Stainless steel profile pipes are produced in a huge assortment, differing in steel grade, section profile, dimensions and surface texture of the product. Another type of stainless pipes - stainless thin-walled pipes - is widely used for domestic and industrial purposes.

Stainless steel profile pipe

Areas of application

Where is profiled stainless steel used:

- Mechanical engineering and shipbuilding - mufflers for vehicles, hydraulic cylinders, outlet pipes of gas turbines and engines, parts of various shafts and valves, accessories for cars.

- Furniture production - legs, stands and frames of furniture.

- Construction - supports, posts, truss columns, chimneys, stairs and stair railings, frames for cornices and awnings.

- Food industry - processing plants (especially for chocolate, mayonnaise), grills, oven heat exchangers.

- Production of commercial equipment - shelving, equipment for bars, restaurants.

- Chemical and oil refining industries - installations for the production of alkalis, acids, ring collectors.

- Department of Housing and Utilities.

- Medicine - manufacturing of equipment, various implants.

Rectangular stainless steel pipes with a mirror surface

Pipes of this type, for the production of which AISI 304 stainless steel or its domestic equivalent are also used, are exceptionally decorative, which is ensured by their mirror surface. Naturally, they are used for the manufacture of structures whose appearance is subject to increased requirements.

Mirror stainless steel is often used for making furniture and commercial equipment

Technical characteristics and properties

Parameters of stainless steel profile pipe:

- Type of rolled pipe profile.

- Geometric dimensions of width, height and length of a segment.

- Wall thickness.

- Weight of 1 linear meter.

- Steel grade and its characteristics.

For the production of profile stainless steel products, the grade of austenitic steel AISI 304 (Russian analogue 08Х18ХН10) is mainly used. This is an acid-resistant material, not subject to corrosion, and can withstand short-term temperatures up to +900 °C. The metal density is 7.9–7.93 g/cm2, the elastic modulus is 193–200 GPa, and the shear modulus is 86 GPa.

Life time

Stainless steel profile metal can be used for at least 50 years without losing its original properties.

Characteristics of seamless pipes

International standards:

- ASTM A312 - Seamless pipes (c/c) of austenitic stainless steel grades,

- ASTM A213 - Seamless Ferritic and Austenitic Alloy Boiler Parts,

- steam superheating and heat exchange pipes.

Surface: Matte Shape: round Length: 5-7m Standard sizes: diameter from 6 mm to 325 mm Wall thickness: from 1 mm to 13 mm

Application areas of seamless pipes

• General purpose pipes, chemical. and nuclear industry • Heat exchangers • Furnaces and chimneys

How are they produced?

Profile pipes are made from stainless steel using two technologies:

- The finished product is formed from a blank in the form of a metal strip (strip).

- A round pipe is profiled.

Strip manufacturing technology

The method makes it possible to obtain a profile pipe made of stainless steel with a seam. Welding of sheet steel strips is carried out using high-frequency electric welding, laser or plasma welding in a conventional environment, as well as tungsten electrodes in inert gas (TIG welding). The production process itself is as follows:

- The strip is cut from stainless steel sheets on special rolling mills and fed into a sheet bending mill.

- The metal strip is formed on the rollers of a sheet bending mill into a round blank with open edges.

- The edges are welded using one of the selected types of welding. Excess metal (grant) is removed with cutters.

- The workpiece is calibrated on rollers to a given profile shape.

- The finished product is cut into pieces of the required length.

To relieve internal stress, the stainless steel profile pipe is subjected to heat treatment (annealing). The workpiece is heated to +550…650 °C for 60–90 minutes, followed by gradual cooling (tempering). As a result, it becomes stronger and more durable.

Profiling

This technology for the production of profile stainless pipes involves the use of seamless cold- and heat-deformed pipes of round cross-section as initial blanks. They acquire the desired profile shape when passing through calibrating rollers in a cold or heated state.

Next, the cold-deformed profile pipe is subjected to heat treatment. At the last stage, the rolled metal is cut into pieces and undergoes surface quality control, tensile tests, and geometric dimensions testing.

Regulations

Technical production conditions, chemical composition of raw materials, geometric parameters for each cross-sectional shape of profile stainless steel pipes are regulated by several regulatory documents (GOSTs).

Standards and GOSTs

Russian manufacturers producing profile pipe products made of corrosion-resistant steel, depending on the technology used, use the following standards:

- GOST 11068-81 - for electric-welded pipe products.

