inferior to electric devices in all respects. A distinctive feature of hydraulic pipe cutters is the drive, which allows you to cut pipes in confined spaces and even under water, which is very important for the installation of underground communications.

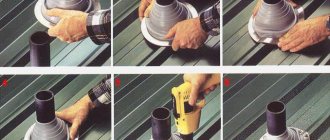

Rice. Types of pipe cutter drives

The choice of pipe cutter depends on the scope of work: for a one-time use, a hand tool will suffice, but for large projects on laying communications it is better to use an electric or pneumatic pipe cutter.

For industrial production, where there are already compressors, pneumatic pipe cutters for steel pipes are most often used. Hydraulic tools are used where high torque is needed, such as cutting thick-walled pipes.

Kinds

Tools can be classified according to the type of drive, design features and cutting methods.

By drive type

In accordance with this parameter, four types of instruments are distinguished.

Electrical

Electric pipe cutters are used for cutting pipes with high strength characteristics and thick walls. Power supply from the electrical network is required.

Electric pipe cutter Exact 280E System. Photos Tehnoveld

The efficiency of DC power is evident when processing pipes with a diameter of up to 40 mm . Electrical safety excludes work in conditions of high humidity. The best representatives of this type are the brands “Ridgid”, “Rems”, “Exact” . Models Exact Pipecut 200; Exact 280E System.

Rechargeable

In the absence of an electrical network, the battery acts as a source of energy. Thus, battery models have autonomy and mobility.

Hydraulic

Hydraulic pipe cutters are less productive than electric ones. However, the power characteristics allow cutting large diameter pipes. Hydraulic fluid creates uniform pressure over the entire drive area of the cutting tool. The reciprocating movement of the fluid is created by a piston pump.

The possibility of its manual drive allows it to be used in places where there is no power supply. On the Russian market, hydraulic pipe cutters are represented by the brands “Reed”, “Husqvarna”, “Milwaukee” and others. Example of a REED UPC 616H hydraulic pipe cutter model.

Pneumatic

Compressed air is used to drive the actuator . The production of compressed air is carried out by a compressor. It is clear that a pneumatic pipe cutter is quite cumbersome and is not used for domestic needs.

Pneumatic pipe cutter EXACT AIR360 System. Photo VseInstruments.ru

It is characterized by low noise in operation only the operating compressor makes noise. They have versatility in choosing pipe materials. Pipe cutters “P”, “Reed” and others are equipped with a pneumatic drive. An example of a REED UPC 648A pneumatic pipe cutter model.

Manual

Manual pipe cutters are mainly used at home. It is possible to activate such a tool using physical force. In some cases, not small. Therefore, work with such equipment is limited to a small number of cuts and is used for minor plumbing repairs.

Hobbi manual pipe cutter for pipes made of non-ferrous metals with a diameter from 3 mm to 28 mm. Antalex Photos

Recently, plastic pipes are often used in residential premises. A manual pipe cutter is the best option for piping. Almost all brands include manual pipe cutters in their range. As an example, a manual pipe cutter for plastic pipes is Ridgid P-TEC 5000.

By type of design

The design features of pipe cutters make it possible to divide them into groups, where the difference in the cutting method is clearly visible.

Roller

The main design element is the rotating rollers. Designed for manual cutting of steel pipes . Depending on the diameter of the pipes, the number of rollers varies from one to four . Smaller diameters are cut with a pipe cutter with fewer rollers. An example of a roller pipe cutter SIBRTECH 78715 25-75 mm.

Roller pipe cutter Pro Fit. Photos Promsnab

It should be noted that the drive handle of a pipe cutter with one roller must be rotated a full turn when making a cut. With more rollers, the rotation angle can be smaller, which creates advantages when working in tight spaces. An example is a Reed brand pipe cutter model H4S .

After each revolution, a special screw creates additional compression . Thus, a through cut is gradually made. At the end of the technological operation, small burrs may remain on the cut surface. To remove them, roller pipe cutters are equipped with deburring devices.

Telescopic

A subtype of roller pipe cutters are telescopic. The main difference is that with roller cutting tools the block of cutting tools is stationary, while with telescopic ones the cutting blade of the roller has the ability to be attracted to the pipe body. An example of a telescopic version is TUBE CUTTER 35 PRO.

Neptun IWS 6-63 telescopic pipe cutter for corrugated pipes. Photo Petrovich

Scissor

Used for cutting standard plastic pipes. By type, these are ordinary scissors a sharpened blade is located on one of the levers .

