Drainage is an engineering system designed to collect and drain excess water from the surface of the earth and deeper layers of the soil. It consists of channels, gutters, perforated pipes, inspection and collector wells, and wells.

Laying drains is a necessary part of the construction work in areas with high groundwater levels, large amounts of seasonal rainfall, and in swampy lowlands. The article highlights the main stages and rules for installing drainage pipes, which will help the developer to effectively drain the site and the area around the house.

Drainage system for draining water away from the house

Purpose of drainage pipes

Increased soil moisture negatively affects building structures, especially building foundations. Under the influence of water and temperature fluctuations, the base quickly collapses, cracks appear on the base and walls. Flooding of a garden plot can cause the death of plants and damage to household structures.

To reduce the impact of floods, precipitation or groundwater, site owners lay drainage pipes with their own hands. Timely drainage eliminates the cause of winter frost heaving, which results in the destruction of foundations, blind areas and paths. In basements or cellars, air humidity decreases and mold spots disappear. The walls of underground structures do not freeze during cold periods.

Draining swampy soil on a personal plot leads to earlier warming up. This has a beneficial effect on plant growth and increases yield. Gardeners have noticed that there are fewer crop pests and mosquitoes. Platforms, paths and other landscaping elements on dry, stable soil last longer.

Water drainage helps preserve landscaping elements of the home

Drainage pipes are widely used in industrial and civil construction for draining pits, laying roads, and in land reclamation.

Advantages and disadvantages

Ceramics

Steel as a material has a fairly significant cost; such pipes are susceptible to corrosion and “overgrowing” with a coating of insoluble calcium and magnesium salts. But the strength of metal exceeds any other type of pipe and sometimes you simply cannot do without it. The service life of products with anti-corrosion coatings reaches 40 years. There are smooth and corrugated.

Ceramics are a fragile, heavy material, it is difficult to install; there are no fittings for them to connect to modern manholes, for connection, or rotation.

The most current and popular type of drainage pipes for private estates is polymer.

Advantages of plastic products:

- low cost;

- ease of installation;

- no corrosion:

- plastic;

- Availability of a huge range of pipes and components (corrugated and smooth, double-layer and single-layer, with and without filter material).

- double-layer drains have very smooth internal walls - this increases the speed of water flow and the volume of water discharged.

Disadvantages: in some cases - if there is a danger of landslides, earthquakes, severe ground subsidence - the strength of the plastic may not be sufficient and a metal drainage system will have to be installed.

The principle of operation of the drainage system

Drainage is an extensive network of drains and wells on the surface of the earth or in its thickness. Water flows into gutters or is filtered from adjacent soil by perforated pipes surrounded by a layer of drainage material. The elements of the system are connected to prefabricated collectors, where the moisture flows by gravity or is pumped.

To ensure that liquid flows into the wells, the pipes are laid with a slope. Water accumulated in collection containers is removed in different ways:

- seeps into the soil;

- moves, following the natural topography, to the lowest point of the site or body of water;

- pumped out for irrigation;

- is disposed of in the sewer or sewer truck.

An extensive network of water pipelines to remove excess moisture

*

In addition, to drain groundwater, lowering wells are drilled to the layer of drainage rocks or common drainage ditches are installed in several areas.

Types of products

There are several types of drainage pipes: ceramic, asbestos-cement, polymer. Nowadays, products made of polymer materials are mainly used. This is due to the fact that such pipes are lighter, cheaper and easier to install. They are divided into several types:

- Drains in geotextiles are pipes with a winding to protect the holes from clogging. The braid additionally acts as reinforcement and filters out impurities. Drains work well on loamy and sandy soils. Typically, geotextiles with a density of 100-200 g/m² are used. Sometimes a denser material is available, but it is a little more expensive.

- HDPE pipes are the most popular products for modern drainage systems. This is explained by good flexibility, high strength, and long service life (50 years). In addition, they have high throughput, so they are successfully used in both private and industrial construction.