- GOST 9940-81 - for seamless pipes manufactured using the profiling method.

The range and standard sizes of profiled stainless steel pipes are established by the following regulatory documents:

- GOST 8639-82 - for square profile.

- GOST 8645-68, GOST 8645-78, GOST 8645-86 - rectangular section.

- GOST 8642-68 - for oval pipes.

GOST stainless steel professional pipe

Metal profiles of various types can be used in such critical areas as the construction of cars, ships, airplanes, and even spacecraft. A stainless steel profile pipe produced in accordance with GOST is guaranteed to have the required characteristics.

In stock at the warehouses of the “Regional House of Metal” there is a large assortment of stainless steel profile pipes 40x10 mm and other sizes manufactured in accordance with GOST, with different wall thicknesses and surface types.

- GOST 9940-81 for square products

- The entire range of stainless steel pipes

- Characteristics of stainless steel steel 18/10

- Product polishing

- GOST 5582-75

- Steel pipe

- Stainless steel

- Steel sheet

- Armature

- Long products

- Pipe systems

- Metal structures

- Reinforcing mesh

- Metalworking

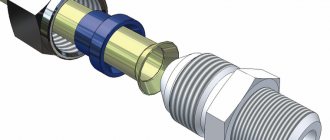

- Pipe parts

- Tsvetmet

- Metal-plastic and fittings

- Finishing and building materials

- Plastic pipes

Types, assortment: sizes and sections

There are different types of stainless steel profile pipes depending on the cross-sectional shape. She may be:

- Oval.

- Rectangular.

- Square.

- Flat oval.

- Drop-shaped.

- With hollow ribs.

Stainless steel pipes and other profile configurations are also produced: in the form of a trapezoid, rhombus, parallelogram, triangle, hexagon, etc. But they are mainly produced by foreign companies according to European or American standards.

The classification of profile pipes by type of surface treatment is as follows:

- Polished.

- Matte.

- Polished to a mirror finish.

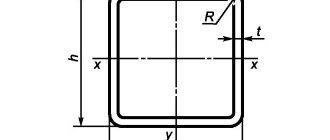

Square

Square profiles are highly durable and reliable. Their advantage is the presence of four stiffening ribs, which increase resistance to bending loads. The production of pipes with a square profile and their assortment is regulated by GOST 8639-92, according to which the external dimensions of the edges range from 10 × 10 mm to 180 × 180 mm. The minimum wall thickness is 0.8 mm, the maximum is 14 mm. The length of the products can be:

- Unmeasured. Seamless hot-deformed - from 4 to 12.5 m, seamless cold-deformed and electric-welded - from 1.5 to 11 m.

- Measured. Seamless hot-deformed - from 4 to 12.5 m, seamless cold-deformed - 4.5–11 m, electric welded - from 5 to 9 m.

- Multiple measured. With an allowance for each cut of 5 mm.

Rectangular

Stainless steel pipes with rectangular profiles can withstand high loads, the same in magnitude as solid products. In addition, it is convenient for installation, transportation and storage. It is used in the construction industry and mechanical engineering for the manufacture of frame metal structures and support posts.

Standard profile dimensions for rectangular pipes are shown in the table.

| Section parameters, mm | Wall thickness, mm |

| 15×10; 20×10; 35×30; 60×20 | 2 |

| 20×15; 25×10; 25×15 | 2,5 |

| 30×10; 30×15; 30×20 | 3 |

| 35×15; 35×20; 35×25 | 3,5 |

| 40×15; 40×20; 40×25; 40×30; (42)x20; (42)x30; 45×20; 45×30; 50×25; 50×30; 50×35; 50×40; 80×50; 100×60 | 4 |

| 60×25; 60×30; 60×40 | 5 |

| 70×30; 70×40; 70×50 | 6 |

| 80×40; 80×60; 90×40; 90×60; 100×40; 100×50; 100×70; 110×40; 110×50; 110×60 | 7 |

| 120×40; 120×60; 120×80; 140×60; 140×80 | 8 |

| 140×120 | 9 |

| 150×80; 150×100 | 10 |

| 180×80; 180×100; 180×150 | 12 |

Regulatory documents provide for the possibility of producing stainless rectangular pipes with non-standard dimensions, for example, an extended range of wall thickness from 0.8 to 20 mm and edge sizes from 28 × 25 mm to 230 × 100 mm.

The length of the segments according to GOST 11068-81 is:

- Measured (5–9 m).

- Unmeasured (1.5–9 m).

