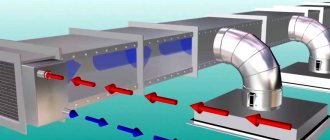

Fire protection of smoke exhaust ducts is an essential component of a properly equipped ventilation system, which otherwise is an active distributor of smoke and fire. When forming a fire barrier on air ducts, the problem is the complex configuration of the ventilation ducts and the hard-to-reach places it creates. In addition, there is a need to ensure long-term fire resistance of the structure, regardless of any external conditions.

What is

Fire protection for air ducts is a passive means of fire protection and consists of creating a heat-insulating protection (screen) with high heat and fire resistance on the surface of ventilation ducts.

The screen must protect for a specified time:

- near sources of ignition - the air duct from destruction and, if possible, from heating;

- in the rooms above and below, walls, ceilings - combustible structures and materials adjacent to the air duct pipes, from secondary fire.

Fire protection is carried out by applying special compounds or thermal insulation with various products made of non-combustible materials (mineral wool, asbestos, sometimes ceramic materials - for example, expanded clay concrete, brick).

Fire protection of air ducts - insulation that does not burn or melt!

The presence of fire retardants and modifying additives in the thermal insulation does not at all give it the right to be called fire protection. Non-flammable insulation does not ignite when exposed to an open flame. However, the material must not only be non-flammable, but actively resist the effects of destructive elements.

Both types of mineral wool thermal insulation demonstrate flame resistance. The high melting point of the fibers explains everything.

- Basalt wool

deservedly bears the name fire-retardant insulation, since fibers from molten stones easily tolerate heat up to +750 ° C. With such values, the insulation boards do not sag and do not lose their geometric shapes. The products can significantly increase the fire resistance of a structure. A full 180 minutes of extra time in case of fire. This will be enough to localize the fire and make a decision to evacuate people. You can buy fireproof basalt insulation in the form of slabs, mats and cylinders.

- Fiberglass insulation

It is based on fibers made of glass and quartz sand. The melting point of glass wool is +400°C, but it is better that the heating of mineral wool does not exceed 300°C. Under such conditions, structural changes and loss of thermal insulation properties are already possible. Optimal use in the form of thermal insulation for pipelines in private construction and for objects with moderate operating temperatures.

The role of fire protection for ventilation systems

The ventilation system ensures comfort and safety in the premises. An important part of ventilation is smoke exhaust ducts, which help remove toxic combustion products. It is smoke that causes the greatest harm to human health and can lead to death even at the initial stage of a fire. Therefore, reducing indoor smoke increases the time for taking measures to save people and property.

However, safety can be fully ensured only with a sufficient level of fire resistance of ventilation ducts.

The pipes through which air circulates are made of lightweight materials so as not to overload the building's supporting structures, but their fire resistance in the event of a fire is only enough for 15 minutes. In this case, smoke removal ducts are most often located in the same shafts where conventional ventilation supplies the premises with fresh air.

If the walls of ventilation and smoke exhaust pipes that do not have insulation burn through, smoke quickly spreads through the ventilation ducts throughout the building and causes no less harm than fire.

Uninsulated air ducts also pose another danger: when they heat up, they can lead to the spread of fire throughout the building, especially if there are flammable materials near the pipes. If ventilation ducts hidden in walls and ceilings overheat and burn out, load-bearing structures will be damaged.

Fire protection allows you to isolate pipes that have different purposes from each other, protect against overheating and destruction of the ceiling, and prevent fire and melting of finishing materials.

We recommend that you familiarize yourself with: Fastenings for fixing heated floor pipes

Insulating air ducts slows the spread of fire and smoke, increasing the chances of saving property, health and life. In addition, some types of fire-retardant materials foam when heated, preventing the flow of oxygen into the room engulfed in fire. As a result, the fire gradually dies out without receiving oxygen supply.

Fire protection installation procedure

Installation of thick-layer coating is carried out at the construction stage of the building

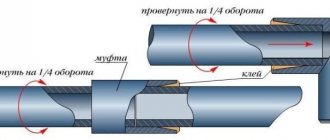

The procedure for arranging fire protection is determined by the type of material used (slabs, basalt wool or liquid mastic). Mats based on basalt fibers, for example, are attached to pipes with glue using special fasteners. In this case, the sequence of operations looks like this:

- The protected surfaces are thoroughly cleaned of traces of grease and dirt, and degreased using a solvent.

