Want to make a table from pipes with your own hands, but need some inspiration first? In this article you will find 25 examples with metal, copper, PVC pipes of different styles and designs to suit every taste. The use of water pipes without problems allows you to create individual table frames of various configurations. The step-by-step instructions provided will leave you with more time to focus on the design, rather than spending a ton of time figuring out how to put it all together. Having figured it out, how to make a table from pipes, you will probably have your own creative ideas. But let’s not forget about PVC pipes, which are also an interesting and creative way to create artistic furniture for your home. The materials are inexpensive and do not require assembly skills, so make a table from PVC pipes even a child can do it. Or maybe you want to make an elegant table with legs made of copper pipes? There are also such examples in this article.

DIY coffee table made from pipes

Loft furniture will always be popular because it is not just a fashion trend, but a special character of the interior. Metal and wood are hallmarks of industrial style. Threaded steel pipes form the perfect frame for a coffee table , which is very easy to assemble with your own hands. Calculate the number of parts needed and their length, then use the connectors to assemble the frame. Spray paint the frame and attach the plywood table top. You can leave the homemade pipe table as is or apply a clear varnish. Plywood is a better choice for the top because it is less expensive than planks.

To assemble the frame, connect two 20 x 200mm pipes using T-fittings for the legs.- Then make brackets from 250mm pipes and screw them to the T-fittings for the legs.

- Connect the legs with a crossbar made of 900 mm pipe. Attach the end caps to the bases of the legs.

- Apply a coat of primer to the frame, then apply 2-3 coats of spray paint. Tip: When spraying, wear a protective mask and work in a well-ventilated area.

- To attach the coffee table top, use a circular saw to cut a sheet of plywood to measure 1000 x 750mm.

- Lay the top face down, center the frame, and attach with screws through the exposed elbows.

- Sand the surface with sandpaper and apply a coat of clear varnish.

Photo source: www.handyman.net.au/diy-steel-pipe-table

Desktop

Various tables and small tables are among the most popular types of furniture. We suggest making a simple desktop with your own hands from polypropylene pipes and a hollow door leaf. This tabletop size will allow you to place a laptop, textbooks, notebooks, maps, diagrams, etc. on the surface. Therefore, the product can become a workplace for both a school student and an office employee.

Prepare everything you need

Tools and materials:

- A hacksaw or miter saw to cut material to the desired size.

- A screwdriver or hammer drill will help attach the legs of polypropylene structures to the working surface.

- Threaded screws for 1.25, 1.5 – 15 pcs.

- PVC glue can be replaced with small self-tapping screws.

- End caps – 5 pcs.

- Desk plugs – 5 pcs.

- Cross-shaped plugs – 4 pcs.

- T-shaped regular plugs – 4 pcs.

- T-shaped four-way connectors – 4 pcs.

- PVC pipe sections: 5 pcs. 0.075 m (3 inches), 10 pcs. 0.3 m (12 inches), 4 pcs. 0.5 m (20 inches), 4 pcs. 0.75 m (30 inches) each. In the diagrams, the dimensions of polypropylene pipes are presented in inches.

All T-connectors can be replaced by soldering. Please note that this will slightly reduce the final cost of the table, but its appearance will suffer.

Description of work

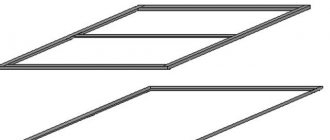

- First of all, we start assembling the left side of the frame. The assembly includes 4-way and regular T-connections, tabletop and flat plugs. All details are shown in the picture.

First, we simply assemble the structure to check the accuracy of the plastic parts. Then we disassemble it and assemble it completely, fastening the joints with glue. After using a special adhesive composition, it will no longer be possible to redo the work.

PVC glue should be applied to the inside of the connecting element. Check that all parts are correctly placed, only then forcefully press the pipe into the hole of the fitting connector and hold for about 30 seconds.

Attention! The adhesive is not recommended for use indoors, so instead you can seal the connection between the pipe and the connector with a screw. Also, if you do not want to erase markings from plastic pipes with acetone or another solvent, place the parts when assembling so that the inscriptions are on the back side.

