A modern private house is usually built with an attic or second floor. The construction of such a house costs much less than a one-story house of the same area. The second floor, basement or attic is reached and descended by stairs, which simultaneously perform decorative and practical functions.

We welcome our regular reader and offer him an article about what a staircase made from a profile pipe is and how to install it with your own hands.

Advantages and disadvantages of such a ladder

Profile pipe – a pipe having a rectangular, square or oval cross-section. The pipes have a cavity inside and relatively thin walls - due to this they have a relatively low weight and high strength, which allows them to be widely used in metal structures.

A staircase made of metal profiles has many advantages compared to other types of stairs:

- The frame made of steel corrugated pipe has very high strength and does not lose it over time.

- Pipe is a relatively light material (when compared with rolled metal of a solid section), and the structure of the staircase will be much lighter than reinforced concrete and not much heavier than wood.

- Very long service life - in dry residential conditions, the service life of steel structures can reach or exceed 100 years.

- Steel pipe is a very technologically advanced material, and designs of any complexity can be realized.

- A staircase made from corrugated pipe can be manufactured and installed very quickly.

- Steel profiled pipes are an affordable material.

- Steel does not rot, is not damaged by bugs, does not dry out or crack.

- Stairs made from metal structures can be installed in an already built house, and they can be modernized at any time.

- Steel construction is more compact and versatile than reinforced concrete and wood.

Disadvantages of such stairs:

- Steel is susceptible to corrosion - structures will need to be painted periodically (and in damp places, such as a basement, cleaned and treated with special anti-corrosion agents).

- Lightweight structures spring a little when going up and down.

- The decorative value of a metal structure is small, so in residential premises the steel structure is decorated with steps, railings and fences made of wood, glass and plastic.

- To make the structure reliable, welding is used for its manufacture - you will need a welding machine and a craftsman with certain experience.

Safety regulations

In order to avoid injury while working on a ladder, follow a few simple rules:

- If you work at a height of more than 1.5 m, be sure to use a safety belt.

- When using an extension ladder or stepladders, it is not allowed to install them on other objects in order to increase the height.

- A structure installed at an angle of 60 degrees is considered safe. If the slope of the stairs is steeper, be sure to secure it at the top.

- More than one person is not allowed to work on portable ladders and stepladders at the same time.

- Do not move heavy objects along the stairs or pull on electrical wires.

- Do not use electrical equipment or large-sized welding machines on the attached structure.

- When moving up the stairs, be sure to hold onto them with your hands.

Types of staircases made of corrugated pipe

The main types of staircases made of corrugated steel are: marching, spiral, stepladders and extensions. Attached ones are simple and it’s easier to buy a ready-made one, but we’ll tell you more about the other types.

Marching

A flight staircase consists of one or more flights connecting interfloor landings and floors. The steps in the spans rest on one or more stringers, the spans are rectangular in shape, and the steps are also rectangles. Stringers can be straight or broken.

Single-flight staircases are installed in spacious halls or long wide corridors; more often they use the usual two-flight design - it can be installed in a staircase. There may be more marches. A single-flight staircase is convenient because in the space under the stairs you can equip a pantry, dressing room or small bathroom.

The convenience of a single-flight staircase depends on the angle of inclination. A steep angle of inclination of stringers is usually made at flights leading to the attic or basement - rarely visited rooms.

Screw

Spiral staircases are often installed in residential areas - for example, living rooms. They are very original and decorative, compact, but not very convenient to use. The advantage of a small ladder is its compactness - it can be placed in a circle with a diameter of 1600 mm. Spiral structures are usually installed in small houses in order to save space (in large houses a spiral staircase can be installed for beauty and a marching staircase for other purposes).

The consoles for the steps are attached to the central support along a helical line; along the outer perimeter, supports for the railings are installed on the console - from the outside, the staircase is covered with a lattice, adding rigidity to the structure.

The steps are triangular in shape; when going up and down, it is advisable to hold onto the railings with your hands for safety; going up with objects in your hands is very inconvenient. The most significant drawback is the inability to lift any large pieces of furniture to the second floor.

