Rectangular ducts

Round ducts

One of the main components of any ventilation system is an air duct, which is a pipeline-like structure used to move air. The duct system has straight sections and fittings that affect the direction of air flow, as well as their connection and separation. It is recommended to approach its choice thoroughly, depending on the individual parameters of your system and the conditions in which they will be used. Let’s try to understand the variety of types of air ducts, because your choice depends on this.

First, let's look at the appearance of the air ducts. They can be classified according to their cross-sectional shape. Divided into:

- rectangular

- round

Air ducts are also divided depending on the material from which they are made. Come from:

- galvanized steel

- of stainless steel

- aluminum

According to the design they are divided into:

- straight-seam

- spiral

By connection method:

- flanged

- connection using busbar and angle

- rack and pinion

Let's talk about the different shapes of air ducts.

Round ducts

Round-section air ducts are divided into spiral-wound and straight-seam. They can be used in general exchange, supply and exhaust ventilation, as well as in pneumatic transport and aspiration systems.

Let's look at the advantages and disadvantages of each of these types.

| Options | Spiral-wound air ducts | Straight-seam air ducts |

| Production time | + | _ |

| Ease of production | + | _ |

| Manufacturing cost | + | _ |

| Application in aspiration and pneumatic transport systems | _ | + |

| Setting the system to vacuum | _ | + |

| Rigidity | _ | + |

| Strength | _ | + |

| Wear resistance | _ | + |

| Cost calculation | + | _ |

Other connection methods

The flange connection of air ducts is quite reliable, but not particularly relevant due to its high cost. It has a high level of rigidity. On the one hand, this is a plus, but on the other, a minus, since with the slightest configuration changes, unsuitable parts can simply be sent for remelting.

There are many options for fastening such a connection. But the most common is spot welding. This method is the fastest and easiest. The disadvantage of this connection is that it is not reliable enough, especially when working with galvanized parts. Since zinc can burn out during welding, there is a high probability of corrosion of the welding seam, as a result of which the fixation of the structure will weaken. To avoid such consequences, it is recommended to use corrosion-resistant rivets for fastening instead of welding.

Main components of round air ducts

Ventilation outlet 90⁰

Ventilation outlet 60⁰

Ventilation outlet 45⁰

Ventilation outlet 30⁰

Ventilation outlet 15⁰

For ordering there is a symbol: d - diameter (mm)

α - turning angle ° R - turning radius (mm)

When R=d - not specified R =1 xd In a standard bend, the turning radius is equal to its diameter. The radius, if necessary, can be any.

Go to the air duct catalog

Go

Round ventilation transition

Central Single-sided Offset

Used to narrow or widen the cross-section of the air duct. It is extremely difficult to do without such a product on site, since manufacturing the transition is quite a complex and lengthy process if done manually during installation.

When ordering, indicate small and large diameters. If the order is non-standard, then the length and offset (for offset transitions) are also indicated.

d1 - diameter (mm) d2 - diameter (mm)

When ordering a non-standard length, please indicate:

Length (mm) - L Offset (mm) - C

Round ventilation tee

First type:

Used to branch air flows. Sometimes, in order to save money, they order tie-ins instead of tees and make a branch on site, but this method takes more time in installation.

There is an ordering symbol:

d1 - diameter (mm) d2 - diameter (mm) L - length (mm) H - height (mm)

Any size ratio possible (subject to technical limitations)

Second type:

There is an ordering symbol:

d1 - diameter (mm) d2 - diameter (mm) L - length (mm) α - angle

Any size ratio is possible (subject to technological limitations).

Third type:

There is an ordering symbol:

d1 - diameter (mm) d2 - diameter (mm) d3 - diameter (mm) L - length (mm) α - angle

Any size ratio is possible (subject to technological limitations).

Fourth type:

Sometimes you have to make a branch of a rectangular section. This may be necessary, for example, to connect small rectangular distribution grids that are inserted into the channel.