Scissor pipe cutter for polymer pipes NEO 0-45 mm. Photo VseInstruments.ru

Soft plastic is cut using pressure using a sharp blade. It is not recommended to cut thin-walled plastic with a pipe cutter, as it may crack due to insufficient strength. An example of the FIT 70985 scissor pipe cutter model.

Guillotine

To obtain a perfect cut without chips and burrs, this type of pipe cutter is one of the most preferred. It is made in the form of a frame , which serves as a guide for the cutting blade. of the blade is given by the lead screw to which it is attached.

Guillotine pipe cutter Rothenberger ROCUT XL 315. Photo AllInstruments.ru

Strictly perpendicular entry into the pipe creates uniform pressure over the entire cutting surface . The obtuse angle blade distributes the force without creating a sudden increase in force. An example of a pipe guillotine cutter from REED, model HPC8TN.

Ratchet

The ratchet mechanism built into the design allows you to regulate the cutting force , which creates comfortable working conditions. The rest of the design is similar to a scissor pipe cutter.

Ratchet pipe cutter EXPERT 42 mm. KRAFTOOL. Photo VseInstruments.ru

The main thing in the work is to maintain the perpendicularity of the cutting edge of the pipe surface so that the cut does not turn out oblique and does not have to be modified. Example of a ratcheting pipe cutter Expert 42 mm Kraftool .

Incisive

Here the cutting tools are steel hardened and sharpened discs . They are built into the steel body of the pipe cutter.

Pipe cutter REMS PAC CT 113100. Photo 220 Volt

The position of the discs is set depending on the pipe size. Application is limited to pipe diameters up to 100 mm . Examples of pipe cutters: manual for steel pipes 113100 Rems; 72035 6-38 MASTERCOOL.

Chain

require minimal work space to function . The design does not provide rotating handles, and there are no volumetric tool modules. Here is a chain in the form of cutting discs sequentially attached to it step by step.

Chain pipe cutter NEO. Photo 220Volt

The chain is tightened around the pipe and the pipe is compressed by force (mechanical or any other). The pipe is not cut with such a tool, but is, as it were, pressed through. Example of a chain pipe cutter: Rothenberger article 70285.

Cutting methods

According to the methods of cutting pipes, they can be divided into four groups.

Mechanical

During installation and dismantling work, all types of pipe cutters described above are used. The design features make it possible to use them in cramped conditions . Depending on the size of the pipes and the scope of work, they can be manual or have electric, hydraulic and pneumatic drives.

Other types of equipment for mechanical pipe cutting are varied . These can be hand hacksaws for metal, hacksaws, grinders, circular saws, band saws for large diameter pipes, as well as mechanical equipment such as lathes and milling machines.

Laser

concentrated in the beam ensures the melting of the metal. The molten metal is then blown out by a stream of gas. In this case, only the cutting line is heated ; the rest of the pipe is not exposed to heat and therefore is not deformed.

The cutting width is minimal. Using control programs, you can cut profile pipes. The type of material and physical properties (fragility, ductility) do not play a special role in the cutting process.

Plasma

A jet of ionized gas (air, nitrogen, oxygen, argon and others) comes into contact with the metal, and the metal evaporates almost instantly .

Pipe cutter for plasma cutting of pipes TR-2. Photo AVERS TECHNO

The high temperature of the jet makes it possible to make the cutting speed quite high, which makes the plasma pipe cutter a highly productive piece of equipment . The software makes it possible to obtain any shape of pipe cutting.

Cumulative

These are single use devices. Pipe cutting is based on the use of explosion energy . The concentration of explosion energy in the desired direction is ensured by the design of the charge of such a pipe cutter. When an explosion occurs, a cumulative effect is created , due to which the pipe is cut.

The explosion has virtually no effect on the surrounding structural elements. Such pipe cutters are used in the oil and gas industry when cutting pipes during emergency and repair work.

For steel, aluminum, cast iron pipes and more

Not all pipe cutters are suitable for cutting pipes made of a particular material. Some hand tools are only designed for plastic pipes . Others cut steel pipes but leave burrs and warp copper and aluminum pipes. The cutting tool of many pipe cutters can destroy brittle cast iron.

