One of the main elements of a modern drainage system is a sewer well. We often come across the hatches of these structures, even if we are just walking along the city streets. But the autonomous sewer system, which a private owner installs on his property, also uses wells.

We suggest that you familiarize yourself with the classification of wells for sewage systems presented by us. They were divided into types according to their functional purpose and the material used in their manufacture. The article will help you understand the varieties and choose the appropriate option.

The detailed information we offer about the types and operational features of wells, which are an essential component of the sewer system, is supplemented with diagrams, videos and photos for visual perception.

Installation of a plastic well

The use of ready-made plastic structures equipped with shaped parts will not only provide significant time savings, but will also make it possible to carry out installation independently even in the absence of experience and training.

It is only important to strictly comply with the requirements regarding the location of structures and the choice of their size, which are determined by a set of system parameters (diameter of pipes, straightness or presence of turns in the main, laying depth, etc.). The rest of the installation is carried out in several steps:

- digging a pit,

- construction of the foundation (sand-crushed stone cushion, poured base),

- installation of the structure (and its anchoring if necessary),

- connecting the well to the system.

Installation of the tray part of a sewer inspection well in a pit

Sewer wells - SNiP, design and installation diagrams

The technology for arranging sewer wells has been worked out to the smallest detail and documented. Construction regulations prescribe a basic series of regulations that the work carried out must comply with. In particular, SNiP has number 2.04.03-85 and is called “Sewerage. External networks and structures.” The document regulates the locations of different types of structures, dimensions and requirements for the structures being erected.

Regardless of the purpose, private or public use, the installation of sewer wells must be carried out in accordance with the rules and requirements. For example, an inspection object must be located in front of the entrance of the local sewerage system to the centralized sewer, outside the red building line.

Construction of a filtration well: functions, diagram, device

A well designed to filter wastewater is installed in the sewer system after the septic tank.

Its task is to accept wastewater that has undergone preliminary treatment and then pass it through a layer of soil, which, in this case, acts as a filter.

Most often, this water treatment element is installed if there is no possibility of draining wastewater into the central sewer network or underlying soils.

Photo: filtration well

1. Manhole cover 2. Exhaust pipe 3. Neck body 4. Insulating cover 5. Supply pipe 6. Outer gravel layer 7. Well body 8. Shield 9. Internal filter layer

Important! When planning a site for a filtration well, it is worth considering the distances to nearby buildings and wells for drinking water (according to SNiP this is no closer than 10 and 30 meters, respectively). It doesn’t matter what shape the filtration structure will have, but if you plan to construct a sewer well from concrete rings, then something like a foundation is made around the perimeter of the base

It does not matter what shape the filtration structure will have, but if it is planned to construct a sewer well from concrete rings, then something like a foundation is made along the perimeter of the base.

Photo: sewer well made of concrete rings. Gravel, expanded clay, broken bricks and other material with a fraction size of approximately 10 to 70 mm are poured inside the well.

Outside, along the entire perimeter, bedding is made from the same composition as inside the well, but not more than 1 m. The supply pipe should be approximately 15 cm above the filter layer.

Important! To prevent erosion of the bottom filter, a wooden shield pre-treated with an antiseptic compound is placed under the stream of water.

Construction of a drainage well made of concrete rings

A drainage well made of concrete rings or other material is required if the aquifer is located close to the site. The system helps protect structures located underground from erosion by water, allows excess melt and storm water to be drained away and the fertile soil layer to dry out. A drainage well is a mandatory element of the entire system, but it can be made from scrap materials or from durable plastic or concrete structures.

The design of the wells is simple: installation on a pad that serves as a filter layer. The thickness of the cushion is at least half a meter, composition: crushed stone, medium gravel and sand. A backing is required, even if the bottom ring is equipped with a filtration bottom. In this case, storage and revision structures are placed on a compacted base filled with a cement screed or bottom slab.

The installation of the rings must be strictly vertical; the joints must be sealed with bitumen-based mastics or coated with a solution containing concrete. The depth of the hole for the well is at least 1.5 meters, and the best place for digging is lowland.

For the device to work well, it is necessary to make a hole in the link located closer to the surface for the pipe, which is sealed at the joints. And to give strength to the entire structure, the prefabricated elements are fastened from the inside with metal plates, which you can make yourself. After installing all the links, the space between the walls of the shaft and the ground is filled with gravel, then the surface is leveled and, if necessary, covered with a lid or geotextile.

