Such devices for pipes make it possible to carry out replacement and repair work on the main line without cutting off the entire network.

They are used to seal holes, cracks and porous areas in lines that transport liquids. The sealing collar on these devices has a cellular structure, which makes it possible to reliably seal the damage. Tests by manufacturers have shown that such a connection can withstand a pressure of 30 bar.

Where are they used?

Repair clamps, or pipe couplings as they are also called, are used to work with pipelines made of any material. Their main advantage is that they can be used repeatedly. With such couplings you can make inexpensive and urgent repairs of highways made of:

- Cast iron.

- Become.

- Polyethylene.

- Metal plastic and asbestos cement.

Types of damage that can be repaired with clamps:

- Post-weld.

- Pipe breaks.

- Longitudinal cracks formed.

- Needle hole.

- Post-corrosion fistula.

- Holes due to impact.

The advantages of clamps are obvious:

- Installation is simple and completed very quickly.

- The emergency zone is quickly sealed.

- The products are low cost.

- With these couplings you can reduce the cost of repairs.

- When used for repairs, there is no need to disable the entire system.

- The design formed by the clamps is reliable and has a long service life.

Manufacturers of this product line

The building materials market provides various products from domestic and foreign manufacturers. Professional craftsmen deservedly highlight the high level of quality of goods from Israeli and Swiss companies.

Watch the video

Repair clamp "Gebo"

According to experts, the products of Dutch and German companies differ in the same level of quality. A lower level is occupied by products manufactured in Poland and China. The next place is occupied by clamps from domestic manufacturers. And the list ends with products from Denmark.

Almost all products that can be found on sale are manufactured according to European standards. They have all the necessary certificates for use in our country.

The line of these repair products is offered for sale in a very wide range, which allows them to be used on any mains, with any pipe diameter. The list of such highways also includes systems for transporting drinking water.

Types of clamps and their application

Mega Fix products are well known among our customers for their quality, reliability and competitive prices in this market segment. We produce clamps that are used in various industries and the national economy. Our catalog also includes products from other companies, the quality of which is beyond doubt and is tested for compliance with technical specifications in our laboratory.

Let's look at clamps of different types and purposes, which you can always find and order from us.

Where are our clamps used?

Our products are widely used in almost all industrial and operational areas, including:

- automotive industry;

- energy and energy industries;

- petrochemical industry;

- ferrous and non-ferrous metallurgy, metalworking;

- chemical and petrochemical industry;

- light and heavy engineering;

- wood processing industry;

- glass and porcelain-faience industry;

- microbiological and medical industry;

- production of agricultural feed;

- printing and advertising production;

- radio engineering and electronics industry.

Of course, this is far from a complete list of industries and types of economic activity where clamps of various types and purposes are used. They are also widely used in the construction field, in the field of maintenance of facilities, buildings and structures, and in engineering companies. There is a large share of the use of our products in everyday life; those fasteners that are sold by retail chains are widely used by home craftsmen, so we can say that the sale of our products at retail is justified for the majority of specialized stores and retail chains. Let us dwell in more detail on the types of clamps that are in demand in each of these industries.

What clamps do we offer?

Our product range covers almost all areas of application and we have fasteners that are used in a wide range of applications. If we talk about the types of clamps and other connections, you can always select and buy from us:

- power clamps. Used for reliable fastening of flexible hoses and sleeves to pipes in high-pressure systems. These are, as a rule, hinged clamps, which provide uniform tightening and high holding force. There are also two-bolt ones that can withstand significantly larger loads. It is almost impossible to single out a specific area of application here, since they are used everywhere where there are increased requirements for pressing force and connection reliability;

- worm clamps. One of the most popular and sought-after types of products due to its versatility and the ability to adjust the working diameter over a wide range. Also used for attaching hoses and sleeves to pipes. Here it is necessary to note the presence of a wide range of sizes, as well as the ability to use clamp tape to quickly produce clamps on site to the required size yourself;

- spring clamps. They are used almost everywhere, mainly in fuel systems and liquid cooling systems. They are in demand in industries that use internal combustion engines and machine tools with liquid cooling systems. The peculiarity of their design makes it possible to compensate for thermal expansion of the crimped connection within a wide range of temperature changes;

- Spiro bridge clamps. The main area of application is the fastening of ventilation and transportation flexible corrugated air ducts. They are used in centralized and local ventilation systems, for the transport of liquid and bulk materials, including abrasive materials, for the removal of production waste in the woodworking and metalworking industries;

- nylon clamps or ties. They have a wide range of applications, mainly where fixing or bandaging of cable connections and flexible pipes is required. The key area of application is the radio engineering industry, power supply, mechanical engineering;

- plastic staples or rubbers. Mainly used for securing cables. They are widely used when laying cable networks at facilities for various purposes, as well as in energy generating companies. Often used for fixing pipes and hoses.

We also have a number of modifications of fasteners that are designed taking into account the operating conditions and are intended for use in a specific industry.