Matrix pipe cutter for cutting plastic and non-ferrous metal pipes with a diameter of 3 to 28 mm. Photo StroyDiskont

In general, among mechanical devices it is difficult to choose a completely universal option . To increase the number of jobs performed by a particular pipe cutter, it has the ability to replace the cutting tool designed for steel pipes with a tool for cutting non-ferrous metal pipes. Chain pipe cutters have the greatest versatility. The uniformity of multi-roller compression allows cutting of most types of pipe materials, including brittle cast iron.

The most versatile pipe cutters that use thermal energy in terms of pipe material are plasma and laser . The difference here can only be in the settings of the laser beam or plasma jet.

CNC: for profile and round pipes

The most adapted to the use of technologies with software are methods of cutting pipes using a laser beam and a plasma jet. To cut a profile pipe, the feed of the cutting head using the program is coordinated with the rotation of the workpiece around its axis.

In this case, the cut can be programmed to any desired shape . CNC pipe cutters produce absolutely identical cut shapes.

Stationary and portable

Portable pipe cutter CG2-11L (manual drive) Feji. Photo Chief welder

Stationary pipe cutters are used in industrial production , where a large number of different pipe products are processed. In order to maximize the range of standard sizes, they have quite a large weight and dimensions.

Portable pipe cutters are used to perform installation and dismantling work in the so-called field conditions . They must be easily transported, so they are subject to minimum weight and size requirements. Structurally, portable tools with a mechanized drive must have a special system of fixation to the pipe. An example of a portable electric pipe cutter PTM 14-60.

Detachable

Often, when carrying out dismantling work, the pipe must be cut in a specific place . This problem can be solved using a split pipe cutter. Its design consists of two body halves, which are assembled onto a pipe into a single whole.

Thus, you can work with the pipe without worrying about where its end is located. The mobility of detachable tools creates conditions for their use in installation and repair work. Examples of split models (with electric or pneumatic drive) can be found in the P3-SD series of pipe cutters.

Reference. Some models of tools have a simple structure, so they are easy to assemble with your own hands.

Classification of pipe cutters for steel pipes by type of cutting elements

Pipe cutters use different cutting devices: cutters, saw blades, rollers, cutters.

Roller pipe cutters

have from 1 to 4 cutting rollers. Depending on the number of rollers, a pipe cutter can cut pipes of different diameters: one roller will cut a steel pipe with a diameter of up to 50 mm, and a three-roller can handle a diameter of up to 100 mm. Roller tools are suitable for working in conditions where it is not possible to make a full rotation of the pipe cutter around the pipe. The disadvantage of roller tools is that it is impossible to obtain a clear cut without roughness; the ends will need to be further processed in the future.

Pipe cutters with cutters.

They are an iron cage that covers the workpiece. Sharp and durable cutters can cut through virtually any material, including thin steel pipes. The moving part of the unit is moved by a threaded rod. Simple models are equipped with only two cutters, and the rod element also serves as a handle. These tools are suitable for cutting metal up to 1 inch (25.4 mm) thick. For pipe material with thicker walls, you will need to buy special cutters. Such tools make it possible to obtain a perfectly smooth cut.

Chain pipe cutters.

This tool resembles a saw with a saw blade; it has a tension mechanism, swivel arms and chains with rollers. A saw-type pipe cutter can effortlessly cut single-layer metal with a cross-section of up to 3 centimeters. Chain pipe cutters work for a long time and reliably, withstand significant loads and provide a smooth cut without roughness. After cutting, the ends of the pipe do not need to be further processed for welding, which significantly saves time during repair and installation work.

Rotary pipe cutter

. The pipe is cut using identical interchangeable rollers that are securely fixed around the product. The pipe cutter is driven by a removable handle, and the working elements reliably and accurately carry out the cut. Advantages of a rotary pipe cutter: quick cutting of pipes with a wall thickness of up to 19 millimeters; The pipe cutter can work in difficult conditions, for example, under water, at the bottom of trenches, in pits, etc. Disadvantage: the high cost of the device, but in industrial production it quickly pays for itself. Suitable for large enterprises engaged in commercial repair, installation, communications and construction activities.

You should purchase a suitable pipe cutter based on the size of the pipe and its wall thickness. You also need to take into account the location of the work and how important it is to immediately obtain a smooth, neat cut that does not require further processing with a beveling machine.

Rice. Cutting elements of pipe cutters

Application of pipe cutter

Of course, the pipe can always be cut using a regular hacksaw. But you need to remember that this old method will probably leave burrs. It is also impossible to achieve high precision when cutting with a hacksaw. Therefore, in order to give the edges a smooth look, you will have to use an additional tool.