- Move on to preparing the fasteners. To do this, pieces of soft steel wire are welded to the duct body, through which the fire-resistant fabric is then attached.

- The protective material is cut into blanks corresponding in size to the diameter of the pipes. To arrange the base of the protective box (its lower plane), a solid canvas is taken. The sides and cover are cut according to the diameter of the pipe with a small margin for the design of joints (up to 10 cm).

- The surfaces of the plates and the air exhaust pipe are treated with a pre-prepared adhesive composition.

- Protective materials are applied with a layer of foil outward, and then fixed using standard hardware or wire.

Application of liquid fire protection by spraying from a spray gun

If the protective material has a liquid consistency, it is applied to the surfaces to be treated by spraying from a spray gun, or using special rolling rollers. In the simplest case, ordinary brushes are used for these purposes. Upon completion of the gluing and painting operations, the treated structure is allowed to stand until the protective composition is completely dry. Only after this is the full operation of the ventilation unit allowed.

In addition to the adhesive method of fastening, there are other methods, but mechanical options are the most widespread. Among them, the use of special bandage tapes and fastening using welded pins or needles stand out

When using them, special attention is paid to the fire protection of air duct fastenings, the quality of which determines the reliability of their operation.

Typical errors

When carrying out protective measures, it is important to consider the following points:

- In areas where strips of basalt sheet meet, it is not allowed to overlap it.

- The same mistake should not be made when joining fire-retardant material to elements of enclosing structures.

- Brackets, hangers and other duct fastening components must not be left without fire protection.

Norms and rules for organizing air ducts

In order for the ventilation system to effectively cope with its tasks and not increase the scale of the tragedy in the event of a fire, it is important to comply with the rules and regulations established by fire safety equipment:

- The fire resistance class of materials of ventilation ducts and shafts and their decorative finishing cannot be lower than B1 (semi-fire-resistant), while throughout one compartment its internal part can be made of low-flammable materials of class B, and the channels passing through escape routes, corridors, as well as ceilings and walls can only be made from class A materials with zero flammability.

- The fire resistance level of finished smoke exhaust ducts must be at least 60 - withstand fire temperatures (about 850 ͒ C) for at least an hour. That is, if the fire resistance of a ventilation pipe without a protective coating is at the level of 15, then the thickness of the fire protection is calculated so that its fire resistance is equal to 45 or exceeds this figure. In corridors, it is allowed to reduce the resistance limit of air ducts to 45. However, the larger the building, the higher the fire resistance limit. In multi-storey buildings this figure cannot be lower than 150.

- Along with the fire-retardant coating, the ventilation system, to increase evacuation time, is equipped with fire dampers and air valves that can withstand high-temperature exposure for at least half an hour, and fans that operate in high-temperature conditions for at least 2 hours.

Which premises need protection first?

Premises in which it is necessary to install fire protection for air ducts are, first of all:

- Warehouses for fuel, lubricants and flammable materials.

- Places with large crowds of people: office buildings, business centers, residential apartment buildings, shopping centers.

- Buildings with high temperatures: baths, saunas, boiler rooms.

The ventilation system, which carries air through the floors, has several compartments with valves and upholstered in fire-resistant materials. In this way, isolation of each individual room is achieved.

Ventilation, air conditioning and smoke exhaust pipes must be covered with insulating materials . The latter are made to remove smoke from the building, so they need increased protection.

Why do you need fire protection for air ducts?

According to statistics, during a fire, the greatest harm to people is caused by smoke, not fire.

Fire-insulated air ducts

Since air conditioning and ventilation are an integral part of any room, they become extremely dangerous during a fire, as they quickly spread smoke. Fire protection for blowers is designed primarily to delay the time of combustion products entering the ventilation.

Its second goal is to isolate the fire so that it “suffocates” without receiving the necessary oxygen. The third is smoke removal, removal of flammable gases from the room.

The material covering the outside of the ventilation ducts foams during excessive heating, thereby creating additional thermal insulation. Fire-retardant plaster, impregnation for fabric coverings, and special paint are common. These materials are designed to protect finishing materials from fire, which tend to ignite easily and emit toxic smoke.