- Polypropylene products have a number of positive properties, which include a long service life, the ability to withstand high loads, ease of transportation and installation, and lack of clogging. Their assembly requires electrothermal welding, which solders the pipes into a monolithic structure.

- Due to their high cost, drains with coconut winding are rarely found in construction, but they have a number of advantages: resistance to loads, do not rot, and do not become clogged. In addition, the coconut wrap is 100% natural material.

- Polyvinyl chloride (PVC) pipes are mainly used for deep drainage, as they have high strength. The maximum depth for their laying is 10 m. In severe frosts, polyvinyl chloride becomes brittle, so transportation in winter should be carried out very carefully.

There are also drains made of white asbestos, which are considered environmentally friendly without harmful impurities. They differ in that water enters them not through holes in the walls, but through pores.

Types of drainage and design features

Based on the nature of water collection, a distinction is made between surface and deep drainage systems. In cases where the soil is poorly permeable and groundwater is located deeper than 3 m, the first type of drainage is used. In lowlands, when there is a high level of moisture in an area with clayey rocks or in the vicinity of a reservoir, both options are used at once.

Surface drainage

Designed to collect water from the area adjacent to the house - rain or melt water. The liquid flowing from the roof, blind area and paths ends up in equipped grooves or wells and does not moisten the soil layers adjacent to the foundation.

Surface drainage of the area

Surface drainage is arranged in the form of:

- linear system - a network of shallow channels laid along the perimeter walls of the building, closed on top with gratings or without them;

- point drainage - open or closed drainage collectors located near drains, basement walls, retaining walls, terraces.

Surface drainage is made of pipes, trays, sand traps, storm water inlets, superstructures and plugs. Light and durable plastic profiles have replaced concrete and metal structures. They are placed in grooves with a slope on the prepared base and protected with gratings.

Deep drainage systems

With the help of deep drainage, low-lying areas with groundwater coming to the surface, clay and loamy soils prone to waterlogging, peat bogs, sapropels, as well as areas adjacent to the reservoir are drained. The underground drainage system is more complex and labor-intensive, sometimes performed in several levels.

Deep drainage device

In low-rise construction, underground dewatering systems are most often used:

- horizontal - drainage pipes are laid with a slope in trenches, connected to drainage wells and covered with earth on top;

- vertical - they drill reduction wells or dig wells 20-50 m deep, from which water goes into the lower permeable layer or is pumped out by a pump;

- combined - combine horizontal pipe laying and water drainage through vertical water-absorbing structures.

Depending on the soil conditions, topography and assigned tasks, various structural forms of drainage are used:

- ring - to protect a group of buildings on sandy soils;

- wall-mounted - to remove moisture from the foundation of a building at high groundwater level on clay soil;

- reservoir - for removing interlayer water into a bowl under the base of the structure, filled with drainage materials.

When installing surface and deep water drainage, it is desirable to provide for the natural flow of liquid into wells or boreholes. If this cannot be achieved, drainage pumps are used to pump wastewater to the desired point.

Arrangement of a closed system

Before you begin this labor-intensive procedure, you need to prepare and purchase bulk building materials:

- Crushed stone of medium/large fraction, which is needed to obtain a stable layer that prevents dirt and bulky soil fragments from entering the system. This material also protects the corrugated pipe from the increased pressure of the earth layer.

- River sand creating a filtration cushion.

In addition to bulk substances, the following will be useful:

- Drainage pipes that form the drainage system itself. Depending on the intricacy of the project, the diameter and number of pipe products are selected. Recently, PVC products have become relevant.

- Drainage pumps providing mechanical drainage. They are used when the site has suffered serious damage due to flooding by underground runoff.

Technical requirements for the placement of the drainage system

*

Engineering systems for water drainage are designed in accordance with the requirements of SNiP 2.06.15-85, 2.06.03-85. The standards regulate the location of drains, water receivers, connecting units, and inspection wells.

Placement of system elements in accordance with building codes:

- Drainage collectors - at the lower points of the site;

- Drainage wells - at canal turns and every 20 m.

- The minimum slope of pipes is 2 cm per 1 meter in clayey soils, 3 cm in sandy soils.