Moreover, in some places it is impossible to work with a hacksaw. It is also clear that with this tool you cannot think about efficient cutting.

If you need to make cuts at an angle of 90 degrees, then you need to use a pipe cutter.

- Only with it will you be able to make precise cutting.

- The pipe cutter is a true leader in terms of productivity.

- Its scope of application is water supply and heating.

- It is also impossible to imagine pipe installation without a pipe cutter.

With the help of a pipe cutter you can work even where there is no connection to an outlet.

Design features of the clamping unit

The clamping unit can be presented in three types: clamp, lever and screw

.

- Clamp clamp

pipe cutters work quickly and cleanly, withstand heavy loads and handle pipes up to 12 inches thick and up to 324 mm in diameter. They have one long handle and one auxiliary one. This design allows the operator not to put extra effort into cutting, and the equipment can be adjusted directly during operation. Clamping devices completely cover the part during cutting, the load is distributed evenly over the entire area and cutting occurs almost perfectly. The advantage of clamp pipe cutters is that a full rotation of the device around the pipe is not necessary and cutting of material can be carried out in cramped conditions, limited spaces and even by the rolling method. - In lever

models, the part is fixed by pressing the lever. - In screw

parts, the part is held in a constant position by screw elements. To prevent the pipe walls from being crushed during processing, the part is clamped medium-strong and held in this position until cutting.

Rice. Pipe cutter clamping mechanisms

How to choose a blade for a tool

For a high-quality cut, the pipe cutter blades must have a hardness that is 15...20 HRC higher than the hardness of the pipe being processed. This parameter can be determined using a “spark test”. It will reveal the approximate percentage of carbon and help determine molybdenum, tungsten and manganese. Thanks to this method, you can understand the initial hardness and grade of pipe steel.

For cutting alloy and non-alloy steel pipes, we recommend purchasing a set of cutters of varying hardness.

How to determine the hardness of a pipe material

To carry out the test, the end part of the part is processed on an emery grinder and the spark generated in the process is carefully examined:

- A more continuous sparkling beam of light yellow color means low-carbon non-alloy steel;

- A medium-carbon composition is indicated by a beam of the same color, but more branched, with a certain number of bright flashes;

- Standard quality steel produces a fine spark stream with short branches and virtually no flash;

- Alloy steel has increased strength and is not prone to brittle fracture. The stream of sparks is deep yellow, and instead of light flashes, elongated shiny arrows are observed.

Having detailed information about the quality of the steel from which the pipe requiring processing is made, choosing the appropriate cutting equipment will be easy and quick.

How manual models work

In everyday life, cutting steel pipes is most easily done with a roller pipe cutter. This tool has several circular knives and can easily handle material with a diameter of up to 100 millimeters.

Types of manual pipe cutters

To cut pipes of various diameters, different types of pipe cutters are used:

- Pipes with a diameter of up to 100 mm.

For household work cutting steel pipes, use a roller pipe cutter. It has multiple disc cutters and easily cuts pipes up to 100 millimeters in diameter. It is not suitable for cutting steel pipes with a diameter greater than 100 mm, since significant efforts will have to be made, and it is unlikely to achieve an ideal cut. - Pipes with a diameter of 150 mm.

We recommend cutting large diameter pipes of 150-900 mm with a rotary pipe cutter. It is equipped with a telescopic mechanism responsible for turning the cutting rollers, thanks to which it can cut pipes in cramped conditions of pits, excavations and trenches. In a rotary pipe cutter, rollers are attached to the outer perimeter of the pipe. When acting on a lever with a mechanical amplifier, they are pressed against the surface of the pipe and make a clear, even cut without nicks.

Rice. Manual pipe cutter for large diameter pipes

Manual pipe cutters are suitable for small jobs. For large-scale repair and installation work, use pipe cutters with electric or pneumatic drive.

What are the types of electric and pneumatic pipe cutters?

When it is planned to lay a large-scale communication system or carry out global repair and installation work, industrial tools are used: electric or pneumatic pipe cutters. They are equally suitable for production and field work, and process pipe as quickly and cleanly as possible. Most models of automatic industrial pipe cutters simultaneously remove a chamfer while cutting, preparing it for further welding.

Automatic pipe cutters are divided by type of design into pneumatic, electric and hydraulic.

The main difference between electric pipe cutters and pneumatic ones: dimensions. Due to their compact drive, pneumatic pipe cutters are much smaller in size and weight than electric ones.