Rules and regulations for the operation of fire protection for air ducts

The set of rules established by the legislative act SP 7.13130 of 2013 on fire safety technology regulates the installation of ventilation, heating and air conditioning systems.

When laying ventilation systems, it is allowed to use only non-flammable insulating and cladding materials “A” class. Within one fire compartment, low-flammable materials of class “B” can be used. “B1” - semi-fire-resistant materials are allowed for use in air ducts that do not pass:

- through ceilings (including suspended ceilings) and walls;

- in corridors and escape routes.

Ventilation system with fire protection

According to these rules, the ventilation system, in addition to the fire-retardant coating, must have: air valves, fire dampers. According to technical fire safety standards, fire protection must withstand heating during the evacuation time. For each individual case, a certain time interval is calculated.

Materials must be certified according to fire resistance standards. The fire resistance of a structure is determined by the time from the onset of excessive heating to the moment of destruction of the surface. Fire protection material must withstand temperatures up to 1000º, given the average fire temperature in the room is 850º.

The use of perlite-phosphogel sheets, asbestos-cement, gypsum fiber, plasterboard, basalt slabs, special spraying and fire-retardant paint coating increases the maximum fire resistance time to 240 minutes. According to the standards, this time cannot be less than 150 minutes.

List of fire retardant compounds for air ducts

Ventilation systems create vibration and noise during operation. Hence the technical requirements for all materials for processing, regardless of their type and composition: sound insulation qualities and vibration resistance. Products that meet these requirements are available in all groups of fire-retardant materials. There are several groups:

- structural protection of air ducts, also known as fire-resistant thermal insulation. These are slabs, mats, rolled materials made of vermiculite or basalt fibers mixed with Portland cement;

- sprayed basalt fiber;

- thick-layer fire protection - applying plasters or mastics;

- thin-layer – thermally expanding paints, varnishes, enamels;

- combined - basalt sheets + glue, which is also a fire-retardant material.

Thick-layer and thin-layer fire protection is carried out with fire-resistant compounds.

Fire-retardant plasters have the same main disadvantage as conventional building plasters: large volume. Because of it, problems arise when processing hard-to-reach places - for example, when the pipe runs too close to the wall. In hard-to-reach places we use paint and varnish.

The weight of fire-retardant plasters is, as a rule, less than that of conventional building plasters: the compositions are made on the basis of super-thin basalt fiber. Therefore, additional supports during installation are not required.

Thermally expanding (intumescent) varnishes and paints under normal conditions are a thin film. They begin to increase in volume when the temperature rises strongly. As a result, a layer is formed tens of times thicker than the original one - a coked crust, which serves as an obstacle to the penetration of flame to the surface. And the surface remains at a non-critical temperature, because The swelling process occurs with the absorption of heat.

The disadvantage of fire-retardant paints and varnishes in comparison with plaster compositions is that they are more expensive. The cost depends on the consumption, and the consumption depends on the required regulatory fire protection limit.

How to choose high-quality fire protection for air ducts?

You should not decide to buy fire-retardant insulation based on appearance and composition alone. Here's our selection of things to look out for.

- Documents and mandatory certificates

quality. A conscientious supplier will easily provide photocopies and originals; if there is a problem, it is better to postpone the purchase.

- Thermal insulation thickness

naturally increases its protective properties. However, going too far in this matter threatens to inflate the purchase price of fire protection and installation. Thick technical insulation requires more time for installation, and along with it, the amount of payment to the craftsmen will increase. To choose the optimal thickness, it is better to contact specialists.

- Foil or foil film

? This factor must be taken into account, especially if you need to buy fire protection for the air duct with a reflective layer. Products made of mineral wool covered with foil film belong to the fire safety group KM1. Look only for metal foil coated materials.

- Durability of foil coating

is also important. To prevent the lamination from crumbling over time, choose only proven brands of thermal insulation and dealers who work directly with the manufacturer’s factories.

- Presence of mullite silica

qualitatively improves the fire-resistant properties of insulation. These are wool-like fibers made from aluminum and flint. In high-quality thermal insulation it is found as an internal fire-retardant layer, as it perfectly withstands temperatures below 1500 °C.