Important! Most often in low-rise construction, water pipelines with a diameter of 110-160 mm are used.

Diagram of the drainage system of the house

To ensure that work on draining the site does not lead to counterproductive results, it is necessary to determine:

- depth of the drainage pipe;

- optimal drainage slope;

- number and location of wells;

- method of removing water - into a drainage ditch, reservoir, sewer system, sewer machine or for irrigation.

Pipelines for surface drainage are laid to a depth of 1 meter. They are placed along paths, platforms, drains. Stormwater drainage cannot be combined with underground drainage. In the event of heavy, prolonged rain or melting snow, the system may not be able to withstand a multiple increase in fluid volume. When the common channel overflows, water flows back into the drainage. This causes waterlogging and erosion of deep layers of soil. As a consequence, the forces of frost heaving intensify in winter, the destruction of the blind area, and damage to the foundation.

The result of soil heaving

For the installation of underground wall drainage, calculate:

- Laying depth. To prevent the water in the pipe lumen from breaking into ice and breaking the walls, the channels are laid below the freezing point of the soil. Its coordinates are determined by SP 131.13330.2012 or a table on the Internet. The height of the crushed stone cushion of 40 cm is added to the value.

- Laying the base of the foundation. If the base is a shallow tape, the laying depth is taken according to the calculation from point No. 1. In other cases, the drainage is located 30-50 cm below the level of the structure.

After calculating the parameters of the drainage system and completing a detailed drawing, the consumption of basic materials is determined - pipes, fittings, wells, geotextiles, crushed stone for filling.

Work order 10 steps: step-by-step instructions

Drains are laid in the following order:

- a plan is drawn up and markings are carried out on the ground;

- trenches are dug along the marking line, their depth should be below the freezing point of the soil;

- a layer of sand up to 10 centimeters thick is poured onto the bottom and thoroughly compacted with a roller;

- crushed stone or gravel is laid on top (layer thickness 20 cm);

- pipes are laid on the prepared cushion;

- the system is mounted using couplings, and then the angle of inclination of the pipes towards the water collectors is checked;

- inspection wells are installed at the joints and turns of pipes (a piece of plastic pipe is cut off and a protective cover is installed);

- backfilling is carried out - a layer of crushed stone, sand, and soil is laid out sequentially;

- You can lay turf on top or sow herbaceous plants;

- at the end of the outlet pipe after the collector, a check valve is installed or a well is installed to collect water (a sealed plastic tank is used).

Drainage pipe selection options

To drain areas, drains made of various materials are used:

- ceramics;

- metal;

- asbestos cement;

- concrete;

- chrysotile cement;

- polymers - polyethylene, polypropylene, PVC.

Plastic products are the most popular in private construction. They are durable, lightweight, and not subject to corrosion. You can install drainage pipes yourself. With proper use, profiles last up to 50 years.

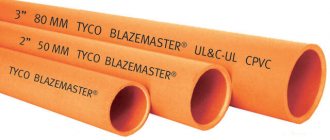

Various types of drainage pipes

When choosing pipes, the main criteria are:

- ring stiffness class - the higher it is, the deeper the product can be laid;

- volume of discharged liquid - the flow must pass freely;

- presence of a filter cover - if it is missing, protection against siltation must be done during installation yourself.

Polymer drainage is produced in the form of single-layer and double-layer perforated pipes. They vary in characteristics and price. The latter are 2-2.5 more expensive.

Single-layer products are made from low-density polyethylene HDPE. Since they are not very rigid - class SN4, they are laid in trenches up to 2.5 m deep.

Double-layer drains are much stronger. They are made of 2 layers of polyethylene - low-pressure HDPE and high-pressure LDPE. The products are characterized by greater rigidity - SN6. Pipes can be buried up to 5-6 meters.

To prevent silting of the holes, covers made of geotextile or coconut fiber are used. Filters allow water to pass through, but retain debris, soil or sand particles.

