The ventilation device for a private house, basement or garage is rarely complete without air ducts. In an apartment, even then you need to connect the kitchen hood to a vertical shaft located inside the wall. The range of air channels sold is quite wide and the user traditionally faces the problem of choosing the right product. The purpose of our review is to review existing ventilation pipes, outline the scope of application and identify the shortcomings of various types of air ducts.

Advantages and disadvantages

The popularity and high consumer demand for galvanized air ducts are due to a number of undeniable advantages of these pipes.

- High anti-corrosion resistance. Thanks to the zinc coating, air duct pipes do not require additional protection from moisture and can be used in rooms with high steam generation, for example, in swimming pools, bathhouses and catering kitchens. In addition, if the zinc layer is damaged, for example, by tightening a self-tapping screw, the material does not lose its anti-corrosion properties. This phenomenon is explained by the formation of a galvanic couple with the participation of steel and zinc, and the occurrence of certain chemical reactions, as a result of which the cut is covered with a thin oxide film.

- Comfortable cost allows you not to save on material and arrange ventilation ducts in accordance with strict GOST standards.

- As a result of the low weight of the air ducts, the load on the load-bearing walls of the structure and fastening elements is significantly reduced.

- The durability of galvanized elements distinguishes them from air ducts made of other materials. In addition, the products are easy to install and do not require special maintenance.

Round tracks

Round pipes are manufactured with different diameters and wall thicknesses. Such air ducts are designed for higher pressure than rectangular ones, and their use reduces operating noise. Round channels are more practical and are used more often. The sections are connected using the nipple method using a coupling.

The edges are secured with rivets and self-tapping screws using an internal or external connecting piece. The flange connections in the structure are hermetically sealed and reduce air loss during transportation. This connection is made using a special spring device or screws. The use of springs speeds up installation and increases the degree of tightness. If factory parts have fastening flanges at the ends, then the connection is made without additional fixation.

Sometimes round pipes are connected using a bandage. This device is placed on the flanged edges of the air duct. A simple method provides high tightness, but increases the cost of work. The connection using the method of different diameters is used - when the outer diameter of one piece is equal to the inner diameter of the other section. The ends are inserted into one another and screwed with self-tapping screws. Advantages of round air ducts:

- lower resistance to air flow;

- shape without corners saves up to 15% of material;

- cleaning of the internal surface is not required;

- There is no turbulence zone inside the outlets when transporting flows.

Spiral wound method

For production, a solid galvanized strip is used, which is formed into a spiral of the required diameter. Connecting the side joints results in a pipe with a continuous surface. The advantages of such a product are increased strength, since the joints give rigidity to the channel. The length of the produced sections increases.

Air ducts are produced on automated lines, which help increase productivity. Galvanized steel spiral ducts require constant cleaning. The inner surface is corrugated, so dust is deposited on it.

Straight seam method

Channels are produced by rolling a whole sheet into a pipe of the required dimensions. The seam is secured with a flange connection and riveted. An air duct made from such pipes has lower aerodynamic resistance. The price list of the elements is less than that of spiral-wound sections, which significantly reduces the price of long-distance ventilation.

Connecting sections to each other requires a large number of standardized inserts if straight-seam channels are used in small rooms and are limited in length. Ventilation is installed in the form of small systems; these types of pipes are not used in critical industries.

The concept of ventilation ducts

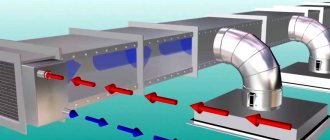

Air ducts are a structural system of pipes of different diameters and cross-sections, which are connected using shaped components. During production, the weight of galvanized steel in the duct is taken into account. The calculator for calculating the circular cross-sectional area takes into account the diameter of the pipe, and in a rectangular product, the important criteria are length and width. The value is multiplied by the length and the volume of air passed through is calculated.

Diversion channels are selected taking into account design features, design requirements, sanitary and construction standards. Small air ducts are made of galvanized steel 0.5-0.6 mm, and large-section bends are made of sheets 0.7-1.0 mm thick. The following types of ventilation are distinguished depending on the internal pressure indicator:

- Class H - normal pressure. Used in ventilation and smoke removal systems. The requirements for tightness are minimal; a certain percentage of losses during transportation of air masses is provided.

- Class P - dense type. It is installed at atmospheric pressure in the channels above 0.6 kPa. The connecting seams are sealed and a locking connection is made.

The weight of a linear meter of a 0.5 mm galvanized round pipe with a diameter of 100 mm is 1.4 kg. Diameters over 400 mm are made from 0.7 mm sheet, a linear meter weighs 7 kg. A powerful flow requires a pipe size of 110 or 120 mm, a meter of pipe weighs 28 or 31.5 kg.

Purpose of products

Industrial production requires the movement of gas, aerosol mixtures or air flows. For these purposes, ventilation ducts are manufactured in accordance with building codes and meet the required standards. Unified connecting inserts, turns and branches are used, manufactured in the factory with an existing quality certificate. Ventilation ducts are used:

- when installing ventilation;

- to remove smoke at the appropriate temperature;

- in case of movement of gas flows to the production site.