- The steps for assembling the second side part of the base exactly repeat the previous ones, but with a mirror image. T-shaped four-way fittings are turned in the opposite direction.

- Let's start assembling the rear part of the support structure. The table plug, flat fitting, 2 cross connectors should be used. Using them, assemble pieces of plastic pipes of 30 inches, which is equal to 75 cm, as shown in the diagram below. To ensure that long parts are installed exactly parallel to one another during assembly, place them on a flat surface, such as the floor, while working.

- At this stage, we assemble ready-made fragments of the PVC structure. It is necessary to place the ends of the polypropylene pipes with their backs into the fittings that correspond to them on the sides: left and right. Everything is shown in detail in the diagram. Assemble the fragments and check for correct assembly. Then completely disassemble and reassemble using adhesive.

Apply the chemical to the inside of the first side fittings, holding the connection for up to 30 seconds until the chemical cures. Then do the same with the second side fragment of the structure. The base frame is completely ready.

- The last stage of DIY work is installing the tabletop on the base. Since the work surface is a hollow door leaf, care should be taken. The space inside is filled with foam, cardboard, or completely free. Inaccurate drilling can damage the entire structure.

Recommendations

- We recommend placing the door face down on a clean, level surface. Install the finished PVC structure symmetrically - the way it should be positioned in its finished form. The table caps will be adjacent to the door.

- Use a pencil to make marks where the holes should be drilled. After this, remove the base from the tabletop.

- Using a screwdriver or drill, screw the screws into all marked places. If the job was easy, you can insert a screwdriver instead of a screw to widen the holes. If there were difficulties (the screw got into the bar), you will not need a screwdriver. For now the screw needs to be removed.

- Place the PVC base on the door, adjust the position so that all the holes line up. Insert the screws and connect the work panel and legs.

It is better to use varnish or paint as a finishing touch. While working at the table, various contaminants will certainly fall on it. Therefore, the coating will protect this furniture from rapid damage and make it easier to care for.

Tools and Assembly

After purchasing the materials, you need to prepare the tools. Cutting is done with pipe cutters. Round-shaped products are cut with your own hands using special scissors.

The sections are assembled together using fittings, usually for diffuse welding. They are easy to work with and inexpensive. You can also use special glue or chemical mixtures. This method is especially preferable if there is no welding device.

However, you need to know that in this case the connections will be monolithic and cannot be disassembled. For mobility and further modifications, it is recommended to use threaded fittings made of metal-plastic.

In addition, you can use combined schemes. For example, the frame for a structure made of polypropylene pipes, such as a table, is made by welding, and the legs are fixed with threaded fittings. If necessary, the legs can be easily removed, and accordingly they can be transported and modified.

The nuances of working with the material

Models made from water pipes turn out to be unusual and original. They decorate the room, garden plot. Handmade plastic furniture will add zest to the interior and attract the attention of guests.

Furniture is made from plastic pipes. Two types of materials are used in production: polypropylene (PP) and polyvinyl chloride (PVC). Each of them has its own characteristics and is suitable for the production of different products. Polyvinyl chloride is a cheaper material. It is more often used for sewer pipes. Its advantages include:

- strength and durability;

- ease of installation;

- low cost.

The disadvantage of PVC is that when exposed to high temperature water, the pipes begin to deform. In contrast, products made from polypropylene are not subject to change in shape at high water temperatures. They are able to withstand liquid heating up to 60 degrees, and even more if the pipe is reinforced.

Both materials are equally suitable for making furniture. In addition, there are a huge variety of items that are made from scraps. These are shelves, stands, mirror frames and more. The furniture is easy to assemble. The structure consists of pipes and fittings, the elements are also glued together. Even a beginner can make pieces of furniture from PVC pipes with his own hands.

Final work

At this stage, all PVC fragments are combined into a single structure. The ends of the long pipes are inserted into the four-way connectors of each side frame. The result is a support in the shape of the letter “P”.

