In connection with the start of the new construction season, many novice developers are thinking about the question of how to fence their site. Our portal has already repeatedly talked about different options for constructing a fence, from stone to wooden fences made from unedged boards. The topic of today's article will be a step-by-step guide on how to independently build a fence from profiled sheets.

Features of a fence made of corrugated pipe

A do-it-yourself profile pipe fence is most often made from oval, rectangular and square products. This is explained by the fact that this configuration gives the profile high reliability with equal wall thickness, in contrast to rolled pipes with a round cross-section. The design of these fences is also very diverse.

Near the road

The range of metal fences made from profile pipes is quite extensive. For private construction the following are most often used:

- thin-walled professional pipes. This group contains metal profiled products with a cross section of 30x30 mm; the thickness of the walls in these pipes is around 1 mm. As a rule, these pipes are used to fill spans;

- professional pipes, which are of medium size. This category includes a profile pipe for a fence with a cross-section of up to 110x110 mm and a wall size of up to 5 mm. They are most often used to support fences.

Large-sized profile pipe, with a cross-section of more than 220x220 mm and a wall thickness of more than 7 mm, is, as a rule, not used for the manufacture of fences. Most often, these products are used to install the frame of prefabricated structures.

In addition, bases for large-sized machines are made from these pipes.

Office center

When making a fence from a profile pipe, you can use a different sectional structure, which is based on welded metal structures. These products can be framed, in which angles or other types of rolled metal are used as a frame, or they simply have supporting transverse connections.

All parts of the structures are firmly connected to each other by welding, creating a single structure. This makes it possible to withstand significant fracture loads, while the fence receives increased strength.

Section preparation

To install a fence from a profile pipe, steel with various additives that improve characteristics is most often used. In appearance, the pipes for fencing construction are similar to all-metal ones, but at the same time they have a hollow profile.

If you use a corrugated pipe for intake, its shape can be of different sections. Which pipe is suitable and which one is best to choose depends on individual circumstances.

The photo shows a fence made of corrugated pipe at the dacha.

private hedge

Hammering with a sledgehammer

The ideal way to quickly install fence supports without spending additional budget funds is to hammer in fence posts with a sledgehammer. This method is appropriate when constructing a fence up to 1.5 meters high; it is very difficult to hammer in higher fences with a sledgehammer.

Hammering poles with a sledgehammer Source www.masterovit.ru

At least two people must perform the driving. One must hold the support in a vertical position, the other must hit it with a sledgehammer. The impact point on the support is softened by a special wooden spacer. Cramped conditions are excluded here. The goal-scorer needs to have a full swing.

The process of hammering supports with a sledgehammer is quite labor-intensive. When performing work with different intensity (human factor), the rack may become skewed relative to the vertical axis. Therefore, the vertical support is checked with a level at certain intervals.

Advantages

Before welding a fence from a profile pipe, it is necessary to consider all the advantages and disadvantages of this fence.

The main advantages of barriers:

- Fences made from profile pipes are almost as reliable as all-metal products, this is due to their design feature.

- The corrugated pipe has an angular cross-section - this significantly increases strength, while the frame is light in weight and does not require additional material.

- The structure used is almost impossible to damage, since it is made of solid coils.

- Due to the fact that fences welded from corrugated pipe have a hollow structure, their production requires much less material, unlike solid fences. Taking this into account, the price of a fence or gate is much lower. This is especially true if a fence is required for a large summer cottage. In this case, even if the price is insignificant, the overall cost significantly increases installation costs.

- The section has a clear geometry. This gives the fence an attractive appearance. Due to this feature, a fence made of corrugated sheets can be installed on different objects.

Great option for a front garden

In addition, there are many more advantages if you install a welded fence. There are many types of welded fences, and these fences have a number of additional advantages, which in certain situations are the main selection criteria.

Corrosion protection methods

Without protection, metal quickly corrodes and loses strength, spoiling the appearance of fence posts. To prevent such a phenomenon and extend the service life of a metal pipe, its surface is galvanized by hot immersion in a zinc solution. The finished surface does not react with oxygen, water and chemical compounds in the air and soil.

Another way to protect pipes in production is to coat them with polymer films. They are applied in a thin layer to the metal surface. This method of insulation is effective for an almost unlimited amount of time, provided that the layer is intact.

The most reliable pipes have double protection with both zinc and polymers at the same time.

Even the highest quality protective coating is not able to withstand the elements of the earth for a long time and soon the galvanization and polymer layer are damaged, and the oxidation of the metal begins. To eliminate this process, the buried part of the pillar must be additionally isolated from the aggressive environment.

