Civilization can no longer exist without sewerage. There is a sewerage system in every house. But what if it is not possible to lay pipes at the required depth?

We welcome our esteemed regular reader and offer him an article on how to insulate external sewer pipes on your site and solve the problem of pipes freezing when laid shallow.

Optimal materials

- minimum degree of thermal conductivity;

- resistance to negative influences caused by the environment;

- ease of installation;

- long service life;

- complete tightness;

- high level of fire resistance.

Based on the above parameters, you can choose the most optimal insulation for insulating water pipes.

Glass wool

In most cases, it is used as insulation for metal-plastic pipes.

The advantages are low cost and simplicity during installation, because the material is wrapped around the pipes and secured. Mineral wool is sold in rolls or slabs.

Basalt based products

It is used for the manufacture of cylinders of various diameters, used as a heat-insulating material for water pipes.

This product fits perfectly onto the pipe and can be easily installed with your own hands. Its cost is slightly higher than that of the previous material from the list. External protection, such as glassine, is also required.

Expanded polystyrene

Foam shells can be applied even without additional coating.

This insulation can be used several times, and its durability can be the envy of many other thermal insulation products.

Insulation with mineral wool

According to the standards, the material belongs to the fibrous class and is made using molten rocks and metal slag. There are three main types of mineral wool:

- Glass wool - a mineral thermal insulation material that is obtained from the same materials from which glass is produced. It has received great demand due to its affordable cost and low thermal conductivity - 0.030...0.052 W/m*K. Cotton wool also exhibits good resistance to vibration loads and chemical resistance. Density in a loose state is no more than 130 kg/m3. Glass wool differs in its properties from other varieties. It has a fiber thickness of 3-15 microns, and a length 2-4 times greater than that of stone (basalt) wool. The insulation is resistant to temperatures up to 450 °C. The disadvantages include the fragility of the material and its increased fragility. Also, when working with this material, it is necessary to reliably protect your hands, since upon contact, small sharp needles easily penetrate through the gloves and cause an unpleasant burning and itching. Inhalation of air in which glass wool particles are floating is considered more dangerous. They immediately cause long-term irritation of the lungs and are eliminated very slowly. The same applies to the organs of vision;

- Slag wool – produced from slag waste obtained during iron smelting. It has high friability and residual acidity. In this regard, when used in conditions of high humidity, oxides form on its surface, which negatively affect the surface of plastic or metal pipes. The thickness of its fibers is 4-12 microns. The thermal conductivity index is significantly higher than that of glass wool - 0.46...0.48 W/m*K, as is the water absorption coefficient. In addition, slag wool has low environmental properties. The insulation retains its properties when heated to a temperature of no more than 300° C, but is unstable under temperature changes. Because of this, the service life is significantly reduced;

- Stone or basalt wool – made primarily from molten gabbro-basalt rocks. It is a non-flammable material that can withstand record high temperatures without starting the melting process - up to 870°C. However, when exposed to temperatures reaching 600-700°C, it begins to disintegrate and turn into dust. The structure of the material is porous, due to which it has high thermal and sound insulation. The thermal conductivity coefficient is quite low - 0.035...0.039 W/m*K. This is achieved due to the fact that the air in the pores of the material is in a static state. The vapor permeability indicator is 0.25...0.35 mg/m kV.*h*Pa. Stone wool density indicators range from 30 to 200 kg/m3. and depend on the form of release. For example, stone wool slabs can withstand a load of 700 kg/m2.

Glass wool and stone wool can be produced with an additional protective layer of foil, fiberglass or kraft paper. Stone wool does not absorb water, but constant exposure to moisture can gradually damage the structure of the insulation.

Pipe laying technology

Preparing the trench

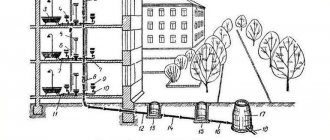

Having decided on the material, familiarize yourself with how to properly lay sewer pipes. Installation of external sewerage begins with preparing a trench, which can be dug manually with a shovel or using an excavator.