- Multiple measurements (no more than 9 m with an allowance of 5 mm for each cut).

Matte

Profile pipes with a matte outer surface are used as structural elements, the decorative appearance of which does not require high requirements. For example, for installation:

- Production shelving.

- Work sites.

- Support structures, etc.

Sanded

Polished stainless steel profile pipes combine aesthetic appearance with high strength, wear resistance and durability. They have no planar or structural flaws; they are in demand in areas where impeccable smoothness of surfaces is required.

To process stainless steel profiles, 2 technologies are used:

- Electrochemical. The workpiece is immersed in a solution of concentrated acid. If the outer surface is polished, then the product is then surrounded by round electrodes. To treat the internal surface, the electrode is inserted into the cavity of the pipe. Electric current is then applied to them.

- Abrasive. For primary processing, coarse abrasives with a grain size of 180–320 microns are used; a polished surface is obtained by using abrasive materials with a finer grain size. For final polishing, felt sanding belts are used.

Stainless steel pipes with a polished surface are endowed with decorative qualities, therefore they are used for interior decoration, the manufacture of cabinet furniture elements, fences, and railings.

Pipe wall thickness: what is the importance of this parameter

The dimensions of the ribs of stainless steel profile pipes are important for assembling structures, but the strength characteristics of rolled metal and its load-bearing capacity depend only on the wall thickness. The larger it is, the more resistant the finished product is to various types of deformations and loads.

Standard sizes and markings

Marking of profile stainless steel products is applied to their outer side at the factory after manufacturing. It consists of information about the standard size of the product, as well as the steel grade and the manufacturer’s trademark.

For example, let’s decipher the marking 100×100x5 09G2S:

- The first two positions indicate the size of the ribs in mm. In this case, 100 mm and 100 mm, since the pipe has a square profile.

- The third is the thickness of the walls.

- The fourth is the steel grade (set if necessary).

Standard sizes and markings

Marking of profile stainless steel products is applied to their outer side at the factory after manufacturing. It consists of information about the standard size of the product, as well as the steel grade and the manufacturer’s trademark.

For example, let’s decipher the marking 100×100x5 09G2S:

- The first two positions indicate the size of the ribs in mm. In this case, 100 mm and 100 mm, since the pipe has a square profile.

- The third is the thickness of the walls.

- The fourth is the steel grade (set if necessary).

Advantages and disadvantages

Stainless steel profile pipes have the following qualities and advantages:

- High strength characteristics with low weight.

- Due to the flat edges, they are more convenient to install than round profile pipes.

- Resistant to temperature changes.

- The ability to withstand any type of load (transverse, tensile and torsional), since they are distributed to the walls at right angles.

- High corrosion resistance, long service life.

- Heat resistance.

- Good weldability.

- Aesthetic appearance.

- Wear resistance.

- Frost resistance.

- Completely inert to chemical influences.

The disadvantages of profile products include:

- Relatively high cost.

- Inability to use for water supply pipelines and heating system wiring.

Profile pipes for construction

The properties of the structures under consideration allow them to be used very widely. They are used in almost all areas of industry. With their help, you can build structures that are characterized by high levels of strength and aesthetics. At the same time, the cost of installation and related construction work will be minimal.

The key advantage of stainless steel pipe products is their strength, reliability, and low weight. The products in question are often used as an alternative to load-bearing and supporting structures. This building material is resistant to corrosion processes.

With its help you can easily and quickly create different types:

- commercial equipment;

- public transport stops;

- window blocks;

- frames;

- pavilions;

- gate, etc.

The building material in question can also be used for the construction of hydraulic structures. It is used in the construction of chimneys and stoves. For the construction industry, the most relevant is a pipe product marked AISI 304. It is made from a special type of stainless steel.

The key advantage of this type of product is:

- level of plasticity;

- wear resistance;

- ease of machining;

- significant strength indicator;

- good weldability;

- resistance to temperature changes.

Tips on how to choose

Stainless steel profile pipes should be selected taking into account operating conditions, based on the following indicators:

- Maximum load.

- Duration and intensity of mechanical, thermal and chemical influences.

Depending on these parameters, the technical characteristics of the products are selected:

- Steel grade.

- Profile shape and dimensions.

- Wall thickness.

- Production technology.

The quality of purchased stainless steel products must be confirmed by factory certificates.

Approximate price and best manufacturers

The price of a stainless steel profile pipe depends on the grade of material, length of the section, wall thickness, type of surface treatment and manufacturer. The volume of the supplied batch can influence the final cost of the product.