- Firmware quality

has a high value because the wire inside the stone wool acts as a frame. Weak wires and weaves can cause the duct insulation to fray. A good galvanized wire is not subject to corrosion processes and will ensure uniform distribution and support of the insulation.

- Resistance to mechanical damage

important for fire protection of the air duct. Fire-resistant thermal insulation of air ducts, regardless of the presence of lamination, must return its shape well and maintain integrity after folding and compression.

What are the dangers of ventilation during a fire?

The ventilation system in case of fire creates two types of danger:

- distribution of smoke-laden air through air ducts. Uninitiated people underestimate the danger of smoke - and according to statistics, most of those injured and killed during a fire died from suffocation. But this article will not talk about smoke prevention;

- spread of fire and secondary ignition of combustible structures and materials from contact with the hot walls of the air duct.

Most public, industrial and office buildings use natural ventilation (that is, without the use of fans) or mixed (some of the systems are equipped with fans). In private and multi-apartment residential buildings, only natural ventilation is usually used.

The air ducts of any ventilation system are practically not blocked by any valves or dampers (in modern systems special fire dampers are installed, but there is always a possibility that the valves will not operate, and modern systems are not installed everywhere).

In large modern buildings there are smoke removal systems - separate exhaust ventilation removes combustion products from places of fire occurrence and from adjacent rooms, supply ventilation pumps air and creates excess pressure in staircases and elevator shafts and prevents them from becoming smoke-filled.

Hot air from the fire zone will rush upward, heat up the air ducts, carry away sparks and flames - and cause secondary fires on the upper floors, attics, and roofs.

Design and installation

Any work on fire protection of public and residential buildings is carried out by specialized organizations with a project in place. However, no one forbids additionally insulating the ventilation duct in your apartment. Fire protection of ventilation systems in private housing construction is practically not controlled by anyone.

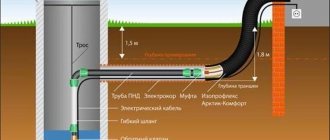

Fire protection is advisable in the following cases:

- if the housing has two or more floors, including a usable basement;

- if the ventilation ducts in a one-story house pass close to the chimneys of the heating system. In a small one-story house, fire protection of ventilation ducts in the attic is a matter of your desire.

You can apply intumescent paint yourself or insulate using mineral wool boards. Working with asbestos-cement or gypsum-fiber boards is labor-intensive; the use of asbestos-cement in residential premises is not allowed.

Before carrying out work, you should complete a project or make a drawing, think over the method of fastening, and calculate the quantity of all components.

Most often, basalt mats are used at home.

Installation technology:

- It is necessary to degrease, rinse and degrease the surface of the air ducts (using acetone). Do not forget to open the windows - you can work only with sufficient fresh air and as quickly as possible;

- the mats are cut around the perimeter of the air duct, taking into account an overlap of 100 mm;

- special glue for gluing mineral wool sheets is mixed, protruding elements of the air duct (for example, joints, clamps) are coated;

- First of all, protruding parts, brackets, and joints are glued. the foil will be on the outside of the mat; pieces of mat are glued with an overlap of 100 mm;

- the smooth part of the air duct is coated and glued;

- at the joints of mats and protruding parts, mineral wool slabs must overlap; if necessary, the joints are glued with aluminum foil;

- It is advisable (but not necessary) to secure the mats on top with wire, clamps, or metal brackets.

Watch the technology in more detail in our video:

Criteria for choosing fire-retardant coatings

Protective coatings have different fire resistance limits. Depending on the value of this limit, taking into account the conditions in which it will have to work, the material is chosen.

Types of fire retardant coatings:

- Coatings made of liquid glass or silicophosphate. Provides a fire resistance rating of up to EI. Its disadvantage is destruction due to vibration and poor adhesion to the base. Not suitable for wet areas.

- Coating made of heat and fire retardant boards. Fire resistance EI 60 - EI Disadvantage - complex element-by-element installation, preliminary cutting and adjustment of sheets is required. Can serve as a decorative finish.

- Mineral wool covering. Fire resistance limit EI 60 - EI Preliminary cutting of the canvas is required.

