In order for the sewer system to work reliably, efficiently and efficiently in your home, you need to ensure that it is installed correctly. During the arrangement, attention is paid to everything: fittings, pipes, connection options. One of the most important points is the choice of sewer pipes.

The first thing a consumer looks at when choosing a pipeline is the material from which it is made. Today, the most popular are plastic and cast iron components. You also need to choose the correct length and diameter of the products. The number of connection points of elements in the sewerage system depends on the length indicator. The more there are, the higher the likelihood of congestion.

When you are in a building materials store, you may notice that sewer pipes are offered in different color options. Each color naturally indicates the purpose of the product and its scope of application. To get more information follow the link.

Painting products in different colors makes it easy to choose a product for arranging an external or internal pipeline. For example, a gray sewer pipe is one of the most preferred options for installing intra-house communications.

If the proposed tubular products do not match the color of your home, that is, they contrast sharply against the background of the walls and decoration of the premises, you can buy products of a different color after studying their parameters and consulting with a specialist.

How can a beginner determine which sewer tubes he needs to buy: gray, white or red?

What determines the color of sewer pipes?

For polymer, and this is the material from which modern sewer pipes are made, color is not at all important. More precisely, its characteristics are not affected in any way by coloring: it is needed to communicate the properties of the polymer, and not to change them. Plastic can be painted in any color, not just gray, which allows it to be used as an indicator: such markings are unlikely to be confused or accidentally erased.

Gray

It can be not only gray, but also white. Products of this type are used only for internal pipelines. They are designed for use at temperatures of about 60 °C; for a short time the temperature can reach up to 95 °C. Thickness 2.7 mm, diameter 32, 40, 50, 110, 125, 150 mm. They are connected with a socket; some manufacturers apply divisions for ease of installation.

Orange

This class includes brown or red ones. Pipes are intended for outdoor use. They are much stronger and stiffer than gray ones, usually multi-layered. The first class of such pipes has a wall thickness of 3 mm, the second, designed for greater depth, has a wall thickness of 3.2 mm. The temperature of the working environment should not be higher than 45 °C. Orange is not afraid of freezing and can withstand pressure, but not constant. For main sewerage, pipes of a different type are used.

Green

Sometimes blue. It is used for drainage. They are flexible, yet tough. Withstands relatively high temperature changes. Products with green markings are intended for pressure main pipelines. Available in diameter 110 mm or 160 mm.

Black

These pipes are not designed for use under pressure. They are used for non-pressure drains. Black is used for storm drainage.

Is it possible to use gray pipes for external sewerage?

Gray pipes are not suitable for external sewer networks. Instead, materials from a different series are used - brown. In terms of price they are almost the same.

Rules for laying the external collector

The reliable operation of the sewer depends on compliance with technical regulations when installing external networks. This is due to the fact that the sewer pipe is laid in the ground to a certain depth. Finding and digging it out in the event of force majeure circumstances - clogging, ice plug formation, mechanical damage - seems to be a labor-intensive task. Especially if this is the case in winter.

- It is imperative to comply with the required slope specified in the technical documentation - SNIP (Sanitary Norms and Rules).

- There should be no sharp objects in the trench. The stones must be removed.

- The bottom must be made as smooth as possible, without depressions or depressions. It is advisable to lay the pipe on a “bed” of fine crushed stone and sand. They can correct the shortcomings of the trench.

- The pipe must be filled with soft soil, without containing large or heavy objects. A fall from a height can damage the collector walls.

It is permissible to use a propylene pipe as an external sewerage system. A number of activities will need to be completed:

- it is advisable to insulate the collector;

- In order to reduce mechanical loads from the ground, it is necessary to build an unloading casing.

But, it is still better to use for external installation exactly those pipes that are designed to work in such conditions.

Tell your friends about us:

0

Purpose, technical characteristics and properties

Gray or white material is intended only for internal sewerage. Differences in strength:

- SN2 - less durable, lightweight, with a wall thickness of 2.3 mm.

- SN4 – medium strength and lightness, thickness from 2.5 mm to 12.3 mm.

- SN8 - the most durable, heaviest, thickness from 3.2 to 15.3 mm.