A positive aspect is the quick start-up of the well - the device can operate after the sealant has dried.

Recommendations for cleaning reinforced concrete sewer manholes

Even with all the modern devices, sewer wells are often cleaned manually. This happens as follows:

- One of the workers goes down into the tank in order to push a wire in the direction of the formed blockage.

- The second group of workers, who are at the top, diligently rotate its opposite end.

There is another classification of wells, which affects the difference in:

- Laying depth, as well as dimensions. According to these criteria, objects are divided into 2 types - serviced and inspection. The first category requires immersion within the service personnel. The process of completing the assigned tasks is fraught with significant difficulties. But inspection wells provide the ability to monitor performance and technical condition directly from the surface.

- Regarding the dimensions, the dimensions of the serviced containers were determined in such a way that a person would not only fit into the treatment facility in question, but could also work there normally. Accordingly, the transverse size of the structure must be at least 700 mm. The most commonly used standards are: one thousand, one and a half and 2 thousand mm in diameter. Adjusted to the listed standards, round slabs used as a base are produced.

Regarding the available structural components, from the point of view of cleaning a sewer well, it is customary to highlight:

- The base or bottom, which can be in the form of a circle or rectangle;

- Rings included in the shaft;

- The upper ceiling with a round hole made in it, intended for a hatch;

- Manhole cover, which may consist of cast iron or polymer material.

The preference for a round shape can be attributed to the fact that a structure with just such a geometry provides the best possible resistance to the surrounding soil. After all, the manufacturer does not have information regarding where and how prefabricated reinforced concrete elements will be used, so they are made in a standardized, even form. Moreover, they are supplied only with embedded parts - hinges, which are necessarily used during the installation process.

In order to insert the pipeline into the well, it is necessary to make a hole in the lower ring, and create a tray of the required shape on the lower plate.

This design underlies inspection and differential wells - in the latter case, minor modernization of the devices can be carried out, adjusted for the features of a particular design model. The height of the object is determined by the number of standard and additional rings - they are the main structural components used in the process of its construction. In order to ensure that the installation of each subsequent ring is carried out as close as possible to the previous one, it is necessary to remove all excess mounting loops. Be sure to monitor the quality of sealing cracks with cement. This will reduce contamination of the surrounding soil with wastewater, as well as the intensity of groundwater penetration, which will penetrate into the reservoir and contribute to its overflow.

Remember - sewerage systems (in fact, like all other structures) require systematic and professional maintenance. Their condition must be closely monitored: maintain the specified operating functions, periodically carrying out routine repairs. If the system becomes clogged, emergency intervention may be necessary. So, one of the purposes of sewer tanks is to ensure the possibility of implementing all the processes listed above.

Moreover, once again you should pay attention to the advantage of reinforced concrete wells - only due to their reliability, durability and ease of installation, which does not require much effort. They still remain competitive in the market and also hold a leading position

Experts in the field of construction and sewerage installation authoritatively state that it is unlikely that in the near future there will be a “worthy rival” to reinforced concrete wells, because the disadvantages of polymer analogues are too significant. They make themselves felt especially often in regions with cold winters - it is rare for a plastic well to serve properly for more than 3-4 seasons.

Installation features

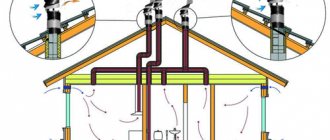

Let's consider the algorithm for constructing an external sewer system:

- creating a project. It includes the calculation part, layout diagram of components, system elements, specification for materials, components;

- acquisition of necessary materials, pipes, containers;

- production of earthworks. According to the diagram, markings are made, then trenches are dug for laying pipes, nests for containers, wells, and collectors;

- installation of containers, septic tanks, and other reservoirs. In conditions of high groundwater levels, a concrete anchor is first installed at the bottom of the nest to fix the position of the container. Alignment along the axes, waterproofing (if necessary), and insulation are immediately performed;

- Pipelines are being laid. They must have a given slope that corresponds to the diameter of the pipe. So, for elements of 110 mm, the level should decrease by 2 cm for every meter. The larger the diameter, the smaller the optimal slope;

- pipes are insulated. Different materials are used. The best choice is a foam shell. It tightly covers the pipe, completely eliminating the loss of thermal energy;

- tests are being carried out. They pass water through the channels and see how tight the connections are. Detected defects, leaks or other defects are eliminated. After this, the trenches are covered with soil. From this moment the system can be considered put into operation.