The price range is quite large. For example, the price of a matte stainless square profile pipe can range from 3 to 30 dollars per meter, while rectangular steel pipes range from 4.5 to 42 dollars per meter.

Characteristics of electric welded pipes

International standards: electric welded pipes made of austenitic steel grades ASTM A554, A270, A312, A249, A269, DIN 17457, 17455 Seam welding type - TIG, laser seam. Surface: • Matte • Sanded (180, 320, 400 Grit) • Mirror (400,600 Grit)

Symbols for determining the surface type of an electric-welded pipe

| Surface type | Designation | |

| Matte | Matt, Mill finish | Matte |

| Sanded | Brushed | Cleaned, primary grinding |

| Satin 180 Grit Satin 320 Grit Satin 400 Grit | Grinding degree | |

| Mirror | Mirror 400 Grit Mirror 600 Grit | Polishing degree |

Shape: • round • profile Length: 6 m (custom pipes of any length can be supplied to order). Standard sizes: • diameter from 6 mm to 325 mm • cross-section from 10x10mm to 300x300mm, 400x200mm Wall thickness: from 0.8 mm to 6 mm

This is interesting: Packaging steel tape - application, characteristics, production

How to bend stainless pipes

When bending such products, it is important to prevent changes in the original cross-sectional configuration and the formation of creases on their inner surface. Deformation will weaken the load-bearing capacity of such a part, reduce its throughput, and increase the likelihood of corrosion.

In industrial conditions, bending of stainless steel pipes is carried out in the following ways:

- Run-in.

- Winding.

- Rolling.

- Drawing.

- Hydrostatic.

- By pushing.

- Using two supports.

Such pipe bending technologies allow you to obtain high-quality results, but require special equipment.

At home, you can bend a stainless steel profile using a manual pipe bender. In this case, to support the walls from the inside, the following is used:

- Clean dry sand and two plugs. First, one of the plugs is installed. Then the pipe at the future bend is filled with sand through the free end, carefully compacted and clogged with another plug. Next, the pipe is bent around a blank of the required size.

- A bundle of wire. The pipe cavity is filled to capacity with pieces of thick wire. After bending, the wire is removed one by one.

- A spring of the appropriate shape. It should be wound from wire 2–4 mm thick in such a shape that it fits freely into the cavity of the pipe at the bend. At the end of bending, the spring is removed using a wire previously left outside.

To bend a profile with a significant bending radius, the walls are preheated with a blowtorch or gas torch. Heated metal bends more easily.

Range of rectangular products

Rectangular pipes according to standard 8645 have the parameters given in the table.

table 2

| Side length, *102 mm | Side length, *10 mm | Wall, mm | Cross-sectional area, *10-1 cm2 | Weight of one meter, *10-1 kg |