All joints are glued with cement and the manufacture of the tabletop begins. A door or a piece of laminate is laid on the floor, and a finished pipe structure is placed on top (upside down).

Carefully center the location of the support and make appropriate markings on the table top. Mark the places where the plugs come into contact with the countertop.

The PVC structure is removed and set aside. Using a drill, screw a screw into each point (if the screws fall into voids, be sure to insert screws). Afterwards, the screws are removed, a PVC structure is attached, and then the fasteners are again driven into the resulting holes.

Painting the frame

The pipe table is ready. It can be painted and varnished or decorated in another way - the matter is limited only by the creative imagination of the master.

Selection of materials

1. Hollow or solid. First of all, it depends on what the table will be used for. If you do not plan on heavy work on it, you do not need to use particularly durable materials. If you need stability, purchase a solid door or a ready-made countertop; the latter option will cost more. Keep in mind that a solid door is much heavier than a hollow one.

2. What kind of fastenings will be required? Firstly, desktop plugs, secondly, cross-shaped and T-shaped connectors. For greater savings, instead of using the latter, you can solder the pipes. Please note that with connectors the tables will look more aesthetically pleasing.

3. Select pipes. You need to look for them in a plumbing supply store; of course, there are also special furniture ones, but they will cost more in price. These tubes are stronger and will last longer.

Assembling the holder with “taps”

The next step is to assemble the holder. First decide on its height. Next, cut two lengths of racks from the PVC pipe. Place knees on the ends of the posts.

Assemble the upper part of the holder from three pieces using cross fittings. Connect the assembled top of the rack through the knees. Make sure that the free outlets of the fittings are positioned strictly vertically.

Lost weight: what Sofia Tarasova sacrificed for the sake of “VIA Gra” (new photos)

A student at the Vietnam Police Academy shared how she takes care of her facial skin.

The money tree pleases with lush flowering: my secret is in caring for the leaves

Assemble two taps from short pieces of PVC pipe using elbows. Attach the valves to the lower connections of the cross fittings.

Attach the assembled holder to the table through the tees on the short sides of the top frame. As a final step, install large funnels into the top pipes of the cross fittings and place the bathtub in place.

It is not necessary to paint the table holder. This way you can create contrast and make the design of the entire structure more attractive.

Organizers and shelves

Desk organizer

A simple organizer made from glued and painted PVC pipes looks cool and helps get rid of clutter on your desk.

Bathroom organizer

Toothpaste, brushes, comb - with such an organizer everything will be in its place, and you won’t have to look for anything.

Shoe compartments

With such a budget organizer made from PVC pipes, shoes will not be lying around in the hallway and getting under your feet at the most inopportune moment.

Wine shelf

If you love wine and like to stock up, this wine cabinet with PVC pipe shelves will keep all your supplies organized and safe. It looks great and is quite easy to make.

What you will need

To make a table you will need:

- PVC pipes with a diameter of ¾ inches;

- straight and angled plastic tees;

- plastic elbows;

- 2 cross fittings with 4 pipes;

- 4 plastic plugs for legs;

- several plastic funnels;

- large plastic container-bath;

- universal glue;

- spray paint.

Buy fittings for assembling the table, of course, in accordance with the diameter of the purchased pipes. Instead of a plastic bath, you can use any other unnecessary container, for example, an old basin. The glue can be used either universally or directly intended for gluing PVC.

Stylish interior elements made from PVC modules

It’s hard to imagine that amazing golden vases are made from ordinary PVC pipes

Very small fragments of plastic products are useful for decorating the interior and creating objects useful in everyday life. Using holes in the pieces, you can make several types of organizers - for shoes, stationery, toys, cleaning products. 5-15 wide elements, glued together and fixed to the wall, turn into a convenient shelf for bottles. A decorated PVC pipe with a longitudinal cut, hung above the bar counter, is a great place to store empty glasses.