Advantages of galvanizing

Connecting elements are made of galvanized steel. In this case, the use of black steel with a thickness of 0.4-1.2 mm is allowed. The production of galvanized steel air ducts provides a large number of standard sizes. The air duct network is constructed from standardized components and branch units. Galvanized steel is used because it has many advantages:

We recommend that you read: Forced ventilation

- Attachments can be used for up to 20 years while maintaining quality and without changing their appearance. Pipelines resist corrosion.

- During installation, painting costs are saved; products are installed without the use of a protective primer layer. External air ducts withstand exposure to the sun and precipitation. The products do not require painting due to the attractiveness of the metal.

- During production, the sheets are bent and stamped without damaging the external galvanized coating. The layer remains inseparable, chips and cracks are not observed.

- The material is considered environmentally friendly and has no harmful effects on health.

- The cost of galvanized air collectors is lower than the same products made of stainless steel and other materials.

- Air ducts are durable and have low aerodynamic drag.

- Installation is simple. After installation and during operation, the pipeline does not require complex maintenance. The internal smooth surface does not contribute to contamination of the walls.

- In case of fire, the material does not burn and has a high fire resistance. Channels are installed in buildings of varying degrees of fire hazard.

- The lightness of the material facilitates transportation and reduces transportation costs.

- Air pipelines are made of rectangular and circular cross-section. Each of these types has advantages and disadvantages. During installation, various connections of pipe sections to each other are provided.

Manufacturing Features

Galvanized steel sheets with a thickness of 0.5 to 1.25 mm are used as raw materials for the manufacture of pipes. Such thickness indicators are due to the need to maintain an optimal balance between the rigidity of the model and its weight. The production of air ducts is carried out using two methods: spiral-wound and straight-seam.

The essence of the first method is as follows: a special machine winds strips 137 mm wide into a pipe of a certain cross-section. In this case, adjacent turns are overlapped, which results in a tight fit of the previous turn and a slight deformation of the metal in the form of a girth. The winding method ensures high rigidity of the finished product. This is due to the fact that the role of a stiffener is played by a screw seam.

The thickness of the sheet metal depends on the cross-sectional size of the product and is 0.55 mm for pipes with a diameter of 150-355 mm, 0.7 mm for products with a diameter of 400-800 mm, and 1-1.25 mm for large air ducts with a diameter of up to 1250 mm. The length of the modules varies from three to six meters and can be reduced or increased at the request of the customer. The spiral-winding method is characterized by high productivity, which allows about 60 meters of sheet material to be wound in a minute. The pipes are connected to each other using the nipple method.

Distinctive features of galvanized steel duct

Pipes made of galvanized steel for ventilation systems are manufactured, among other things, with sections of both round and rectangular shapes. The thickness of the galvanized sheet from which the pipeline frame is created varies between 0.51.25 mm. Products made of galvanized sheets, which have rectangular sections, are joined together using a connecting unit in the form of a flange, and with existing round sections using a connection such as a nipple.

An air duct made of the specified material has the following properties:

:

1. Low price;

2. Low specific gravity, which ensures lightness of the structure;

3. Long service life;

4. The process of installing and maintaining the structure in proper condition is simple and easy.

Special elements are made for such galvanized pipes, serving as connecting units, and the joining areas are also buried. Such shaped parts are also made from galvanized steel.

Rectangular ducts

Pipes that are made in the form of a rectangular or square section of various cross-sectional areas are called rectangular ducts. They are connected by a flange press fit onto the busbar using a sealed gasket. Along the perimeter of the channel, ridges are made at a distance of 250-350 mm from each other or diagonal bends are made to create rigidity of the air path. Zig is a ring-shaped connecting scar that is made on rolling seam units.

A rectangular air duct made of galvanized steel is mounted using clamps and traverses. Fastening elements are made of striped metal, loaded cross-arms are made of angle iron. With a flange connection, the sides are riveted to avoid long-term subsidence.

Advantages of galvanized steel air duct

Since such products are made from ordinary galvanized steel sheet, the cost of all structural parts is low compared to other types of materials. But the democratic pricing policy does not in any way call into question the reliability and durability of such products. In addition, galvanized steel pipes are easy to assemble and easy to install.

Features of the production of rectangular air ducts

The use of galvanized steel as a material for the manufacture of air ducts is explained by the fact that it ensures the tightness, strength and durability of the finished products. The wall thickness of the ventilation ducts in such a system may vary. The most optimal values depend on the specific object.

Another popular raw material for air ducts is aluminum. Its distinctive features:

- non-flammability;

- corrosion resistance;

- low susceptibility to harmful effects of chemical and physical nature.

If it is impossible to use rectangular air ducts made of galvanized steel due to the specific configuration of the facility structure, you can use a ventilation system based on a flexible material - for example, polyvinyl chloride plastic. Such air ducts are easy to install, but they require preventive maintenance much more often.

However, rectangular air ducts made of galvanized steel remain the most common type of ventilation systems. made of galvanized steel remains the most common type of ventilation system. The pipes used as its components have a standard length of 125 cm, but if necessary, longer products can be produced. To increase the rigidity of the finished structure, flanges are mounted on them, and the stability of the frame is ensured by creating kinks on each side of a separate pipe.

By default, these products have a tightness class of “H”, which allows for small air losses during operation. If necessary, you can order a class “P” air duct treated with sealant at the junction points of the air duct and flanges.

You can buy rectangular air ducts at a low price from PC Ventas. Contact our company staff by phone or email.

| Name/Description | Straight section length Rectangular Duct | Shaped standard products Standard Fittings | Nonstandard items Nonstandar d Items | ||||

| L = 1250 mm | L>1250 mm | L < 1250 mm | |||||

| t, mm | Flange | A x B, mm | rub. / m2. | rub. / m2. | rub. / m2. | rub. / m2. | rub. / m2. |

| 0,55 | Tire №20 | up to 500 x 500 | 489,43 | 555,76 | 827,11 | 824,53 | 1494,80 |

| 0,70 | Tire №20 | up to 1000x 1000 | 533,65 | 614,05 | 896,46 | 894,51 | 1689,90 |

| 0,70 | Tire №30 | up to 1000x 1000 | 567,82 | 637,16 | 917,56 | 915,60 | 1736,08 |

| 0,90 | Tire №30 | up to 1500 x 1500 | 662,29 | 751,74 | 992,94 | 990,39 | 1942,49 |

| 1,00 | Tire №30 | >1500 x 1500 | 747,72 | 795,96 | 1082,38 | 1079,55 | 2194,14 |

[email protected] You may also be interested in

- Steel bends 90 degrees

- Round air ducts made of galvanized steel

- Stainless air ducts

- Welded black steel

- Insulated air ducts

- Ventilation system details

Under what conditions is it necessary to use different types of air ducts?

Operation of galvanized piping structure for ventilation

According to the state quality standard, in conditions where air temperatures reach no more than 80 degrees, while the humidity does not exceed 60%, galvanized steel products for ventilation are used, which are created by cold rolling and have a wall thickness of not more than 1 mm.

We recommend: Exhaust pipes

But, some parts of the ventilation system can be made from steel that has been hot-rolled. The thickness of its walls, excluding the coating layer, is no more than 0.9 mm. The steel can subsequently be primed or painted.

Operation of an air duct made of stainless steel sheet

According to state quality standards, it is stipulated that to move an air mass whose temperature reaches no more than 500 degrees or to move gases that contain chemicals and unfavorable substances, pipelines must be used that have a high level of resistance to corrosive formations and a high degree of strength and resistance to high temperatures.

Characteristics

A ventilation duct is a pipeline system that serves to remove polluted air from a room and transport clean air in the opposite direction. In this case, the movement of air masses through the pipes can be carried out either using natural draft or forced. The scope of application of galvanized air ducts is quite wide. They are used to install supply-type ventilation units, as well as rooftop and central air conditioning systems. In addition, with certain modernization of the pipeline system, the supplied air can be additionally purified using a filter system or heated. Galvanized air ducts can be seen in residential buildings, private cottages, office premises, catering establishments, shopping centers and production workshops of large industrial enterprises.

Air ducts and ventilation ducts are made from metal of varying thickness and quality. Thus, for the installation of ventilation systems for apartments and private houses, models made of cold-rolled sheet material with a thickness of 0.5 to 1 mm are used. The upper temperature limit for such products is 80 degrees, while the humidity level is limited to 60%. These indicators, which meet the requirements of GOST 14918 80, are quite sufficient for the operation of domestic ventilation. When installing ventilation at large industrial enterprises or in public catering organizations, they use models that can withstand temperature increases of up to 500 degrees and are resistant to aggressive environments. For the manufacture of such air ducts, corrosion-resistant heat-resistant steel is used that meets GOST 5632 72.

Installation technology

Installation of all parts of the ventilation system must be carried out strictly in accordance with the norms and requirements of SNiP.

If air ducts made of galvanized steel will be installed during the construction of the building, then all components should be laid in special grooves.

In other cases, the method of installing ventilation ducts is chosen by the owner, but in any case, fire safety rules must be observed.

For example, you cannot lay the air duct close (at a distance of less than one meter) to the gas pipe.

If the air duct runs along the outer wall of the building, it must be insulated.

Otherwise, at low ambient temperatures, water will condense on the walls, which can cause corrosion of the material, especially in areas with damaged coating.

You should also pay special attention to the attachment of channels to supporting structures, especially when it comes to those systems where additional equipment is installed to ensure air flow. Air ducts in such cases must be attached using reinforced clamps, with a greater number of fixation steps than usual

It would be optimal to install clamps every three meters

Air ducts in such cases must be attached using reinforced clamps, with a greater number of fixation steps than usual. It would be optimal to install clamps every three meters.

Square and rectangular galvanized ducts for ventilation are connected using the flange method with the mandatory use of sealing gaskets. It is also common to use studs and profiles, and fastening with self-tapping screws.

To give additional rigidity, the structures are reinforced with profiles, and if the cross-sectional side of the box is more than 400 millimeters, then special hangers can be used, securing them every 30 centimeters.

Round air ducts are fastened with clamps and studs. If during installation there is a need to provide additional strength to the structure, the clamp can be further strengthened using perforated galvanized metal tape.

The installation process of a round galvanized steel box

It is worth understanding that if the system is subjected to excessive load due to the high speed of passage of air masses, then even a strong metal tape will not be able to firmly hold the air duct.

Over time, it will begin to rattle quite a lot; to avoid this effect, you should use more reliable reinforcement.

Ventilation systems with large weight and dimensions are secured using special profiles (Z-shaped or L-shaped); in addition, rubber gaskets should be used.

They will help the ventilation pipes by taking on part of the load resulting from the passage of air flows at high speed. Without such gaskets, air ducts begin to deform over time.

Long and massive ventilation ducts made of galvanized steel must be installed using drive-in anchors.

Particular attention should be paid to the joints of individual modules so that the connections are as tight as possible. Pipes can be connected in different ways:

- using nipples or couplings. The nipple will be a separate short section of pipe, narrower than the air duct. The nipple is simply inserted into it with force and rotated, securely fixed. The coupling is mounted according to the same principle, but its diameter must be larger than that of the air duct;

- flange method. The two flanges at the ends of the pipes are connected using bolts;

- fold method. The two ends of the pipes are joined, their walls are applied to one another and bent, ensuring a reliable seal.

In general, the entire process of installing galvanized steel boxes is carried out according to the following algorithm:

- Assembling parts into single modules.

- Sealing joints.

- Installation of fasteners on load-bearing structures.

- Next, the assembled modules are raised to the required height and fixed with clamps, galvanized perforated tapes, etc.

- Using various shaped elements, all modules are gradually connected into one common ventilation network.

- Thermal insulation is installed.

- If desired or necessary, the pipes are covered with decorative elements.

Shaped elements

Standard unified connectors are used to install an air duct of the required configuration. Sometimes circular sections are connected to rectangular ones, which requires branching into two or more routes.

Increased demands are placed on the docking sections, since they are located in areas of increased turbulence (at turns or diametrical transitions) and carry an increased load. Any change in the geometry of the air duct is carried out using shaped elements. Standard types used:

- round and rectangular bends for turning the direction of the route, available at 15, 30, 45, 60 and 90°;

- transitions from one pipe diameter to another;

- tees provide branching of lines and connection of two air ducts into one line;

- a round nipple is used to connect pipeline sections (inserted inside);

- the coupling connects sections of a round pipe and is placed over the joint;

- a rectangular insert is used to join two lines at an angle;

- the cross connects rectangular and round air ducts at an angle of 90°;

- a duck (S-shaped element) is used to connect lines that do not coincide in plane or axis; there are options for combining pipes of different diameters;

- The plug is placed at the end of the channel and closes it hermetically.

Advantages and disadvantages

In general, pipes made of galvanized steel have the following advantages:

- the material allows the use of boxes for transporting hot air;

- they are quite easy to install - you can choose the appropriate mount for any design;

- long service life, which is ensured by applying zinc to the surface at high temperatures;

- good resistance to acid fumes and aldehyde resins;

- the system configuration can be anything;

- the ability to install additional elements, for example, dampers, additional ventilation ducts, etc.;

- wide scope of operation.

- ease of installation and use;

- mechanical stability and strength. The structure is rigid regardless of the type of section;

- products are practically immune to fire, as well as the effects of aggressive chemicals and mechanical pollutants;

- aesthetic appearance;

- the assembled system is very compact and does not take up much space;

- high level of tightness of connections.

Galvanized ventilation boxes, of course, are not without some disadvantages:

- the cost of these structures is higher than those made from other materials;

- if there are obstacles (for example, protrusions) in the path of the air duct, it will be impossible to make a smooth transition;

- small maximum material thickness.

Varieties

Based on their shape, ventilation ducts are divided into round and rectangular models. The former are produced in a wide variety of diameters and are connected using the nipple method, using self-tapping screws and special rivets. This type of connection significantly reduces pressure losses inside the pipeline and prevents possible leaks of air masses. In addition, the stronger and more airtight the connection, the less noise the ventilation system will produce during its operation. The products belong to the H-class of tightness and are distinguished by high aerodynamic properties.

Models with rectangular and square cross-sections are also available in a wide variety of sizes and correspond to tightness classes H and P. Products of class P are distinguished by additional processing of the flange and reinforcement of longitudinal connections using sealants. Class H does not meet such high requirements as the previous one, and allows for slight air leaks from the side. The connection of rectangular and square modules to each other is carried out using the flange method on a busbar using sealing gaskets. To increase the rigidity of the pipeline, models with a cross-sectional side exceeding 400 mm are equipped with special ridges installed at a distance of 300 mm from each other, or strengthened using diagonal bends.

The choice of pipe shape for arranging air ducts depends on the length of the ventilation systems and the nature of contamination of the air masses passing through the pipes. So, for arranging long systems, it is better to use galvanized pipes with a square or rectangular cross-section. However, if the air is heavily polluted with fine particulate matter, it will be more practical to use round pipes. Therefore, the choice of cross-sectional shape when constructing long air ducts must be made taking into account all the nuances. When building small systems, the choice of shapes can be dictated by the amount of solid impurities in the air masses and the personal preferences of the owners.

Types of air ducts

All ventilation pipes intended for organizing air exchange in rooms or local exhaust differ in two characteristics - material of manufacture and cross-sectional shape. Point two: when installing ventilation, homeowners often use pipes from other utilities.

We present a complete list of types of air ducts used:

- round and rectangular, made of galvanized steel;

- the same, made of PVC plastic;

- flexible products of two types - aluminum corrugated pipe and insulated round channel on a metal frame;

- fabric air ducts;

- steel – black and stainless;

- double-walled sandwich-type chimneys made entirely of galvanized steel;

- plastic sewer sections;

- asbestos-cement pipelines.

Note. To be fair, it is worth mentioning the brick and concrete vertical shafts installed in the thickness of the walls of apartment buildings and country houses. Internal ducts are laid during the construction phase of the building and serve for exhaust ventilation.

Examples of a device for extracting from sections and fittings of polypropylene sewerage.

On the left in the photo there is a condensate collector (under the tee). Of the listed ventilation ducts, only the first four varieties are intended for transporting air. The remaining products are chimney, water and sewer pipes used by home owners to reduce the cost of installation.

Galvanized ventilation ducts

Thin-walled metal pipes for ventilation, made of galvanization, meet all regulatory requirements and are clearly recommended for use in any premises - residential, industrial, warehouse, and so on. We list the types and main characteristics of galvanized air ducts:

- According to their shape, the channels are divided into 3 types - round, rectangular and flat-oval.

- According to the manufacturing method, a distinction is made between spiral-wound, straight-seam and seam boxes, shown in the photo below.

- According to the standards, there are 2 classes of air duct tightness - normal and tight. The latter include spirally wound pipes, which practically do not allow leaks at the connections.

- Products are manufactured to standard sizes. For example, the diameters of the most commonly used round air ducts are 100, 125, 160, 180, 200, 225, 250 mm and so on. The thickness of the metal is 0.5-0.6 mm, with a diameter of more than half a meter - 0.7 mm.

- Standard dimensions for square and flat oval pipelines are specified by a maximum aspect ratio of 6.3.

Air lines made using spiral-wound technology, tightness class - tight

Explanation regarding the proportions of the sides of flat air ducts. According to SNiP, the size of one side of a rectangular pipe cannot exceed the size of the second side by more than 6.3 times. Example: the smaller size of the box is 0.03 m, then the maximum size of the second side is 0.03 x 6.3 ≈ 0.19 m = 190 mm.

Let's consider the advantages of using galvanized ventilation ducts:

- compliance with all sanitary and construction standards;

- rigidity, strength and durability;

- nonflammability, resistance to mild chemical influences;

- scope of application – any general ventilation systems (excluding aspiration – dust transportation);

- relatively simple installation;

- a wide selection of shaped elements - tees, elbows, crosses, transitions;

- Thanks to standardization of sizes, galvanized boxes are compatible with all fans and air distributors - dampers, valves, deflectors.

Ordinary tin boxes, tightness class - normal

Reference. The ventilation duct, made of galvanized steel, can withstand exposure to the flames of a strong fire for 30 minutes. Special external treatment increases the specified fire resistance limit to 2 hours. The rigid design will prevent the air duct from collapsing due to heat.

The main disadvantage of galvanized boxes is their high price compared to products made from other materials. The issue is quite controversial - a lot depends on the region, the volume of the order and the specific manufacturer. As of March 15, 2018, the cost of 1 linear meter of inexpensive air duct Ø100 mm is:

- spiral – 320 rub. (5.6 USD);

- straight-seam – 180 rub. (3.15 USD);

- rectangular shape of the corresponding section 10 x 8 cm - 200 rubles (3.5 cu).

Connectors and adapters for tin boxes

Note. We have additionally indicated prices in conventional units, since the cost in rubles may change over time.

Other disadvantages of galvanized ventilation pipes also deserve attention:

- In production, air ducts look very aesthetically pleasing, but galvanization is difficult to fit into the interior of a private house or apartment. The channels need to be hidden behind the cladding - suspended ceilings, plasterboard sheathing.

- Due to the roughness of the metal and zinc coating, the resistance to air flow is quite significant. The nuance becomes noticeable in extended areas and branched systems, where more powerful fans are needed (selected according to aerodynamic calculations).

- The weight of the product is inferior to plastic pipes.

Educational video about the production of shaped parts and spiral air ducts:

Plastic ventilation

Plastic pipes intended for ventilation are also available in rectangular and round sections. But the standard sizes differ from the normal presented above - round ventilation ducts are offered with a diameter of 100, 125, 150, 200 mm and so on. The base material is polyvinyl chloride (PVC), polypropylene (PP) and polyethylene (PE).

Clarification. There are industrial and household series of plastic air ducts. The diameters of the former correspond to the standard range, but not all standard sizes are available to the buyer. For example, Ø14, 16 and 18 cm will have to be ordered separately. We indicated the four most popular diameters of household products in the previous paragraph.

Advantages of plastic ventilation pipes:

- pleasant appearance;

- ease and speed of installation;

- light weight;

- long service life;

- zero internal surface roughness and low air flow resistance;

- wide range of fittings and connectors;

- resistance to various chemicals.

As it turned out, the price of products cannot be attributed to the strong point of plastic air ducts. The cost depends on the type of plastic used and the type of connection - socket, flange or coupling (nipple). We were able to find relatively cheap PVC pipes for ventilation on the Internet - prices for 1 meter of channel Ø100 mm look like this:

- round – 180 rub. (3.15 USD);

- flat equivalent section 110 x 55 mm – 188 rub. (3.3 c.u.);

- rectangular size 12 x 6 cm – 220 rub. (3.85 USD).

PPR air ducts with flange connections are intended for industrial buildings

Reference. Prices for polypropylene boxes with a wall thickness of up to 3 mm, equipped with a flange or socket, reach 1,100 rubles. / 1 m. p.

Now let's take on the disadvantages of plastic pipelines for ventilation:

- Due to the discrepancy between the channel diameters and the standard range of sizes, a special fan must be selected for the air ducts or adapters must be used.

- Despite its rigidity, plastic remains a fragile material. In addition, elasticity is lost over the years - after 5-7 years of operation, the pipe may crack from an accidental light impact.

- Plastic is flammable and “floats” when heated above 200 °C.

- Light-colored boxes quickly turn yellow in certain conditions, for example, in the kitchen or bathroom. To restore a presentable appearance, the ventilation ducts must be cleaned.

- Polymer pipes expand greatly when heated.

Examples of joining polymer ventilation ducts with equipment

The scope of application of plastic ventilation elements is kitchen and bathroom exhaust ducts, natural air exchange systems for residential buildings, chemical laboratories, but only within one room.

Important point. A plastic box laid in transit through several rooms will quickly burn out in a fire, and the fire will spread to adjacent rooms through opened openings. A suspended ceiling made of gypsum plasterboard is weak protection; the plastic will “flow” from high temperatures.

Corrugated sleeves

For ventilation installations, manufacturers offer three types of flexible air ducts:

- An aluminum single-wall corrugated pipe is made on a frame made of metal wire twisted in a spiral. The top “skeleton” of round cross-section is covered with aluminum foil with a sealing polyester gasket. A number of standard sizes are quite rich: 100, 110, 113, 115, 120, 125, 130 mm, etc.

- Corrugated aluminum sleeve insulated with mineral wool made from fiberglass. The design of the pipe is similar - a spiral frame made of wire plus foil and insulation, the outer protective layer is fiberglass. Suggested diameters are 100, 125, 150, 160, 200, 250 mm and so on.

- Industrial flexible corrugations on a wire frame covered with polyester fabric, polyurethane, fiberglass or polyvinyl chloride (PVC). The choice of diameters and sections is very wide; there is no point in listing all sizes.

Corrugated aluminum foil in packed (left) and stretched form (right)

Note. Single-layer aluminum corrugation is sold in a compressed state; the product is 620 cm long and stretches 3 meters. You can buy round and rectangular air ducts.

We present the approximate cost of the listed products per 1 linear meter of flexible hose Ø100 mm:

- single-layer corrugated pipe of the “Aluvent” type – 50 rubles. (0.9 cu);

- insulated flexible air ducts Sonodec DS – RUB 310. (5.5 USD);

- ventilation ducts made of polyester fabric – 408 rubles. (7.15 USD);

- the same, from PVC - 335 rubles. (5.9 USD);

- polyurethane sleeve – 233 rub. (4.1 cu).

Corrugated pipe with ready-made thermal insulation

Although flexible ventilation pipes are made from different materials, the set of advantages and disadvantages of this group of products is approximately the same. Positive points:

- light weight;

- simplicity and high speed of installation;

- quick connection to ventilation equipment using clamps;

- the corrugation can be easily removed for antibacterial cleaning;

- widest selection of standard diameters;

- lack of shaped parts and fittings;

- plastic hoses are resistant to abrasion by abrasive particles and chemical attack.

Now about the negative sides of corrugated pipes. All flexible air ducts for ventilation have a common drawback - low fire resistance. Only aluminum hoses can withstand prolonged heating up to 300 °C; the temperature limit for other polymer products is +125 °C for polyurethane and +90 degrees for PVC.

Important point. It must be understood that each type of flexible air duct is designed for use in a specific area. For example, polyurethane channels are designed for transporting highly contaminated gases and dust (aspiration).

The second significant drawback of corrugated hoses is their high aerodynamic resistance, which forces them to increase the fan power. Therefore, the length of a flexible ventilation duct rarely exceeds 10 m. And lastly: aluminum corrugations often decrease in diameter (collapse) when connected to the suction side of a powerful fan.

Sewage and other pipes

One way to save on ventilation installation is to use asbestos-cement air ducts, as shown in the photo of the cellar ventilation. The positive aspects of this option:

- low price – 100 rub. per linear meter of pipeline Ø10 cm (1.75 USD);

- rigidity and strength of the structure;

- durability;

- the material can be painted;

- resistance to high temperatures - products can withstand over 1000 °C.

It is convenient to install asbestos pipes for natural air exchange in the basement - nothing is required to be connected

Reference. Asbestos (chrysotile cement) pipes are produced with a round cross-section in standard sizes of 5 cm - 100, 150, 200 mm, etc.

Asbestos-cement pipelines are successfully used as chimneys, cable ducts, supports for columnar foundations and other purposes. When using them in the ventilation system, you will encounter the following negative nuances:

- Asbestos dust is harmful to health. Sanitary standards directly prohibit the use of chrysotile cement pipes as supply air ducts.

- The design is not only rigid, but also heavy, hence the difficulty of installation. Plus, there will be difficulties with the connection - elbows and tees do not exist in nature. Special couplings or adapters are needed.

- The appearance of such a ventilation duct, even if painted, is not consistent with the living quarters.

The second popular method of installing budget ventilation is laying air ducts from gray polypropylene pipes intended for internal sewage. The price gain is noticeable - a meter of “weaving” pipeline will cost 140 rubles (2.45 USD), including 1 o-ring on the socket.

The advantages of sewer sections are identical to the advantages of plastic channels, but there are more disadvantages:

- the diameters of the pipes do not match the standard sizes of the ventilation air ducts: 4, 5 and 11 cm;

- shaped elements are made with a large turning radius;

- sections and fittings are large in size due to the sockets;

- Due to the accumulation of static charge in plastic, a lot of dust settles on the inner walls of air lines.

Note. High-quality plastic boxes designed for ventilation have a protective antistatic coating.

Lining of a brick exhaust shaft with a stainless insert

Iron and stainless steel pipelines are a dubious option for organizing air exchange in a private house. Price, heavy weight, the problem of a tight connection - this is a short list of the disadvantages of metal air ducts that are appropriate in industrial buildings. The only method of application is lining brick exhaust shafts to protect against condensation.

An insulated chimney sandwich is appropriate for external installation of ventilation ducts or installation through cold rooms (attic). But you should take into account the considerable price of the material - 1100 rubles. per section Ø100 mm 1 m long. For an example of using a sandwich for exhaust from a gas boiler room, see the video:

Types of galvanized air ducts

Galvanized steel air ducts on a construction site

Galvanized air ducts differ in cross-sectional shape. It can be round or rectangular. Round structures have many options for diameter and wall thickness.

To fasten such an air duct, self-tapping screws and rivets are used (nipple method). Such fastenings can significantly reduce pressure losses in the system and avoid any leakage of air masses to the outside.

In addition, the density and tightness of the structures makes it possible to reduce the noise level during ventilation operation. Such air ducts are usually classified as H-class (“normal”) in terms of tightness and aerodynamic properties.

Square and rectangular galvanized steel ventilation ducts may differ in characteristics.

Among them there are those belonging not only to class “H”, but also to “P” (high density). P-class is characterized by increased tightness of connections and resistance to high pressure.

Advantages of these systems:

- convenience and ease of installation. As you know, in addition to air ducts of various lengths, various shaped elements are also sold (corners, tees and crosses, etc.), which not only simplifies and speeds up installation, but also makes it possible to give the ventilation system an aesthetically pleasing appearance;

- compactness. Systems built on the basis of galvanized air ducts are compact. There is always the opportunity to make a choice in favor of rectangular or circular elements, which allows you to optimally use the available space;

- strength. The metal itself is quite strong, and placing the seams in a spiral, or even a straight line, provides an additional stiffening rib;

- almost complete tightness of the seams, which is achieved either through special ties or through flange elements having a special shape;

- general structural rigidity provided by the physical properties of steel.

Installation details

The arrangement of ventilation ducts must be carried out in strict accordance with the requirements of SNiP. If an air duct is laid during the construction of a building, its elements can be laid in special grooves; in other cases, the channel is formed independently, taking into account fire safety rules. Thus, placing the ventilation duct at a distance of less than one meter from the gas pipeline is strictly prohibited. In addition, installing pipes outside the building requires their mandatory insulation. Otherwise, condensation will form in the system, which over time will lead to the appearance of rust in damaged areas.

An equally important installation point is the fastening of the air duct to the supporting structures. This is especially true for ventilation systems equipped with a forced air outflow function. It is recommended to secure such a structure with reinforced clamps, with a more frequent fixation step than in systems with natural circulation. The optimal frequency of fastening ventilation pipes is considered to be an interval of three meters. This distance between the fasteners will prevent the duct from sagging, and will also ensure the overall stability and rigidity of the structure.

The method of fixing the air duct depends on the cross-sectional shape of the pipes and the thickness of the steel sheet. Thus, pipes with a rectangular and square cross-section are secured using studs and profiles connected to each other using self-tapping screws. Round models are fixed using studs and clamps, and to ensure greater strength, perforated galvanized tape is added to the clamp. Large, heavy ventilation systems are secured using Z-shaped or L-shaped profiles using rubber gaskets. Seals act as compensators and prevent pipes from deforming under the influence of powerful air currents. Installation of long and heavy air ducts is carried out using drive-in anchors.

In general, the process of installing ventilation systems does not require special skills and can be done independently. For this purpose, the links are assembled into modules and carefully sealed. Next, fasteners are installed on the supporting structures, after which the blocks are lifted and fixed using clamps or perforated galvanized tape. Then the modules are connected into a common network using shaped elements. The final stage of work is the installation of thermal insulation and, if necessary, decoration of the highway.

To learn how to properly connect galvanized air ducts for ventilation, see the following video.

Air duct and its types

An air duct is understood as a set of pipes that must be installed in rooms to perform the function of extracting exhaust air from them with the presence of a wide variety of impurities and gases, and the design also helps to distribute fresh air around the perimeter of the room. Such functions are directly performed by exhaust pipes.

We recommend: Plastic ventilation pipes for the roof: dimensions

The air mass is supplied and drawn out over the products in two ways

:

1. By chance (natural way);

2. Using ventilation devices (artificial method).

In addition, thanks to innovations and the introduction of additional elements in this area, it is possible to ensure the cleaning and heating of the air supplied to the room. No ventilation system or air conditioning structure can operate without the use of an air duct.

Shaped elements for ventilation construction

Types of air supply channel

Depending on the shape of the pipe sections, the air duct has the following types

:

1. Rectangular;

2. Round.

Depending on the material from which the air duct is made, in most cases the following products are found:

1. Made from galvanized steel sheets or stainless steel sheets;

2. From sheets created from an alloy of iron and carbon (carbon steel);

3. Made from aluminum sheets (see Aluminum pipe).

Characteristics of galvanized steel ventilation ducts

The purpose of any ventilation system is to remove polluted air from the room and replace it with clean air obtained from the outside. The traction can be natural or enhanced with the help of additional equipment.

Galvanized air ducts, due to the material they are made of, can be used in almost any ventilation system.

For example, they can be used to easily install supply air handling units or central/rooftop air conditioning systems.

They can install additional systems for filtering and/or heating air coming from outside.

All this allows you to install galvanized air ducts almost everywhere - from residential buildings and cottages to various office buildings, public institutions, even large shopping centers or large industrial enterprises.

What are the technical characteristics of such structures? For each type of system and building, you can select air ducts with different parameters.

For example, when installing ventilation in apartment buildings, air ducts are used whose material thickness ranges from 0.5 to 1 millimeter. The temperature limit for them is 80 degrees Celsius.

Maximum humidity level is limited to 60 percent

It is important to select the type and thickness of the material, based on the relevant GOST requirements for certain conditions. For more serious loads, you need to select air ducts from thick and high-quality material

For more serious loads, you need to select air ducts from thick and high-quality material.

Ventilation ducts installed in aggressive industrial environments are quite capable of withstanding exposure to hot air with temperatures up to 500 degrees.

They are also not damaged by chemical compounds contained in the air exhausted outside.

Which is better and where is it used?

The protective layer of zinc resists the destructive effects of open air, moisture and ultraviolet radiation. Therefore, galvanized ventilation ducts are actively used both indoors and outdoors for arranging systems:

- natural and forced ventilation,

- air conditioning;

- aspiration (removal of small particles contained in the air);

- smoke removal (removal of combustion products);

- exhaust gas removal;

- transportation of gas mixtures, air purifiers and humidifiers.

Even the organization of a regular hood in the kitchen is most often done through steel air ducts.

When deciding on the use of one or another type of air ducts, one should be guided by the operational features of the future design:

- Rectangular air ducts are used to save space in small, predominantly residential or office premises (private houses, apartments or offices).

- For aspiration and transportation of harmful gases, round pipes with a welded seam are suitable, ensuring maximum air movement speed and complete sealing of the housing.

- In industry, preference is given to round shapes, which are characterized by both the greatest efficiency and minimum cost.

Features of choice

The shape of galvanized steel boxes for exhaust and air supply should be chosen taking into account several factors. First of all, this is the size of the ventilation system itself, that is, its length.

It is also necessary to take into account contaminants that may be in the air passing through the ventilation pipes.

Galvanized structures can be installed at almost any length of the system, but for long ones, a pipe with a rectangular or square cross-section is most suitable.

If ventilation has to deal with a large amount of pollution (especially in the presence of fine solid particles in the air), it is best to install pipes with a round cross-section.

If the system is small, and there will be little pollution in it, then the choice may be based on the personal preferences of the owners of the premises.

And preferences mainly depend on the convenience of one or another option. The decisive factor here is the type of room and the purpose of its use. In most cases, square or rectangular boxes are most convenient.

They are a more practical option, as they are able to pass more air and have a greater margin of safety. Their large size makes them more practical for industrial use as they are much easier to clean.

Round designs are less noisy than square/rectangular ones. Air masses pass through them at greater speed.

If heavily polluted air is supplied, then, unlike rectangular analogues, there will be much less debris left in them (which accumulates in the corners of rectangular structures).

Air ducts made of galvanized steel with a round cross-section are also easier to install, and their cost, compared to rectangular ones, is slightly lower.

Installation features

Before assembling sections of pipes and standard standardized elements into the structure, a sealing tape is placed along the outer perimeter of the frame. If the air duct is installed without the possibility of disassembling it in the future, then the tape is replaced with a sealed compound. The sides of the connecting parts are fastened together with M10 bolts. Gaps are eliminated using staples, which are placed in 50 cm increments on each side of the channel.

Additionally, stiffening elements are installed depending on the span length (standard threaded rods, profile). The frames are attached to the pipes with self-tapping screws or rivets every 5-7.5 cm. The air duct is ready for installation in the design position.

The boxes are attached to the walls using metal frames and supported by crossbars made of rolled profiles. The noise in the operating duct is reduced if few adapters and turns are used. To prevent heat loss, industrial air ducts are insulated externally with foam. Expanded polystyrene, basalt and mineral wool are also used for this purpose.

Read with this

- How to calculate the cross-section and diameter of an air duct?

- Disadvantages of polypropylene pipes in home heating

- How to attach air ducts to the wall yourself

- What are polyurethane foam pipes and where are they used?

- Calculation of the area of air ducts and fittings, aerodynamic and other indicators

- Dimensions and types of plastic air ducts for ventilation

- Features of using PVC sewer pipes with a diameter of 50 mm

- Soundproofing ventilation: device features and installation methods

- Dismantling of heating systems

- Pros and cons of air distribution from the floor