| 0,15 | 1,0 | 1 | 4,43 | 3,48 |

| 1,5 | 6,21 | 4,88 | ||

| 2 | 7,71 | 6,05 | ||

| 0,20 | 1,0 | 1 | 5,43 | 4,26 |

| 1,5 | 7,71 | 6,05 | ||

| 2 | 9,71 | 7,62 | ||

| 0,20 | 1,5 | 1 | 6,43 | 5,05 |

| 1,5 | 9,21 | 7,23 | ||

| 2 | 11,7 | 9,19 | ||

| 2,5 | 13,9 | 10,9 | ||

| 0,25 | 1,0 | 1 | 6,43 | 5,05 |

| 1,5 | 9,21 | 7,23 | ||

| 2 | 11,7 | 9,19 | ||

| 2,5 | 13,9 | 10,9 | ||

| 1,5 | 1 | 7,43 | 5,83 | |

| 1,5 | 10,7 | 8,41 | ||

| 2 | 13,7 | 10,8 | ||

| 2,5 | 16,4 | 12,9 | ||

| 0,3 | 1,0 | 1 | 7,43 | 5,83 |

| 1,5 | 10,7 | 8,41 | ||

| 2 | 13,7 | 10,8 | ||

| 2,5 | 16,4 | 12,9 | ||

| 3 | 18,8 | 14,8 | ||

| 1,5 | 1 | 8,43 | 6,61 | |

| 1,5 | 12,2 | 9,59 | ||

| 2 | 15,7 | 12,3 | ||

| 2,5 | 18,9 | 14,8 | ||

| 3 | 21,8 | 17,1 | ||

| 2,0 | 1 | 9,43 | 7,4 | |

| 1,5 | 13,7 | 10,8 | ||

| 2 | 17,7 | 13,9 | ||

| 2,5 | 21,4 | 16,8 | ||

| 3 | 24,8 | 19,5 | ||

| 0,35 | 1,5 | 1,5 | 13,7 | 10,8 |

| 2 | 17,7 | 13,9 | ||

| 2,5 | 21,4 | 16,8 | ||

| 3 | 24,8 | 19,5 | ||

| 3,5 | 28 | 22 | ||

| 2,0 | 1,5 | 15,2 | 11,9 | |

| 2 | 19,7 | 15,5 | ||

| 2,5 | 23,9 | 18,8 | ||

| 3 | 27,8 | 21,9 | ||

| 3,5 | 31,5 | 24,7 | ||

| 2,5 | 1,5 | 16,7 | 13,1 | |

| 2 | 21,7 | 17 | ||

| 2,5 | 26,4 | 20,7 | ||

| 3 | 30,8 | 24,2 | ||

| 3,5 | 35 | 27,5 | ||

| 0,40 | 1,5 | 2 | 19,7 | 15,5 |

| 2,5 | 23,9 | 18,8 | ||

| 3 | 27,8 | 21,9 | ||

| 3,5 | 31,5 | 24,7 | ||

| 4 | 34,8 | 27,3 | ||

| 2,0 | 2 | 21,7 | 17 | |

| 2,5 | 26,4 | 20,7 | ||

| 3 | 30,8 | 24,2 | ||

| 3,5 | 35 | 27,5 | ||

| 4 | 38,8 | 30,5 | ||

| 2,5 | 2 | 23,7 | 18,6 | |

| 2,5 | 28,9 | 22,7 | ||

| 3 | 33,8 | 26,6 | ||

| 3,5 | 38,5 | 30,2 | ||

| 4 | 42,8 | 33,6 | ||

| 3,0 | 2 | 25,7 | 20,2 | |

| 2,5 | 31,4 | 24,7 | ||

| 3 | 36,8 | 28,9 | ||

| 3,5 | 42 | 33 | ||

| 4 | 46,8 | 36,8 | ||

| 0,45 | 2,0 | 2 | 23,7 | 18,6 |

| 2,5 | 28,9 | 22,7 | ||

| 3 | 33,8 | 26,6 | ||

| 3,5 | 38,5 | 30,2 | ||

| 4 | 42,8 | 33,6 | ||

| 3,0 | 2 | 27,7 | 21,7 | |

| 2,5 | 33,9 | 26,6 | ||

| 3 | 39,8 | 31,3 | ||

| 3,5 | 45,5 | 35,7 | ||

| 4 | 50,8 | 39,9 | ||

| 0,50 | 2,5 | 2 | 27,7 | 21,7 |

| 2,5 | 33,9 | 26,6 | ||

| 3 | 39,8 | 31,3 | ||

| 3,5 | 45,5 | 35,7 | ||

| 4 | 50,8 | 39,9 | ||

| 3,0 | 2 | 29,7 | 23,2 | |

| 2,5 | 36,4 | 28,6 | ||

| 3 | 42,8 | 33,6 | ||

| 3,5 | 49 | 38,5 | ||

| 4 | 54,8 | 43 | ||

| 3,5 | 2 | 31,7 | 24,9 | |

| 2,5 | 38,9 | 30,9 | ||

| 3 | 45,8 | 36 | ||

| 3,5 | 52,5 | 41,2 | ||

| 4 | 58,8 | 46,2 | ||

| 4,0 | 2 | 33,7 | 26,5 | |

| 2,5 | 41,4 | 32,5 | ||

| 3 | 48,8 | 38,3 | ||

| 3,5 | 56 | 43,9 | ||

| 4 | 62,8 | 49,3 | ||

| 0,60 | 2,5 | 2,5 | 38,9 | 30,5 |

| 3 | 45,8 | 36 | ||

| 3,5 | 52,5 | 41,2 | ||

| 4 | 58,8 | 46,2 | ||

| 5 | 70,7 | 55,5 | ||

| 3,0 | 2,5 | 41,4 | 32,5 | |

| 3 | 48,8 | 38,3 | ||

| 3,5 | 56 | 43,9 | ||

| 4 | 62,8 | 49,3 | ||

| 5 | 75,7 | 59,4 | ||

| 4,0 | 3 | 54,8 | 43 | |

| 3,5 | 63 | 49,4 | ||

| 4 | 70,8 | 55,6 | ||

| 5 | 85,7 | 67,3 | ||

| 0,70 | 3,0 | 3 | 54,8 | 43 |

| 3,5 | 63 | 49,4 | ||

| 4 | 70,8 | 55,6 | ||

| 5 | 85,7 | 67,3 | ||

| 6 | 99,4 | 78 | ||

| 4,0 | 3 | 60,8 | 47,8 | |

| 3,5 | 70 | 54,9 | ||

| 4 | 78,8 | 61,9 | ||

| 5 | 95,7 | 75,1 | ||

| 6 | 11,4 | 87,5 | ||

| 5,0 | 3 | 66,8 | 52,5 | |

| 3,5 | 77 | 60,4 | ||