The depth of the furrows depends on the depth of soil freezing in a particular area. According to SNiP P-G.3-62, the depth of laying sewer pipes is 0.5 m less than the soil freezing mark and is approximately:

- 3 ÷ 3.5 m – in the northern regions of the Russian Federation;

- 2.5 ÷ 3 – in the middle zone;

- 1.25 ÷ 2 – on the Black Sea coast.

The indicated figures are not categorical and may vary within certain limits depending on the terrain and groundwater level. However, laying sewer pipes in the ground must be done at least 0.5 m from the surface.

The trench has its own characteristics:

- The bottom of the trench is leveled, the necessary slope is created, as a rule, 1-2 cm for each linear meter of the pipeline.

- After leveling the bottom, it is necessary to thoroughly compact the soil and arrange a cushion of gravel or sand 10-15 cm high.

- A sand or gravel bed must be compacted in an area located 2 m before the inspection well and at the junction of the pipeline with the inlet pipe.

- Where the sockets will be located in the sewer system, pits should be formed.

Pipeline installation

Next comes the actual installation of the pipeline. It is better to start laying from the foundation of the building.

The technology for laying sewer pipes looks like this:

- The pipes are laid with the socket down in prepared trenches.

- To connect two pipes to each other, the socket of one and the smooth end of the other are cleaned of dirt.

- The joints are lubricated with special compounds.

- The pipe is inserted all the way into the socket.

- All pipeline elements must be combined in a similar way.

If there is an outlet in the foundation of the house, the external sewer pipe is connected to it; if it is not provided, then a hole must be made. Diamond drills are ideal for this task.

For the turning device, bends are used - 15, 30, or 450. When the length of the sewer pipeline is more than 15 m, an inspection is installed in such sections.

Backfilling the trench

After laying the pipes, the slope angle is checked. If everything is done correctly, the trench can be backfilled. For backfilling, it is allowed to use the soil formed when digging furrows, but in this case it is necessary to remove large stones from it and break up dense blocks of soil.

The trench is gradually backfilled to a height of 0.3 m, in layers of 5 cm. Each layer is well compacted on the sides of the pipe; compacting the area above the pipe itself is prohibited.

Is it possible to install a treatment plant in winter?

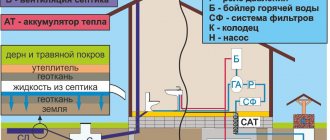

Surprisingly, many experts advise installing a wastewater treatment plant in winter. Installing a septic tank in winter has the following advantages:

- Since construction and renovation work stops during this period, you won’t have to wait for a specialist. Also, the masters will be able to give you maximum attention.

- It is better to install a septic tank in winter for the reason that the groundwater level during this period decreases to a minimum, so digging a pit and a trench for the supply and drainage of wastewater will not arise.

- In principle, there is no difference when installation work is carried out. The only problem may be unfavorable weather conditions.

- Since no one lives at the dacha in winter, the work will not bring any inconvenience to the household.

- In winter, discounts often appear on many building materials and services provided, so you can save money.

Installation of a septic tank in winter is carried out in the same sequence as at other times of the year:

- First, a pit and trenches are dug for the supply sewer pipeline and the discharge of treated wastewater.

- After this, sand cushions are made at the bottom of the pits, which are then compacted.

- A septic tank is installed, a pipeline is laid and connected.

- The pit and trenches are backfilled.

What is important to know when insulating sewers

In cases where the sewer system is insulated with heat-insulating materials, it should be taken into account that such insulation itself does not heat the pipe. It only helps conserve heat, slowing down the process of heat transfer.

This means that if there are no sewer drains for a long time, the pipe will sooner or later still cool below zero degrees, which will lead to its freezing. Therefore, if there is expected to be no regular drainage at the site where the sewerage system is laid, it is better not to use insulation materials, but to immerse the communications in the ground below the freezing level.