PVC material can be plasticized (PVC) and unplasticized (PVC-U). The latter have greater strength and rigidity and are less elastic. They are of higher quality and more expensive.

Areas of use

Gray and white pipes are used for sewer systems in multi-story or one-story buildings and are connected to the central treatment main. They are not designed for external loads and are not resistant to temperature changes.

What makes it unique?

Gray or white sewer products are elastic, inferior in strength to other samples, but do not crack with slight deformation. Standard wall thickness is 2.7 mm.

Basic requirements for a sewer pipe

The material of such products must be fire resistant. They are made of self-extinguishing plastic, must withstand short-term temperature exposure to hot water, and be plastic.

What material is used to make gray sewer pipes

The gray ruler is made of polyvinyl chloride (PVC) or polypropylene (PP). Below I will describe their characteristics in more detail by category. Different manufacturers use different types of additives. Many of them are kept as trade secrets, as is the manufacturing technology.

Characteristics of corrugated pipes

Corrugated sewer pipes are assessed according to the following characteristics:

| Index | Variety | Meaning |

| Ring stiffness, kN/m², not less | Light Heavy Extra Heavy | SN 2 – SN 6 SN 8 – SN 12 SN 16 – SN 24 |

| Impact strength at 0°C | TIR | <10% |

| Creep coefficient, less | PE, PP PVC-U | 4 2,5 |

| Breaking load during tension of a pipe weld, N, more | DN<400 400 600 DN>800 | 380 510 760 1020 |

| Softening temperature, ºС | PVC-U | 79 |

| Tightness of connection | at water pressure 50 kPa (0.5 bar) | no leaks for 15 minutes |

High-quality products with 30% deformation and after heating to +70ºС should not have cracks, delamination, warping, breaks or bubbles.

Corrugated sewer pipes are an excellent option for most modern sewers.

Advantages and disadvantages

Here are the main pros and cons. First the advantages:

- Chemical resistance allows long-term use in acidic and alkaline environments.

- Withstands short-term temperature exposure up to 95 °C.

- Ease of installation.

- The exterior, although gray in color, does not require painting and remains attractive for a long time. For greater decorativeness, the white variety is used.

There are still some disadvantages:

- Water frozen at low temperatures can damage the product.

- Temperature range -10…+95 °С.

- If installation errors are made, the gray plastic pipe may bend.

Polymer products for sewerage

Products made from polymer materials have been replacing traditional designs for the last couple of decades. The reason for this is the successful combination of high performance characteristics with affordable product costs. The main advantage of all types of polymer products is high throughput. It is achieved due to the internal smooth surface of the walls.

Polyethylene

Polyethylene pipes are famous for their plasticity, making them resistant to bending. Flexible elements are not damaged even if the deformation coefficient exceeds the 3% specified by the manufacturer.

Polyethylene pipes are excellent for arranging risers and laying external sewer networks

HDPE products are made from low-density polyethylene. Among the main advantages of the product it is worth highlighting:

- low thermal conductivity coefficient;

- resistance to hydraulic shocks;

- ability to withstand the effects of aggressive environments;

- Possibility of operation at temperatures down to -70°C.

The only drawback of polyethylene products is insufficient heat resistance and a high coefficient of linear expansion under high temperature. HDPE products are characterized by low mechanical strength. In addition, under the influence of ultraviolet radiation they lose their properties.

Separately, it is worth highlighting corrugated pipes. Thanks to the corrugated layer on the outer shell, they are highly resistant to compression under loads.

Corrugated pipes are used in the construction of external networks, the strength of which is subject to increased requirements.

The inner walls of such products have a smooth surface, which ensures unhindered water flow. The outer wall, made of thick polyethylene, has a corrugated structure, due to which it provides high strength to the product.

Polypropylene

The main advantage of polypropylene products is a high degree of heat resistance. PP structures are famous for their high diffusion resistance to moisture and the ability to withstand the aggressive effects of acids and alkalis. High-quality products can last over 100 years.

Polypropylene structures can be used for drainage of wastewater, the temperature of which reaches +45° C

Polypropylene pipes are excellent for designing internal sewer lines. Due to the increased softness of the walls, which can simply deform under the influence of loads created from the outside, PP structures are not recommended for use in external networks.

