We install bored piles with casing in Moscow and the Moscow region

Buy Larsen sheet piling Installation of bored piles in water-saturated soils Bored piles using hollow auger technology (CFA method) Retaining wall made of bored piles

The Arctic Hydro Stroy enterprise installs bored foundations for all types of structures in Moscow and the Moscow region.

In conditions of complex loose soils, where the walls of the well are easily destroyed, we use the technology of bored piles with casing.

What is a casing pipe for bored piles

Bored piles are reinforced concrete rods that are not delivered to the site in finished form, but are formed right on the spot: wells are drilled, a finished frame is placed in them, and concrete is poured. On dense soil, strengthening the walls of the wells is not required. When they are moderately loose, they are strengthened using a bentonite (clay) solution, which is used for washing.

On very loose soil, the best option is to install bored piles using casing pipes: simultaneously with drilling, the casing pipe is lowered into the well.

After drilling, reinforcement and pouring of concrete, the pipe is sometimes left in the ground: it continues to serve as a frame for the pile and performs the function of waterproofing. But wherever possible, they extract it: the turnover of casing pipes is one of the ways to reduce the cost of the foundation construction process.

The sequence of installation of bored piles with casing pipe and grillage:

- Geological surveys at the work site, selection of optimal technology.

- Calculation and design of piles.

- Site marking.

- Equipment adjustment.

- Drilling a well with simultaneous immersion of the casing. At great depths, the pipe is extended to form a column.

- Removing soil from the face (for example, washing).

- Reinforcement.

- Pouring concrete.

- Sectional removal of casing.

- Formation of the pile head.

- After installing all the piles, install the formwork, reinforcement and pour the grillage.

We have been installing bored piles for over 10 years

For any questions call: 8 800 707-72-09

We will help you choose the most suitable and economical option for manufacturing a bored foundation.

CONSTRUCTION AND INSTALLATION OF REINFORCING FRAMEWORKS

- Reinforcement of piles when fencing a pit is constructed using spatial frames with symmetrical working reinforcement.

- Sections of reinforcement cages are manufactured on a specially equipped site (reinforcement shop), transported to the construction site by long vehicles and stored in a specially designated place.

- The enlarged assembly of frames should be carried out in a specially designated place (reinforcement shop) on the construction site with the corresponding entry being made in the welding log. Welding of frame sections is carried out using electrodes. Welding seams are standard, according to GOST 5264-80* and GOST 14098-91. Unspecified and non-standard seams are performed by electric arc welding. The leg of the weld is based on the smallest thickness of the elements being welded.

- Store the finished frames on wooden supports under a canopy or cover with a tarpaulin (waterproof fabric).

- Sections of reinforced frames are supplied with a passport for the finished product, and before installation they are inspected and accepted according to the report by the commission. Before diving into the well, it is necessary to clean and remove rust and oil from the fittings.

- The reinforced frame is lowered into the well using a drilling and crane rig at a time, and the method of slinging, lifting and lowering must prevent the occurrence of deformations in it.

- When lowering the reinforced frame, observe the following conditions: keep the frame from swinging and rotating using flexible hemp rope guys.

- The frame should be lowered in a position that ensures its free passage into the trench with geodetic control of verticality and ensuring the design value of the protective layer between the load-bearing reinforcement and the ground. Temporary mounting spacers located inside the stiffener rings must be removed. All workers must stay out of the danger zone. Move the frame to the place of lowering into the well in a vertical position.

- Slingers use the mounting loops of the reinforced frame to rig the hook of the drilling and crane rig. At the signal from the senior slinger, the driver tightens the sling to ensure that the frame is slinged securely, after which the frame is slowly raised, hung in a vertical position and slowly moved to the well. The slingers hold and guide the frame during the lowering process. If it stops due to misalignment, at the signal of the senior slinger, the driver slightly lifts the frame and the slingers level its position. When the reinforced frame has reached its design position in height in the well, slingers secure it in the foreshaft or casing with pipe sections.

- When manufacturing frames, welding work should be carried out in accordance with design documentation, GOST 14098-91, GOST 10922-90 and RTM 393-94 (NIIZhB GOSSTROYA RF). At low temperatures (below -20°C), welding joints of reinforcement is carried out with preheating with gas burners up to 150°-200°C on both sides of the joint at a distance of 3-4 dH of reinforcement, welding work is performed with a welding current 10-15% higher compared to usual. At negative temperatures (below -5°), welding of joints of reinforcement bars is carried out without interruption, with the exception of the time required to change the electrode and clean up the seam during multilayer welding. If there is a forced long break in welding work, it must be resumed after cleaning the seam from slag from the previous seam and preheating the joint in the above manner.