Content

- Budget methods for insulating a septic tank

- Average price category of insulation

- The most expensive methods of insulating the wastewater system

- How to insulate septic tank pipes?

- Additional tips for carrying out work

- Conservation

- Reconservation

- What to do if the septic tank still freezes?

Insulation of the septic tank is necessary to prevent freezing.

It is believed that if the installation rules are followed and the container is installed deep enough, the sewer system is not afraid of frost. But there are two dangers here. The first is that installation recommendations are often not followed. Secondly, the climate is becoming unpredictable, so it’s better to play it safe once again. Freezing of the sewer system is dangerous due to its complete shutdown. It happens suddenly, and you won’t be able to use either the toilet or the kitchen sink in the house until specialists arrive to defrost everything.

Sudden freezing of water causes damage. Due to internal expansion, pipes crack and leak. To repair them, you will have to dig through the frozen ground and spend a lot of money.

Insulating the septic tank for the winter will be a way out of the situation. We'll tell you about the basic methods and materials. For convenience, we will divide them into three categories - budget, medium and most expensive.

Alternative methods

If for one reason or another it is impossible to insulate communications using special materials, there are several alternative options for thermal insulation of pipelines.

Winding with electric cable

If pipes are laid in areas where sub-zero temperatures last for a long time, a new heating method can be used. To do this, the pipe is wrapped with a heating cable. The wire connects to electricity, heats the pipe and prevents the contents from turning to ice. The disadvantage of this method is its energy dependence and electricity costs.

High blood pressure

In small country houses, non-traditional methods of thermal insulation of communications can be used. It is known that water under high pressure does not freeze. Before the onset of winter, when leaving the dacha, you can use special equipment to increase the pressure. In the spring, when the temperature rises, the pressure is released

However, this method should be used carefully; there is a danger that the pipe material will not withstand the pressure and will crack.

Coaxial pipelines

Another option is to lay the sewer pipe in another, larger one. The space between them can be heated. For example, if there is a cellar nearby, its ventilation hole can be connected to a larger diameter pipe. The temperature in the basement is always positive. Warm air will go out into the street, simultaneously heating the sewer pipe.

How to reactivate a septic tank

The process of “awakening” a septic tank is no more difficult than its preservation. In fact, it implies the same actions, only in reverse order:

- removal of insulation;

- dismantling the rope-bottle mechanism;

- returning to their original place the removed devices - pump and air compressor;

- inclusion of the station in the network.

Depreservation is usually carried out in early spring, simultaneously with the start of work on the garden plot. To “wake up” completely, bacteria need 2-3 days.

Preserving a septic tank is a last resort if you are leaving your home for a long time. Even rare use of sewerage in winter will maintain the normal functioning of microorganisms. Taking into account the small losses of electricity, this is still more advisable than preserving the septic tank for the winter.

All owners of autonomous treatment facilities know that inside plastic tanks live living bacteria (aerobic and anaerobic), which help purify wastewater so much that it can be used for watering a garden or as process water. However, the septic tank is often left unattended in winter if you leave the dacha, or if you live in the house all year round, it is exposed to low temperatures. What happens to the microscopic workers of this structure? And how to protect them and wastewater from freezing in winter? Some owners are interested in the question of how to install a septic tank that will work in winter, or how to build this structure in winter? You will find answers to these and many other questions in our article.

Some owners, fearing that the septic tank would freeze in winter, made one big mistake - they completely drained the wastewater from the treatment plant and pipeline. Most likely, they did this by analogy with the heating and plumbing system, fearing that if the water froze, the plastic tank would expand and rupture. You shouldn’t do this, because the result will always be sad:

- If you return to your dacha in the spring, you will find your septic tank on top, floating in the pit. The thing is that during a flood, groundwater will easily push an empty container upward, since its volume is quite impressive and its weight is small.

