Hot-rolled seamless steel pipes are the most common format, successfully used in all economic sectors. These products are known for the greatest reliability, especially for laying communications for various purposes. Most often, hot-deformed seamless steel pipe GOST 8732-78 is used in the construction of monolithic-frame structures, where reliability is paramount under such impressive loads.

Seamless steel pipes have practically no competitors in terms of resistance to high loads

Main characteristics

This type of rolled pipe is capable of withstanding high pressure of the transported medium, and the enhanced wall thickness parameters and high quality of the alloys used allow it to be used on the most critical pipelines, in complex components of machines and ships.

Products are made from carbon, alloy or low-alloy steel.

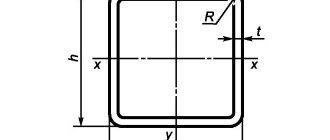

Classification of a pipe as thick-walled is determined by the ratio of the external section and wall thickness. A coefficient from 6 to 12.5 is a sign that the rolled product belongs to this class. An indicator less than six indicates a particularly thick-walled product.

Standardized parameters for seamless steel pipes are:

- Outer diameter.

- Wall thickness.

- Length.

When choosing a product, the manufacturing method is important.

Classification and types

Seamless thick-walled pipes are divided into two types: hot and cold rolled.

According to their characteristics and manufacturing methods, they are divided into 4 categories:

- “B” - made from steel standardized in terms of chemical composition with a minimum degree of oxidation.

- “B” – using heat treatment.

- “E” – without hardening.

- “D” – with passing hydraulic tests.

Difference between hot and cold rolling

The main difference is the operating temperature. With the hot method, the metal is easier to process, but the surface quality and geometric accuracy of the product produced will not be of the highest level.

Cold wire rod allows you to obtain a smooth, even surface and maintain the specified accuracy parameters. The products are distinguished by higher strength and quality. But their cost will be higher.

Application area

The high strength and low specific weight of seamless steel pipes make them in demand in many economic sectors. When constructing pipelines intended to move gases and liquids under high pressure, most bends are used without longitudinal seams.

Mining of oil and gas

In the gas and oil production sectors, thick pipes are used for transporting gas and liquid media over long distances, as well as for drilling. At great depths of excavation, the risks of increased soil pressure and rock shifts increase, which requires the use of a particularly strong casing structure. Seamless channels with reliable walls, made of high-quality alloys, will ensure trouble-free operation of drilling equipment.

Arrangement of hydraulic systems

Hydraulic systems are present in many lifting installations, important components of automobiles, and are used in industry and construction. Their work is distinguished by extreme temperature and high pressure force. Thick-walled steel pipes, which have a large margin of safety, successfully withstand these conditions.

Chemical industry

In the chemical industry, pipes with both thick and thin walls are used. Durable, thick-walled ones are used for transporting gases and toxic substances where there is high pressure. Thin-walled tubes are actively used in laboratories and medical instruments.

Energy production

Power plants are characterized by constant changes in internal excess pressure and high ambient temperatures. In these extreme operating conditions, the use of thick-walled seamless pipelines is optimal.

Shipbuilding and aircraft manufacturing

In these industries, one of the main tasks of designers is to minimize the weight of the main product. For this purpose, materials are used that must be reliable in operation and have low weight. The highest tensile strength and light weight of the seamless pipe fully meet these requirements of aircraft and shipbuilders, so the products are widely used among them

Application areas of seamless hot-rolled products

The main feature of seamless steel pipes GOST 8732-78 and 70 is the absence of a welding joint, which is noticeable in welded products. This guarantees the greatest strength and sufficient resistance to external influences, as well as to internal pressure of a liquid or gaseous medium.

Seamless pipe products are the basis for water and gas pipelines for various purposes and locations

The main advantage of seamless cold-deformed steel pipes GOST 8732(78) is a sufficient margin of safety along the entire length. Due to this, they are usually used in environments where other types of pipes do not meet the increased reliability standard. These products can withstand impressive internal pressure, which is why enterprises turn to these products:

- oil and gas industry;

- automotive industry;

- aviation;

- producing gas cylinders;

- heavy engineering;

- chemical industry;

- national economic profile;

- construction companies;

- engaged in laying communications.