This algorithm applies to almost all complexes. Each project has its own characteristics, but the general construction procedure remains unchanged.

Waterproofing of sewer mines

High-quality waterproofing is the key to the proper functioning of the sewage disposal system. The tightness of the structure ensures the absence of foreign water, in particular groundwater, in the sewer line. Their entry into the sewer accelerates the process of accumulation of sewage in the well. Accordingly, poor waterproofing affects the frequency of calling a sewer truck to pump out wastewater.

Waterproofing is carried out in accordance with the following rules:

- Before applying sealing compounds, the joints of reinforced concrete rings are cleaned of dirt and then moistened to increase the adhesion of the mastic to the concrete surface;

- Waterproofing is carried out using waterproof mastics, which fill the gaps between reinforced concrete rings;

- The waterproofing must dry evenly over the entire area of the gap, so it is prudently covered with polyethylene.

A sewer well is the main element of a sewerage system, which can have several functional purposes. Some types of structures are used as a waste collection point, while others are used to control the operation and clear the sewer line of blockages. In the process of assembling sewer shafts, it is necessary to take into account SNiP standards, which relate to the parameters of the installed equipment, as well as the level of the pipeline and the distance between structural elements.

https://youtube.com/watch?v=Lg7l8vHw13s

Water protection

The control well on the sewer must be impermeable to water to prevent contamination of the soil and the environment by runoff. For this purpose, water protection is carried out using special means. It can be:

- rolled materials (roofing felt, waterproofing, PVC film);

- cement mortars;

- mastics;

- coating mixtures;

- membrane materials.

Waterproofing is carried out as follows. First, prepare the surface, clean it, and level it. Then the joints and joints are filled, only then the entire inner surface is covered.

Sewerage service control points can be divided into two types:

- serviced;

- managed.

The first type of device has a hatch; it is opened for periodic inspection of the condition of the system. In controlled points, control occurs using a special control cabinet. There is no need to go inside when the measurement occurs automatically. Equipment inside the monitoring well measures environmental indicators and shuts off the water if the measurement results differ from the norm.

The sewer system includes control wells for monitoring communications, periodic inspection, cleaning and maintenance. Solving all problems related to testing the quality of wastewater and the functionality of the entire system is impossible without control points.

Drop tanks

Quite often there are areas located on the slopes of the area, where elevation changes range from one to 10 meters. In such cases, for proper installation of the sewer system, differential wells are installed in the areas. The maximum angle of inclination of the pipe should be no more than three meters; otherwise, it is better to make a stepped structure with a gradual drop of no more than one and a half or two meters.

The distance in this case will be considered the same as with turning ones. In both cases, installation will take place in places where the angle of the pipe changes. Accordingly, when making calculations, one should proceed from the bends of the sewer line and install mechanisms that level out the strong slope of the terrain.

Conclusions and useful video on the topic

This video material clearly presents the advantages of models made from modern polymers over reinforced concrete products.

Modern plastic wells not only look more attractive than their reinforced concrete counterparts, they weigh less and are better waterproofed. The future is definitely theirs.

Without a sewer system it is impossible to imagine the life of a civilized society. And without wells of various types, not a single sewer system can carry out its work. Now you have an idea of what these structures are like, how they are designed and what materials they are made from.

Do you have any questions while reading the material we offer? Do you have useful information that you want to share with site visitors and us? Please write in the block below.

Stages of sewerage installation

- Drawing up and coordination of the project. A sketch of the pipe layout is created, the types of installation work are determined, and the required amount of materials and components is calculated;

- Preparatory work. This includes, for example, dismantling old sewers or digging trenches and drainage holes;

- Installation of risers and sewer pipes, connection to plumbing points;

- If available, installation of an external sewer pipeline and treatment system;

- Checking connections;

- Commissioning.

The cost of sewer installation will depend on the need to dismantle the old system, the complexity of the work to be done and materials.

Installation of internal sewerage

In other words, this is the installation of a sewer system within the boundaries of an apartment or house. This includes replacing or installing a riser and laying a pipeline from it with subsequent connection to devices.

When replacing a riser in an apartment, the pipe is replaced within one or several apartments of a common riser. In a private house, the riser is led outside, its upper part acts as a ventilation hole. The remaining pipes are laid horizontally, at a slight angle to ensure gravity flow.

