Here you will learn:

- Purpose of the casing pipe

- How to choose the right casing

- How to correctly calculate the diameter of pipes

- Types of pipe materials for wells

- Well casing device

To choose and understand which pipes are best for a water well, we will consider all possible options and their characteristics - durable and expensive metal, corrosion-resistant asbestos cement, affordable and durable plastic, or a combined pipeline option.

Purpose, features and requirements for casing columns

Tasks of the casing:

- Protection of well walls from collapse;

- Ensuring the integrity of the structure under ground pressure and displacement of soil layers;

- Prevents the penetration of surface groundwater and wastewater into the water intake part;

- Helps not to silt;

- When a well is cased with one pipe, it acts as a production string and contains a column of water.

The entire life of a water intake well is primarily affected by the quality of the casing pipes:

- High-quality material, its strength and resistance to deformation during the entire period of use;

- 100% sealing of walls and pipe connections;

- The pipe material should not affect the chemical composition of groundwater;

- Non-corrosive to chemical elements.

Two-pipe designs

In our company, two-pipe structures are presented in two categories:

- Steel Ø133 and plastic Ø117

- Steel Ø159 and plastic Ø125

The structure itself is a steel pipe with a plastic production string of smaller diameter inside.

Let's talk about the advantages that the union of metal and plastic gives us.

- A metal pipe on the outside will ensure rigidity of the structure, a plastic pipe on the inside will protect water from rust, since it is absolutely not subject to corrosion.

- Service life - 50 years.

- High sanitary and hygienic properties (the plastic pipe does not contribute to the development of pathogenic microorganisms).

- High tightness.

Thus, you get a combination of all the advantages of metal with the environmental friendliness of plastic. Such an artesian well is much more reliable and will last 50 years, and the water in it will be of much better quality, since it is in a plastic column and does not come into contact with a metal pipe. Read more about drilling artesian wells in the Moscow region, price.

Selection of casing pipes by parameters

There is no single correct well design for drilling. For each specific area, the drilling engineer selects the design individually, taking into account many factors:

- The structure of the geological section of the soil at the drilling point;

- Aquifer and groundwater levels;

- Characteristics of the well pump;

- Depth and diameter of well drilling.

To make a decision, it is necessary to take into account the important parameters of casing pipes:

- Material.

The cost of implementing the project, whether repairs will be possible and the reliability of the structure depend on the material of the pipes. - Pipe connection option.

The connection of the pipes to each other is selected depending on the material of the column, to what depth the well is being drilled, and what diameter of the casing pipe is used. The connection must be airtight, because during use, groundwater and other impurities may enter the water. In this regard, the well pump may fail and the well itself will become unusable. - Diameter.

The optimal pipe diameter is calculated taking into account peak water consumption per day. A larger pipe diameter gives a higher well flow rate.

Which well is better made of plastic or metal?

At the end, we will summarize, especially for those who are too lazy to read all the material, we will immediately resolve the question of which casing pipe is better than HDPE or steel. Plastic is good and allows you to reduce the cost of drilling, it works great, but if protected by an iron pipe. A steel pipe is also good, but it is installed before the limestone, and the limestone itself must be lined with plastic. In our area (in the south of the Moscow region) it is impossible to leave limestone without casing. Therefore, the ideal combination is iron and plastic. If you don’t trust HDPE, you can overpay and make metal and metal.

Types of materials and their characteristics

Metal casing pipes

Structures based on metal columns are the most reliable and have been proven over many years of use. Steel pipes with a diameter of 133-159 mm are installed in individual wells, but the wall thickness can be different. When choosing a drilling company and design, it is important to pay close attention to this. For a well to operate for more than 50 years, the pipe wall thickness must be at least 4.5 mm - photo 1.

Polymer pipes

PVC-U pipes.

Some drilling companies believe that metal pipes can be replaced entirely with pipes made of dense, unplasticized polyvinyl chloride. For many, to this day, this is a rather controversial issue. But still, since 2011, uPVC pipes have been used as the main casing - photo 2.

Disadvantages of uPVC pipes:

- Ground movements and interlayer pressure lead to column flattening, wells fail and cannot be repaired;

- The thread cannot withstand the load and, when twisted, cracks in the internal threaded connection. And such a connection becomes not airtight;

- Unplasticized polyvinyl chloride is prone to drying out and cracking over time, so there is no need to talk about reliability and durability;

- The caisson is attached to the uPVC casing through a clamping coupling, so the caisson often comes off, which complicates installation work.

PVC-U pipes have only one advantage - the pipes do not corrode.

At the Customer’s request, we can also use PVC-U pipes in our work in accordance with GOST P 51613-2000, but our engineers still recommend installing time-tested metal pipes.

HDPE pipes are low pressure polyethylene.

HDPE pipe is less durable; it is installed with an additional internal pipe in a two-pipe structure (metal + HDPE or uPVC + HDPE).

Rolled steel casing pipes

Advantages of rolled steel pipes:

- Structural strength (suitable for shallow and deep wells);

- Reliable assembly between each other;

- Steel does not emit harmful elements when in contact with water;

- High maintainability – high strength allows cleaning and additional drilling.

Galvanized casing pipes

When in contact with water and soil, the pipe walls are more resistant to corrosion. Galvanized pipes can be installed in a well for individual water supply. But such pipes are used less often than steel pipes due to the difference in price.

Stainless steel casing pipes

A stainless steel pipe has similar advantages to a rolled steel pipe, but has a very high cost. Stainless steel is not subject to corrosion and therefore lasts a very long time. It is almost not in demand due to the high price.

Well casing device

There are only three main units that are included in the casing complex:

- Bottom filter. Prevents sand and clay from entering the pump, leaving it clean and operational.