Specialized modifications of our fasteners

To solve special problems, the following modifications of fasteners can be used:

- In energy generating, transportation and service companies, clamps with grounding are used. Also, such clamps can be used in explosive industries;

- In the oil production and oil refining industry, products with a copper coating are often used, which is necessary to prevent sparks. Spark-extinguishing copper plating is also used in fasteners in explosive industries;

- in the metallurgical industry, in the production of ferrous and non-ferrous metals, heat-resistant clamps made of W5 stainless steel, which does not have magnetic properties, are often used;

- Stainless steel clamps are used in the chemical industry, where they work in aggressive environments.

Our company offers the manufacture and sale of clamps from different materials in different modifications. Therefore, to optimally select a product, it is necessary to take into account not only the load capacity and performance characteristics of the clamp, but also the specific operating conditions.

When you order fasteners from us, tell our specialists not only the technical parameters of the products and the required types of clamps, but also their operating conditions. In this case, we will help you choose the optimal modification, which will allow you to effectively spend your budget on supporting the operation of your systems and equipment.

Let's look at what types there are

Repair clamps for metal and other pipes, depending on the material of manufacture, are divided into:

- Steel. Made from material not coated with anti-corrosion protection.

- Steel. Made of stainless material.

- Steel. (Galvanized).

- Cast iron.

Depending on the type of fastener, coupling devices for metal and other highways are:

- One-sided.

- Double sided.

- Standard.

- Two-part.

- Three-part (for large-volume metal pipelines).

In addition to these models, manufacturers provide a set of composite parts for metal systems with large diameters. And the number of component parts for such repair devices depends on the volume dimensions.

Watch the video

Repair clamp IGE INOXGIS

Products for metal and other pipes differ in several features of working designs, which means that they are easy to select for any network.

Main technical characteristics of repair devices

Crimping repair clamps for pipes consist of the following parts:

- Bandage. This is a crimp element (stainless steel or galvanized), which has a thickness of one or two millimeters. Carbon steel (one and a half to three millimeters thick) is also used to manufacture this structural element. And often cast iron parts are used for this task.

- Cuff. It serves as a sealant on crimping devices. It is made from cellular rubber 6429 - from 8 to 13 SHAFT.

- Fastening elements of crimping mechanisms are made of stainless steel or galvanized.

Acceptable standards for the operating pressure that crimping devices can tolerate are from 6 to 10 atm. The working medium for them is water, air, or any inert gas.

The temperature standard for crimping devices is from -20 to +600C. And their diameters range from 1.5 to 120 cm.

Types of steel clamps

Installation of different types of pipelines requires fastening elements of different designs. Specialists use the following types of steel clamps:

- Spiral clamps - connect reinforced parts of pipelines; there are simple models, power ones, with a bridge;

- Power models of clamps for connecting elements of systems operated under high pressure;

- Reinforced fastening options are used for thick-walled or reinforced hoses with a high-pressure working environment;

- Wire clamps are suitable for hoses and corrugated pipes that experience strong vibration;

- Worm-worm clamps are also used in areas with high vibration, most often in water supply and heating systems;

- Pipe clamps are used in cases where it is necessary to rigidly secure a section of pipe in an open manner. Rigid fixation helps reduce stress in the pipeline. Pipe clamp fasteners look like two half rings or brackets with a tightening mechanism;

- Spring clamps are used for pipes with hot working fluids;

- Repair copies with sealing sealing inserts are used by plumbers in carrying out restoration work. With their help, damage to systems is effectively eliminated: cracks in pipes, fistulas, defects in welding seams. One of the simplest samples for repair purposes is a metal ring with bends at both ends. A rubber gasket is placed under the ring, a bolt is inserted into the bends, and the nut is tightened tightly. The cellular rubber from which the gasket is made hermetically seals off leaks in the water supply system at maximum compression.

Manufacturers offer various types of clamp fastenings. They are usually classified according to materials of manufacture, shape, purpose, installation methods, the presence of additional elements, as well as other design features.

What are steel clamps made of?

Stainless steel is used to produce the simplest two-piece models. The brackets for fixing the hoses are made of galvanized metal. Pipe clamps are made from stronger materials that are reinforced with nickel fibers.

Fastening devices can be in the form of a split ring, a semi-oval shaped bracket, or a strip. There are double versions; they are used to fix pipes located at a very close distance from each other. According to their purpose, clamps can be fastening or repair.

Fastening with clamps can be movable or rigid. Movable fastening is used in the installation of hot water supply systems, when exposure to the working environment can lead to changes in the size and shape of the pipes. Movably fixed pipes can move and return to their original position. Rigid fastening does not allow the fastened element to move from its place and ensures resistance to maximum loads.

Some clamp models have rubber gaskets. They dampen vibration, reduce noise levels, and increase the tightness of connections. These specimens have a higher cost, which is compensated by the strength and reliability of the connections.