- Combined mineral fiber coating with liquid glass coating. Complex implementation, fire resistance limit EI 60 - EI Positive side - a smaller coating thickness is needed to ensure fire resistance.

- Plastering air ducts with special compounds using the surface gunite method. Fire resistance limit EI 60 - EI Requires clear technology and good specialists for implementation.

Before choosing a material for fire protection of ventilation systems, you need to calculate its consumption for various cases in order to determine the most economical and reliable option.

Types and features of existing thermal insulators

Fireproof coating for ventilation ducts

Fire protection for ventilation ducts that are part of forced ventilation systems is represented by the following special materials:

- fire resistant insulation;

- fibrous structures based on basalt;

- thin-layer and thick-layer fencing;

- elements of a combined type.

The first position is represented by mats of mineral wool or vermiculite, as well as basalt blocks of suitable shape. To install these materials on air ducts, separate fastenings such as self-tapping screws or steel wire are used.

Fire protection based on basalt

Basalt fibrous structures attract users due to their resistance to vibrations and aggressive environments. In addition, they are completely safe for humans, characterized by lightness, lack of shrinkage and low moisture permeability. These coatings are applied to the protected surfaces by spraying.

Thick layer structures

Fireproof plaster is applied by spraying to the air duct

Thick-layer fire protection elements include the following types:

- plasters of various types;

- special phosphate pastes;

- special mastics;

- asbestos and mineral fibers.

Liquid mixtures prepared on the basis of these materials are applied in a layer of up to 1 cm onto a metal mesh pre-fixed to the surfaces. In this case, possible deformation and cracking of materials due to sudden changes in temperature and humidity must be taken into account. In addition, when using massive thick-layer protection, the entire air exhaust structure becomes somewhat heavier, which forces the use of additional fasteners and spacers during its installation. When the gap between the wall and the duct is too small, this will be very difficult to do.

Combined and thin-layer types of protection

Silicate slabs to protect the air duct from fire

To install fireproof insulation of combined type air ducts, mastics and roll compounds of various classes with a basalt base are used. In the process of protective treatment, the material is first applied to a pre-prepared adhesive base and then covered with a foil shell. Thin-layer fire protection consists of various dyes, as well as enamels and varnishes prepared on an organic (water) basis.

When the ambient temperature increases, a special carbon layer is formed in the listed compositions, characterized by good thermal insulation characteristics. The advantages of liquid dyes include:

- durability;

- ease of application and light weight;

- aesthetics;

- efficiency.

Methods and materials for protection

Now let’s look at what means can be used for fire protection:

- Basalt protection.

- Fire retardant paint.

- Sprayed material.

Below we will consider each option in more detail.

Balsat fire protection for air ducts

Basalt is a substance of volcanic origin, including impurities of iron, calcium, magnesium and 47% silicon dioxide. It is thanks to silica that basalt is widely used as fire protection. When exposed to high temperatures, the material does not lose its shape, solid properties and does not emit hazardous substances.

Basalt fiber, which is used to insulate pipes from fires, is created from the original rock without the participation of foreign additives that reduce its natural properties.

Comprehensive fire protection with basalt material and paint

The most popular and reliable brands are:

- Rockwool (Wired Mat). Hydrophobized heat-insulating boards, light and rigid, are available in rolls. Size of 1 roll: 800x600x50 mm.

- Pro-Vent. Roll dimensions: 10000x1000-1200x20-80. There are options for one-sided lining: foil, reinforced foil, glass, basalt, silicon fabric, metal mesh.

- TIZOL. Roll sizes: 1000-1200x500-600x40-200. Covered with fiberglass and foil. Price on average from 326 rubles/m².

- Buffalo. Roll size: 6000x1000x20-80. The material can be lined with basalt, silicon, glass, aluminum foil, metal mesh. Price from 200 rub/m².

- MBF. Maximum roll length 31000x1000-1500x5-20. The material has a foil coating. Price from 320 rub/m².

Advantages of using basalt fire protection:

- comparative cheapness;

- high degree of protection;

- non-toxic;

- non-flammability.

The main disadvantage is the requirement for additional fasteners . As a rule, metal brackets are used for this, which are destroyed at high temperatures, causing the insulation to simply fall off the ventilation duct. It is safest to glue rolls of basalt protection using fire-resistant adhesives.