| 4 | 86,8 | 68,2 | ||

| 5 | 105,7 | 83 | ||

| 6 | 123,4 | 96,9 | ||

| 0,80 | 4,0 | 3 | 66,8 | 52,5 |

| 3,5 | 77 | 60,4 | ||

| 4 | 86,8 | 68,2 | ||

| 5 | 105,7 | 83 | ||

| 6 | 123,4 | 96,9 | ||

| 7 | 140 | 109,9 | ||

| 5,0 | 3 3,5 4 | 72,8 | 57,2 | |

| 84 | 65,9 | |||

| 94,8 | 74,4 | |||

| 6,0 | 3,5 | 91 | 71,4 | |

| 4 | 102,8 | 80,7 | ||

| 5 | 125,7 | 98,7 | ||

| 6 | 147,4 | 115,7 | ||

| 7 | 168 | 131,9 | ||

| 0,90 | 4,0 | 3,5 | 84 | 65,9 |

| 4 | 94,8 | 71,4 | ||

| 5 | 115,7 | 90,8 | ||

| 6 | 135,4 | 106,8 | ||

| 7 | 154 | 120,9 | ||

| 6,0 | 4 | 110,8 | 87 | |

| 5 | 135,7 | 106,5 | ||

| 6 | 159,4 | 125 | ||

| 7 | 182 | 142,9 | ||

| 1,0 | 4,0 | 4 | 102,8 | 80,7 |

| 5 | 125,7 | 98,7 | ||

| 6 | 147,4 | 115,7 | ||

| 7 | 168 | 131,9 | ||

| 5,0 | 4 | 110,8 | 87 | |

| 5 | 135,7 | 106,5 | ||

| 6 | 159,4 | 125,1 | ||

| 7 | 182 | 142,9 | ||

| 7,0 | 4 | 126,8 | 99,6 | |

| 5 | 155,7 | 122,2 | ||

| 6 | 183,4 | 144 | ||

| 7 | 210 | 164,8 | ||

| 1,10 | 4,0 | 4 | 110,8 | 87 |

| 5 | 135,7 | 106,5 | ||

| 6 | 159,4 | 125,1 | ||

| 7 | 182 | 142,9 | ||

| 5,0 | 4 | 118,8 | 93,3 | |

| 5 | 145,7 | 114,4 | ||

| 6 | 171,4 | 134,6 | ||

| 7 | 196 | 153,8 | ||

| 6,0 | 4 | 126,8 | 99,6 | |

| 5 | 155,7 | 122,2 | ||

| 6 | 183,4 | 144 | ||

| 7 | 210 | 164,8 | ||

| 1,20 | 4,0 | 5 | 145,7 | 114,4 |

| 6 | 171,4 | 134,6 | ||

| 7 | 196 | 153,8 | ||

| 8 | 219,4 | 172,2 | ||

| 6,0 | 5 | 165,7 | 130 | |

| 6 | 195,4 | 153,4 | ||

| 7 | 224 | 175,8 | ||

| 8 | 251,4 | 197,3 | ||

| 8,0 | 5 | 185,7 | 145,8 | |

| 6 | 219,4 | 172,2 | ||

| 7 | 252 | 197,8 | ||

| 8 | 283,4 | 222,5 | ||

| 1,40 | 6,0 | 5 | 185,7 | 145,8 |

| 6 | 219,4 | 172,2 | ||

| 7 | 252 | 197,8 | ||

| 8 | 283,4 | 222,5 | ||

| 8,0 | 5 | 205,7 | 161,5 | |

| 6 | 243,4 | 191,1 | ||

| 7 | 280 | 219,8 | ||

| 8 | 315,4 | 247,6 | ||

| 12,0 | 6 | 291,4 | 228,8 | |

| 7 | 336 | 263,7 | ||

| 8 | 379,4 | 297,8 | ||

| 9 | 421,7 | 331 | ||

| 1,50 | 8,0 | 6 | 255,4 | 200,5 |

| 7 | 294 | 230,8 | ||

| 8 | 331,4 | 260,1 | ||

| 9 | 367,7 | 288,6 | ||

| 10 | 402,8 | 316,2 | ||

| 10,0 | 6 | 279,4 | 219,3 | |

| 7 | 322 | 252,8 | ||

| 8 | 363,4 | 285,3 | ||

| 9 | 403,7 | 316,9 | ||

| 10 | 442,8 | 347,6 | ||

| 1,80 | 8,0 | 7 | 336 | 263,7 |

| 8 | 379,4 | 297,8 | ||

| 9 | 421,7 | 331 | ||

| 10 | 462,8 | 363,3 | ||

| 12 | 541,7 | 425,2 | ||

| 10,0 | 8 | 411,4 | 322,9 | |

| 9 | 457,7 | 359,3 | ||

| 10 | 502,8 | 394,7 | ||

| 12 | 589,7 | 462,9 | ||

| 1,50 | 8 | 491,4 | 385,7 | |

| 9 | 547,7 | 429,9 | ||

| 10 | 602,8 | 473,2 | ||

| 12 | 709,7 | 557,1 |

Installation Tips

When assembling metal structures from stainless steel profile pipes, the parts are connected by welding or fastening with clamps. The elements can be fixed using electric arc, gas or resistance welding.

When arc welding, it is important to choose the right electrode. The quality of the weld depends on its diameter. If it is too thin, the welding process will be interrupted; if the electrode cross-section is too large, a thin-walled pipe can be burned.

Electric arc welding should not be performed in open areas. Such work is carried out in special premises. In this case, the ends of the parts to be welded must first be cleaned and degreased.