Pipes are classified according to the ratio of internal and external diameters:

- small – within 114 mm;

- average diameter - within 114 - 480 mm;

- maximum diameter is 480-2500 mm (like a thick-walled steel pipe GOST 8732-78 or 70).

The widespread use of seamless products is due to their multifunctionality and versatility. They are used:

- for main pipelines and communications to the private sector;

- for small-diameter branches when installing water supply and gas pipelines in country houses and dacha communities;

- in the production of frame-type steel structures in cars and mechanisms for various purposes;

- when producing fragments of metal structures, multi-span ceilings and covered galleries;

- to enhance the strength of technical structures and hangars in industrial and agricultural production;

- for installation of highways and bridges, tubular type lighting poles;

- for foundation piles in construction, etc.

Pipes produced using seamless technology successfully serve as load-bearing and decorative structures in construction

Advantages and disadvantages

Solid-drawn pipes produced by the cold rolling method are distinguished by greater strength and better workmanship than the hot rod range.

Treated with galvanizing and chrome plating, they perfectly resist corrosion.

Thick walls allow them to be used in difficult operating conditions.

According to experts, there is only one drawback - the high price per ton, almost twice as much as that of hot-deformed analogues.

No seam plus or minus

Seamless pipes are more reliable compared to electric welded ones. However, they are significantly more expensive.

Suture products can be made with a larger diameter and longer length than seamless products. The range of their diameters and sections is significantly wider.

Both types are in demand in their niches. Electric-welded ones have fully justified themselves for water and heat supply, primarily from an economic point of view. Seamless rolled steel is used where there is high pressure and greater strength is needed.

Standards for Thick Walled Products

Thick-walled seamless pipe GOST 8732 is a high-strength product used for the construction of all kinds of metal structures or transportation of gases and liquids under high pressure. Welded products are used less frequently; preference is given to seamless pipes, and steel of different grades is suitable for this.

To increase resistance to corrosion, pipes are coated inside and outside with a protective layer of zinc, chromium or nickel

To prevent the inside of the pipe from rusting (important for supplying liquids of a certain chemical composition), thick-walled products are made from non-ferrous metals or are nickel-plated on the inside. They are used in the chemical industry and for transporting liquids from great depths.

Visually this is almost always noticeable, but there are standards by which thick-walled products are produced - within the range of 6mm - 12.5mm. If the hole inside is small and the wall is impressive, then these are especially thick-walled pipes. They are produced only by hot method.

The quality indicators of thick-walled pipes classify them according to the main standards: “B”, “C”, “D”:

- “B” - standardization of the chemical composition of the metal, including GOST 19281-89, GOST 4543-71, GOST 1050-88 and 8732-70;

- “B” - standardization of thermal indicators;

- “D” - without special regulation, but with internal pressure tests.

GOST 8732-70 also regulates the length of thick-walled pipes - products of unmeasured and measured lengths:

- non-dimensional format from 1.5 m to 11.5 m;

- dimensional format from 4.5m to 9m;

- length, a multiple of the measured length, within 1.5 m - 9 m (with an allowance of 5 mm for each segment).

Thick-walled pipes bend poorly, but they are products of increased strength and resistance to mechanical stress. Their main function is to transport gaseous and liquid media under pressure. But they are also indispensable as frost-resistant building materials; large-format welded products are also suitable for this. These products are subject to the requirements of GOST 8732-78 and TU 14-3-1128-2000. To produce workpieces with thick walls, the following steel grades are usually used:

- 10G2;

- 09G2S (low alloy alloy for welded structures, silicon and carbon up to 1% and 2% manganese).

On a note! Welding of pipes with a seam is carried out with or without preheating. The less carbon in the steel grade, the easier the welding. When welding, the steel does not overheat, does not harden, and the viscosity does not decrease. And the alloy’s resistance to low temperatures makes it possible to effectively use 09G2S products even in the Far North.

At the customer's request, steel pipes GOST 8732-78 and 8732-70 can undergo additional hydraulic pressure tests to ensure their strength. The maximum pressure is about 20 MPa, which is allowed only in thick-walled products.

Finished products are tested not only for strength, but also for compliance with GOST standards for length, weight, wall thickness

Standards and regulations

The production of seamless thick-walled pipes is carried out in accordance with the requirements of state standards and other regulatory documents. Standardized:

- Standard sizes.