Other disadvantages include: comparative difficulty of installation, heavier structure.

Basalt foil fire protection for air duct

Installation is carried out in several stages:

- Surface preparation. Cleaning, leveling, drying, removing rust and unevenness.

- Application of adhesive. One layer is enough for fire resistance of 30-150 minutes, for longer a second layer is needed.

- The material is glued in strips. Material consumption per 1 m² is 1.1 m². When installing double protection, the layers are offset from each other and the consumption is 2.05 m².

- If glue is not used, the roll is unwound over the entire surface of the pipe and secured with metal staples.

For basalt rolls, the fire resistance limit is 180 minutes with a thickness of 70 mm. The greater the thickness, the higher the protection, and vice versa. Options with foil increase resistance to heat energy. Use together with paint or sprayers provides comprehensive and most reliable protection .

Fire retardant paint

During strong heating, when exposed to temperatures in the region of 100º, such paint foams, forming new layers of carbon fire protection and additional thermal insulation.

Popular brands:

- Thermal barrier. Paint consumption for minimum protection of 45 minutes is from 0.95 kg/m² depending on the thickness of the metal structure (the thicker the air duct, the less paint is required).

- Kedr-Met-V. Consumption averages 1 kg/m².

- Ecofire. Average consumption: 1.11 kg/m².

- CROZ. Average consumption: 1.37 kg/m².

Pros of fire retardant paint:

- ease of application;

- speed of repair after a fire;

- the structure is not heavier.

The first disadvantage is that the thickness and integrity of the coating must be constantly monitored, since the paint peels off over time, falls off, and runs off. Water-based paints may not have time to foam if the fire is carbon-type (if the temperature rises sharply in the first five minutes). In this case, the paint is ineffective, and the possibility of this type of fire should be considered in advance.

Water-based paint is applied by spraying or brushes. It provides protection for 120 minutes with a thickness of 0.8 mm. The more paint is applied, the higher the fire resistance time.

The more paint is applied to a surface, the more often it needs to be revised and checked for integrity.

The result of using fire retardant paint for wood (video)

Sprayed fire retardant material

A composition applied by spraying for fire protection of surfaces. It is created from mineral microfiber substances, an inorganic binder and additives with a very high fire resistance limit (2-3 hours).

Famous brands:

- POLINOR;

- Thermal spray;

- Corundum.

Pros:

- no need for preparatory work;

- good adhesion to the surface;

- spraying can be painted with an additional layer of protection;

- the most durable method (the layer can remain effective for up to 50 years).

Sprayed fire protection

Minuses:

- release of toxic substances;

- high price;

- spraying must be carried out with all precautions and in a protective suit.

Sprayed fire retardant material is a mixture that is granulated in a gunite hopper and applied to the surface under the influence of an air stream.

From the water nozzles, the mixture is wetted, allowing it to evenly coat metal, wood, concrete and any other structure. In one spraying stage, the thickness of the refractory layer is formed up to 20 mm. According to the correspondence table, 8 mm is sufficient for 30 minutes of ultimate fire resistance, and a layer of 25 mm thick is enough for 180 minutes.

Application of sprayed fire protection (video)

Coating with mixtures

In addition to cladding with slabs, we provide fire protection to structures using special plasters. We most often use Promat Fibergain plaster. It is a dry powder consisting of stone wool, Portland cement and special additives. According to regulatory documents, fire retardant treatment of air ducts with such a composition is considered acceptable.

Important!

Promat Fibergain is used to insulate ventilation systems. It can only be used in enclosed spaces where moisture does not penetrate. The operating temperature can be positive or negative.

It is applied by dry shotcrete using special equipment. Work is carried out at a temperature of at least +150C. The walls of the air duct should not have traces of condensation on the surface.

The applied coating resembles a thin “fur coat”; the presence of fiber in its composition makes it resistant to vibrations. To make it decorative, you can use fire-resistant paints of various colors.

Fibrogame plaster coating is an environmentally friendly product. This allows it to be used for fire protection of natural ventilation air ducts; standards allow this to be done in residential and public buildings.