The standard installation of pipes in an apartment involves running three lines from the riser leading to the bathroom, bathroom and kitchen, where plumbing fixtures are located.

For a home, the distribution of appliances does not matter, because any number of risers can be installed there. Sewage pipes can be laid both on top and inside the floor or walls.

Installation of external sewerage

A private house must have its own sewage drainage system. Therefore, an underground pipeline with a thickness of 11 to 20 cm is laid, which will discharge wastewater into a cesspool or treatment plant.

Pipes underground must be protected from destruction by soil, so a layer of sand is poured under them and on them and filled with water. At the entrance of the pipe to the cesspool, the depth must be at least a meter, otherwise there is a risk of freezing. Every 25 meters or at turns, at differences in height of the pipeline being laid, inspection wells are installed.

There are two methods of operating a sewer pipeline: gravity and pressure, in which wastewater is discharged by pump pressure.

Installation of an autonomous cleaning system

The installation process involves digging a pit at a depth of up to 3 meters. For a station with soil post-treatment, you need to install either a filter well or an absorbent trench - special drainage pipes.

If you plan to install a biological treatment station, an additional filtration well or drainage ditch is dug.

Blitz tips

- It is not recommended to make the trench depth too large , because you will need to add soil, which will subside over time. As a result, the highway may change the correct slope.

- To avoid damage to the pipeline, it is prohibited to place solid objects under the pipes during their installation .

- When choosing a site for the construction of a filtration or storage collector, it is necessary to provide for the possibility of equipment access to clean the structure.

- Despite the fact that a sewer septic tank is a wet type of well, its tightness must be ensured. This is necessary in order to minimize the penetration of wastewater into the environment. To waterproof the ring joint areas, special waterproof compounds are used.

- During the period of providing a waterproofing layer for 3 days, it is necessary to exclude the impact of mechanical loads and low temperatures on the surface. During this time, the treated areas should be regularly moistened using a regular sprayer. You can also cover the surface with a film, which helps reduce moisture evaporation.

Alternative to plastic insert

First, it is necessary to empty the storage tank or septic tank to be repaired by pumping out the contents with the involvement of a team of vacuum cleaners. The service of pumping out a septic tank and removing its contents is provided by utility services and private companies. It is cheaper to negotiate directly with the municipal services sewer man.

Sewage transport will need an access area to the work site. Moreover, the shorter the transport arm of the vehicle, the shorter the access distance will be. Its permissible length is up to 180 meters and even more - up to 500 m, if it is a high-pressure polyethylene hose.

Pumping out a septic tank should be carried out by trained specialists; amateurs will not be able to do it. Work on cleaning a septic tank is carried out with a special pump - a sewer (fecal) pump.

Waterproofing concrete septic tank joints

To seal the gaps between the concrete rings of the well, you need to reach them from outside the structure. It is necessary to dig a ditch around the septic tank to a depth that allows you to work with the joints between the reinforced concrete sections.

Accordingly, the more rings there are in the tank structure, the deeper the ditch will have to be dug. The width of the ditch is at least a meter. It will be difficult to work in a narrow ditch.

Having dug up the walls of the septic tank, you need to dry them. By the time waterproofing work begins, there should be no dark spots on the concrete walls. The seams must be cleared of accumulated debris and soil, exposing a cavity at least 70 mm deep.

If rain is expected, the well and the ditch dug around it should be covered with moisture-proof material (plastic film, tarpaulin, etc.).

If you dig out a septic tank with a narrow trench, there will not be enough space for waterproofing work

To fill the seams, you need well-punched clay and a plaster float. The clay should be kneaded with your feet in a basin or other similar container. Packing joints between concrete rings with unpressed clay is ineffective - its structure will be uneven and include voids that allow water to pass through.

The external seams between the concrete sections of the septic tank can be sealed with a cement-sand mortar mixed with liquid glass. Composition of the mixture: liquid glass, cement and sifted fine sand in a ratio of 1:1:3.

The mixture should be prepared in small portions - when liquid glass is added, the solution quickly hardens. The seams are filled with this solution using a spatula.

The joint mortar is also prepared from a mixture of cement and PVA construction adhesive. Proportion: 5 parts cement to 1 part PVA. After filling the joints with mortar, two or three layers of liquid glass can be applied on top. This will enhance waterproofing.

Before filling the joints with cement mortar, it is necessary to treat them with a primer. Technical priming materials are used for septic tanks. For example, this is one part bitumen to three parts gasoline.