Pipe with geotextile

An alternative option for installing drainage without a crushed stone cushion is to lay a pipe with a filtration layer of polystyrene foam. Products can be installed in channels without backfilling with non-metallic materials. Their role is played by small polymer balls.

Flexible pipes are rolled into coils and sold by the meter, while rigid pipes are sold in lengths. Perforations on drains are located over the entire surface or on part of it; they are slotted holes for the penetration of water from the surrounding soil. Solid non-perforated products are used to drain collected water outside the site.

Perforation around the perimeter of the drainage pipe

The inner surface can be corrugated or smooth. In the first case, the pipe is elastic and easily rolled into coils. When installing corner sections, the profile is bent without the use of joining elements.

Pipes with a smooth inner layer do not bend. They are harder - product class SN8 or SN16. They can be laid to a depth of 6 m. They are produced in sections of 6-12 m with or without sockets. Additionally supplied with connecting parts.

How to choose pipes?

The main element of the system is the pipeline. For this reason, special attention is paid to the choice of pipes or drains, as they are more often called. Experts recommend paying attention to the following technical parameters:

Material

Manufacturers offer products made from asbestos cement, polyethylene (with perforation) and polyvinyl chloride (you can do the perforation yourself). Asbestos cement is the cheapest material. However, serious doubts arise about its environmental safety. Therefore, an increasing number of buyers are choosing products made from durable plastic. Ready-made drains with perforation are sold wrapped in geofabric. Cheaper PVC pipes require additional processing - cuts are made in a checkerboard pattern up to 5 mm wide. Processing is carried out on both sides. The distance between cuts is 50 centimeters. Additionally, you will need to purchase geofabric to wrap the pipe before laying it in the ground. The fabric serves as a filter and prevents liquid dirt from clogging the perforated pipes.

Diameter

The diameter is selected depending on the amount of groundwater and precipitation. Typically this value is from 5 to 8 centimeters.

Soil type

Soil type is one of the most important parameters when choosing pipes:

- In soils with a high content of crushed stone, products with perforation are installed, but without a geofabric filter.

- In sandstones, geotextile-wrapped and perforated pipes are used. Additionally, it is recommended to make a coating of crushed stone to prevent pipeline deformation.

- Perforated products with a coconut fiber filter are installed in clay soil. A cheaper option is to use geofabric. A backfill of crushed stone must be made, covering the pipeline by 15-20 centimeters.

- For loam, perforated pipes wrapped in geotextile are used.

In any soil, you can also use ordinary PVC pipes with homemade perforations and geofabric wrapping. This will significantly reduce the cost of the drainage system.

Installation of drainage system

*

To reduce the risk of flooding from groundwater, rain or flood waters, you need to know how to properly lay a drainage pipe on your site. For this you will need materials:

- crushed stone, gravel, sand for cushion;

- geotextiles for filtering wastewater;

- fittings for system assembly;

- shovels, wheelbarrows and other equipment for work.

The technology for self-laying drainage pipes includes:

- Preparation of channels. During the period with the least amount of precipitation, the route is marked using pegs and cords. Dig trenches of the required depth using hand tools or using construction machines. Maintain a slope towards the catchment area of at least 2 cm per 1 m. The walls must be vertical. Geotextiles are subsequently attached to them.

- Installation of widening of floor collectors in places corresponding to the project. Their diameter should exceed the size of the canal by 20-30 cm.

- Backfill the bottom of the trench with sand with a layer of 15-20 cm.

- Laying geotextiles and securing panels to the walls of the pit.

Pipe installation with geotextile laying

- Backfill the route with crushed stone 30 cm thick. A depression is made along the axis.

- Installation of drainage pipe. They are joined with clamps, couplings, bends, tees, crosses. You can use sewer fittings of the appropriate diameter.

- Controlling the deviation of the drainage pipe using a stretched cord and a building level.

- Sprinkling the water pipeline with crushed stone.

- Laying geotextile panels overlapping over the backfill.

- The installation of inspection wells is done in widening, connecting to the system using couplings and adapters.

- Filling the cavity between the collector and the trench wall with crushed stone, expanded clay, and foam plastic. This will protect the revision from freezing.