Polyvinyl chloride

Products made from polyvinyl chloride are characterized by resistance to low temperatures. At the same time, the maximum temperature is limited to +60° C. Prolonged exposure to high temperatures can destroy a structure made of low-quality polymer.

Polyvinyl chloride elements are used for laying external gravity sewer networks

PVC pipes are famous for their strength and resistance to ultraviolet radiation. But they are not able to withstand the effects of aggressive environments, and during the combustion process they release poisonous phosgene gas.

Depending on the ring strength class, there are 3 types of products:

- SN2 – lungs. Designed for installation in trenches up to 1 meter deep that do not cross roads.

- SN4 – average. Used for installation under a six-meter layer of soil in trenches located under small roads.

- SN8 - heavy. They are placed in ditches over 8 meters deep under highways.

The range of non-pressure PVC structures is presented in the diameter range from 110 to 630 mm. The length of the segments varies from half a meter to 6 meters. The color of the products depends on the purpose of the latter: for internal wiring - gray, for external wiring - orange.

Types and differences

Plastic sewer products are classified according to their type of use and color. The material may also vary.

Polyvinyl chloride

They have relatively high mechanical strength and resistance to temperature changes. The maximum temperature of the working environment should not exceed 40 °C, otherwise the material will be destroyed. A short-term increase in temperature does not cause any consequences. Available in gray and orange.

Polypropylene

They have better heat resistance characteristics and greater rigidity. In everyday life it is used as gray sewer; it is not suitable for external sewerage.

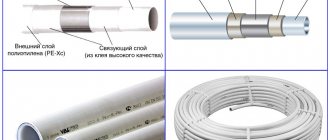

Polyethylene, corrugated

Available in large diameters from 250 to 850 mm. Used in local external sewer systems. I note that the corrugated pipes are smooth inside.

Sewer pipes are also classified according to their ability to withstand internal pressure.

Smooth

This characteristic of plastic pipes suggests their non-pressure use. Water moves in them by gravity. The material can be either PVC or PP. Gray sewer is most often smooth. The socket contains a rubber sealing ring. The connection can be glued or fixed by “cold welding”.

Nadornaya

Such elements withstand a certain pressure - not only internal, but also external. Some types are designed for 12.5 atm. The service life of such products is more than 50 years.

What makes it unique?

Having passed tests for years, gray plastic sewerage is very quickly displacing pipes made from materials such as cast iron, metal, and asbestos from the sales market. Today, no one is embarrassed by this sewer system.

Advantages of PVC pipes over others:

- Light weight.

- Easy to install and operate.

- Resistant to various acids and alkalis.

- Anti-corrosion.

- Smooth interior surface reduces the risk of clogging.

- The appearance of the pipe remains the same.

Fear of severe frosts is a disadvantage of plastic sewerage.

Multifunctionality of pipes

These pipes are gray and red (more precisely, orange). Gray pipes are used indoors, where the temperature does not fall below -10 degrees. Red sewer pipes are laid underground on the street; they are more frost-resistant and have a thicker wall.

How to choose gray pipes

Before purchasing sewer pipes, you need to decide what type of product you need: gray or orange. Then take measurements, trying to reduce the distances. When calculating, take into account the slope: 5 cm per 1 m is enough.

It is advisable to select pipes and fittings for them from the same manufacturer, from the same material: then there will be no problems due to thermal expansion.

Although components from branded manufacturers are more expensive, they will last longer. If the soil is sandy, I use PP material; if it is rocky, then I use unplasticized PVC. I advise you to watch a video on this issue.

RESULT

Guys, if you sum it up and ask yourself the question - which sewerage pipes are better? It becomes clear that plastic pipes are much better than ordinary cast iron pipes. They are easier to work with, better, they do not clog over time (no sediment on the walls), do not rot or rust. If you are changing pipes in an apartment, then it is better to take a closer look at pipes made of PP polypropylene (look for exactly this icon on the pipes), but if you need pipes that will work underground and under pressure (but at positive temperatures), look at pipes made of unplasticized polyvinyl chloride (PVC -U), it is stronger and its walls are thicker! Just remember, it is advisable not to freeze them and not to heat them too much above 70 degrees!