Repair coupling for 300

Repair pipe clamp 300 is used for repairs on large diameter pipelines. This device copes excellently with problems such as:

- Formation of cracks running longitudinally (with a possible deviation of 5 degrees).

- The appearance of a dimensional fistula on a steel and cast iron main.

Using repair tools for 300, you can connect steel and cast iron lines with polyethylene ones. The 300 part allows you to eliminate the leak without cutting off the entire system.

These couplings use gaskets made of certified food grade rubber. And the use of random materials on devices is completely excluded. Therefore, such products are characterized by a high level of environmental friendliness.

The 300 device is a reliable and high-quality device because it is made from high-quality raw materials. To all these advantages should be added its affordable cost.

Clamp for repairing steel lines

Repair clamps for steel pipes are made of steel, and most often these devices are installed on the water supply network. This part for steel pipes is folded:

- Several galvanized or steel coupling halves.

- Gaskets.

- Bolts, nuts and washers made of steel or galvanized materials.

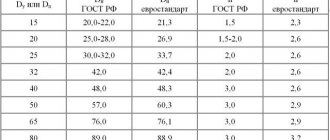

The nominal volume of such a device for steel pipelines is from 1.5 to 60 cm. These devices are made in the form of a tape, the edge parts of which are fastened with galvanized tubes.

The cuff on these devices is made of cellular material, which creates a hermetically sealed passage of the mechanism to the emergency location on steel pipelines. The thickness of the metal on them is 1 mm.

They are not subject to corrosive formations, and their use is economical and simple.

Their features

A repair clamp for cast iron, metal, polyethylene pipes has a large number of advantages. It can be used for fragile cast iron and any other system, and everywhere such devices turn out to be multifunctional.

Installing these mechanisms is simple, and anyone can carry out such work with their own hands. During operation, these fasteners allow you to connect cast iron and any other pipe.

When installed on a metal system, they make it possible to extend the life of the line.

Such a device for a cast iron system can be installed by anyone without special skills. These mechanisms for cast iron and any other network can withstand high temperatures.

But in order for these technical characteristics to meet all requirements, you need to buy products only from a trusted manufacturer.

Application and installation sequence

It has already been noted that installation in this case becomes quick and uncomplicated. A brief description of such work looks like this:

- The mechanism must be wound around the circumference of the pipe and secured to the part opposite from the accident.

- Then the nuts are attached; they must fit tightly to the pipeline.

The quality of installation in the emergency zone directly depends on the material of the coupling and its strength. An important detail during operation is the peculiarity of the interface between the fastening device and the system.

There is no need to change the mounted device; it can last the same period as the pipe product itself. Therefore, it is economically beneficial to buy several clamps for repairs, rather than spending money on replacing a pipeline or a separate piece of it.

When selecting the right device for repair, it is necessary to take into account the degree of damage. At the same time, metal, plastic and other devices are installed that most effectively help cope with the resulting breakdown.

Each repair mechanism is designed in the form of a semi-closed cuff and a screw tie. All components of this design are tightened using bolts. Its diameter must exactly correspond to the dimensions of the highway; only this condition becomes the key to reliable sealing.

Watch the video

repair clamp

The described fastening method is versatile and simple. Although difficulties often arise during installation that will require certain skills. For example:

- Stable mounting option. The main points of support with a fixation zone are considered to be those places where a pipe product is secured with a clamp without the likelihood of its subsequent movements. This fastener is made near the socket point on the body. This system makes it possible to use devices of various shapes and creates a durable structure.

- Floating fastening method. Metal or steel coupling mechanisms are connecting parts, but such a coupler requires a lot of effort. Another option for this method is plastic types. They need to be selected for a larger diameter; only in this case can an effective level of fastening be ensured.

Metal and plastic clamps

The pipeline installation process involves a variety of shapes and sequence of coupling attachments. And only in this way is the stability of the reproducible structure created. And additional devices are used in the area of branching and turning of the highway.

It is advisable to use rigid and immovable fasteners for a metal or plastic coupling in a heated room. In other options, plumbers use a movable fastening method using elastic inserts.

If the system is under the influence of high temperature, the pipe needs to be fitted with coupling devices of various shapes with a movable design and an elastic gasket.

The use of various options: metal, plastic, steel, aimed at performing plumbing measures associated with eliminating defects in systems. An option for fastening them is to fix them to the wall with sharp metal studs.

For example, fastening a polypropylene pipeline is carried out at a distance of 2 m, and a plastic pipeline is allowed to be fastened at less frequent intervals.

Features of clamps for CV joint boot

The boot is necessary to protect the automotive CV joint (constant velocity joint) from external influences and preserve the lubricant. Metal clamps are usually used for fastening, which are usually supplied with the boot.

The tie is a solid or perforated tape with a locking device. To ensure reliable fastening and create complete tightness, it is recommended to tighten the clamp with a special device and not use conventional tools.

Need some advice? Request a call! Send a request for fasteners

24.10.2020