The second significant drawback is the complexity of design and especially manufacturing.

In large houses, you can install a turning staircase with a large rotation angle and rectangular steps - it looks very impressive, it is convenient to walk on it and carry things, but it takes up a lot of space. Typically, such buildings have a luxurious antique-style finish and serve as decoration for large mansions.

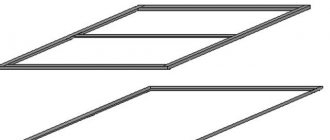

Ladder

This is the simplest type of staircase - two interconnected rectangular structures made of pipes, rungs can be on one side or on both. The frames are connected to each other using a special hinge. Triangular pointed tips are attached to the underside of the posts.

Preparatory work

Making a staircase is a step-by-step process, the first stage of which is preparatory work. First of all, measurements are taken and sketches are made. A project is selected that meets all building standards and suits the appearance of the residents of the house.

Then you need to draw up a drawing in which you indicate the following data and parameters:

- place of the structure in the house;

- stringers;

- steps;

- supports;

- handrails;

- filling the railings;

- fastening to supporting structures;

- platforms in a multi-flight structure;

- connections to the floor and ceiling.

Based on the diagrams, calculations are made, materials and missing equipment are purchased.

You must first prepare the opening

After this, you should address the following questions:

- Prepare your workplace. In order to weld and cut rolled metal smoothly and efficiently, you need a flat and stable surface.

- Remove away all objects that could interfere with or ignite from contact with sparks.

- Mark and cut the profile into blanks.

- Clean parts in places where it would be difficult to do after assembly.

- If the staircase is installed inside the building, you will need to prepare an opening to enter the upper level. The ceiling is first strengthened with supports, then a hole of the appropriate length is made in it. Its edges are equipped with steel corners.

This completes the preparation. All that remains is to wait for favorable weather and begin construction.

Calculations of the main parameters of the stairs

Standard parameters of the staircase: step width 30 cm, height 15 cm. Staircases with exactly these parameters are installed in high-rise buildings. But such a staircase would be too cumbersome for a home. To make the staircase more compact, increase the angle of its steepness. It is undesirable to increase the slope angle beyond 45°.

Calculator for the dependence of the length of the horizontal projection of a staircase on the angle of its steepness

The length of the horizontal projection depends on the height of the floor as follows:

Projection length = ctg α x span height, where α is the angle of steepness.

The height of the floor necessarily includes the thickness of the ceiling with the thickness of the floor covering.

Calculator for calculating the length of a flight of stairs

The length of a flight of stairs is calculated in two ways:

- If there is a steepness angle, then the length is equal to the height of the floor divided by sin α; or the length of the projection onto the horizontal divided by cos α.

- According to the Pythagorean theorem: the square root of the sum of the squares of the projection length and floor height.

Calculator for calculating the size of steps of a flight of stairs

The optimal height of the steps is 15 cm, from 12 to 20 cm are allowed. The height of the floor is divided by 0.15 m, a fractional number is obtained, the nearest whole number (more or less) is chosen - this is the number of steps. The height of the floor is divided by the exact number of steps and the exact height of the step is obtained (accurate to mm).

The depth of the tread should be at least 30 cm. This value allows even men with large feet to use the steps comfortably. If necessary, you can reduce the tread depth by 3 cm, but no more. If the horizontal projection of the march is too small to accommodate the required number of steps, then the steps are made winders - the upper step hangs over the lower one. This ladder should be used with caution when descending.

The width of the tread is usually in the range from 80 to 120 cm, in the most extreme case it can be reduced to 70 cm.

Preparation of the drawing and what to consider when making calculations

The quality of a future structure built from a profile pipe depends on the correctness of the preparatory work and the development of the drawing. By preparing a drawing, you can fully understand the dimensions of the future structure.

In addition, in this way, you can see how the future project will look. A well-drawn drawing of a staircase made from a profile pipe greatly facilitates the assembly work. Therefore, everything needs to be depicted on it in very detail.

Also at the preparatory stage, you need to mark and cut profile blanks to the required dimensions. If you plan to make a simple structural model, then careful calculation of the markings is not necessary. But, for a complex structure, all parts will require numbering so as not to get confused during assembly.