Product size and diameter

For indoor sewerage, I use parts 1.5 m long, 3 m long, the smallest is 0.3 m, but some are 25 cm long. I try to make as few connections as possible. In this case, the structure is rigid and durable.

It is preferable to use the following diameters:

- 30–40 mm for sinks, bidets.

- 40 mm for sink, bathtub, shower.

- 50 mm – combined drain for bathtub, sink, shower.

- 65–75 mm for branches from the central riser.

- 100 mm for toilet, central riser.

Pipes that are too thin quickly become clogged, pipes that are too wide take up a lot of space, and when draining they gurgle due to air congestion.

Popular manufacturers

I will briefly describe the brands of the best-selling sewer pipes.

- Rehau

The German manufacturer is famous for producing high-quality windows. High-tech sewer pipelines are of no less quality. They have a high degree of sound absorption and are resistant to high temperatures.

- Wavin

It is one of the main producers of plastic products in Europe. Applies new technologies to produce products that have high strength and wear resistance.

- Pragma

This brand also occupies a leading position in the production of plastic products in Europe. They are famous for their innovative technologies in the development of sewer wells. The offered product has an optimal quality-price ratio.

- Polytek

This domestic manufacturer occupies 11% of the plastic pipe market in Russia. Huge selection, wide range. Therefore, you can choose everything, while the quality of the material is at a high level.

approximate price

For better orientation, I took the prices of Moscow online stores with an average markup factor. A gray plastic sewer pipe with a diameter of 50 mm and a length of 25 cm costs 45 rubles, 0.5 m - 55 rubles, meter - 90 rubles, 2 m - 150 rubles. Plug – 15 rubles, couplings, adapters – 35 rubles, bends – 30 rubles, tees – 50 rubles.

The same pipe with a diameter of 110 mm, a length of 25 cm - 105 rubles, 0.5 m - 155 rubles, a meter - 220 rubles, 2 m - 360 rubles. The plug costs 25 rubles, couplings, bends and adapters cost 70 rubles, tees – 115 rubles, crosses – 315 rubles. The orange one costs almost the same as the gray one.

What diameter of pipe for street sewerage is needed?

Sewer pipes should be selected according to their purpose, length, diameter, and wall thickness.

In the external (external) sewer system, pipes with the following characteristics are used:

- to install a collector that drains wastewater from the house, the pipe diameter should be 110-160 mm;

- for a sauna or bath pipe 150-200 mm;

- for drains of swimming pools, fountains, decorative ponds - from 200 mm and above;

- for connecting several collectors into one drain on flat areas - from 200 mm;

- for organizing industrial wastewater – from 300 mm.

Understanding the pipe diameter is necessary to correctly determine the drain load: each drain point in the sewer system should not exceed 50 mm in diameter.

Installation nuances

Before carrying out installation work, I advise you to draw up a diagram of the entire system, additionally measuring all distances. It is necessary to avoid connections at right angles; it is better to make a rounding of several bends, for example 2 at 45°.

In places of bends, I recommend installing a tee with access to the surface and closing it with a plug. This will provide access for cleaning in case of blockage.

If in the future you plan to connect any plumbing fixture, then it is better to install a tee with a plug in such places. This will not affect the sewerage itself, but if you really need additional drainage, it will be much easier to do it.

Connection methods

I will tell you about several main types of connections.

Into the bell

The simplest and most commonly used method. The pipe is selected with a special sealing ring. The advantage of such a connection is the possibility of dismantling without damage.

Glue or chemical welding

Using glue or cold (diffuse) welding, you can increase the reliability and tightness of the connection into the socket. The glued sides must be sanded with sandpaper. This type of connection is inseparable.

Using a soldering iron

You can qualitatively connect 2 segments with a special soldering iron. You will need a fitting with an internal diameter equal to the external size of the pipes being connected. The pieces must be inserted into the fitting without gaps, but also without excessive force.

A soldering iron is used to heat the inner surface of the fitting and the outer surface of the pipe simultaneously. When the surface of the polyethylene has melted, the tube with the fitting is removed from the soldering iron. The plastic cools quickly, forming a reliable connection.

coupling

This is also a common option. It is desirable that the couplings be made of the same material. This will have a positive effect on the tightness and appearance of the connection.