The drainage pipe is led into a drainage ditch, pond, or well. The trench must be covered with sand or buried. If the products already contain a shell of filtration material, they are laid on a crushed stone bed without a geotextile backing. Polypropylene profiles are joined by welding; for PVC, glue can be used.

Tools and materials

For work you will need:

- shovel and bayonet shovel;

- garden wheelbarrow for soil;

- manual roller for compacting sand and crushed stone;

- assembly knife for cutting pipes;

- drill or grinder, if you need to make notches (perforation);

- geotextile scissors.

You should also prepare building materials:

- pipes;

- adapters for inspection wells and collector;

- fittings for pipe installation;

- plastic pipes with a diameter of 30 to 50 cm for arranging inspection and drainage wells (you can also purchase ready-made wells with a hatch or plastic tanks);

- geotextile in rolls;

- crushed stone or gravel, sand.

Common mistakes

The installation of a drainage system will not lead to the expected result if errors were made during calculation and installation:

- the slope towards the drainage wells is not maintained;

- deepening of pipes is not enough;

- The diameter of the drains is too small or the type of perforation that does not correspond to the type of soil is selected;

- there is no crushed stone backing, no geotextiles are laid;

- the number of water pipelines is insufficient;

- the drainage well fills up too quickly.

Important! Ineffective operation of the drainage system may result from the use of low-quality materials, improper assembly of elements, or clogged pipes.

Flooding of the site with groundwater

Basic moments

The drainage system must meet technical requirements. Amateur activity in this matter is not encouraged. For this reason, owners should pay attention to some important points:

- To carry out the work, you will need to create a vertical site plan taking into account the occurrence of groundwater in a specific area. Specialists will help you compile it for a fee.

- The exact depth of the pipeline, its diameter and type are calculated. At this stage you will also need the help of specialists.

- When digging a trench, you need to ensure that its size is approximately 40 centimeters larger than the diameter of the pipes used. The slope of the trench is from three degrees (from 0.5 to 1 meter of slope).

- Inspection wells are located no closer than fifty meters from each other.

- Installing a check valve or arranging a water collector is a prerequisite for the proper functioning of the entire system.

Drainage system maintenance rules

To prevent the pipe lumen from becoming clogged with sediment, the system is cleaned once every 3-4 years.

Ways to remove blockages:

- flushing with a garden hose;

- blowing with compressed air;

- mechanical cleaning with a metal cable with a wide nozzle;

- hydrodynamic impact on pollution using pneumatic equipment.

The pipes are flushed through inspection wells on both sides. Installing sand traps will significantly reduce the entry of insoluble particles into the channels. Special services are invited to clean deep routes.

Cleaning the system from contaminants

It is not recommended to plant trees at a distance of 1.5-2 m along underground structures. When roots grow, they can damage the lines and disrupt the natural outflow of water.

Pipes for storm drainage

Storm drain pipes will help drain melt and rainwater away from the building. They, together with gutters, trays and storm inlets, form above-ground or underground storm drainage systems and ensure the safety and durability of the structure. Requirements for materials: strength, resistance to solar and mechanical influences, sedimentary reagents, temperature changes.

For the construction of drains, cast iron, polymer or reinforced concrete pipes are used (laying under roads). It is important to choose the correct diameter so that the storm drains do not overflow. For private houses, sewer pipes Ø 100 mm are used.

Selection parameters

The performance of the drainage system depends on the diameter of the pipes.

When choosing, consider the following:

- Drainage volume;

- Soil structure;

- Installation depth (a certain size has a maximum installation depth);

- Possibility of soil freezing;

- Dimensions of the trench (it is always 40 cm larger than the diameter of the pipe).

Installation of domestic drainage requires 200 mm pipes, while for large drainage systems pipes from 300 mm to 400 mm are used. 110 mm drains are most common when arranging a summer cottage.

Pipes larger than 400 mm are used for production purposes. They are necessary when building a well; they can be connected to pipes of smaller diameter, fixing the mount using a special adapter.