Installation of thermal protection screens

One way to protect air ducts from fire is to install screens made from Promat Promatect brand slabs. These slabs are made of silicate material, the binder is cement. They do not perceive moisture, are quite rigid, and non-flammable. Available in thicknesses from 6 mm to 25 mm, plate size 2.5 x 1.25 m.

The surface of Promat Promatect slabs is treated in such a way that no traces of oils, gasoline and various salts remain on it. If necessary, they can be plastered and coated with fire-resistant paints, and finished with ceramic tiles.

These slabs are self-supporting and do not require an additional frame when lining air ducts. A box-shaped structure is made, the elements of which are attached to each other at the ends with screws or staples.

Table: Comparison of properties of popular fire protection for air ducts

| Material | Brand | Name | Peculiarities | Application temperature |

| Basalt wool | Rockwool | Wired Mat 50, 80 and 105 | Mats with wire, with/without lamination | from -180 to +650 °C |

| TECH MAT | Plates with and without lamination | from -180 to +570 °C | ||

| Glass wool | Ursa | Geo M-125 | Fiberglass mats | from -60 to +270 °C |

| Geo M-125 F | Laminated mats | from -60 to +270 °C | ||

| Stone wool | Xotpipe | TR Alu | Non-flammable fire protection of air ducts | from -180 to +500 °C |

| TR Combi | Mullite silica, basalt wool, wire | -200 to +1000 °C | ||

| Lamella Mat Outside | Rock wool, fiberglass, aluminum foil | -180 to +500 °C | ||

| FP Alu | Mineral wool lamellas fixed on aluminum foil reinforced with fiberglass mesh. | -200 to +750 °C |

We will simplify the choice of technical insulation as much as possible! Dial the number, free consultations and calculation of the amount of materials are waiting for you! Our managers have been helping you buy building materials in Moscow at a competitive price for more than 10 years. Find out from them about discounts and special offers now!

Have questions? Call the number

8

Head of Sales Department

Advantages of basalt fire retardant rolls

Basalt fire retardant rolls are widely used due to the list of advantages:

- High fire resistance up to 3 hours

- Low load on the main surface - this is achieved due to the minimum thickness of the roll

- Durability – retains its properties for at least 50 years

- Securely fixed to the surface of air ducts

- Simplicity and high speed of installation

- Resistance to moisture and vibrations

- Environmentally friendly material - does not emit toxic substances

- Aesthetic appearance

According to experts, basalt rolls for fire protection of air ducts and ventilation can be used in any region of the country with different climatic conditions - the temperature range of their operation starts from minus 60, humidity can reach 90%.

Quality control.

The quality of installation of complex fire protection is controlled as follows:

- the appearance is assessed visually: the coating must be continuous, without tears or damage;

- During the installation of the OGNESPAS VENT fire protection system, control of the thickness of the temperature-resistant composition can be carried out on the wet layer using a measuring comb of the “Constant GU” type, a wire probe with a diameter of 1.5-2.0 mm by puncture or other measuring instruments.

After installation of the system the following can be measured:

- total thickness of the coating (using electromagnetic devices such as Constant-5) with partial opening of the foil coating and subsequent sealing of the damaged areas with aluminum tape. The average thickness of the installed coating should be for: E1 30 - at least 4.4 mm; EІ 60 – not less than 4.6 mm; EІ 90 - not less than 8.0 mm; EI 120 - no less than 10.8 mm; E1 150 - no less than 40.6 mm; EІ 180 - not less than 50.7 mm;

— the thickness of the dry layer of the temperature-resistant composition by partially removing the MVBOR or TIB-1F material and its further restoration. To avoid thinning of the wet layer of the temperature-resistant composition due to excessive rolling of the pasted surfaces, you should use the techniques specified in general construction regulations (layer-by-layer application, application with an installation allowance, etc.); - the use of basalt roll material that has significant mechanical damage is not allowed;

— after gluing the basalt roll material, it is not allowed to sag or lag behind the surface of the air duct.

Review of manufacturers and brands of fire-resistant paints

Most brands of fire-resistant paint for metal structures are suitable for protecting air ducts. A certain range of intumescent compounds is produced specifically for smoke removal, ventilation, and air conditioning systems.