When the steps during the construction of a staircase are made of plywood or wood, it is necessary to prepare them in the required dimensions.

Watch the video

ladder

For additional fastening to the floor, take modules for assembling stairs from a profile pipe. This condition is optional. Mounting modules for assembly is carried out only in situations where it is important to reduce vibration when using the structure. If you decide to install modules for assembly, then they need to be taken into account when developing the circuit.

Making a staircase from a professional pipe with your own hands

A metal structure that all family members will walk through several times a day will only be reliable if it is assembled by welding. If you have some welding skills, then it is quite possible to weld and install flights of stairs in a private house with your own hands. Homemade designs look no worse than purchased ones. Below we will look at the installation of a single-flight structure with straight steps and straight stringers - it is the simplest structurally.

Required tools and materials

To weld metal structures you will need:

- Welding machine. For a home craftsman, it is enough to have an inverter welding machine with a welding current of 160-200 A.

- Electrodes.

- Drill, screwdriver.

- Jigsaw or grinder, cutting wheels for cutting metal, grinding wheels.

- Hand milling machine – for grinding weld seams.

- Tape measure, metal folding meter, square, protractor, plumb line, building level.

- Plane.

- Hammer.

- Clamps.

- Sandpaper, brushes.

- Anti-corrosion primer.

- Dye.

- Dried boards 40 mm thick for steps.

- Wood varnish.

Drawings and diagrams

The construction of a staircase requires very precise cutting of blanks and their welding, as well as the installation of finished structures. Therefore, before starting work, it is necessary to draw an accurate drawing or detailed diagram, accurately indicate all angles and dimensions.

Work order

Before performing work, carefully mark the profile and cut the frame blanks. Then the stringers are installed, the side supports for the steps (“zigzag”) and the transverse support bridges are welded. The welds are ground or milled, the entire frame is cleaned with sandpaper, and painted. Then the steps and fencing are installed.

Production video

Features of assembling structures using welding are shown in the video:

Assembly and installation of the structure

Below is a step-by-step description of the technology for welding and finishing the frame.

Frame preparation

Before welding the workpieces, it is necessary to grind or mill off the burrs at the cutting sites of the workpieces. Support plates are welded to the lower end of the stringers. Blanks for stringers are installed in their place and welded to mortgages or anchors previously laid in the wall. This work cannot be done independently - you will need an assistant. Carefully measure the angles of inclination before and after installation. Then they carefully mark the installation location of the lower step, weld two pieces to create a side support for the step. Then they repeat on the other side, welding the crossbar - and so on until the top of the stairs.

After welding each seam, it is necessary to allow the metal to cool, otherwise the structure will “lead.” When welding, the metal becomes very hot and can be deformed, so after each stage of welding it is necessary to check the dimensions and correctness of the angles and the horizontal-verticality of each part.

When welding, it is necessary to take breaks so that the metal has time to cool and does not “lead”. The seams are sanded or milled - protruding rollers greatly spoil the overall impression of the structure.

Installation of steps

The board is sawn to size, sanded, coated, if necessary, with water-soluble paint to give the desired tone, dried, and varnished 2-3 times. Drill holes and screw the boards to the side and transverse supports with self-tapping screws.

Mounting the fence

Modern fencing is usually mounted using bolts and nuts or self-tapping screws. A flange with holes is made on the underside of the fence posts and screwed to the side zigzag supports. It is impossible to weld the fence if there are wooden treads. True, you can weld the posts to the side of the structures, but such placement of the fence is not very aesthetically pleasing.

Painting and finishing work

Before installing wooden steps, the metal frame must be sanded, treated with an anti-corrosion primer, and painted twice.

Recommendations from professionals

In order for a homemade metal staircase to serve for a long time, experts advise following certain rules during installation and operation:

- support posts, bowstrings or stringers should be installed on concrete platforms or logs reinforced with additional bars;

- when connecting the stairs and the wall, the thickness of the capital structure should be at least 20-25 cm;

- If the street structure is made of structural steel, the surfaces should be regularly painted, first cleaning them of rust.