- Weight.

- Limit deviations.

- Manufacturing methods.

- Structure of the chemical composition of alloys.

Guests

For the manufacture of BT, two main GOST standards are used.

GOST 8732-78 regulates the range of hot-rolled pipes, GOST 8734-75 applies to cold-rolled products.

For the production of rolled tubular products for special purposes (for example, for PJSC Gazprom), other state standards or technical conditions are used.

From 2010 to 2015, the national standard GOST R 53383-2009 was in force, which was subsequently replaced by GOST 32528-2013.

Weight and tolerances

Accurate determination of the mass of products is necessary for calculating loads in structures and selecting suitable lifting equipment for transporting products.

The weight is calculated per unit length of the pipe. It depends on the outer diameter and wall thickness. The tables of the relevant GOSTs indicate the standard weight values of rolled products for each standard size.

Standardized deviations in weight do not exist, but in case of deviations in size, the mass is calculated based on the arithmetic average of the minus and plus tolerances indicated in the corresponding GOST tables.

Dimensions

The diameters of hot-rolled pipe products according to GOST 8732 78 are calculated in the range from 2 to 55 centimeters. Wall thickness – from 25 mm to 75 mm. Pipe lengths from 4 to 12.5 meters are cut.

Cold-rolled products according to GOST 8734-75 are presented with slightly smaller diameters: from 5 to 250 mm. The wall thickness ranges from 0.3 to 24 mm.

Measured and unmeasured rolled lengths are allowed from 4m to 12.5m.

Formula for calculating mass

State standards provide a formula for calculating the theoretical mass of one meter of a product in kilograms.

M=0.02466 x S (D - S),

wherein:

- D – external section in mm.

- S – wall thickness (mm).

- M – mass.

The steel density value taken for calculations was 7.850 g/cm3.

Pipe making process

The modern technological process for hot-rolled pipe production is well-established, which makes it possible to obtain durable and multifunctional products from rolled metal blanks. According to GOST 8732-78, products are produced from:

- open hearth rolled ingots;

- prepared pipe blanks;

- forged blanks;

- continuously cast billets.

The production of hot-rolled steel pipes GOST 8732-78 goes through several stages:

- forming a gap in a metal workpiece using a special piercing mill, which consists of a frame for piercing and conical shafts;

- heating steel to 1200°C;

- bringing the product using special equipment to the expected format that complies with GOST.

In accordance with GOST 8732-78 and 8732-70, hot-deformed seamless products are produced in a wide range of assortments. Thick-walled products, with an outer diameter in the range of 25mm - 700mm and wall thickness in the range of 2.5mm - 75mm, are used for various technical and economic needs.

The range of unmeasured length is limited to 4m - 12m, and the measured length assumes sizes up to 12m. Larger products are difficult to transport.

Attention ! All questions regarding the standardization of GOST 8732-70 for seamless steel pipes and the selection of products for various purposes should be compared using tables. Clients usually receive all advice and recommendations from the managers of the issuing enterprise or through the information website.

Manufacturing methods and technologies

Seamless pipes made of ferrous metals are produced in one of two ways:

- Hot rolling.

- Cold deformation.

The process takes place in industrial conditions on pipe rolling units. The basis is a cylindrical metal blank, which is heated until the steel crystallizes and acquires the required degree of ductility. Next, on a piercing machine, a through hole is pierced with a mandrel and a hollow pipe blank is obtained.

Hot deformed

Then the billet is rolled out at high temperature in a rolling mill, where, using rolling, a pipe of the required diameter with the required wall thickness is obtained from it.

The product is cooled with water.

The final calibration is performed using rolling.

The process is completed by cutting standard sections in accordance with GOST standards, as well as taking into account the customer’s requirements.

The entire production process is carefully controlled. Defective products must be melted down. Manufactured products are tested according to established methods.

Cold-worked

The process of manufacturing cold-deformed pipes at the first stage is similar to the production of hot-rolled pipes. But here the cooling procedure is carried out immediately after manufacturing the workpiece on a piercing machine. At the same time, for cold wire rod, hot-rolled products with a slightly larger diameter are used - the so-called “roll”.