Convenient shoe organizers made from large-diameter plastic pipes

To decorate your interior, you don’t need to buy expensive decor. It is enough to cut a thick plastic pipe into pieces of various lengths, paint the resulting elements in different colors, decorate them with sparkles, shells, pieces of colored glass, and you will get a magnificent set of flower pots. Plastic rings are an excellent material for creating festive compositions in the form of wall panels. Christmas tree decorations, hearts, flowers or Easter figures are placed in its holes, depending on the festive occasion.

Stylish shelves for towels, napkins and household items

An original and convenient organizer for stationery

As you can see, ordinary building pipes in skillful hands become comfortable furniture, useful home equipment, and exquisite decor.

Features of plastic

In this case, plastic refers to the materials used in the manufacture of pipes - polyvinyl chloride (PVC) or polypropylene (PP). The first of them is a cheaper type of plastic. It is used mainly in sewerage installations, since it has all the advantages of polymers.

These are: high strength, affordable price, ease of installation, durability. PVC pipes have one drawback - they are deformed under the influence of liquids at high temperatures.

As for PP products, they have the same properties, but they react much better to hot water - the temperature can reach 60 degrees, and in the case of reinforcement - even more.

Both materials are great for creating furniture and other structures - they are easy to assemble. It is enough to come up with a sketch, buy pipes and assemble them in the required order.

The simplicity of the design of the fittings and the possibility of gluing pipe products makes furniture made from plastic pipes easy to assemble.

As a result, you can get interior items with excellent qualities, since they will:

- sustainable;

- durable;

- lungs;

- safe;

- durable;

- cheap.

They are not afraid of moisture, are easy to assemble, disassemble, and can be modified.

Decoration

One of the options for decorating furniture made from pipes is to use different colors of the material. A table with blue legs will become a bright element in the room. Products come in different colors: white, black, blue, blue, yellow. Connecting elements also come in different shades. Thus, the pipes will be one color, and the fasteners will be another. Combinations of white and blue or black and red look beautiful.

When it comes to armchairs and chairs, they are decorated with decorative pillows. The foam lining on the back and seat is covered with a beautiful bright fabric. Decorative pillows decorate the product, making it cozy, comfortable, and original. They come with embroidery, buttons or tassels. The color range of pillows is varied. When choosing it, it is necessary to take into account the overall design of the entire room.

Children's furniture should be interesting and colorful. It is recommended to cover the chair or high chair with durable fabric with a bright pattern. This could be a cartoon character, toy cars, dolls, stars and much more. Pay special attention to furniture made from PVC pipes for children; it must be safe, without sharp elements. Otherwise, the kids may get hurt.

Making furniture from PVC pipes is easy. It will become a highlight in the room and will attract the attention of guests. Plastic pipes are inexpensive, so you can save a lot of money, since new furniture is expensive.

Plastic pipes can be used not only to create pipelines, heat and water supply systems. If desired, unique things can be created from plastic products - for example, furniture. DIY crafts made from PVC pipes can become original creations that will be a source of pride for their owner.

Variety of plastic pipes

It's no secret that plastic pipes come in different purposes, colors and sizes. Their physical characteristics also vary greatly; the pipes withstand different power loads and operate in different temperature zones (for example, for cold and hot water).

The plastics from which pipes are made today are divided into three groups:

- Polyethylene - PE. Do not behave well at high temperatures, the material is elastic and pliable even after exposure to sunlight! Consider the conditions in which your invention will operate; if it is in contact with hot water, then choose a different material.

- Polypropylene - PP. Today, products made from this material are considered the highest quality, durable and toughest. Unfortunately, these are also the most expensive pipes.

- Polyvinyl chloride - PVC. The main advantage is resistance to chemical attack and reduced flammability. In terms of price-quality ratio, we recommend using PVC pipes for various crafts.

Some manufacturers, for the convenience of their consumers, apply color markings to the surface of the tubes to indicate ownership. So, the blue stripe is for cold water, the red stripe is for hot water. It happens that there are 2 stripes on the pipe, which means that it is suitable for both hot and cold.

To increase the rigidity of plastic, manufacturers produce reinforced pipes. A layer of aluminum or fiberglass is inserted between two layers of polymer. Reinforced pipes are much stronger and more reliable, but their price is considerable.