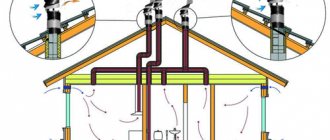

The principle of sewerage pipeline construction. The operating principle and sewage system in a private or apartment building have common and different features.

In an apartment building, all areas for draining water from plumbing fixtures are connected using pipes to a riser located vertically. All apartments located under each other are connected to one riser. Common pipelines from different entrances flow into the house collector, located horizontally. The collector has a slight slope so that the water flows by gravity further into the sewer well. Next, the waste is transported through pipes equipped with technological hatches to the centralized sewer main in the city.

The main devices that make up the sewer system

The sewer system of an apartment building includes certain elements that have a specific purpose and operating features:

- The comb is a pipe to collect wastewater from all plumbing fixtures. The pipe is laid horizontally through the partitions of the bathrooms with bathtub and kitchen. The cross section of the comb is fifty millimeters; for the toilet, the diameter is 110 centimeters. The difference in the pipe due to the slope is about three centimeters per linear meter of pipe. Plastic combs are attached to brackets or mounted to the walls with clips or clamps, leaving an intermediate distance of about fifty centimeters. The joints at the points of connection with the outlet pipes must be sealed using a cuff or special seals.

- Riser is a large pipe to drain liquid from apartments that are located on top of each other. The riser consists of pipes of 110 centimeters, which are laid from bottom to top. Interfloor ceilings are equipped with tees to connect to the combs. Every two or three floors are equipped with a hatch for carrying out cleaning and repair work in the system. Inspection hatches must be installed at the ends of the riser and in front of the entrance to the bunker in the basement.

Important! The basic principle of the pipeline design is the gravity flow of wastewater through the system.

What problems may arise during the operation of risers:

- Complete or partial blockage of the pipe. The riser is cleaned using a hatch that is installed above the garbage plug.

- Riser noise. To reduce noise during pipe operation, soundproofing material is used in the form of roll insulation. The riser can also be retracted into a box constructed using wall panels and drywall. It is possible to replace the pipes with silent plastic products with thicker walls, but such pipes are much more expensive.

- Presence of leaks at joints. In plastic structures, you can change the seal or cuff. If a leak occurs when connecting a cast iron pipe to a socket, then it is necessary to make a new element, removing the concrete seal with the cable in advance.

- Destruction of a cast iron riser can occur due to corrosion or the formation of cracks in couplings and sockets. The destroyed area must be cut out, and instead of the old element, it is necessary to install a pipe equipped with a coupling for sealing. If the element is made of plastic, then it is possible to completely replace it.

- The vent pipe is the upper part of the central pipe and is considered the ventilation outlet to the roof. The pipe for organizing the ventilation system can be installed above each riser, or it can be used to connect the outputs of many risers at once. The fan socket removes gases and odors to the street and ensures the operation of the water seals of the devices. In winter, ice may form inside the pipe, which interferes with the operation of the system. To prevent this from happening, the pipe is insulated using a special material.

- The ladder is presented in the form of a horizontal pipe located in the basement; it connects all access risers. The lounger is installed with an inclination in the direction of the drainage pipe into the well. The lounger is laid on the supports of the basement bulkheads, or with the help of steel supports. Plastic pipes have supports at a distance of a meter from each other. Increasing the pitch of the supporting structure may cause the pipeline to sag. At least one suspension or support device is installed under one cast iron pipe. The sunbeds are equipped with inspection hatches, which must be in places with turns or every eight meters on straight sections of the route. Lezhnevki suffer from blockages; pipes are cleaned through a hatch located slightly above the blockage.

- The pipe leading to the well is laid with a slope from the deck and passes through the foundation. Upon release, waste water from the deck flows into a special container. The part of the pipe that runs along the street is laid in a trench below the freezing layer of the soil. The pipes must be very durable. Cast iron pipes or orange plastic pipes are used. The inspection window is installed near the sun lounger. Through it, blockages are removed using sewer wire.

- The well is considered the final destination for wastewater from an apartment building. The container is made of reinforced concrete rings, fastened with brackets, the bottom of the tank is securely concreted. At the bottom, a drain is formed for drainage into the next well in the form of a tray, then the liquid flows into the collector of the general city sewerage system.

Standard sizes of sewer pipes table, markings, GOST

To install a sewerage system, it is necessary to purchase pipe products and connecting elements of the sizes specified in the project. The trade offers standard sizes of sewer pipes in a fairly wide range, which allows you to create a pipeline of any configuration with any wall thickness.