Laying rules

The pipeline is laid at an angle to the catchment area. If the area is flat, the slope is created with your own hands. The installation depth of the pipeline is determined depending on the location of underground sources, but not less than half a meter.

The distance between the drainage mains when they are installed is determined by the amount of water in the territory: the more there is, the closer the pipelines are located.

Also decide on the placement of inspection hatches necessary to check and remove possible blockages. They should be installed at turning points in the highway.

Before installation, be sure to create a project with a scale drawing. This allows you to calculate how many and what cross-section and stiffness of pipes will be required to construct a drainage network.

Stages of laying a drainage pipeline:

- A trench is dug to a depth of at least half a meter and a width exceeding the cross-section of the pipeline by 50 cm.

- A sand cushion 10 cm thick is poured onto the bottom.

- Gravel is poured on top of the sand in a layer of 10–20 cm.

- Pipe sections are laid, connecting to each other and to inspection wells.

Burial occurs in the reverse order: a layer of crushed stone, a sand cushion, a layer of soil.

At the final stage, the pipeline is taken out beyond the boundaries of the site and connected to the reservoir. If it is necessary to increase the throughput of the drainage main, a system assembled from several pipes of different sections is placed in the trench.

Application of pipes in air conditioning systems

The products have expanded use; they are actively used in air conditioning systems to remove condensate formed on the internal parts of air conditioners. Moisture is removed to the sewer network or to the street. At the same time, the connection with the sewer allows you to get a completely autonomous system.

Using a drainage pipe to remove condensate Source trubamaster.ru

Such systems use plastic products that are moisture resistant, durable, and have high throughput. Their surface can be smooth or corrugated. The first ones have a low cost, but require connecting elements at the corners. Corrugated pipes are more flexible and easier to assemble.

Why is perforation of drainage lines necessary?

It has already been mentioned that perforation helps remove excess moisture from the soil. But you should be careful here too - fanaticism has never led to anything good. If the drainage pipe is too large, and the perforations are very large and frequent, then there is a danger of drying out the soil of the garden plot.

Good to know! Too large a perforation creates the preconditions for the drainage to quickly become clogged with dirt and silt up. Even if the drainage line is clogged by a third, there can be no question of any high-quality outflow of water. And the well will have to be cleaned quite often.

Schematic example of installation of a site drainage system

Possible mistakes when arranging drainage

The efficiency of the drainage system and the quality of installation are interconnected. Any errors during operation can damage the drainage, and this, in turn, will require repair of the problem area or a complete reinstallation of the entire system.

The list of errors that occur during installation is quite wide. Below are the most common ones.

- When selecting the pipeline, soil conditions were not taken into account.

- Incorrect angle of inclination or it was not provided at all.

- There is no filter element or geotextile.

- The pipes were not soldered in good faith.

- The technology for arranging the drainage system was not followed: installation was carried out without filling sand/crushed stone.

By correctly installing drainage, you will reliably protect the basement and ground floor of your home from the destructive effects of wastewater.

Plot

0 votes

+

Vote for!

—

Vote against!

The most effective way to protect the foundation of a private house from the destructive effects of groundwater and storm water is a high-quality drainage system. This is especially important when water accumulates in the upper layers of the soil, as it can cause flooding of the basement or basement, wetting and deformation of walls, as well as the occurrence of fungal formations. This article will discuss how to lay drainage pipes.

Pipes for the drainage system, which are installed along the entire perimeter of the site, allow you to create high-quality drainage. After all, the danger of flooding is posed not only by groundwater, but also by flood water. Damage can also be caused by precipitation that exceeds permissible limits.

Drainage pipe photo

Unlike waterproofing the foundation, the drainage system can be installed after the house is built, if there are grounds for it. But under certain conditions, it is better to install it at the initial stage of construction. The following reasons are needed for this:

- flat location of the site, facilitating significant accumulation of water;

- clay and loamy soil, which have poor drainage characteristics;

- statistics of excess precipitation levels characteristic of the area in which the building is located;

- increased level of groundwater (less than 1.5 meters to the ground surface).