There are pores in the structure of the concrete stone, so septic tanks assembled from reinforced concrete rings allow water to pass through, albeit in small quantities. When freezing, the water in the pores will crystallize, increase in volume and ultimately destroy the monolithic compound.

To avoid destruction of concrete by crystallizing water, it is necessary to impregnate the concrete from the outside with bitumen mastic at least 0.5 m below the depth of seasonal freezing in the region

Installation of roll waterproofing

Having completed the work on the seams of the concrete rings, we begin to form the surface layer to protect the tank from moisture. If clay was used for the joints, then roll materials cannot be applied over them - the clay plaster will be broken when the adhesive mastic hardens.

The outer surface of the concrete well must be completely covered with a primer, for example, bitumen-gasoline. This will improve the bonding of rolled waterproofing with concrete rings. Then the walls are coated with heated tar mastic, and the rolled bitumen material is glued in two or three layers.

Note that bitumen mastic is not suitable for waterproofing the walls of a septic tank with rolled materials - it cracks when it cools.

If there is a high groundwater table in the region where the septic tank is installed, then it is recommended to carry out waterproofing to the entire height of the sewer well shaft

To reduce or eliminate the likelihood of soil heaving around a concrete shaft, sand and crushed stone backfill is used (40% sand, 60% crushed stone). It fills a ditch previously dug around an underground reservoir to repair the seams between well rings.

If there is sand without clay inclusions, gravel or crushed stone deposits under the soil layer on the site, then backfilling can be done with soil from a dump formed during the development of a pit around the septic tank.

Material of manufacture

The sewer well shaft can be made of various materials. The most common:

- brick;

- concrete;

- plastic.

| Brickwork | High strength; if you know how to use a trowel, installation will not require much time. Holes in the walls are made during the construction phase. |

| Concrete | Installation - using formwork or installing ready-made rings. Holes for pipes in poured structures are made during pouring, in rings - with a hammer drill or other tool. |

| Plastic | Made from Eurocubes or barrels. There are also factory containers that include trays with various types of wiring. May require anchoring to concrete base. |

For brick and concrete wells, waterproofing of the walls, outside and inside, and the bottom is necessary.

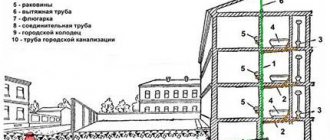

Network composition

Various sources can be used for water supply. There are social and autonomous types. Public ones have high power and are capable of providing water to large settlements. Autonomous are wells or wells designed to supply a certain, relatively small number of consumers.

The public complexes include:

- main lines or water intake;

- stationary treatment plant with a preparation complex;

- pumping station providing standard pressure in pipes;

- system of pipes, wells, shut-off valves, and other technological components.

Sewage systems are also divided into public and autonomous. The first has a branched structure, largely replicating the water supply network. Installation of sewerage networks is carried out according to our own standards, of which sanitary requirements come first. The drainage systems include:

- pipeline complex;

- wells for one purpose or another (inspection, rotary, extinguishing, differential);

- pumping stations;

- open trays (for rain nets);

- filters, sand traps, settling tanks.

Treatment facilities are also part of the sewer system, but form a separate group of structures. In autonomous systems of private houses, waste disposal is carried out independently. There are structures that accumulate wastewater, but require periodic pumping. There are more modern installations that can process organics partially or completely. They are built according to their own rules, which cannot be ignored.

Peculiarities

Any drainage system must have a sewer well or chamber. Such equipment should be located at the entrance to the septic tank, which is located on a suburban area. Sewerage structures also have a different name - wet or drainage well.

An autonomous type sewer system is a complex standard design of an engineering system, the installation of which will require plumbing and construction knowledge. The key component of each autonomous sewer system is a special well.

The system should have several wells:

- observation;

- turning;

- well for household waste;

- well for rainwater.

The owner of a country property must understand the features and differences of each type of structure.

Features of the creation of sewer wells are described in the sanitary and technical standards of SNiP. The documents describe the location of wells, markings and the need for preliminary preparation.

Features of the arrangement according to SNiP are as follows:

- before work you need to decide where the well will be located;

- markings will be required on the ground;

- trees and bushes that interfere with construction work must be uprooted;

- easy passage of equipment must be ensured to the construction site;

- You will need to draw up a detailed diagram that is agreed upon with the water utility and neighbors.