Metal stairs are practical and durable. They have earned popularity due to the ability to be combined with various finishing materials. You can make a metal structure yourself. Finishing begins after removing rust and thoroughly sanding the surface.

Photos – options for finished structures

There are many design options for staircases; our photos show the most decorative of them:

Sequencing

If you need a staircase made of a profile pipe, the photos on the page will tell you the best options. Let's write down the sequence:

- Pre-mark the work site - according to the resulting markings you will lay out the stair elements;

- Mark the profile pipe taking into account the drawings, then cut it into pieces at a 45-degree angle;

- Align the parts so that they form at right angles;

- Sand the ends with a grinder;

- After cutting out all the parts, lay them out on the table and secure them with clamps;

- Take your time to cook - use welding to make potholders;

- After making sure that the results are correct, connect all the elements completely;

- After re-checking, make the final welding of the iron corrugated pipes with a continuous seam;

- Clean the frame with a grinder until you obtain a flat, smooth surface;

- After completing the work, place them on the two parts of the frame and check the geometry is identical. It must be perfect;

- Degrease and paint the stringers;

- The staircase to the second floor from a profile pipe and its frame are secured in this way: weld the stringers to the reinforced concrete floor reinforcement, or secure the structure with dowels and anchors;

- Once you have finished installing the frame, begin attaching the steps and railings (if they are included in the drawing).

For finishing you can use different materials - wood, glass, stainless steel and so on. It all depends on your preferences and the overall style of the interior. Selecting decorative materials in Moscow will not be difficult. When the staircase made from a profile pipe with a platform is ready, you need to check it for creaks.

If it is important for you to know how to weld a staircase from a profile pipe, the videos on our page will tell you what to do.

Preparatory work

staircase from a profile pipe on stringers

No business begins without preliminary calculations and a drawing. With their help, you can accurately determine the amount of material that will be needed. To work comfortably and not have to be distracted, you should prepare the necessary tool in advance, you will need:

- Electrodes and welding machine;

- Grinder and circles for working with metal;

- Hammer with a set of drills;

- Hammer.

During preparation, it is worth making markings and cutting the material according to the required dimensions.

Metal stairs made of profile pipes

Recommendation: To prevent the process of assembling a complex staircase from becoming a puzzle, the parts should be numbered at the pipe cutting stage, from bottom to top.

Staircase made of profile pipe

Profile steps for installation in a building

Appearance of the staircase

As products made from profiles are becoming more and more popular, you can find any modifications of stairs made from profile pipes online. Even quite bold solutions in the form of glass structures without railings or a “duck step”, that is, an almost vertical flight of stairs with a step width for one leg, were not ignored. However, the easiest way for novice builders is to make a staircase from corrugated pipe with their own hands, which is most popular among home owners.

To correctly select the parameters of this design, you can make drawings of a staircase from a profile pipe with your own hands, taking as a basis one of the most suitable projects and adapting it to specific dimensions.

A march is a structure that is located between the turning platforms. There are straight, two- and multi-flight structures. If we are talking about a spiral staircase, then all the steps in it are located around the same axis. They are used for climbing inside a building - between floors or to the front door, as well as for crossing uneven landscapes.

Stationary stairs made of square pipes are considered the most durable and reliable. However, if necessary, you can use folding portable products.

To assemble a flight of stairs, the following materials are used:

- metal elements - corners, welded parts, profile pipes;

- wood;

- reinforced concrete;

- composite materials.

There may be several methods for installing parts for a flight of stairs, however, welding of metal structures is considered the most reliable.

Fastening the steps of the stairs can be:

The set of materials that will be needed to build a staircase from a profile pipe with your own hands will depend on the method of attaching the steps. To make it easier to choose the type of construction for a specific room or area, you can view a number of photographs.

Some experienced craftsmen recommend making only stringers or the base of the structure from a profile pipe, and using materials with less weight for the steps. The best choice for the base of the stairs would be a profile with dimensions of 60x40 mm.

We recommend: Plasterboard putty: step-by-step instructions

It is worth noting that profile structures have a number of undoubted advantages:

- Good resistance to mold and corrosion, making them acceptable in areas with constant temperature changes and without heating.