Main parameters of the pipeline

- outer diameter of the sewer pipe,

- inner diameter,

- conditional diameter (Dу or Ду) - nominal or rounded value of the internal section,

- nominal cross-section (Dn or Дн),

- wall thickness.

The marking of all plastic pipe products indicates the outer cross-section and wall thickness, while for cast iron pipes the nominal bore in millimeters is indicated. Problems may arise when combined fittings (made of metal and plastic), which are marked in millimeters and inches, are used during installation. In such situations, it is necessary to compare elements in different measurement systems.

SNiP 2.04.01-85 determines the calculation of the diameter of the sewer pipe. But for a house or apartment these formulas are too complex. In practice, a different approach is used - in an apartment or standard country house it does not exceed 10 cm.

Based on this:

- for sink, bathtub, washbasin, urinal, bidet - 5-7.5 cm,

- for the toilet - plastic pipes with a diameter of 100 or 110 mm,

- outlets from washing machines and dishwashers - 2.5 or 3.2 cm,

- wiring around the house or apartment - 5 cm,

- riser in a house with no more than five floors - internal Ø 110,

- riser in a house above five floors - Ø160,

- connection of several risers (lounger) in a multi-storey building - 200,

- drain outlet outside - 16 or 20 cm,

- yard system - Ø 300,

- outlet to the well, the area between two wells is 20 cm.

If plastic materials are used to lay the sewer, then instead of 5 cm you can use 4 cm, instead of 10.1 cm - 10 cm, etc. This is due to the smooth inner surface of these products, which during operation is practically not covered with rust or other deposits.

There is such a thing as the smallest permissible standard size, defined by Sanitary Norms and Rules (SNiP):

- for intra-block drainage and street network - 20 cm,

- for intra-block storm drainage network - 20.2 cm,

- for street storm network - Ø 250.

The cross-section and wall thickness are interrelated parameters - the larger the cross-section, the thicker the wall. Weight is also directly proportional to the cross-section. For example, an external cross-section of 16 cm - weight 2 kg, or 10.1 cm - weight just over 1 kg. An important indicator is the length of the segments. The shortest is 1 m, the longest is 6 m.

Plastic pipe products for sewerage

Manufactured from polyvinyl chloride (PVC), polypropylene (PP) and polyethylene (PE). To determine their internal cross-section, you need to subtract the wall thickness multiplied by two from the external cross-section (they are indicated in the marking).

According to GOST R 51613-2000, the diameter of non-pressure PVC sewer pipes can be 5, 7.5, 9, 10, 1.1, 15, 16 cm. To drain wastewater from industrial facilities, products with a cross-section of 25 and 30 cm are used. Their main advantage - they are mounted in the same way as thin ones - in a socket.

The size of polypropylene materials is determined by GOST R 51613-2000 and GOST 22689.2-89 - 5, 10 and 15 cm. But there are large diameters with a wall of 5 mm. These products are used for installation of large main pipelines.

Standard sizes made of polyethylene are regulated by GOST 22689.2-89. The choice of these products is not large - 4.5 cm, 90 and pipe 110 internal diameter. The wall thickness of low-density polyethylene products is 3 - 5 mm. Sold in lengths from 2 to 9 meters.

The diameter of the plastic sewer pipe must be selected based on the availability of connecting elements of appropriate sizes. For example, for material with a cross-section of 7.5 or 9 cm, it may not be possible to find fittings.

To connect a plastic indoor sewer system to a cast iron riser, you can use a combined fitting or a rubber gasket, which is sealed with silicone or linen winding. If there is a large hole in a cast iron riser, you can combine a fitting and silicone or a fitting and a winding.

Sewage system in a private house

In a country house, you want to have the same level of comfort as in the city, but there is no way to connect pipes to the central highway. In this regard, it is necessary to arrange an autonomous sewage system.

Attention! The structure of the internal sewerage system of a country house and a high-rise building looks the same, the difference lies in the installation of the outer part of the pipeline.

Autonomous sewerage has two parts of the system connected to each other:

- A system inside the house, which consists of pipelines with water inlets. When installing a house on several floors, a riser is installed with horizontal pipes leading from it to plumbing fixtures.

- The system outside the building consists of a pipeline laid underground with the slope of the pipes in a horizontal position. Water flows through the pipes by gravity to the treatment plant or to the central main line.

If pipes are being laid in a house under construction, then the sewerage from the kitchen, bath, and toilet are located close to each other, literally through the partition and close to the wall in which the discharge to the outside of the building will take place.

Attention! In a multi-storey country house, it is recommended to place plumbing units one below the other to simplify installation work and minimize the number of risers.