In addition, it is worth focusing on the depth of construction of other buildings on the site. The presence of a buried foundation next to the main building not only prevents the natural outflow of groundwater, but also contributes to its accumulation, thereby increasing the risk of flooding. The concrete blind areas and asphalt pavement installed on the site are also a barrier to the free circulation of water. In such a case, it is considered competent to connect storm drains to the main drainage system.

Laying a drainage pipe will help prevent the consequences of changes in groundwater levels and accumulation of moisture in the soil around the building.

Types of drainage systems

There are two main options for designing a drainage system:

- Open (surface) - used to remove excess moisture resulting from the accumulation of precipitation or melt water. The open drainage system is presented in the form of ditches and trenches.

- Closed (deep) - installation uses pipes with perforations, which are laid to a certain depth in a previously prepared trench. The main function is to drain groundwater and protect the foundation of the house.

Materials required for laying a closed drainage system

The process of installing a drainage system is quite labor-intensive and requires thorough preparation. From bulk building materials you will need:

- Sand . River sand is mainly used in drainage work. Its main function is to create a filtration cushion around the drainage pipe.

- Crushed stone . To set up the system you will need a medium and large fraction. The purpose of crushed stone is to form a stable layer to prevent the penetration of dirt and large parts of soil. In addition, crushed stone prevents excessive soil pressure on the corrugated pipe.

Basic materials:

- drainage pumps . They are used only in case of significant flooding of the area with groundwater. Promote mechanical drainage;

- drainage pipes . With their help, the main drainage system is formed. The quantity and diameter depend on the complexity of the laying pattern. Plastic pipes are most often used for drainage;

- geotextiles – protects the drainage pipe from soil contamination. As a rule, interlining or dornite is used. In addition to strength, both types of textiles have filtering ability;

- couplings - necessary for attaching drainage pipes to each other.

As a rule, the drainage system needs periodic cleaning; for this purpose, inspection wells are installed along its perimeter. A collector well is installed to collect water into the system.

Selection of drainage pipes

Before installing a drainage system, special attention should be paid to the selection of pipes for work. The first thing to consider is the use of perforated pipes in the arrangement of the drainage system. The second is the diameter and the presence of holes for moisture outflow and air exchange. And no less important is the material from which the pipes are made.

Currently, the following types of pipes are presented on the building materials market:

- asbestos-cement;

- ceramic;

- from polymer materials.

The most popular in arranging a drainage system are polymer drainage pipes. Their advantage over other types is as follows.

- Long period of operation - up to 70 years.

- High strength indicators.

- Resistance to corrosion processes and aggressive environments.

- Reduced weight, which simplifies the process of transportation and installation.

- Self-cleaning ability due to smooth surface.

- Resistance to siltation.

- Value for money.

- Easy to maintain. Thanks to the geotextile filter, the system does not need to be flushed.

Diameter of drainage pipes:

- up to 150 mm – for a drainage system that drains a small amount of water;

- up to 300 mm – for systems with high loads.

For a branched drainage system, you will need pipes of both small (for branches) and large diameter (for the main branch of the system).

Plastic drainage pipes

Polymer pipes, which are usually used for laying drainage systems, are made of PVC, polypropylene or polyethylene and are available in the following types:

- single-layer or double-layer . The choice of the number of layers depends on the density of the soil;

- flexible and rigid . Rigid pipes are suitable for simple drainage schemes, while flexible pipes allow you to create complex branching throughout the area;

- pipes with or without filter casing . As a rule, drainage pipes already have holes along their entire length. But if the purchased material does not have special holes, you can make them yourself using a drill and a thin drill bit;

- corrugated or smooth.

As for covering with geofabric, as a rule, samples already covered with filter textile are presented on the building materials market. When purchasing uncoated pipes, you can wrap their surface yourself by securing the material with rope or thin wire around the perimeter of the pipe.

Design of drainage pipe installation

Before starting work on installing a drainage system, it is worth first drawing up a plan for its location on the site.