How to treat metal fence posts in the ground:

- Bitumen mastic;

- Special polymer mastic for metal processing.

The choice is small, but these products are highly effective and inexpensive. Coating is carried out at the stage of preparation for the construction of the fence. It is necessary to allow the mastic to dry before deepening the structure. Rolled materials are completely ineffective, so installing them in a drilled hole is pointless.

Preparatory work

First of all, you need to prepare the gate, gate and the fence frame itself. To do this, the galvanized pipe is cut to the required dimensions. Step-by-step instruction:

- First you need to create a drawing and cut profile pipes for the vertical rails of the fence. In this case, all parts must be made exactly to size. When working with an angle grinder, you should follow safety precautions.

- The corrugated pipe for vertical supports should be sawed taking into account which fastening scheme is chosen for the installation of the underground part. For reliable fastening, the future frame is deepened into the ground by 1/3. So, to the required height of the corrugated board fencing you need to add the appropriate size.

- The pitch of the horizontal joists will depend on the distance of the installed supports.

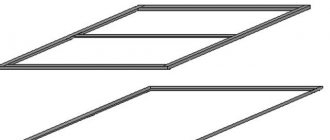

A drawing of the fence section is presented below.

Section drawing

The smaller the distance between the support pillars, the more reliable the fastening of pipes in spans will be.

Briefly about the main thing

To install support posts for a fence, 3 methods are used: concreting, backfilling, driving.

Hammering fence posts is an effective method of constructing supports, economical, but labor-intensive.

The advantages include quick installation and use in many types of soil. Disadvantages: fragility (up to 10 years) and labor intensity.

For light decorative or temporary fences up to 1.5 m high, driving is done using a sledgehammer; to speed up the process, use a hammer drill (using a special attachment).

For high posts (up to 3 meters high), it is advisable to drive the posts using a headstock; if you need to mount the fence quickly and do not take into account the financial issue, you can drive the posts using a piledriver.

Ratings 0

Manufacturing of sections and installation

Installation of fences from profile pipes is usually made from products with a cross-section of 45x45 or 55x55 mm, while the thickness of their walls is approximately 4 mm.

You can also choose different modifications that are made to order. In this case, there may be pipes with forging elements, or they may have any other modification.

Diagram with dimensions

Profiled fence pipes are more reliable and economical in contrast to modular fencing. But there is one difficulty - welding the material.

If you have the skills to work with a welding machine, then you can start installing profiled pipes yourself:

- First you need to select and align the products. This procedure is mandatory, since the size of industrial rolled products may vary.

- Then the corrugated sheet is cut taking into account the installation pattern used.

- After this, they begin to assemble the gate and panel frame using welding.

- It is necessary to weld a thin profile and all decorative elements to the frame. To prevent all parts of the future panel from moving towards each other during welding, they are clamped together using clamps.

- Then, when the required size and number of panels are selected, installation begins.

Welding drawing

Installation of pillars

At the bottom of a well with a diameter of 200 mm to a depth of 1200 mm, drilled with a hole drill, a sand cushion 100–150 mm thick is poured. After this, 110x110 mm supports are inserted and secured with small crushed stone or broken brick. The most important thing is to clearly control the vertical level and size of the pipes’ depth. This is especially important when the profile pipe for the fence forms an opening for the gate.

For fence posts made of corrugated sheets, similar rolled products are used.

Then the concrete solution is prepared and poured into the well. It takes about one week for it to completely harden.

During the installation of pillars and their cementing in the marked areas, temporary vertical fastening is required strictly at level. For this purpose, supports are used. So the future fence is left until the concrete has completely hardened.

Pole installation diagram

Before the concrete mixture hardens, you can select the appropriate size of the profiled sheet and choose gates, which can be ordered from a forge, or they can be made by hand. After the concrete has hardened, facing material is hung on the spans. Fastening is performed in different ways, depending directly on the material.

This is how the outer part of the fence is mounted. The side parts are easier to attach. For this, as a rule, a metal mesh is used, which is stretched between the supports. In most cases, it is not necessary to build a foundation.

Fastening sections

Through holes are made in the horizontal joists of the fence; this is necessary for attaching the vertical posts. When the holes are prepared, veins are installed in them. To make everything as smooth as possible, use a square or tape measure.

Section installation

It is advisable to treat the intersection areas with spot welding, since this significantly increases the strength of the structure. Also, vertical beams are often installed using self-tapping screws, having first made holes in the required areas of the supports.