Two types of sewage disposal: pressure or non-pressure. The free-flow type is considered the easiest to install; the main thing is to correctly calculate the angle of inclination of the structural elements when laying the pipeline.

Dimensions

Red sewer pipes with a diameter of 110 mm can have different wall thicknesses - from 5 to 150 mm. This depends on the internal diameter and installation location - in a pressure or non-pressure line. In systems where liquid is transported under pressure, the walls must be thicker to withstand constant loads and not deform.

The length of the pipe section for each material is determined by GOST standards. Some plastic products can be transported in coils for the convenience of customers. The required length is measured and twisted, then secured.

Features of laying external sewer pipes in a private house

To properly arrange the sewer system outside the building, the following features must be taken into account:

- Features of the site's relief. In order for wastewater to flow by gravity into the septic tank, it is necessary to locate the treatment facility at the lowest level of the site.

- Looseness of the soil, height of water underground. These conditions dictate which type of treatment device to choose, and also determine the depth of laying the external sewer pipes.

- Dimensions of the site and its location. The site must be provided with free access for specialized equipment to carry out repairs or pump out wastewater if necessary.

When laying pipes inside a building, you must remember not to install the pipes from the plumbing to the common riser at an angle of inclination so that the water is transported by gravity.

Attention! SNiP specifies the parameters of the angle of inclination for pipes with different sections. If the diameter of the pipe is fifty millimeters, then the angle of inclination is correspondingly three centimeters per meter of pipeline. Pipes with a cross-section of 110 millimeters are laid with a slope of two centimeters per meter of pipe.

The length of the outlets from the devices to the riser is approximately three meters. According to the requirements specified in regulatory documents, the most distant device can be located at a distance of five meters from the riser. The toilet should be located at a distance of one meter from the riser.

Drying installation technology for another type of foundation - strip and columnar

We do the following work:

- we make a ditch around the foundation of the structure;

- we clear the base of the structure from the soil;

- we take a technical break to allow the base to dry;

- apply a bitumen primer to the foundation;

- we take a technical break - 2-3 days;

- apply bitumen mastic to the dried base;

- glue the reinforcing mesh onto the mastic;

- we take a technical break - a day;

- apply a layer of bitumen mastic to the mesh (waterproofing the foundation);

- we are constructing a collector well to which pipes will be connected;

- we dig a trench;

- fill the trench with sand - 5 cm;

- We lay geotextiles at the bottom of the trench;

- fill in gravel - 10 cm;

- lay pipes on gravel with a slope of 2°;

- we join the pipes with adapters and corner connectors;

- We make sure that at the corners of the structure all pipelines enter the inspection wells;

- We lay pipes from inspection wells that drain water into a drainage pit or collection well;

- fill the pipes with gravel - 10–20 cm;

- We cover the contents of the trench with geotextile on top;

- we fix the geotextiles with synthetic ropes, but it is possible without them;

- we fill the trench with earth or make a soft blind area (concrete can also be used).

That's all the manipulation. The drainage system is ready! Tell me, is this a very difficult job? Of course not, but I’ll be honest, it’s quite labor-intensive. But it is of enormous importance!

If the drainage structure is constructed correctly, no moisture is harmful to the foundation of any building. Thus, the drainage system is a guarantee of the durability of your cozy home!

I will end here, I hope this was informative. Good luck to everyone and peaceful bright skies, bye!

Wisdom Quote: Those who shout the most shake especially (Publius Cornelius).

https://youtube.com/watch?v=DloSGrkFtYA

Types of treatment structures

Autonomous sewerage requires the presence of a treatment facility. They come in three types:

- In the form of a cesspool. Easy to do with your own hands. To do this, prepare a pit, which is laid with rings of concrete, tires, or brick. As the pit fills, it must be pumped out manually, with a pump, or using machinery.

- In the form of a septic tank. The device is intended for collecting and processing waste using mechanical or biological methods. The recycled wastewater can then be used on the farm.

- In the form of an autonomous cleaning station. The station can treat wastewater up to almost one hundred percent using a biological method. The device regularly receives oxygen, which promotes the growth of beneficial microorganisms. Due to them, organic waste quickly disintegrates.

When constructing a pit, it is important to remember that wastewater can seep into the soil and pollute it; the design is suitable for summer cottages and temporary use. In houses with permanent residence, a type of structure in the form of a septic tank or an autonomous station is suitable. The installation of a septic tank requires the presence of a filtration well on the site. It can be equipped with low levels of groundwater flow.

Advantages

Plastic pipes can be used both for external and hidden installation, as they look aesthetically pleasing and are not conspicuous. There is no need to paint them, and the audibility of flow movements in plastic is much lower than in metal.

