Fire protection of reinforced concrete structures Review of fire retardant compounds for air ducts Checking the quality of fire retardant treatment of air ducts Fire protection of air ducts with paint

According to the standards, fire protection of smoke exhaust ducts must meet fire safety requirements.

We’ll talk further about what materials and designs are used for this, and how it works.

TekhStroyGarant provides comprehensive services for organizing fire protection of air ducts using modern effective materials

Why do you need fire protection for air ducts?

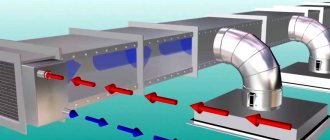

Ventilation ducts, namely air ducts, are an engineering system through which fresh air is supplied and polluted air is removed from residential and industrial premises. If a fire occurs, the air duct heats up, and the gases contained in it may burn, which will cause the fire to intensify.

When the air ducts through which fresh air is supplied are heated, damage to the duct walls may occur. Hot air or flame, having penetrated the damaged duct, will be easily transmitted through it to other parts of the building, facilitating rapid spread.

The role of fire protection for ventilation systems

The ventilation system ensures comfort and safety in the premises. An important part of ventilation is smoke exhaust ducts, which help remove toxic combustion products. It is smoke that causes the greatest harm to human health and can lead to death even at the initial stage of a fire. Therefore, reducing indoor smoke increases the time for taking measures to save people and property.

However, safety can be fully ensured only with a sufficient level of fire resistance of ventilation ducts.

The pipes through which air circulates are made of lightweight materials so as not to overload the building's supporting structures, but their fire resistance in the event of a fire is only enough for 15 minutes. In this case, smoke removal ducts are most often located in the same shafts where conventional ventilation supplies the premises with fresh air.

If the walls of ventilation and smoke exhaust pipes that do not have insulation burn through, smoke quickly spreads through the ventilation ducts throughout the building and causes no less harm than fire.

Uninsulated air ducts also pose another danger: when they heat up, they can lead to the spread of fire throughout the building, especially if there are flammable materials near the pipes. If ventilation ducts hidden in walls and ceilings overheat and burn out, load-bearing structures will be damaged.

Fire protection allows you to isolate pipes that have different purposes from each other, protect against overheating and destruction of the ceiling, and prevent fire and melting of finishing materials.

We recommend that you read: How to prevent clogging of storm drains - routine cleaning and prevention

Insulating air ducts slows the spread of fire and smoke, increasing the chances of saving property, health and life. In addition, some types of fire-retardant materials foam when heated, preventing the flow of oxygen into the room engulfed in fire. As a result, the fire gradually dies out without receiving oxygen supply.

Regulatory regulation of the use of fire protection for air ducts

The entire range of fire protection measures is specified in the relevant standards. The main ones are GOSTs R 53300-2009 and 53295-2013. They stipulate methods for testing ventilation structures for fire resistance and control test methods.

When installing ventilation systems with sufficient fire resistance, the following information should be taken into account:

- Installed air ducts require a certificate of conformity.

- All elements must be non-flammable.

- When determining the fire resistance limit of structures, you need to use the methodology from GOST R 53299.

- The tightness of air ducts must correspond to class B (SP 60.13330.2012).

We have been engaged in fire protection of air ducts for more than 10 years. We know exactly how to protect air ducts from fire and corrosion

Call 8 (495) 150-5-987

Classification of air duct structures

The degree of fire resistance is an indicator that reflects the possible limits at which pipes begin to lose their thermal insulation properties and enter the melting stage. If we are talking about the smoke removal process, then the limit here should be at least 45 minutes. Therefore, air ducts made of plastic have the smallest safety margins.

In accordance with SNiPs, the degree of flammability is divided into different strength classes, starting from 0. For a serviced fire compartment, the fire resistance limit will be El 30 according to standards, and EI 150 outside.

And what classes are the air ducts themselves divided into, and on what principles is the division made:

- Thermal insulation is indicated in the marking by the letter l and corresponds to the time required to heat the outer surface of the air duct to 140 °C.

- Integrity is reflected by the letter E, which indicates the time it takes to maintain the integrity of an object under high-temperature conditions.

- Load-bearing capacity corresponds to the letter R and is responsible for the ability to withstand the load created by a fire.

Characteristics of air ducts and requirements for their fire resistance

It is worth highlighting a number of characteristics of ventilation structures that most determine their ability to withstand fire. In doing so, pay attention to the following points:

- structural materials and technologies that ensure fire resistance of individual elements;

- connection points of individual parts of ventilation sections;

- materials used for fire-retardant coatings and application method;

- designs of units located in places where the building’s enclosing elements intersect;

- method of hanging fire-resistant air ducts.

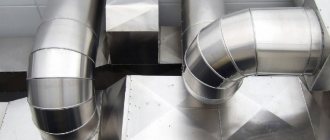

Air ducts are made from separate parts, joined together using connecting elements. Made from sheet steel, thickness from 0.9 to 1.2 mm. It can be galvanized or simply black, coated with a primer.