- This requires taking into account the type of soil and the height of groundwater. The most often used is a branched scheme, at the joints of which inspection wells are installed.

- The distance between the branches directly depends on the type of soil. For clay soil it is 10 meters, for loamy soil - 20 meters, for sandy soil - 45 meters.

Laying drainage pipes with your own hands

First you need to determine the location of the drainage system. There are only two placement options:

- “wall” drainage - passes only near the foundation of the house and prevents moisture from entering directly into the building itself;

- a drainage system located along the entire perimeter of the site protects not only the base of the building, but also other outbuildings and plantings located on the territory.

Stages of work

- The first step will be to mark the area for placement of drainage ditches. To facilitate the process, you can use a special laser rangefinder. Particular attention should be paid to places where moisture accumulates after rain - this means that water exchange in this area is difficult due to the density of the soil or the presence of obstacles.

- Trench. The recess under the drainage trench must be made taking into account differences in height. The main task of the prepared ditch system is the rapid and unhindered outflow of water.

Tip: during work, you can use a watering hose, running a certain volume of water - make sure that water does not accumulate in certain parts of the trench.

- Before installing drainage pipes, the bottom of the trench must be thoroughly compacted. Then any filter material is laid, and its ends should extend beyond the trench. Next, river sand and crushed stone are poured, first coarse, then medium fraction, to a thickness of no more than 20 cm.

- Drainage pipes are cut according to the dimensions of the diagram using a jigsaw or a special device - a pipe cutter. Next, you should begin laying the pipes, connecting the joints using fittings. In order for the joint to be strong, it is necessary to join the parts after pre-heating the joining sections.

- The pipes must be carefully wrapped with geotextile, securing the joints with rope or thin wire. The choice of such material is not accidental, since it must allow water to pass through the perforation. In addition to throughput, the functions of geotextiles include protecting the perforations of the pipe from clogging.

- Pipe laying must be done at a slope, connecting the ends to inspection wells. The system can use two types of wells: sealed, which allows the collected water to be used for technical purposes, and absorbent - the water will go back into the soil. The slope of the drainage pipes depends on its diameter; the larger it is, the less slope is required.

- The next step in installing drainage pipes will be filling the surface with crushed stone and sand. After which the structure is wrapped with sheets of filter material located on the surface and covered with a layer of soil.

Drainage pipes video

Drainage system maintenance

When arranging a site with a drainage system, it is important not only its thoughtful and high-quality installation, but also compliance with operating rules. This will allow the system to operate for as long as possible.

Approximately once every four years, it is mandatory to inspect the condition of pipes and wells as a preventative measure. In addition, once every two years it is worth measuring the water level in the wells; a significant change in it may indicate the following factors:

- damage to the integrity of the pipe;

- formation of dense blockage;

- accumulation of silt deposits on the entire surface of the pipe;

- partial settlement of the pipeline due to soil movement.

In order to avoid such problems, it is necessary to promptly inspect the drainage system and clean it from various types of contaminants.

Errors in laying drainage pipes

The efficiency of drainage directly depends on the quality of the installation. Any disturbances during operation will lead to system failure. In the best case, you can repair the damaged area, in the worst case, you will have to completely reinstall the drainage system.

The most common mistakes include:

- selection of a pipeline system without taking into account soil quality. For example: on loamy soil it is not recommended to use pipes without a filtration system;

- violations associated with a change or absence of the angle of inclination of the drainage system;

- initially there is no option for draining water from the well;

- the technology for arranging drainage pipes is not followed - the installation was carried out without filter filling of crushed stone and sand;

- absence of geotextiles and filter material;

- poor-quality pipe soldering;

- no perforation.

When choosing the type of drainage system, you should base it on the location of the site and the quality of the soil. To independently arrange a drainage system, it is necessary to plan the drainage layout in advance. When choosing materials, preference should be given to the most practical and durable. These include plastic corrugated pipes with perforations. By following all the stages of laying the drainage system, you can obtain a high-quality drainage system. In addition, drainage guarantees protection of the basement or basement of the house from the harmful effects of groundwater.