- An electric pipe cutter operates from a regular outlet. When cutting pipes far from power grids, the pipe cutter can be easily connected to a gasoline or diesel generator.

- A compressor is required to operate a pneumatic pipe cutter.

- To operate a hydraulic pipe cutter, you need a hydraulic station.

Automatic pipe cutters are divided into one-piece and detachable according to the type of design.

Rice. Two types of designs of automatic industrial pipe cutters

One-piece pipe cutters

are located at the end of the pipe and are fixed using a self-centering clamp. They have compact dimensions and do not require a large space around the pipe.

- One-piece devices are quickly mounted on a pipe element and have the ability to qualitatively cut both thin-walled and thick-walled (up to 100 mm) parts made of alloy and non-alloy steel

- Split machines for cutting steel pipe material are easily attached anywhere in the pipeline.

- The device consists of interchangeable modules and is placed on the outer part of the surface.

- Despite the fact that the working elements occupy minimal space around the pipe, the cut when cutting is very accurate and does not require additional processing.

Rice. One-piece pipe cutters

Split electric pipe cutters

not only do they cut steel pipes into fragments of the required size and make trims, but also remove the chamfer from the top edge.

- The cutting element in the pipe cutter is a pair of cutters; the operation of the tool is activated by an electric or pneumatic motor, depending on the drive.

- Thanks to its two-part detachable body, the split pipe cutter can be placed on a functioning pipeline and quickly eliminate sudden breakdowns and carry out repairs of any complexity.

- To increase the processing speed, one of the cutters is attached to the edge of the pipe, and the second one cuts a chamfer during the process. The device is fixed with special cams. Usually there are from 4 to 8 pieces.

Rice. Split pipe cutters

Automatic pipe cutters with electric and pneumatic drive can provide an accurate cut without burrs; in most cases, they are equipped with an additional cutter for chamfering and can carry out two operations simultaneously: cutting the pipe and chamfering the end. In rare cases, pipe cutter models are equipped with additional options for boring pipes for welding.

For complete control of all processes, the device is equipped with a servo drive. It makes it possible to closely monitor the torque and timely adjust the speed of cuts.

Pipe cutter diameters

To understand which pipelines the pipe cutter is intended for, the manufacturer indicates the diameters of the pipes, which are the boundaries for the device.

- As an example, it is worth citing units with a ratcheting mechanism.

- Thin-walled copper pipes are not a problem for them if their diameter does not exceed 30 mm.

- If you are working with PVC products, then the permissible maximum diameter increases and is already 42 mm.

150 cm is the maximum diameter for devices powered by electricity. The same applies to pneumatic pipe cutters. Cutting models can work with pipelines up to 10 cm, roller models can work up to 5 or up to 10 cm, depending on how many cutting rollers are in the device.

How to cut small diameter pipes

For cutting small-diameter steel pipes in everyday life, hand tools are most often used. A manual roller pipe cutter is the most convenient and practical option for processing small-diameter steel pipes at home. To use it, you do not need professional skills or knowledge.

Rice. Manual pipe cutters

- The pipe is secured with the clamping mechanism of the pipe cutter; the handle of the pipe cutter is turned clockwise so that the cutting roller comes into contact with the metal surface.

- Then make another turn of the handle, making sure that the beginning and end of the cut line touch and create a closed circle without interruptions or distortions.

- If this step is completed, the adjusting handle of the tool is moved another half turn and the cutting element is pulled closer to the pipe.

- When the cutters clearly enter the metal, the scrolling is accelerated a little and the handle is rotated until cutting occurs.

For work in flow mode at large enterprises, we recommend using one-piece pipe cutters with electric or pneumatic drive. They are perfect for quick automatic cutting of pipes with a diameter of 14 mm.

Cutting large diameter steel pipes

In everyday life, cutting steel pipes with a diameter of more than 400 mm is not necessary; such large pipes are processed with a special industrial tool. In addition to the electrically or pneumatically driven pipe cutters described above, laser and gas cutting machines can be used.

Rice. Pipe cutting machines

The laser machine can cut steel pipes with large diameters and large wall thicknesses effortlessly and at high speed. Laser machines are usually equipped with CNC and, through a computer control system, the operator can set the machine the desired program for cutting of any complexity.

If you need to make a single section of pipe with a diameter of more than 400 mm, it is not necessary to purchase professional equipment. You can use a regular grinder: you need to install a cutting element for metal on it and make a careful cut.