The contact type of welding forms a welding seam of increased reliability. There are no restrictions on ambient temperature and other weather conditions for its use.

General recommendations for carrying out any type of welding are as follows:

- When choosing a welding temperature, you should proceed from the thickness of the metal, since profile products are more susceptible to deformation than round ones.

- To maintain the internal clearance of the profile, it is necessary to prevent molten metal from entering the stainless steel profile pipe.

- When performing welding, it is necessary to carefully check the geometric coincidence of the ends of the parts being welded so that distortions do not occur in the metal structure.

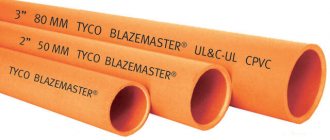

Alternative to profile pipes

The use of profile stainless pipes is not always technically and economically feasible. It's not cheap. In addition, it cannot be used for laying pipelines transporting liquid and gaseous media under high pressure. This is especially true for electric-welded products with a seam: due to the presence of different angles inside such pipelines, blockages can quickly form at the bends. For the installation of such communications, only round pipes are used. And it doesn't have to be stainless steel.

Modern pipe products made of reinforced polypropylene are not inferior in a number of technical characteristics to stainless steel, but are much cheaper. Profiles made of plastic are more often used as ventilation ducts. They are available in white, so they fit more harmoniously into the interior of kitchens and bathrooms.

An alternative option for constructing a chimney could be a galvanized sandwich pipe. Galvanized steel is just as fire-resistant and fireproof as stainless steel, but is less resistant to corrosion from condensation. But the price of galvanized sandwich chimneys is much lower, as is the cost of installation. And in order to slow down the corrosive destruction of the metal, the surfaces of the chimney are coated with a special heat-resistant paint for galvanizing.

Aluminum pipes are also of good quality. They are lightweight, corrosion-resistant, and are a good option for making indoor decorative elements, furniture parts and other lightly loaded structures.

Requirements for this range

Stainless steel pipes GOST 9941 81 are manufactured in compliance with the following requirements:

- The extreme parts of the finished product are cut at right angles, and they are carefully cleaned of burrs. This sometimes causes a slight roughness to appear on the surface and a chamfer is formed. The described standards allow the presence of such formations. Often, customers specifically discuss with the manufacturer the presence of a chamfer on a product that has a wall thicker than five mm, as this makes it possible to more effectively fasten the structure together by welding.

- On a meter-long piece, these pipes may have a slight curvature. This is two millimeters for a structure with a wall of 0.05 cm and a cross-section of 1.5 cm. It is also one millimeter for options with a wall of more than 0.05 cm and a cross-section of more than 0.5 cm.