Combined installation method (partial concreting)

For heaving soils, you can choose the method of partially concreting metal pillars. It, like the previous method, is suitable for both strip foundations and point installation of pillars.

- Dig a hole to 1/2 or 2/3 of the designed depth.

- The pipe is hammered to the design mark.

- Make a crushed stone cushion for concrete 10-15 cm.

- The formwork is placed and the frame is installed as with the full concreting method.

- Concrete solution is poured.

- After 5-7 days, remove the formwork and fill the hole with soil.

Price

As for the price, in this case the most important thing is to take into account the material of the canvas. For example, the price of a fence made of corrugated pipes 2 m high per linear meter is about 4,500 rubles. This cost includes installation of poles, filling of spans and painting. The most common price ranges are:

- The cost of the simplest option is approximately 3,000 rubles. per 1 linear meter.

- Average level - about 4400 rubles. per 1 linear meter.

- Business class – 5800 rub. and above per 1 linear meter.

Span drawings

In any case, the price of the fence will depend on its components. Since sometimes the supports are made of concrete or brick, this significantly affects the final cost.

Sketches

As practice has shown, if you choose the right profile pipes and follow all installation technologies during installation, you can get an original and practical fence. And positive reviews and visual photos are a clear example of this.

How to paint metal fence posts

After installation, the poles can be painted. This is a necessary measure to additionally protect the metal from corrosion.

Painting with bitumen varnish

Bituminous varnish is one of the most affordable means for processing metals.

- The pipe must be thoroughly degreased and cleaned of contaminants. If necessary, it can be washed with soapy water and then dried thoroughly.

- A metal brush is used to remove rust and create a relief for reliable adhesion of the composition to the base.

- After cleaning, the pipes should be wiped with a cloth soaked in solvent.

- You can apply bitumen varnish. If its consistency is very thick, it is diluted with white spirit. Apply the solution with a brush in 1-2 layers.

Enamel for metal

Metal paints are divided into 3 groups:

- 1) Primer enamels are independent products that combine the functions of a primer and a finishing layer. Enamels are applied to a previously degreased surface in 1-2 layers. When applied correctly and operating conditions are observed, the coating can last for several years, protecting the metal from corrosion.

- 2) Conventional enamels that require additional priming. Primer GF-021 is used as a base layer, which is applied to the metal in 1 layer. After drying, apply colored enamel in 1-2 layers depending on the desired color intensity.

- 3) Rust-resistant enamels are a modern product that does not require priming or preliminary cleaning of the surface from rust. The composition neutralizes pockets of corrosion and protects the metal from subsequent oxidation.

All compositions are available for purchase at any building materials stores.

- Fences

Which professional sheet to choose

It is enough to read any instructions on how to make a fence to understand that the methods of construction and the resulting decorative effect are largely determined by the choice of source material. Any project begins with a search for a suitable source in much the same way as a sculptor searches for good clay. Any step-by-step instructions about a do-it-yourself corrugated sheet fence contains a detailed description of which corrugated sheet to choose.

Sheet options

The requirements for the quality of the material are as follows:

- sheet thickness (experts recommend taking the MP series for fence construction, as a lightweight, convenient and inexpensive option, which, although thinner than other series, is very easy to install and performs its functions perfectly);

- the length of the product can be variable, but usually it is cut to the required length at the point of sale (if you make all the dimensions in advance, you can bring home ready-made blanks for the assembled structure);

- color (nowadays there are numerous color options in corrugated sheets, you just need to decide what you need, and even if it’s not there, you can always order it from the warehouse);

- metal coating, which may vary, but polyvinyl chloride, pural (polyurethane, acrylic and polyamide) or matte polyester have earned favorable consumer reviews;

- pattern (with a high wave, wide or narrow, imitation, with rounded or reinforced ridges, groove, and so on);

- useful usable area (the width of the sheet, which is used to create a decorative component and does not go to waste).

It can be installed from any, even the simplest and thinnest corrugated sheet, especially if this structure is planned as a temporary means of demarcation. Then the simplest galvanizing will do.

If you are planning a permanent fence made of brick and corrugated sheets, then the selection should be taken responsibly. For example, for a general area, buy from the PM series, and for a gate, buy a permanent one that is resistant to damage.

An example of a beautiful hedge in the photo below.

Fencing on a suburban area

Screw piles

Progress does not stand still, so modern technologies can be used when constructing a fence. In this case, we are talking about installing screw piles, which are an ideal solution for complex and heaving soils. They are easy to install to the required depth and you can be sure that they will stand securely.

Screw piles

If you do not have a modern laser level, then the best way to control the correct vertical position of the pipe will be a plumb line.