- Fine filter. Purifies water from small inclusions, making it suitable for domestic use.

- Header. A kind of sealed casing cover that has holes for connecting pipelines and laying power cables.

The casing walls themselves can be metal, plastic or asbestos-cement at the request of the customer. The only limitations can be the technological features of the site and the qualitative composition of the soil cut.

Don't forget about the meaning of the destination and source type:

- Abyssinian well for irrigation. Concrete pipes are suitable, as their cost is completely justified.

- Sand well. Plastic is suitable, since the depth of such a well is no more than 90 meters.

- Artesian spring. Metal pipes. Artesian water is located at a depth of 100-350 meters.

At great depths, the corresponding pressure that the metal can withstand. If you have the opportunity to purchase stainless steel, great. The water will be safe to drink at all times. Galvanization lasts a long time. Enameled pipes do not corrode substances contained in the soil. But the choice is dictated by the allocated budget.

Casing connection options

- Seamless pipes with spiral or longitudinal welding seam.

They are used if the formation pressure is no more than 16 kg/cm2 and the temperature is less than 300 degrees. Service life 40-45 years. - Seamless pipes are called seamless pipes.

Produced using special high-tech machines. The cost of seamless pipes is 500 rubles more per 1 linear meter. The temperature and pressure characteristics are slightly greater than those of a seamed pipe.

Since there are no such temperatures and pressures in the underground environment, you can install seam pipes and not overpay for seamless ones.

Types of casing connections:

- On the thread.

The conical internal and external threads are connected to each other, the pipe fits into the pipe. - On the thread through the coupling.

There is an external conical thread on both ends, and an internal thread on the coupling. This connection is called reinforced. - Welding.

The quality and tightness of the seam depends on the professionalism of the welder.

Our experts advise choosing a conical connection, when the internal and external threads are connected to each other, the pipe fits into the pipe. Do not save money when choosing a welding connection, since the quality of the weld depends on the experience of the welding master, and the benefit is not great at all.

Fastening wells during drilling

- Well performance;

- Well lifespan;

- The strength and tightness of the channel through which the extracted product will flow from the horizon to the surface;

- Protection of the operating channel from corrosion;

- The strength of the well walls in places where the rocks are not stable enough;

- Tightness of separation of all permeable horizons from each other.

Securing oil wells involves the use of special columns or packers. The use of columns is the most popular method, which allows you to make the well strong, durable, and also isolate permeable horizons. Such columns are made up of special pipes called casing.

Table 2. Which casing pipe is better to choose for well reliability?

| Metal 133 mm (wall 4.5 mm) | Outside metal 133 mm (wall 4.5 mm + inside HDPE 117 mm wall 6.5 mm) | uPVC 125 mm (wall 8 mm) |

| Well guarantee | ||

| up to 10 years | up to 10 years | 5 years |

| Well life | ||

| 40 years | 50 years | 40 years |

| Cost of drilling with a large rig | ||

| 1800 rubles | 2100 rubles | 2100 rubles |

| Cost of using a well per year (60 meters deep)*, rub. | ||

| 2700 rubles | 2520 rubles | 3150 rubles |

Conclusions of drilling engineers based on many years of work experience:

- For many decades, the most reliable metal casing pipe has been in a two-pipe design (outer metal pipe with a conical connection + inside HDPE). This well design will last at least 50 years, since the additional plastic pipe is not subject to corrosion. Our warranty ranges from 3 to 10 years.

- If the goal is to save money, then it is possible to drill a well and install one 133 mm metal pipe. But this design is not applicable in all areas of the Moscow region (depending on the geological section and groundwater levels). The service life of such a well is on average 40 years.

- If you are a supporter of new technologies, then you can choose a design with a 125 mm PVC-U column. But such a well has its drawbacks: high cost, possible short service life, since it has not been tested by time.

The chief drilling engineer, with extensive experience, will recommend the optimal design option for your well over the phone, but it is always the project customer who makes the decision on the choice of casing pipes.

Determining the required pipe diameter

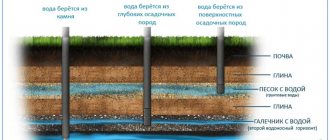

There are three types of aquifers: surface (or perched) at a depth of up to 15 m, on sand up to 30 m deep and in limestone layers. The surface horizon is suitable for digging wells, and it does not always contain high-quality drinking water. Sand wells are relatively cheap, but they are prone to siltation, which shortens their service life, and often have unstable water flow.

Limestone wells are the best source option, even taking into account the higher cost of drilling. They provide the highest water quality, flow rate and well life. The answer to the question of what pipe diameter to choose for a well depends on the dimensions, type and performance of the submersible pump, as well as the magnitude of the peak water demand.

The determining factor in choosing the diameter of the pipes is the dimensions of the well pump. Calculation of the pipe size suitable for it is carried out as follows:

- to the diameter of the pump casing in mm, add a minimum gap between the casing and the pipe walls of 4 mm, thereby obtaining the required internal diameter;

- Based on the result obtained and the available wall thickness options, select the appropriate pipe size.

For example, if you choose a pump with a casing diameter of 74 mm, then by adding a gap and a wall thickness of 5 mm, we get a result of 88 mm. This corresponds to pipes with an outer nominal diameter of 90 mm or thicker wall pipes of Ø 113 mm.

Note that only Grundfos produces reliable pumps of such a small diameter and they are very expensive. Therefore, to equip wells, submersible pumps in housings with a diameter of 100 mm are often chosen. They are much cheaper with an almost unlimited choice, but their installation requires pipes Ø 125 mm. When operating inexpensive vibration-type borehole pumps, you will need pipes with an outer diameter of 140 mm.