Fire-resistant paints for air ducts are produced by many large foreign companies:

- Leighs Paints (Firetex FX4002 and Firetex M90 formulations);

- NULLifire Ltd (brands FireSHIELD MW, Unitfire WB, Unitfire CH, NULLifire S 707-60);

- Promat (Tehstrong Fireshield-M paint);

- Brandschutz (Flammoplast paint);

- Rudolf Hensel GmbH (Hensotherm line of compounds).

The use of domestically produced fire-resistant paints and varnishes is expanding.

At a lower cost compared to imported materials, water-soluble paints have a high level of quality:

- VUP-2 (NPP Neohim LLC);

- VD-AK-511 (JSC NPK YARLI);

- Akvest-01V (LKM Akvest plant);

- Stabitherm-317 (NPF Laboratory of Fire Protection LLC);

- Kedr-met-V (NPO Khimtsentr).

Fire retardant compounds have good adhesion to almost all types of surfaces (unprimed, galvanized, anodized):

- VDM (ZAO NPP Spetsenergotekhnika);

- Texotherm (Fire Protection Technologies LLC);

- NEO VD-AK-503OV (LLC Lakokraska-Ya).

A number of manufacturers produce complex fire-retardant materials:

- NPO Stroyzashchita (KRAUZ-Vent paint with KRAUZ-P finishing coating for open contour);

- NPP Teplokhim (splend, neoflame paints, adhesive mastic for flange joints and seams Natrsil-S 541);

- JSC Eurostil (aqueous and organic compositions Defender-A, Defender-M(S), Defender-ME, Defender-ME plaster and primers Defender EP, Defender FA, Defender FL).

The products of Khimprom-M LLC (universal paint SGK-1 for rooms with 100% humidity, high content of oxygen, salt vapors, acids, alkalis) successfully compete with the best brands of imported paints, and often surpass them in technical capabilities.

Elox-Prom Holding produces silicone materials with excellent adhesion to black and galvanized steel and very high heat and frost resistance (up to -60°C), moisture and corrosion resistance: fire retardant compounds Silotherm EP-6V, Sintosil S-61, sealants Silotherm EP- 71 and Silotherm EP-120.

The cost of water-dispersion fire-resistant paint and varnish compositions is 160-270 rubles/kg. Paints based on organic solvents are more expensive, 280-510 rubles/kg.

Requirements for smoke exhaust ducts

According to construction and fire safety regulations, facilities where there are large crowds of people are equipped with shafts and channels for smoke removal.

These include:

- large manufacturing enterprises,

- administrative and office buildings,

- educational institutions,

- shopping and entertainment centers, concert halls, cinemas, theaters,

- medical institutions - clinics, hospitals, dispensaries and sanatoriums,

- hotels and hotels.

The connection of air duct sections is regulated by the requirements of SNiP No. 2-04-05 and 3-05-01 of 1985 and 1991, and can be either welded or seam. Smoke removal ducts are made of galvanized or black low-carbon steel.

We recommend that you read: How to choose ventilation grilles for external ventilation

GOST No. 19.904 of 1990 establishes the wall thickness of air ducts:

- from cold-rolled steel - from 0.9 to 1.4 mm,

- from hot-rolled - 1.5-2mm.

Elements of smoke exhaust ducts are marked depending on the fire hazard class:

- “N” - for premises with low fire hazard, belonging to categories “B” and “G”. For class “H” air ducts, lower requirements for the tightness of connections are applied: minor leakage of gases during their removal is allowed.

- “P” - intended for buildings with a high fire hazard class - “A” and “B”. The connection of type “P” air ducts is distinguished by a high degree of tightness, since they are used in industries with a high explosion hazard. The air in such premises contains a high concentration of flammable dust or combustible gases. Therefore, hot smoke leaking from the duct can cause the fire to spread even further.

Supervision over the compliance of the operational and technical characteristics of air ducts with SNiP and GOST standards is the responsibility of operating organizations and fire inspectors.

Correct solution

In order for the installation of fire protection for air ducts to be carried out efficiently and reliably, and to comply with all established standards and requirements, the work should be entrusted to specialized companies. As a rule, employees in such organizations are well trained and equipped with all the necessary tools and equipment. During the work process, technologists carry out strict quality control, and upon completion of installation, the customer is provided with a work completion certificate for approval, which indicates all the main parameters of compliance with the requirements of the governing documents.