Air ducts have certain requirements for their fire resistance. In doing so, they must ensure the following:

- block open flames and prevent their spread through ventilation ducts;

- remove combustion products hazardous to human breathing;

- supply clean fresh air.

Requirements for fire protection of air ducts must be taken into account and ensured at the design stage of utility networks. To ensure high-quality fire protection of the ventilation system, take into account:

- fire retardant capabilities of materials;

- correctness of design documentation;

- quality of installation of the air duct system;

- compliance of fire protection with fire regulations;

- full control over the quality of work.

Our licenses

License No. 50-B/00378

SRO extract N0000627

More details

Which premises need protection first?

First of all, they need fire protection:

- warehouses for fuels and lubricants;

- production using open fire or molten metals and minerals, welding, plasma cutting, electric furnaces for various purposes;

- places with large crowds of people - shopping centers, shops; entertainment institutions (theatres, cinemas, entertainment complexes, sports facilities); office buildings, domestic buildings at industrial enterprises, children's and educational institutions; catering enterprises4

- underground structures.

At the household level, first of all, rooms with heating devices (especially those using open fire) need protection - rooms with stoves and fireplaces, baths, kitchens, boiler rooms and the rooms and attics located above them. However, all air vents should be protected - fires also occur for other reasons (cigarettes, pranks, short circuits).

We should not forget about high-quality and correct thermal insulation and sufficient fire resistance of chimneys, especially in places where they pass through walls, ceilings and roofs.

Criteria for choosing fire-retardant coatings

Protective coatings have different fire resistance limits. Depending on the value of this limit, taking into account the conditions in which it will have to work, the material is chosen.

Types of fire retardant coatings:

- Coatings made of liquid glass or silicophosphate. Provides a fire resistance rating of up to EI. Its disadvantage is destruction due to vibration and poor adhesion to the base. Not suitable for wet areas.

- Coating made of heat and fire retardant boards. Fire resistance EI 60 - EI Disadvantage - complex element-by-element installation, preliminary cutting and adjustment of sheets is required. Can serve as a decorative finish.

- Mineral wool covering. Fire resistance limit EI 60 - EI Preliminary cutting of the canvas is required.

- Combined mineral fiber coating with liquid glass coating. Complex implementation, fire resistance limit EI 60 - EI Positive side - a smaller coating thickness is needed to ensure fire resistance.

- Plastering air ducts with special compounds using the surface gunite method. Fire resistance limit EI 60 - EI Requires clear technology and good specialists for implementation.

Before choosing a material for fire protection of ventilation systems, you need to calculate its consumption for various cases in order to determine the most economical and reliable option.

Examples of fire protection work performed by TechStroyGarant specialists

Fire protection of air ducts in the Museum of Private Collections in the center of Moscow

TechStroyGarant specialists performed fire protection for air ducts at the Museum of Private Collections in Moscow on Solyanka Street. Fire retardant plaster FIBROGAINE (Fibrogain) from the manufacturer Promat (Promat) was applied by semi-dry shotcrete using an EOLA plastering station.

Read more >>

Fire protection of air ducts in the Sky House business class residential complex in Moscow

TechStroyGarant specialists completed fire protection of air ducts in the premium residential complex Sky House in Moscow on Mytnaya Street. The work was carried out using fire-retardant plaster.

Read more >>

Installation of fire protection for air ducts in business class residential complexes New Vatutinki

A set of installation works has been completed to install a fire-retardant coating for ventilation systems based on the fire-retardant material “FIBROGAINE” at the construction site of the “New Vatutinki” housing complex near the village of Desna (Moscow, NAO settlement Desenovskoye).

Read more >>

VIEW ALL PROPERTIES

structural fire protection

Fire protection methods for air ducts

In the previous section, we looked at the types of fire-retardant coatings, and then we will tell you how to perform them correctly. With any method of protection, you need to prepare the surface of the structure to be insulated. For ducts, an additional complication is that access to them is not always possible.

In preparation we perform the following work:

- we clean the surface from rust, scale, dirt mechanically;

- We wash off greasy stains with organic solvents;

- Apply a layer of primer using a brush or spray.

Next, we proceed directly to the fire protection work, choosing the most suitable method.

Installation of thermal protection screens

One way to protect air ducts from fire is to install screens made from Promat Promatect brand slabs. These slabs are made of silicate material, the binder is cement. They do not perceive moisture, are quite rigid, and non-flammable. Available in thicknesses from 6 mm to 25 mm, plate size 2.5 x 1.25 m.

The surface of Promat Promatect slabs is treated in such a way that no traces of oils, gasoline and various salts remain on it. If necessary, they can be plastered and coated with fire-resistant paints, and finished with ceramic tiles.