There is an ordering symbol:

d - diameter (mm) H - height (mm) A×B - insert size (mm) n - flange: 20 (mm), 30 (mm), (without flange: 0) L - length (mm)

Any size ratio is possible (subject to technological limitations).

Round ventilation cross

For a standard part: H2 = H3 − 0.5d1 + 50 (mm)

If l > (d2 + d3) / 2 + 120 (mm), then it is possible to consider using two tees. Typically, such products are not ordered in advance, but are manufactured on site using tees.

There is an ordering symbol:

d1 - root diameter (mm) d2 - diameter (mm) d3 - diameter (mm)

Height (mm) — H2,H3 L — part length (mm) If l = 0, do not indicate l — distance between cut-ins (mm) α — angle between cut-outs from d3 to d2, °

Any size ratio is possible (subject to technological limitations).

Round ventilation nipple

Serves to connect air ducts of the same diameter to each other. The air ducts are inserted from different sides of the nipple in one simple movement. Without nipples, it can be extremely inconvenient to connect pipes, since you have to roll them (“make a flower”) and insert one into the other. It looks ugly and is inconvenient to do.

There is an ordering symbol:

d —diameter (mm)

Total length of ventilation nipple:

up to Ø 500 - 140 (mm) up to Ø 900 - 180 (mm) up to Ø 1250 - 200 (mm)

Round ventilation coupling

Connects shaped products and air ducts. Made from galvanized steel. become. Unlike a nipple, it is put on top of the parts to be fastened. For small diameters they are usually not used, but are cut from pieces of pipe, but for large diameters (more than 400mm) it can take much longer to cut the pipe on site, so it is more profitable to order them in advance.

There is an ordering symbol:

d—diameter (mm)

Each diameter corresponds to a certain coupling length L–mm. (See Appendix 1).

Round ventilation plug

It is the end element of the system to block the channel cross-section.

Required when ordering:

d—diameter (mm)

From 100 to 1250 mm.

It is also possible to choose any diameter and length and make it with a handle at the end.

Round ventilation duck

It is a shaped product and is used at the joints of multi-level air ducts. Can also be used at the junction of air ducts located to the left or right of each other. You can also get by using two bends of 30 or 45 degrees instead of a duck.

When ordering please indicate:

d1 - diameter (mm) d2 - diameter (mm) L - part length (mm) H - height (mm).

If d1= d2, then indicate one size

It is also possible to use any size (subject to technological limitations).

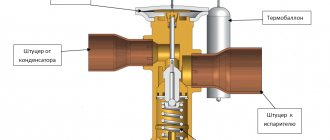

Throttle valve for round air ducts

Galvanized steel is used for production. It consists of a pipe, a canvas and a control sector. The so-called vane, located on the outside of the valve, is installed on the control unit. It can be rotated using the handle. The valve cross-section is closed at the required angle using a spatula. The blade is secured with a wing nut. Using a graduated scale, the angle of rotation is determined. Throttle valves are recommended for use on main lines or at air duct branch points.

The correct location and number of throttle valves is very important so that you can correctly balance the system and set the required flow rates for the branches.

Roof umbrella for round air duct

Protects the air duct from precipitation. Typically used on vertically installed exhaust pipes.

To order use:

d - diameter (mm) (from 100 to 710 mm)

D and height H depend on d.

Round ventilation insert

A shaped part installed in the walls of air ducts. Used instead of a tee to branch the flow. It takes a little longer to install than a tee, but is cheaper and allows you to install it anywhere.

There are three types:

- For installation in a rectangular duct or a round duct

- For connecting round ducts

- For corner ducts

When ordering please indicate:

d - diameter from 100 to 1250 mm I - length 40, 60, 80, 100 mm,

also for if necessary

H - height (not less than 50 mm) α - angle, °

It is also possible to use any size ratios (subject to technological limitations).

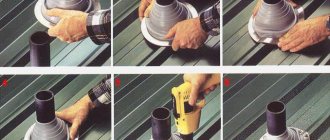

Roof passage unit for air ducts

It is used in places where ventilation shafts are installed on the roof. The main task of the passage unit is to seal the passage opening.