- The welding area and the welder's workplace must be protected from precipitation and strong winds. At temperatures below -30°, welding work during installation is prohibited. Work may only be carried out in an equipped greenhouse. Welding materials should be supplied to the work site immediately before welding in the kit required for the period of continuous work of the welder, having previously dried them in an oven for drying electrodes in accordance with the manufacturer’s recommendations. At the workplace, store coated electrodes in closed cases to prevent moisture.

Advantages of installing bored piles in casing pipe

Casing pipes themselves are a technological solution for a certain type of soil. Its advantages include the turnover of casing pipes when installing bored piles: depending on the nature of the soil and the type of casing pipe itself, the turnover can vary from 5 to 300 cycles.

In addition to drilling construction, they can also be used to strengthen water and oil and gas wells.

The advantages of bored piles themselves are as follows:

- The large load-bearing capacity allows the construction of both light log houses and urban multi-storey buildings on such foundations. Everything is determined by the parameters of the piles;

- versatility - any soil except rocky and coarse soils is suitable for installation;

- suitable for constructing foundations on slopes;

- possibility of installation in urban conditions - the absence of noise and vibration allows you to work without risk to surrounding structures and discomfort for people;

- the price of bored piles with casing is relatively low: installation requires less material than slab and buried strip foundations; heavy, expensive equipment for driving finished piles is not needed;

- all stages of pile installation are available for control;

- can be used not only for constructing new foundations, but also for strengthening old foundations of various types.

Completed objects

see all

Installation of sheet piling fencing at wastewater treatment plants of apartment buildings

In 2021, our company installed sheet piling fences at the wastewater treatment plant of a residential multi-apartment building in the village of Rasskazovka

26.06.2016

see all

North-Eastern section of the third interchange circuit

A set of works for the installation of sheet piling to a depth of 14.5 m

5.05.2016

see all

Design and installation of sheet pile fencing made of pipe and pile piles during the construction of a shopping complex.

Our company took part in the construction of an administrative and shopping complex with a parking lot in the city of Zhukovsky, Moscow region.

02.06.2016

see all

Sheet piling fencing of a pit during the construction of a multi-storey residential building

Our specialists carried out comprehensive work on the installation of sheet piling fencing for a pit during the construction of a multi-storey residential building with an underground parking lot and built-in public premises

6.07.2016

see all

Supply, installation and removal of sheet piles during the reconstruction of a sewage pumping station

Our company installed sheet piling during the reconstruction of a sewage pumping station in Shcherbinka (Moscow region).

26.06.2016

see all

Installation of sheet piling from Larsen sheet pile using vibration immersion method

Installation of sheet piling from Larsen sheet piling using the vibration immersion method at the construction site of an administrative building in Moscow, on the street. Baikalskaya, 42.

14.07.2017

Foundation made of simple metal pipes (how to do it correctly).

The columnar type of foundation is used in private construction in suburban and suburban areas. For the construction of a wooden or frame one-story house, bathhouse, garage, outbuildings, and stationary fences, a foundation made of simple metal pipes is suitable.

This method of forming supports allows you to reduce the volume of excavation work, save money on the amount of concrete and the construction of formwork. The optimal choice of diameter and number of pillars makes it possible to significantly reduce the estimated cost and construction time.

Types of inventory casing pipes for bored piles

Casing pipes for bored piles differ in design, material of manufacture and geometric parameters - the height of the column is equal to the depth of the pile, the diametrical cross-section of the pipe is equal to the cross-section of the pile.

According to the material there are:

- made of high-alloy or black steel;

- polypropylene;

- made of low-density polyethylene;

- from unplasticized PVC;

- asbestos-cement.

For bored piles, steel, single-walled and double-walled are most often used. In the second type, the inner wall is smooth, and the outer wall is reinforced with spiral ribs.

Since the scope of application of bored piles is practically unlimited, the range of casing pipes is also very large. The thickness of the pipe wall is related to the diameter. For example, casing pipes for bored piles with a diameter of 620 have a wall thickness of 4 cm.