These slabs are self-supporting and do not require an additional frame when lining air ducts. A box-shaped structure is made, the elements of which are attached to each other at the ends with screws or staples.

Coating with mixtures

In addition to cladding with slabs, we provide fire protection to structures using special plasters. We most often use Promat Fibergain plaster. It is a dry powder consisting of stone wool, Portland cement and special additives. According to regulatory documents, fire retardant treatment of air ducts with such a composition is considered acceptable.

Important!

Promat Fibergain is used to insulate ventilation systems. It can only be used in enclosed spaces where moisture does not penetrate. The operating temperature can be positive or negative.

It is applied by dry shotcrete using special equipment. Work is carried out at a temperature of at least +150C. The walls of the air duct should not have traces of condensation on the surface.

The applied coating resembles a thin “fur coat”; the presence of fiber in its composition makes it resistant to vibrations. To make it decorative, you can use fire-resistant paints of various colors.

Fibrogame plaster coating is an environmentally friendly product. This allows it to be used for fire protection of natural ventilation air ducts; standards allow this to be done in residential and public buildings.

Roll coatings made from basalt fibers

Fire retardant coating Bison is a rolled material with basalt fiber as a base. On one side it is coated with an adhesive composition, with the help of which it is glued to the insulated surface. The front side is covered with foil or metal mesh.

Depending on the thickness of the layer, a certain degree of fire resistance is provided.

| Fire resistance limit | Insulation thickness, cm |

| EI 60 | 2 |

| EI 120 | 4 |

| EI 150 | 6 |

| EI 180 | 7 |

| EI 240 | 8 |

Basalt fiber in the fire retardant coating gives it strength and flexibility. It does not crack from high temperatures, is not afraid of mechanical damage, and can be used in damp rooms and at low temperatures.

The Bison coating does not increase the load on the structure of the air duct and its fastenings, is an additional means of sound and heat insulation, and has a long service life. Not toxic.

We attach the covering to the air duct using a bandage made of metal wire with a diameter of 1-1.5 mm or a Manier metal mesh.

fire protection from experts

What is

Fire protection for air ducts is a passive means of fire protection and consists of creating a heat-insulating protection (screen) with high heat and fire resistance on the surface of ventilation ducts.

The screen must protect for a specified time:

- near sources of ignition - the air duct from destruction and, if possible, from heating;

- in the rooms above and below, walls, ceilings - combustible structures and materials adjacent to the air duct pipes, from secondary fire.

Fire protection is carried out by applying special compounds or thermal insulation with various products made of non-combustible materials (mineral wool, asbestos, sometimes ceramic materials - for example, expanded clay concrete, brick).

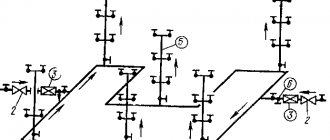

Methods for determining standard fire resistance

The fire resistance of a structure is characterized by the time that lasts from the moment of heating until it reaches the limit, when the thermal insulation ability I and the density of the material E are lost. The normalized fire resistance limit of air ducts is set for certain operating conditions, and is taken into account when testing prototypes.

A sample is selected for testing, which is an air duct coated with the material specified in the project. The aspect ratio of the rectangle of its cross-section is in the range from 1.5 to 2 units. The required length of the heated section is 2.5 m, the non-heated section is 1.5 m. Two connections are placed on the heated section, as indicated in the project.

One end of the air duct must be tightly plugged, and a pipeline for air supply is connected to the second. The test sample is placed in a special laboratory oven and heated. There are methods for this that are specified in regulatory documents.

After the end of the test, the data obtained is collected and analyzed, and the tests continue until the sample reaches any of the limiting states.

By comparing the results with regulatory requirements, we determine whether this ventilation system design can be put into operation.

Quality control of fire protection of air ducts

When carrying out quality control of materials intended for fire protection, pay attention to the following points:

- the compliance of the materials and structures used with the requirements of fire safety standards is determined;

- the condition of equipment and accessories for their production is checked;

- the progress of the technological process of manufacturing fire retardants is monitored;

- the operating conditions of the products are assessed and their compliance with the required standards;

- The condition of fire-retardant coatings is assessed during the operation of structures.

Testing of samples of coatings for fire protection of air ducts and evaluation of the results is carried out in a laboratory that has received accreditation to carry out this work. After the test, the condition of the test sample is visually assessed: the presence of cracks, chips and other damage. A decision is made on the advisability of using this duct design during operation.

Fire protection of air ducts is a vital point during construction and repair work. The main thing is to use a design that will withstand the time required to evacuate people in an emergency. The availability of various fire retardant materials will allow you to choose the most effective method of protection.

We provide fire protection for ventilation air ducts and smoke removal systems in Moscow

We specialize in installation work on fire protection and sell products from Promat Russia and Armacell as official dealers

Call 8 (495) 150-5-987