Rice. Cutting pipes with a grinder

When cutting large-diameter steel pipes, it is not recommended to place a working element for wood or stone on the grinder. A discrepancy between the density of the cutters can cause damage to the workpiece and lead to breakage of the tool itself/

The grinder is suitable only for one-time cutting and cutting work. For regular large-scale events, it makes sense to acquire a more durable and powerful instrument. Rules of operation and care

Cutting methods

The use of a certain type of pipe cutter for pipes is selected based on the technical specifications, and various factors must be taken into account:

- Parameters of the workpiece being processed, including the outer diameter and wall thickness of the product.

- Required cutting accuracy, a particularly necessary indicator when installing and repairing water pipelines.

- The quality of the surface after cutting, which is determined by the need for further use of the part. For example, when making carvings, a smooth surface is required.

- Production volumes take into account the number of necessary operations.

It is based on all these indicators that the required cutting method is selected:

- Laser cutting method.

- Cutting with circular saws.

- Work on disk type machines.

- Cutting on band-type sawing machines.

- Use of professional equipment.

How to care for a pipe cutter

In order for the pipe cutter to serve for a long time and reliably, to perform high-quality cutting and not to damage the pipe walls during operation, it is very important to choose the optimal level of clamping of the steel part. Do not tighten the workpiece too much. This can cause a discrepancy between the beginning and end of the cut line, creating an unaesthetic appearance of a screw thread on the part.

If the steel pipe is clamped in the pipe cutter clearly, but not too tightly, the cutting will take place quickly, there will be no screw mark left on the part, and the edge will come out smooth and even.

The rotation of the mechanism should be carried out evenly and not too quickly. Otherwise, the walls will collapse and excess cut metal will form at the cut-off point.

- For correct and long service after work, the surface of the cutting roller, feed screw and guide rollers are cleaned with a special product and then treated with lubricant.

- The outer surface is inspected for dents or other damage, and chips are sanded so that they do not interfere with subsequent work.

- The cutting elements (cutter or roller) are inspected for dullness and, if necessary, immediately replaced.

- For storage, the pipe cutter is left in a dry and warm place.

- After such procedures and comfortable storage conditions, the device will remain operational for a long time and will easily cope with all tasks.

Pipe cutter: tool capabilities make all the difference

Agree, it would be wrong to purchase a pipe cutter that is not able to cut the material of the diameter you need. It is for this reason that the first thing you need to pay attention to is the capabilities of the tool, that is, its ability to cope with a pipe of a particular diameter made of a certain material. In this regard (according to their purpose), all pipe cutters that exist today can be divided into three types.

- Thin Wall Pipe Cutting Tool – If you are looking for a pipe cutter for copper pipes, then this is the category of tool you need. In most cases, these are roller or cutter type pipe cutters. In addition to copper, they do an excellent job of cutting metal-plastic pipes, brass pipes, and even pipes made of thin stainless steel. A roller pipe cutter is considered the most convenient and durable - in addition, it is also not a very expensive tool on which you can change the cutting rollers.

- Pipe cutter for working with thick-walled pipes - tools of this type do an excellent job with steel and even cast iron pipes. The pipe cutter for steel pipes can be chain, multi-roller or split. The thing is quite powerful and not cheap - it makes no sense to purchase it for one-time work. It’s much cheaper to borrow a grinder from a friend.

- Pipe cutter for fragile materials - these include ceramic or concrete pipes. In principle, this material is not used in everyday life, so you should know about the existence of such pipe cutters only for general development. In most cases, fragile pipes are cut with a chain pipe cutter.

Pipe cutter for copper pipes photo

In principle, when deciding on the choice of one type of pipe cutter or another, you should choose a more universal model of the tool. Undoubtedly, this is a roller pipe cutter for steel pipes, which can also easily cope with copper, metal-plastic, and other thin-walled products of this type.

Video tutorials on cutting pipes in different ways

Reed pipe clamp cutter

How a pipe clamp cutter works: detailed video instructions on how to use a manual pipe cutter equipped with a clamp latch. The reliable unit has good power and copes with parts with a diameter from 32 to 365 mm. It is used not only in stationary premises, but also under water, in deep pits or places where increased noise is unacceptable (residential buildings, pipe racks, etc.).

Manual roller pipe cutter

Cutting steel pipes with a roller pipe cutter: the video clearly shows the process of cutting steel pipe material with a diameter of 3 to 150 mm with a roller unit. The manual model copes well with one-time work, while the electric model is suitable for larger repair and installation projects.