Plastic will last a long time. Even at low temperatures it is resistant to impacts and high soil pressure. The smooth surface of the pipe helps sewage drain faster and more efficiently, allowing it to withstand high water pressure. It also reduces the risk of blockages and damage even when moving dense elements. The low roughness coefficient prevents deposits of limestone and other decay elements, which provides greater strength.

This material is resistant to corrosion, changes in wastewater temperature and melting processes, salts, lime deposits, mineral acids and alkalis. In a private home you will have to deal with this yourself, and this is energy-consuming.

Low weight facilitates the transportation process. It is not necessary to order a car for delivery. Installation will not take much time; installation for a private home can be done independently, since the process is simple and does not require special knowledge.

Materials for piping elements

To organize sewerage systems, structures made of different materials are used:

They are durable and resistant to corrosion, but they are difficult to install and carry out logistics.

Ceramic products- Cast iron pipes have remained popular for many years. The material is suitable in all respects for installing a sewerage pipeline. Cast iron is durable and not subject to corrosive changes. The tightness of the joints is ensured by casting. To increase the quality of connections during installation, caulking is used.

- Plastic pipes are increasingly replacing products made from other materials. Lightness of products, strength, reliability, durability, ease of installation - all this distinguishes plastic pipes. The main method for installing the structure is the socket method.

Dimensions of sockets for sewerage inside the house:

- pipes serving as outlets must have a cross-section of fifty millimeters.

- the socket for the fan pipe or riser must have a size of one hundred or one hundred and ten millimeters.

- the socket leaving the house towards the septic tank is equal to one hundred, one hundred ten or one hundred fifty millimeters.

PE pipes KORSIS and KORSIS Eco

Polyethylene is another polymer. KORSIS and KORSIS Eco pipes are made of high-density polyethylene (HDP) and an external corrugated layer is added. It increases ring rigidity, so the products are suitable for external sewerage.

Advantages:

- durability,

- ease,

- elasticity,

- frost resistance down to −60°C,

- resistance to acids and alkalis,

- soundproofing,

- polished inner surface.

Flaws:

- sensitivity to sunlight,

- maximum temperature of the transported substance: 80°C.

Pipes made of high-density polyethylene, unlike PVC, tolerate low temperatures. At the same time, they are also lightweight, elastic and more reliable for external pipelines.

sells polymer pipes made of PVC and high-density polyethylene. SIS is the official distributor of the Poliplastik Group, a manufacturer of plastic pipes for sewerage, water supply, and heating. SIS sells products from the Polyplastic Group at prices from the manufacturer, and also helps you choose material for pipelines.

How to choose a slope angle - several possible options

There are several positions that guide home craftsmen:

- Make the angle as sharp as possible;

- Make the slope minimal or skip this point altogether when installing sewer drains;

- Create a slope in accordance with SNiPs, GOSTs or specialized reference books.

At first glance, an excessively sharp slope of the sewer pipe will help the water that requires treatment to reach its destination faster. But on the other hand, the pipe is exposed to the harmful effects of wastewater. Because water moves through the drain too quickly, sewage solids, food debris and other debris that is often flushed down the toilet remain in the pipe. Therefore, the maximum pipe slope is strictly regulated. Looking ahead, I will say that it is equal to 15 cm per 1 linear meter.

Silting of the pipe will also be a problem. Over time, the sewer will become clogged and you will have to work to repair it. The service life of such a system is much shorter than the standard one and is less than a year.

A minimal slope or its absence is a serious mistake when installing a sewer pipeline. In this case, the pipe not only silts up, but is practically not cleaned naturally.

Requirements for external pipelines

External sewer networks have to function in difficult conditions. Pipes covered with earth are forced to bear the weight of the soil, on which people, and often cars, can move.

They are also affected by soil water, which can provoke a displacement of the connecting points, which can lead to depressurization of the sewer network.

Systems must constantly withstand the static/dynamic effects of wastewater transported through pipes.

That is why special requirements are imposed on elements of external sewer networks.

Pipes must have the following qualities:

- strength and rigidity;

- the ability to withstand temperature fluctuations without losing performance;

- frost resistance;

- wear resistance, long service life;

- resistance to aggressive chemical environments.

For the manufacture of external sewer systems, various materials can be used (polymers, steel, cast iron), but they all must comply with the above factors.

It should also be taken into account that the quality of the pipeline is influenced not only by the specific properties of the pipes, but also by the quality of installation and laying of the system.

Our website also has other useful materials on sewerage rules.

We recommend that you familiarize yourself with them: