An air duct is a prefabricated communications system that serves for natural or forced ventilation of premises. With their help, they solve the problems of maintaining cleanliness, humidity and comfortable air temperature in domestic and industrial premises, in medical and children's institutions. The basis for the effective functioning of ventilation air ducts is their tightness, which depends on the quality of installation and the methods of connecting the air ducts to each other.

Classification of air ducts

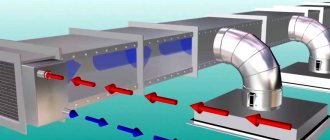

The design of the duct affects the connection method.

The design features of the system influence the choice of connection method. Also, the method of docking depends on the operating conditions and parameters for the removal of contaminated air.

Round and rectangular

According to their geometric shape, round and rectangular structures are distinguished. The advantage of the first option is that there is no risk of vortex flows. The noise level is lower here. This type of duct is more often used in industrial premises.

For residential buildings, a rectangular design is better suited. Thanks to its high throughput, it provides good ventilation. It is easier to hide such a system under finishing material. Thanks to its tight fit to the wall, the product does not take up much usable space.

In rare cases, triangular cross-section elements are used to form an air conditioning system. They are important for the interior.

Rigid and flexible

An example of a rigid air duct made of plastic pipes.

Rigid air ducts have different shapes: round, square, rectangular. Aluminum, stainless steel, and polymer materials are used to manufacture the structure. Flexible options are only round in shape. They are made of aluminum, textiles, PVC. To give additional rigidity to the product, wire is used. An effective system combines both types of ducts.

Air ducts are located inside the wall or outside it. The first option is a ventilation shaft in a permanent structure. It is used in residential areas. External ductwork is more suitable for industrial or technical spaces where design is not always important.

Features of modern installation of ventilation systems

A. V. Busakhin, General Director of LLC “Third Installation Directorate “Promventilation””

The article opens a series of publications examining the features of modern installation of ventilation systems. This material focuses on the types of air ducts, types and methods of their connection. The following articles will discuss fastening methods, in-line installation methods, methods for individual testing of systems, commissioning and commissioning.

Modern projects of ventilation and air conditioning systems, aimed at solving the problems of air exchange and maintaining temperature, as well as controlling humidity, purity of supply air, purification and disposal of exhaust air impurities, intelligent systems for monitoring and managing work, require high-quality and high-tech installation.

Today, during the transition of the construction industry from licensing to self-regulation, installers are waiting for the emergence of technical regulations and standards for installation work. These documents must take into account the specifics of modern installation, new materials and technologies, commissioning, commissioning and maintenance of utility systems for buildings and structures.

Today we have the only document that stipulates the installation conditions - SNiP 3.05.01-85 “Internal sanitary systems”. This document is largely outdated and does not take into account modern conditions, materials and equipment.

Air duct selection criteria

Let's look at some elements of installing ventilation and air conditioning systems. The main one is the air duct. The performance of the designed system depends on the quality of manufacturing and installation of this element. The choice of air duct material remains with the designers. The main criteria for choosing are the purpose of the system and the parameters of the moving environment. The most commonly used metal air ducts (straight and shaped parts) of rectangular and round cross-section, manufactured according to the types and size range adopted in the following documents:

- VSN 353-86 “Design and application of air ducts from standardized parts”;

- TU-36-736-93 “Metal air ducts”;

- TU-4873-193-04612941-99.

To transport air with temperatures up to 80 °C and relative humidity up to 60%, the following materials are used in the manufacture of air ducts:

- thin-sheet cold-rolled galvanized steel 0.5–1.0 mm thick;

- thin-sheet hot-rolled steel with a thickness of 0.5–1.0 mm, GOST 16523-97 “Rolled thin-sheet carbon steel of high quality and ordinary quality for general purpose.”

If the air parameters are higher than the specified limits, stainless steel and, in addition, carbon steel with a thickness of 1.5–2.0 mm are also used.

It must be taken into account that the specified GOST provides a large selection of steel in terms of ductility, rolling method, application of zinc coating, etc. These features must be taken into account when choosing a metal for the manufacture of air ducts.

If there are chemically active gases, vapors, or dust in the air mixture, the air ducts are made of metal plastic, aluminum and its alloys, carbon steel with a thickness of 1.5–2.0 mm with an appropriate protective coating. The tightness of the air ducts is ensured according to class “N” TU 36-736-93 and “B” according to EVROVENT 2/2 with a pressure and vacuum limit of 750 Pa.

Welding methods

The welded method of connecting an air duct is considered the most reliable.

Craftsmen rarely have to connect air ducts to each other using welding, since the process is expensive. This method is used if special requirements are imposed on the tightness of the structure. The welding process can be manual or mechanized.

Manual

Electric arc welding is used if the material thickness is more than 1.5 mm. Gas equipment is necessary if the metal has a thickness of 0.8 mm. The second method is used infrequently.

Mechanized

The mechanized welding method can be semi-automatic or automatic. It is used in enterprises.

Standard distances in relation to building structures and utilities

Air ducts can be fixed to the ceiling, walls and ceiling trusses (the most common options). The axes of the air ducts are laid parallel to the planes of building structures, and the minimum distances between objects should be:

- The distance from the surface of the air duct with a circular cross-section to the ceiling must be at least 100 mm, to walls and other building structures - at least 50 mm.

- The minimum distance between the round air duct and the mains of engineering systems (hot water supply, hot water supply, gas pipes, drainage) must be at least 250 mm.

- The minimum distance between two round air ducts is at least 250 mm.

- The minimum distance from the surface of any type of air duct to the electrical wiring is 300 mm.

- The distance between the rectangular channel and building structures, other channels, as well as pipelines must be: at least 100 mm for channels with a width of 100-400 mm, from 200 mm for channels with a width of 400-800 mm and from 400 mm for boxes with a width of 800-1500 mm .

- Any connections of air ducts must be located at a distance of at least a meter from the plane of passage through building structures.

Connection types

Nipple connection of the air duct

The connection of ventilation pipes to each other is carried out by welding or flanging. In addition, the elements can be fixed with a bandage, nipple or coupling.

Welded

It is possible to connect air duct fragments by welding if they are metal and their wall thickness exceeds 1.5 cm. More often, this method is used in industrial premises where harmful gases accumulate. In this case, the seams should be as tight as possible. Galvanized materials require highly skilled welding to avoid corrosion in the seam area.

Nipple

A nipple is a part of a pipe in the middle of which there is a convex rib. It is inserted into the main structure. The same rib is used for fixation. Another section of the air duct is put on the product. The joint is sealed with metallized tape.

The nipple connection is made using a coupling. Its diameter is larger than the main pipe. The coupling can combine 2 fragments of the structure. The edge in this case is located on the inner surface of the element. This method is used to connect round air ducts.

Flanged

Flange for joining two parts of the air duct

According to GOST, pipes can be connected using the flange method. Spot or solid welding is used to fasten parts. The flanges are secured to each other with nuts and bolts, as well as rivets. To ensure reliable sealing of the weld, it must be painted. A sealing gasket is placed between the steel elements. Despite its effectiveness, the flanged connection of air ducts is labor-intensive to manufacture and expensive.

Bandage

The bandage method of connecting structures is in demand at chemical industry enterprises. It provides high reliability of the joint, but the manufacturing process itself is expensive, therefore it is unpopular for domestic use. The bandage is attached over the connecting seam. Before this, the ends require flanging. The bandage space is filled with a chemically inert sealant. This method is used to connect plastic air ducts to each other.

How to connect plastic and flexible air ducts

Installation of plastic ventilation pipes does not present any difficulties. To assemble plastic systems, manufacturers produce specially selected shaped parts and adapters that match the standard sizes of the air ducts. These connectors are simply inserted into each other and coated with silicone.

Flexible bends in the form of corrugated channels are connected with “aluminum” tape, screw connectors or ordinary clamps.

The compressor outlets are connected with quick connectors and fittings, which can be metal or plastic.

Equipment and materials used

Resistance welding machine for manual connection of a stainless steel air duct

To create a nipple connection of air ducts or a welded joint, the following tools and materials are required:

- stainless steel;

- tape measure, marker;

- hammer, pliers;

- vice;

- metal cutting tools;

- sealant and gun for applying it;

- welding machine;

- pipe fragments of the appropriate diameter.

The technology for installing the structure must be followed down to the smallest detail. If you combine parts of the duct without sealing, the functionality of the system is impaired. The connection of the structure to the hood is carried out taking into account the diameter of all parts. Before installing the air duct, a drawing of it is prepared.

Installation tools

A group of tools for installation: gloves, pliers, wire cutters, screwdriver, knife, marker and tape measure. I think you have most of these tools on your farm.

In addition to the necessary installation tools, you will also need some materials. These are mounting tape and clamps for fastening air ducts.

Duct installer kit

Advantages and disadvantages of welded joints of air ducts

If the weld is poorly made, it will come apart over time.

The welded joint is permanent and does not require additional fixing elements. It has the following advantages:

- possibility of manufacturing large-sized structures;

- weight reduction compared to cast elements;

- high strength and reliability of the joint;

- relatively low labor intensity in domestic conditions.

Residual stress often occurs in a welded joint. In this case, the technical properties of the metal change, which loses its strength over time. If welding is not used skillfully, the seams may be defective. After using the device, the joints must be checked visually and using tools. When the metal is locally heated in the thermally affected area, the mechanical properties of the material can change.

Installation of a rigid rectangular duct

Horizontal metal air ducts have a large cross-section and are most often used at large industrial facilities. For safety reasons, the main part of the assembly of air ducts into large units up to 25-30 meters in length is carried out on the ground, then raised to a given height using special equipment.

Installation of horizontal metal air ducts is carried out as follows:

- Fixing fasteners at design points: anchor connection to the ceiling or laying a beam system (angle, T-beam or I-beam)

- Arrangement of lifting equipment, preparation of scaffolding and towers

- Connection of enlarged units from straight sections and fittings

- Installation of clamps and other fastening means at specified points of the assembled section of the air duct

- Lifting the assembled unit to the design height and fixing it on previously prepared fasteners

- Connecting the last section with a previously installed section of the air duct.

Often, metal air ducts are laid in the inter-truss space or under the ceilings of buildings. These methods are more complex to implement, but they save space and improve the interior.

Scope of application

The correct seam ensures long-term trouble-free operation of ventilation.

Air ducts must be connected to the hood in any room. Welded joints are used in smoke removal systems, moving air saturated with moisture or acid fumes. They are necessary in structures inside which there is high pressure or hot air masses circulate.

This type of connection is used in basements and attic floors. It is suitable for residential and technical premises. This type of air duct installation is fireproof, durable and airtight.

The welded connection of the air duct allows for good quality ventilation. However, work must be carried out strictly according to the instructions.

Types of cushioning materials

Gaskets used when installing elements of ventilation systems play a significant role in terms of sealing.

Therefore, it is important to use the most suitable material or use special sealing compounds.

Air duct arrangement diagram.

To seal joints, the following are most often used:

- Asbestos cord (GOST 1779-83). It is used during installation for sealing at surface temperatures of no more than +400°C. Manufacturers offer these products with a thickness of 0.7-32 mm. To make the gasket, cut a piece of cord to the desired length and lay it on the flange. Next, pass the bolts through the asbestos gasket so that the threads go around them on both sides. The cord must be stored in a dry place.

- Porous rubber. Made from hard rubbers, it has high shock-absorbing and sealing properties. Porous rubber offered on the building materials market can be heat-resistant (up to +140°C), oil- and petrol-resistant, and also resistant to aggressive environments. Rubber of any type retains its qualities in the range from minus 30°C to +50°C.

- PRK. Polymer type material in the form of a tape having a thickness of up to 6 mm and a width of up to 50 mm. The tape is placed on the flange mirror, holes are pierced for the connecting bolts and tightened. The disadvantage of this material is its high rigidity, which is why the holes for the bolts have to be pierced using a beard.

- STUM. Heat-shrinkable cuffs, also made from polymers. Manufacturers offer products with a diameter of 130-355 mm. Use in the temperature range – 40°С – + 60°С.

- "Buteprol." A non-drying compound used for bandage-type connections in round air ducts through which an air flow heated to +70°C passes.

- "Guerlain." Non-hardening flat tape made of non-woven type material. It is used with a flange type of connection at a temperature not exceeding +40°C. Available in the form of a tape 12 m long and 80-200 mm wide.

- "Gelan." Synthetic mastic that does not dry out or harden. Well suited for sealing ventilation system equipment.

In addition to sealing gaskets, when connecting air ducts, fasteners are used, which primarily include bolts, nuts, and rivets. Their dimensions are standardized; the material used is low-alloy or galvanized steel. To install individual parts of equipment, steel self-tapping screws with conical threads are sometimes used.

Where are the products used?

The use of flexible air ducts in a multi-story office building

The use of flexible ventilation ducts is noted in the following conditions:

- installation of air conditioning systems in residential and commercial premises;

- at chemical plants;

- in the food industry;

- in pharmaceutical factories;

- in the oil refining industry, etc.

Such elements allow you to transport even smoke and other contaminated air masses without harm to their internal walls.

Rules and recommendations for installation

Method of connecting flexible parts of the air duct

To install a flexible air duct for ventilation according to all the rules, you need to adhere to the following recommendations:

- In rooms with temperature changes or in unheated buildings, it is necessary to install only insulated air ducts. For these purposes, it is better to call a professional, since the sleeve has an impressive weight and requires careful handling.

- When installing a heat-insulating corrugated sleeve, the joints between the elements must be taped with a special tape. It helps to additionally retain heat and reduce the noise level when transporting air masses.

- Before starting work, flexible air ducts must be stretched to their maximum length. This position reduces the air resistance when air moves in the pipes and reduces the noise level.

- To maintain pressure in the line, it is necessary to make a maximum turning radius. It must be at least two pipe diameters.

- A combination of corrugated PVC pipes with steel or aluminum structures is allowed.

- The main line is located taking into account the direction of the spiral turn in the frame. To do this, you need to focus on the direction of the swirling flow of air masses that the hood transports. Often the direction of the spiral turn is indicated on the packaging with the corrugated element.

- For vertical sections of the line, rigid steel elements are used.

- The maximum temperature load on flexible air ducts must be taken into account when choosing them.

- Under no circumstances should ventilation corrugated hoses be installed in the ground.

- To seal all connections, special flexible inserts are used.

- No bending or sagging of more than 5 mm is allowed between adjacent fasteners.

- The flexible ventilation line must not come into contact with the heating elements.

A competent approach to organizing the ventilation system will eliminate unexpected costs associated with repairs or replacement of equipment.

Specifications

PVC flexible air duct

Flexible corrugation for ventilation is selected according to technical characteristics.

- Material of manufacture (aluminum, PVC, polyester).

- The operating temperature of fireproof and heat-resistant hoses is from -30 to +140 degrees.

- Inner diameter - from 100 mm or more.

- The length in the compressed and extended state is from 1.5 m and above.

- The thickness of the frame wire is from 0.8 to 1.7 mm.

- Friction resistance coefficient is 0.02–0.05. The lower it is, the lower the noise level during transportation of air masses.

- Air flow speed - from 20 m/sec.

Using a corrugated hose for ventilation, you can install the system in limited spaces or place it under a suspended, suspended ceiling.

Safety precautions when installing an air duct

There is a huge difference between installing plastic home ventilation and installing a massive industrial air duct - high-altitude work has always been characterized by a high degree of risk. However, given that ventilation at production facilities is installed by professional climbers, we warn you about the misunderstandings that may occur at home.

- Low heights remain dangerous - choose reliable scaffolding and scaffolding for work. It is highly recommended not to work from a ladder or stepladder without a safety net.

- Work with thermal insulation only with gloves, preferably with glasses. For cutting, we use the sharpest knife or scissors that are available - so that the fiber does not get wet and does not fly around the room.

- If mineral wool does get into your eyes, you should rinse them thoroughly with plenty of water and consult an ophthalmologist. The first symptom is itching.

If you follow these simple rules, you will quickly and easily install an air duct system of any level of complexity at home.