- The steel grades taken for the work for these pipes may contain small inclusions of metals belonging to the rare earth group. But sulfur may contain no more than 0.02%.

- All finished products must undergo heat treatment. This is not carried out only by individual agreement with the consumer. In this case, the curvature and mechanical characteristics of the goods are discussed with each client separately.

- The presence of sunsets, both on the outside and on the inside of this assortment, is not allowed. There should also be no cracks or flaws. When removing these defects, the dimensions of these tubular products should not exceed the limits stated by the requirements.

How is finished goods accepted?

Stainless steel pipe GOST 9941 81 is accepted in batches. They are assembled according to the thermal finishing option, the original alloy and geometric shapes. One batch of stainless steel goods cannot contain more than 200 tubular products.

Quality control of stainless steel products includes the following procedures:

- Check for intergranular corrosion. For control, two pipe blanks are taken from the batch.

- Distributing and flattening. One tubular product is taken for testing.

- Stretching. Two blanks are taken for this test.

If all testing procedures were successful, then such a batch of stainless steel goods is considered to be of high quality. If the testing reveals unsatisfactory quality, then another check is carried out - this is an ultrasonic examination, hydrotesting and analysis of geometric dimensions. And the final size check is carried out on the entire batch of stainless steel products without sampling.

Products 19277

GOST 19277 73 defines seamless stainless steel pipes. In this case, there is no welding seam, therefore, the strength of the finished product is many times higher. GOST 19277 73 applies to the following options: cold-deformed, heat-deformed and hot-deformed.

Pipe metal products GOST 19277 73 show all the best indicators of types of steel products.

Pipe products GOST 19277 73 are produced:

- thin-walled options;

- thick-walled assortment;

- capillary pipe rolling.

The features in this case are as follows: with a similar external volume, this assortment has a greater wall thickness than options produced by the electric welding method.

Accordingly, these products are characterized by a higher strength index and the ability to withstand heavy loads. On larger walls of steel grade GOST 19277 73, you can make a threaded joint and use special reinforcement.

In terms of length, these options are produced in unmeasured form. Their size range ranges from 1.5 to 10 meters. Small volumes include options from 8.9 to 10.8 cm, they are made in segments of seven meters. Large-diameter species reach nine meters in length.

Stainless steel pipes GOST 19277 73 are used in conventional and nuclear energy, in aircraft and automotive industries. They can be found in the oil refining and gas industries. In addition, they are indispensable in various sectors of the national economy.

Dimensions

The dimensions and dimensions of stainless steel pipe assortments can be viewed in special tables that provide all the indicators in detail. Here are some of them:

- Stainless steel pipe GOST 9941 81 has the following dimensions: external volume from 5 to 273 mm. Seamless blanks according to the same standards have a wall thickness of 0.2 to 22 mm.

- This rolled pipe according to GOST dimensions is characterized by a weight that depends on the actual volume and dimensions of the walls, as well as the presence of a coating. For example, similar dimensions of the galvanized version will differ in heavier weight.

All products, which are distinguished by their compliance with standards, have precise dimensions and excellent characteristics. But, when choosing, you need to be able to navigate the wide range of offers from manufacturers. And consultants can help with this, ready to come to the client’s aid at any moment.

Watch the video

Features of operation

Structures made from profile stainless steel pipes do not lose their load-bearing capacity and presentable appearance over time. They do not need painting and can be easily washed with household chemicals that do not contain chlorine. Dried stains cannot be scraped off or removed with a wire brush: use only a soft cloth or foam sponges.

Possible problems

In some cases, rolled stainless steel may be subject to corrosion. Foci of rust appear on the walls of products after prolonged contact with a concentrated chlorine solution. To eliminate the cause of corrosion, it is necessary to thoroughly rinse off the chlorine-rich liquid. The rusting process of stainless steel parts will slow down, and they will retain their anti-corrosion properties.

Packaging, transportation and storage

For ease of transportation, profiled stainless steel pipes are bundled or tightly placed in wooden containers lined with waterproof paper. The packages are tied with wire or metal tape in three or four places depending on the weight. For strapping during loading and unloading operations, bags and containers are equipped with special clamps.

They can be transported by any type of transport. The packages are placed on the floor of the car or in the body of the car in stacks, separating the rows with spacers.

Profile stainless steel products are stored on racks in closed warehouses or under a canopy, where they will be protected from atmospheric moisture.