Profile pipe sizes

When talking about the characteristics of profile pipes, first you should consider what sizes profile pipes come in. Since the production of these products is quite developed almost all over the world, the dimensions of the metal profile pipe can be any - depending on its purpose.

In addition, thanks to the widespread development of standardization, any professional sizes may vary. pipes – values of the sides of the cross-sectional figure, wall thickness, length of the profile pipe. Read also: “Dimensions of profile pipes - production and use options.”

Basic geometric parameters of the product

The state standard stipulates a whole list of geometric parameters that metal profile pipes with a square cross-section must comply with. These parameters include:

- h – side dimensions or profile height;

- b – profile width (this parameter may differ from the height if the pipe has a rectangular cross-section);

- t – wall thickness;

- R – radius of curvature (outer), measured at the intersection of the walls.

Parameters of the cross section of square profiles according to GOST 30245-2003

The regulatory document states that the geometric parameters of profile square pipes may have deviations, which must be within the limits presented below.

Along the outer radius of curvature

- for products with wall thickness up to 6 mm – 1.6t–2.4t;

- for products with a wall thickness of 6–10 mm – 2.0t–3.0t;

- for pipes with a wall thickness greater than 10 mm – 2.4t–3.6t.

According to the height/width of the sides of the steel pipe

- for pipes whose height/width of sides is 100 mm or less – from ±0.5 mm to ±1%;

- for products with side dimensions exceeding 100 mm – ±0.8%.

Based on the angle of intersection of the pipe sides (900), measured in the cross section of the profile

- ±1030´.

Pipe manufacturing

As you might guess, these products are made from ordinary round pipes. The dimensions of the profiled pipe depend on the designed load on it during operation.

The essence of the production process is giving the planned shape to a workpiece of the required diameter as a result of hot or cold deformation (for more details: “How does the production of profile pipes occur - product options, equipment, technologies”). To ensure the quality of fastening, a weld seam is built up on the blank pipe using specific processing.

For example, metal square pipes of any characteristics and sizes can be obtained in two ways:

- using rolling rolls, round pipes are evenly compressed, resulting in a square profile;

- a sheet of the corresponding metal or alloy is cut according to a template, the blanks are bent into box-shaped sections and secured with a weld.

Application area

Cold-rolled products are intended for the manufacture of frames, supports, as well as in the production of various types of furniture.

Thick-walled corrugated pipes have found application in the construction of warehouses and retail facilities, as well as on farms and facilities where it is necessary to use particularly durable structures.

Hot-rolled profiles are popular among companies that produce doors, fences and other similar products made of metal.

Why are profile pipes needed?

All types of profile pipes have undeniable advantages over conventional round pipes:

- such pipes can withstand significantly greater loads without deformation;

- they are cheaper than non-hollow (solid) products of a similar shape due to material savings;

- for the same reason these pipes are lighter;

- such products are easy to manufacture and can be used to assemble structures of any shape;

- profile pipes are characterized by increased strength and resistance to aggressive external influences.

The dimensions of a square pipe or any other shape depend on its purpose. The material from which the pipe is made is also decisive. Thus, products made from particularly resistant steel grades are resistant to the influence of salt water, humid wind and other unfavorable factors.

For example, thanks to the use of special grades, it has become possible to use profile pipes in arctic, coastal and other climates. This allows for the construction of lightweight metal structures quite quickly.

It is also possible, using products of appropriate sizes, to switch from using heavy cement-based materials to lightweight materials, and therefore build taller buildings with significantly less load on the foundation.

There are quite a few possible pipe profiles.

Square Pipe Length Requirements

Steel profile pipes with a square cross-section, in accordance with the requirements of the regulatory document, can be produced in unmeasured, measured, and also multiple measured lengths. When cutting, you should adhere to the following requirements, which are regulated by GOST.

- The length of the cut profile products should be in the range of 4–13 m.

- The most common pipe lengths supplied from the manufacturer's warehouse are 6 and 12 meters.

- Products of measured and multiple measured lengths should not have a deviation along it of more than 60 mm.

- The length of pipes supplied from the manufacturer’s warehouse is determined by the customer, but it must be within the limits specified in the regulatory document.

Long square pipes

Types of profile pipes

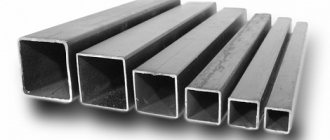

The choice of such pipes is quite diverse. According to geometry, profile pipes are divided into rectangular, square, oval and flat-oval.

Each of the above types is used in a specific area of human activity.

For example, flat-oval pipes are characterized by increased flexibility, therefore they are used in furniture production to create a variety of decorative elements.

Rectangular and square products, thanks to their standard shape, are easy to use in the construction of structures that, during further processing or operation, must stand on a flat surface (read: “Types of rectangular pipes, their advantages and applications”). They are used as construction reinforcement, the basis of spacer frame structures, and many household appliances.

Product standardization

Profile pipes produced in the Russian Federation must comply with GOST 13663-86.

According to this document, according to the manufacturing method, pipes are divided into:

- seamless hot deformation;

- seamless cold deformation;

- electric welded cold deformation;

- electric welded

According to the profile, products corresponding to GOST are:

- rectangular (GOST 8645-68);

- square (GOST 8639-83);

- oval (GOST 8642-68).

GOST also determines such characteristics of profile pipes as the size of the profile sides, wall thickness and length of the produced pipe.

Depending on the planned load on the pipe and the expected environmental conditions - both natural and technological - pipes are initially produced with or without galvanization (so-called black pipes).

Of course, after completing the assembly of the structure, if necessary, you can additionally protect the profile pipes with varnish, paint or other coatings. This not only guarantees the product’s resistance to corrosion and mechanical wear, but also gives it an aesthetic appearance, which is important in the manufacture of household items.

In addition, additional processing of the finished structure from profile pipes allows you to reduce the risk of injury to the product and provide various types of product insulation (thermal, hydro, electrical insulation).

Read and download GOST 30245-2003 and GOST 30245-94

You can familiarize yourself with the contents of the document of state standard 30245-2003, which regulates the main parameters, nuances of the manufacture and operation of square pipes, and also download this GOST below.

GOST 30245-2003

GOST 30245-2003 Bent closed welded square and rectangular steel profiles for building structures. Specifications

Quite often, having set out to become familiar with the assortment of square pipes, people look for GOST 30245-94, which has now lost its relevance due to the fact that it has been replaced by a newer state standard document. But if you still want to compare them and find out what changes have been made, then this GOST can be downloaded for free below.

GOST 30245-94 Steel bent closed welded square and rectangular profiles for building structures. Specifications