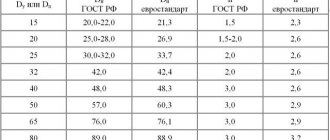

Casing pipe diameters for bored piles and steel thickness:

- from 60 cm (external diameter) to 52 (internal) to 148/140 - 4 cm;

- 180/170 and 190/180 – 5;

- from 200/188 to 250/238 – 6.

Equipment used for drilling

Today there are many different drilling equipment used to create wells for piles. This is often a rig that is mounted on a vehicle, but it has limited functionality compared to a full-fledged drilling machine. Among domestic production there are installations that effectively cope with this task:

- BKM-317 : installation tool - a blade drill, which is capable of drilling to a depth of three meters with a maximum diameter of 0.8 meters. The drill control system is hydraulic;

- BKM-511 : a medium power unit capable of drilling to a depth of five meters with a maximum diameter of 0.8 meters. Also hydraulic system.

Equipment available with us:

- Drilling and piling machine BM-811: a powerful unit capable of drilling to a depth of 8-15 meters with a maximum diameter of 0.5 meters. Hydraulic control system;

Today this is the most optimal technique for drilling wells for piles.

Features of the technology for installing bored piles with casing

Steel pipes are produced in the form of sections from 1 to 6 m. The column is built up mainly by welding or bolting. If the column is made up of sections of different diameters, we use lowering inserts.

There are two ways to immerse pipes:

- shock. The pipe is driven into the ground, welding/attaching the following sections as it is lowered;

- rotational: wells are drilled to the length of one pipe section, a section is placed, and drilled further.

Immersion, holding and retrieving of pipes is carried out using a casing, fixed at the base of the drilling equipment and connected to its hydraulic system.

Our equipment

USA KRAZ-250K

FROM 350 RUB.

Equipped with a tubular diesel hammer UR-1250, UR-1800

UMMC 12

FROM 350 RUB.

Equipped with a diesel rod hammer SP6V, impact part weight 2500 kg

BM-811

FROM 350 RUB.

Equipped with a tubular diesel hammer SP-75A, impact weight 1250 kg

KBURG 16

FROM 250 RUB.

KOMATSU PC 400 KBURG 16, equipped with diesel hammer DD35

Casing pipes for bored piles - GOST and SNiP

- GOST for casing pipes for steel piles, regulating production conditions and standard sizes - 63280 and 53366 from 2009;

- asbestos-cement pipes - 539-80 GOST;

- parameters of plastic pipes - 2248-001-84300500-2009 GOST.

SNiP for bored piles in casing pipes 2.02.03-85. According to the rules, bored piles can be installed without reinforcement only on rigid and hard soils, provided that the immersion depth is no more than 30 meters.

You can order the installation of bored piles using turnkey casing pipes from our specialists

We provide a full range of services and have experience in implementing projects of any complexity.

For any questions call: 8 800 707-72-09

FEATURES OF WORK PRODUCTION AT NEGATIVE ENVIRONMENT TEMPERATURES

- In winter conditions, in addition to the general requirements stated above, additional control is carried out.

- During the preparation of the concrete mixture, control is carried out at least every 2 hours:

— absence of ice, snow and frozen lumps in unheated aggregates supplied to the concrete mixer when preparing a concrete mixture with antifreeze additives;

— temperature of water and aggregates before loading into the concrete mixer;

— concentration of the salt solution;

— temperature of the mixture at the outlet of the concrete mixer.

- The duration of transportation of the concrete mixture should ensure that the temperature of the concrete mixture does not drop below + 10°C. When transporting concrete mixtures, once a shift the implementation of measures for covering, insulating and heating the transport and receiving containers is checked.

- Use concrete with antifreeze additives and hardening accelerators in accordance with the design documentation.

- When laying the mixture, its temperature is monitored during unloading from vehicles and the temperature of the laid concrete mixture.

- The temperature of concrete is measured by remote methods using temperature wells, resistance thermometers, or technical thermometers are used.

- When the air temperature is below minus 25°C, concreting piles is prohibited.

- Before lowering the frames into the pile, they must be cleared of snow and ice.

- Maintenance of concrete pile heads is carried out using a heat-moisture protective coating in 3 layers (1. Covering the surfaces of structures made of monolithic concrete with polyethylene film. 2. Covering the surfaces of structures with Dornit cloth over a polyethylene film. 3. Coating the surfaces of structures with polyethylene film over a layer of Dornit for protection from precipitation).