When ordering please indicate:

d – diameter 100 – 400 mm H – height (mm). α - angle °

It is also possible to use any size ratios (subject to technological limitations).

Round ventilation damper

Shut-off and control device. Made from thin sheet galvanized steel. They are divided into direct (in aspiration and pneumatic transport systems) and oblique (in general ventilation systems) dampers. In this case, the pressure in the system should not exceed 1000 Pa. The main function is to regulate the air flow.

Flexible round inserts for air ducts

Eliminate vibration when connecting high-power equipment, such as radial fans or air handling units, so that vibration noise is not transmitted into the duct system.

Use from 100 to 1600 mm.

Mounting tire (euro tire)

The mounting rail is a specially shaped galvanized profile resembling the letter L. The width of one side of the product can be 20 or 30 mm. The tire rail, together with a special angle, is used to connect rectangular air ducts and corresponding fittings and is attached to the air duct with self-tapping screws. The tire provides additional rigidity and ensures a tight connection of the ventilation parts. The use of eurotires allows you to speed up the process of assembling a ventilation system with a high degree of tightness. Sealing tape or sealant is used at the joints of the tire. On air ducts whose smaller sides exceed 500 mm, additional mounting brackets are installed.

Types of sealing

Connecting two sections of the ventilation system using a nipple coupling does not create maximum tightness of the joint, because the diameter of the pipe section is slightly smaller than the diameters of the sections. Therefore, to ensure 100% tightness, various materials are used. Manufacturers today offer nipples with rubber cuffs (one or two) or without them. In the second case, various self-adhesive tapes and tapes are used for sealing.

The use of tapes for sealing is considered practical, especially for aluminum models and polymer tapes. They will last as long as the ventilation system itself. Of course, provided that the air ducts are operated in heated and dry rooms. Such conditions do not always occur, so tapes often have to be replaced after a certain service life.

In addition, it should be noted that not always clean air moves through the air ducts. So the service life of sealing materials can be reduced to a minimum. But even in this case, it is cheaper than purchasing nipples with rubber cuffs.

Expert advice

When assembling the ventilation system, it is recommended to make as few connections as possible.

When installing the system, it is necessary to provide free access to the unit containing the ventilation filters.

To improve the tightness of the joints, you can use a polymer lining or soft rubber.

The air duct should be fastened directly to the wall using special brackets and studs. The recommended distance between them is 100 cm for the horizontal segment and 1.8 m for the vertical segment.

Equipment and materials used

Resistance welding machine for manual connection of a stainless steel air duct

To create a nipple connection of air ducts or a welded joint, the following tools and materials are required:

- stainless steel;

- tape measure, marker;

- hammer, pliers;

- vice;

- metal cutting tools;

- sealant and gun for applying it;

- welding machine;

- pipe fragments of the appropriate diameter.

The technology for installing the structure must be followed down to the smallest detail. If you combine parts of the duct without sealing, the functionality of the system is impaired. The connection of the structure to the hood is carried out taking into account the diameter of all parts. Before installing the air duct, a drawing of it is prepared.

Order transitions at Ventilation: why is it profitable?

The company has the latest machine park - one of the most modern in the Russian Federation. Depending on the client’s needs, the company produces transitions from any sheet metal:

- black steel (from 0.55 to 8.0 mm);

- stainless steel (0.55-4.0 mm);

- galvanized (from 0.55 to 2.0 mm).

Based on customer requirements, the connection of stainless steel sheets can be made by spot welding, seam connection, or argon welding. In addition, our clients receive the following benefits:

- individual approach to customer requirements;

- manufacturer's prices;

- profitable bonuses and participation in promotions;

- fast order fulfillment;

- prompt delivery.

Do you need guaranteed high-quality ventilation transitions made of galvanized, stainless or black steel? Contact Ventilation and place your order!