The following technical requirements apply to sewer wells:

- inspection structures should be located in increments of 30-40 m if the hatch diameter is 15 cm, or 50 m if the diameter is 20 cm;

- at each pipeline bend, as well as at the branch pipe locations, rotary type wells should be located;

- in places where the diameter of the pipes changes or there is a sharp slope, the installation of a drop well will be required;

- there must be a minimum distance of 3 m between the storage well and the living space;

- the diameter of a modern sewer well can be 40-70 cm; auxiliary pipes can be used for the outlet.

Volume

The volume of the sewer well is greatly limited. Thus, the maximum permissible height is only 2500 mm. The diameter is a maximum of 1 meter, but modern ready-made wells have a diameter in the range of 400-700 mm.

For the calculation, the figure taken is 150 liters of drainage per person per day. For a family of 4 people, the consumption is assumed to be 700 liters per day. Based on this, the well must have a volume of at least 2.4 m3.

More accurately, the volume of the well is selected based on the type of soil in which it is planned to be installed. To increase the volume of the well (if necessary), you should build 1 or more additional wells nearby, connecting everything with overflow systems.

Choosing a site for construction

First of all, it is necessary to find the right place to build a water intake structure and determine its depth. If there are similar structures in neighboring areas, the task becomes easier. To do this, you should talk to your neighbors and find out the following information from them:

- What is the depth of the water intake structure on their site.

- What volume of water does it produce?

- When was it built?

- Features of its use.

When choosing a site for construction, you should be guided by the standard distances from SNiP 30-02-97. According to them, the following minimum distances are allowed between the well and other objects on the site:

- from the foundation of the house to the water intake structure the minimum permissible distance is 5 m;

- the minimum distance at which a well can be built from buildings for domestic animals is 4 m;

- to any outbuildings on the site – 1 m;

- trees must be at least 4 m away;

- a minimum of 1 m is set back from the bushes to the water intake structure;

- there must be at least 50 m from septic tanks and cesspools to the source of drinking water.

According to SNiP, there should be no cesspools above the water intake well.

Types of inspection wells and the permissible distance between them

Observation

Installed for free access and maintenance of the system. The distance between wells is indicated in the table.

| Pipe section (mm) | Distance between wells (m) |

| 150 | 35 |

| 200-450 | 50 |

| 500-600 | 75 |

| 700-900 | 100 |

| 1000-1400 | 150 |

| 1500-2000 | 200 |

| >2000 | 250-300 |

Rotary

Mounted in places where pipes form a turning angle

- The distance between wells is calculated along a straight section of the pipeline.

- The length of the segment is indicated in SNiP. If you do not meet the requirement, you will have to install an additional well.

Variable

Structures are necessary in areas with changes in the height of pipe laying

- SNiP has not established standards for the distance between these structures, but the following requirements are imposed:

- One difference cannot be more than 3 meters. If the slope is greater than this footage, then a stepped overflow system with wells is created.

- If the difference is 50 cm, the well can be replaced with an overflow

Nodal

Used at the junction of pipes. The distance depends on the diameter of the pipe.

| Diameter (mm) | · Distance (m) |

| · 600 | · 1 |

| · 700 | · 1,25 |

| · 800-1000 | · 1,5 |

| · 1200 | · 2 |

When arranging an external sewer line, it should be taken into account that the distance from the sewer to a source of drinking water must be at least 30 meters.

How to monitor the water quality of drinking wells

When the relevant authorities check the quality of water in drinking wells, the surrounding area is also subject to inspection. The main types of water quality control:

- Planned. It is carried out after a certain period of time. Includes a set of basic measures to determine the water quality of all water supply sources (wells, wells).

- Selective. Can be carried out in regions where problems with water supply systems were previously noticed.

- According to one-time applications. The initiator of such a check is the direct owner of the land plot. Performed to check the suitability of water.

Often, the first water intake may include too many harmful bacteria and microorganisms. Then a more in-depth examination of the water is carried out, which determines the cause of the deterioration of the water. All indicators are compared with the standards of the relevant instructions.

To improve the quality of water, the drinking well can be cleaned and subsequently disinfected. If after this the problem has not been eliminated, then the quality of the water is improved by using special preparations with a high chlorine content. If the pollution is of a chemical nature (especially pollution with aggressive substances), then a decision may be made to eliminate the source.

Types of wells in the sewerage system

Drainage networks consist of various elements, each of which has its own functions. Pipelines transport wastewater, shut-off valves regulate this process, and wells of various types allow you to monitor the condition of the system and serve as its end point.