- An extension ladder made from a profile pipe can last for quite a long time, and if it is disassembled, the metal can be sold as unnecessary or scrapped.

- Assembly and installation of a metal modular or welded frame is quite quick and easy.

- Since the appearance of the profile staircase is quite laconic, it will not be difficult to combine it with the existing interior of the room.

- Profile pipes will be quite affordable for most buyers, so the cost of the project will be low. Yes, many people find it easier to work with metal than with wood.

- The metal frame made of profiles is superior in strength to any other similar structures.

- The installation time for a staircase to the second floor from a profile pipe is much shorter than when working with wood, if, of course, you have a welding machine and the skills to work with it.

- An important fact is that due to the presence of a metal base, such a staircase can combine a variety of materials - glass, marble, tiles and even plastic.

Please note that if you plan to assemble a lightweight structure, then it is better to choose a profile with thin walls. It is optimal to use a pipe with a diameter of 5-7.4 mm, which will be strong enough and will withstand vibration from the load.

Structural elements

When using a ladder, a person stands on steps, the width of which can reach the full width of the foot, or reach the heel of the shoe.

In order for the structure to hold, stringers are used - side strips with cut sections on which steps are placed. In addition, bolts can be used to connect the treads and fix the entire structure. Bowstrings are the end and bottom beams that support the steps. The vertical sections of the staircase that support the steps are called risers. They are needed to strengthen the entire structure.

As a rule, one flight of stairs in a structure made from a profile pipe has 18-20 steps laid on stringers. It is installed along walls and corners, or suspended between two floors, and it consists of two flight spans. Often the number of steps is made odd in order to begin and end the ascent of each subsequent march from the same foot. This rule is used both in small cottages and in large office buildings.

Before welding a staircase from a profile pipe, all identical metal elements are laid in pairs, and treads and risers are attached on top. The steps themselves can be made of lightweight materials placed in a metal frame, for example, they can be made of laminate or wood.

The standard calculation of a staircase made from a profile pipe looks like this:

- the gap between adjacent steps (rise height) should be about 14-22 cm;

- the angle of inclination of the flight of stairs is made at 30-40º, which is equal to the ratio of 1:2 or 1:2.5 length to height;

- The width of the steps is 20-30 cm, and if a small slope angle is selected, then it is slightly wider than the stop.

Procedure for carrying out work and procurement of materials

The design of internal and external stairs is completely different, and the simplest is considered to be a single-flight staircase on stringers for the porch. The metal spiral staircase is considered the most difficult.

The sequence of work for assembling a frame from a profile for a single-flight staircase is as follows:

- design and drawing;

- marking;

- dividing the profile into segments of the required length;

- assembly of the main frame for installing steps;

- welding of risers and steps;

- installation of the structure in place and pouring concrete on the site;

- installation of railings;

- laying wood in frames for steps;

- final decoration.

There are several ways to assemble a frame for a staircase from a profile. It can be made from paired profile pipes or steel stringers, or you can use a channel in which the steps will be welded on top of the base or inside the frame.

If we are talking about the design of an internal staircase with wooden steps, then the flight is fastened first at the top point, and only then it is fixed at the bottom. In this case, the ladder is fixed to anchors in the walls and a platform that serves as the first step.

Note that you should not forget about controlling the horizontal position of the steps. When all the main work is completed, you can begin welding the railings.

General technical characteristics of interfloor stairs

Profile steel pipe is a metal material with high load-bearing capabilities. Therefore, a ladder made from it is a durable and reliable structure that meets all safety requirements. There are other advantages:

- full combination with other materials;

- the ability to carry out different types of finishing;

- Can be used for indoor and outdoor installation;

- installation is carried out at any stage of house construction, even with completed finishing of the premises;

- simplicity of the assembly process.

Many people ask whether a DIY staircase made from a profile pipe will be reliable. The quality of assembly of a staircase structure depends on the experience of the workman, on his skills in working with different tools, where the grinder and welding machine are the main ones. If there are no skills, it is better to place the responsibility of production on the shoulders of the master.