The cold deformation process is carried out either by rolling (stretching the workpiece on a rolling mill until the desired diameter and wall thickness are obtained) or by drawing the workpiece through a hole of a smaller cross-section (drawing ring). The second method takes longer, since pulling is carried out in several cycles through a ring that gradually decreases in cross-section.

During manufacturing, cold-rolled pipe is annealed to improve its performance.

Where can I buy

It is better to buy products from reputable manufacturers.

The leader in Russia in terms of the volume of pipe products produced is TMK (Pipe Metallurgical Company). The company has 28 enterprises with an annual volume of about 4 million tons of products.

OMK (United Metallurgical Company), which ranks second in the ranking of manufacturers, specializes in the production of large-diameter pipes.

About 17% of pipe products in Russia come from ChTPZ, an association of metallurgical enterprises headed by the Chelyabinsk Pipe Rolling Plant. It produces and sells almost all types of seamless pipes, including stainless steel.

A wide range of seamless pipes is produced at the Ural Pipe Plant, Volzhsky and Sinarsky Pipe Plants.

All of these companies sell their products both directly and through their dealers.

The price of hot-rolled pipes starts from 31.5 thousand rubles per ton, cold-rolled pipes – from 45 thousand.

A brief overview of the most popular brands

The greatest demand is for products made from steel grade 20. It belongs to the group of high-tech alloys and is easy to process and stamp. Welding does not require initial heating, the seams are strong.

In the production of pipe metal products, the 09G2S grade is widely used. It has high mechanical strength, easy weldability, and resistance to low temperatures.

About 70 percent of stainless products are seamless pipes made from 10Х17Н13М2Т alloy. Its constituent nickel, titanium, chromium, and molybdenum provide the rolled product with anti-corrosion properties, ductility and strength. Products from this brand are in demand in medical institutions, chemical and food industries.

Features of installation of pipes and their connections

The designs of thick-walled pipes make it easy to cut threads at their ends for subsequent connections. The process is facilitated by the absence of a weld and sufficient wall thickness.

Welding joints require preliminary preparation of the end. The edge should be cleaned, dirt should be removed, and the chamfer should be removed. First, the joints are grabbed at two or three points on opposite sides. The weld is made in several layers, depending on the thickness of the walls. The reliability of the connection must be checked by a test run of the working environment.

General characteristics and basic information about solid pipes

Seamless hot-rolled pipes of standardization 8732 are produced from steel billets of the main grades:

- 10th, 20th, 35th and 45th standard;

- 35V;

- 40G and 45G;

- 15X and 40X;

- 9X1;

- 20PV;

- 30ХГСА;

- 17G1S,

- 09G2S;

- 10-20DDD.

Hot-deformed seamless pipes are produced in the form of:

- thick-walled products;

- thin-walled products;

- standard products.

These products are in demand and are widely produced by domestic and foreign enterprises. Hot-deformed pipes are made from steel billets and are produced by rolling heated raw materials using specialized factory equipment. Under other conditions, it is impossible to comply with all GOST requirements.

Seamless pipe production technology makes it possible to produce particularly thick-walled products

Good to know! The absence of a longitudinal welding joint is an important visual sign of the assortment of seamless steel pipes GOST 8732-78.

State standardization remains a guarantee of the reliability of seamless pipes, confirming control over key quality indicators. These include:

- absence of flattening, sagging and bends inside the walls;

- high impact resistance of pipes.

At manufacturing enterprises, metal quality control is periodically carried out and the chemical composition of the alloys used is confirmed. At the moment, seamless (w/w) pipe products are produced in two ways:

- cold-deformed seamless pipes;

- seamless hot-deformed steel pipes GOST 8732-78.

Taking into account the wishes of wholesale customers, chamfers and threads are applied to the cut edges of finished products. Sections are also processed - from one end or from both sides. It is worth clarifying all these conditions for product release with the company’s managers before placing an order.

As a rule, a batch of steel pipes GOST 8732-78 is shipped from enterprise warehouses directly to the customer. Warehouses do not always have finished products in the required volume. The cost of pipes varies periodically, depending on steel grades, so all aspects are discussed in advance with the sales departments. Product length varies from 4.5m to 11.9m. It is recommended to check the available assortment with managers.

The ends of the pipes can be untreated or chamfered