There are several types of sewer wells for various purposes

To carry out control, three types of well structures are installed:

- Observations.

- Drops.

- Rotary.

- Nodal.

The first ones are installed on long sections of sewer pipeline to inspect it and clean it as necessary. The latter are installed in areas with a large slope and allow you to reduce the flow power. Still others are installed at pipe turning points so that in case of blockages they can be cleared. And the fourth ones are installed when it is necessary to combine several water pipelines.

Sewerage pipelines end with a well of one of two types:

- Storage – used for storing wastewater.

- Filtration – designed for clarification and purification of wastewater.

In a private house, the installation of sewer wells of all these types is regulated by the rules set out in SNiP 2.04.03-85 “Sewerage. External networks and structures" (SP 32.13330.2012) and SNiP 31-02-2001 "Single-apartment residential houses" (SP 55.13330.2011),

Reinforced concrete well diagram

According to sanitary standards, septic tanks and sewer wells must be removed at least by:

- 3 meters from trees on a personal plot;

- 5 meters from the foundation and underground gas pipelines;

- 10 meters from the garden beds;

- 30 meters from sources of drinking water.

It is often necessary to install a sewer well at a fairly large distance from a private house. You cannot do without long pipelines; you will have to install additional inspection units.

What are sewer wells made of?

Underground chambers of the external sewer system can be equipped with:

- concrete (reinforced concrete rings);

- bricks;

- factory-made plastic products.

Factory-made concrete rings are available for any size

Types of wells

When installing sewer systems, you need to understand their types, which, according to their purpose, are:

- Inspection rooms - provide monitoring of the uninterrupted operation of wiring, repairs, flushing, and removal of blockages. These structures, depending on their location along the highway, can be linear or rotary.

- Differential - built at different pipeline depths, or if it is necessary to adjust the flow speed. Such structures are needed to bypass underground obstacles.

- Filtration sewer wells - used for post-treatment of wastewater and its disposal into the soil. The bottom of such systems is not sealed; it is filled with filter material. The container also has filtration holes in the walls.

- Cumulative - have the same principle of operation of a cesspool. When installing a storage tank, it is important to maintain the tightness of the joints and ensure unimpeded access for the machine to pump out the contents.

Preparing the base

In order to properly install a sewer shaft and connect it to the pipe system, special attention must be paid to arranging the bottom of the pit. As a rule, reinforced concrete wells are used to assemble treatment facilities

Unlike plastic and other materials, they are more durable because they are not afraid of temperature changes and moisture. However, if they are installed, additional waterproofing will be required, which we will talk about in more detail, but a little later.

So, the construction of a storage type well involves the following finishing of the bottom of the pit:

- Fine-grained crushed stone or gravel is poured into a layer of 15-20 cm;

- After this, the mineral cushion is filled with concrete mortar;

- In order for water to leave the system by gravity, you need to make a slight slope of the bottom towards the outlet pipe.

What standards regulate the location of objects on the site of a private house?

The main document according to which the construction of a house and the installation of communications is carried out is the project. It contains a work plan indicating all distances and dimensions. The distance from the house to the sewer drainage point is also indicated here. During design, we are guided by two standards:

- SNiP 2.04.01-85;

- SanPiN 2.2.1/2.1.1.1200-03 (or 2.1.5.980-00).

These documents detail all the requirements for sewerage and define the minimum permissible distances between objects and buildings. It must be taken into account that instead of SNiP, the updated version of SP 30.13330.2016 is used today. It is more in line with current realities, although there are no fundamental differences. Regardless of where and by whom the sewerage system is built, the rules and regulations must be strictly followed.

Some owners of private houses believe that the location of the sewer system is their own business. This is a wrong point of view. The rules and regulations specified in building and health directives must be followed by everyone without exception. If the system is being built on the site of a country house, the requirements are more relaxed. But, for a residential building, all existing requirements must be met.

It is noteworthy that the issue of the distance from the septic tank to the house is ambiguous. While the minimum value is clearly defined, the maximum value is not mentioned anywhere. Sanitary standards for sewerage for the private sector also do not mention a maximum. It is only noted that it is advisable to make the distance as large as possible. However, if the septic tank is too far away, blockages or defrosting of the pipes are inevitable. Under such conditions, the system will not be able to operate normally. Therefore, the location of the sewerage system on the site must meet not only sanitary, but also operational requirements.