- But worse could happen. Since the soil in which the tank is dug is not static, it can move as a result of temperature changes and changes in groundwater levels. During this process, the septic tank will experience significant loads. As a result, the autonomous sewerage tank will simply burst or become deformed.

As a result of this, the septic tank in winter will become unsuitable for further use. Owners will need to replace the damaged product, buy a new septic tank and install it, which will entail considerable expenses.

What to do if standards are violated

If you find that the radiators in the apartment are cold, you should find out whether this is a problem exclusively for this room or whether all residents of the house are faced with it. A collective appeal always attracts more attention than an individual one.

If the quality of heating is unsatisfactory and does not comply with SNiP, a complaint can be filed:

- to a service organization: homeowners association, management company, housing construction cooperative;

- resource supply company;

- emergency dispatch service;

- housing inspection. It usually operates a special hotline for such requests.

Organizations will receive the complaint over the phone and then register it. After this, specialists will establish and eliminate the cause of the lack of heating, recording a violation.

Later, based on the heating network inspection report, a recalculation for the period of no heat occurs.

If the above organizations do not take any measures to restore heating, you should file a complaint with Rospotrebnadzor and the prosecutor's office.

Who should pay for replacing pipes in the basement - Pravoved.RU

Hello, I live on the first floor, the apartment is divided into three rooms, a hot water pipe in our basement burst (that is, there is no water only in our apartment, there is water in the whole house), the management company says that the residents must replace it themselves. The question is, should we pay money to replace the pipe, or should the management company do it?

Victoria Dymova

Support employee Pravoved.ru

Similar questions

- After replacing the pipes of the in-house heating system, who should eliminate the consequences (if the wallpaper was damaged during a gas weld)? 23 August 2021, 14:56, question No. 1354083 5 answers

- Replacing pipes and faucets in a communal apartment June 14, 2015, 20:38, question No. 871057 2 answers

- At whose expense should it be necessary to replace the pipe from the central water supply to the water pump in the private sector? 28 July 2021, 13:34, question No. 1708933 1 answer

- Who should pay for heating pipe repairs? February 10, 2021, 21:20, question No. 1534698 1 answer

- Should we pay to replace the pipe or should the housing department replace it for free? 16 July 2021, 13:56, question No. 1316494 1 answer

Protection of insulation from negative factors

Protection against freezing of a water supply system located in the ground has its own specifics. The material should not completely or partially lose its thermal insulation properties under the influence of external factors.

Re-insulating or repairing the outer layers requires expensive and time-consuming excavation work, so immediate care must be taken to maintain the integrity of the protective structure.

Destructive effects of earth and water

The underground water supply system experiences soil pressure, so the material used for insulation may be crushed. This can significantly increase its thermal conductivity. To prevent such developments, it is necessary to create a hard outer shell using larger diameter pipes or special trays.

To protect mineral and glass wool, additional means of protection are used - plastic pipes larger than water pipes, which at the same time solves the problem of insulation collapse.

You can also use the following materials to create a waterproofing shell:

- rolled aluminum foil;

- reinforced (plumbing) tape;

- roofing felt;

- high density polyethylene film.

Polystyrene foam and extruded polystyrene foam weakly absorb moisture, but over time they also become unusable with constant defrosting. Foam glass, polyurethane foam, and heat-insulating paint are completely unaffected by wrinkles and moisture.

Solving the problem of insects and rodents

Another cause of damage to the insulation of the water supply system can be rodents and insects. Ants gnaw numerous passages in the thermal insulation that is attractive to them, and mice use it to build a nest. These actions expose parts of the pipes, which negatively affects the quality of insulation.

Neither insects nor mice can spoil polyurethane foam or foam glass, but they do an excellent job with basalt wool. It and similar materials for external insulation of water supply pipes must be protected from rodents if they are located at a depth of less than 2 meters. Earth ants do not penetrate below 1 meter, while forest ants build a large anthill, the above-ground part of which is impossible not to notice.

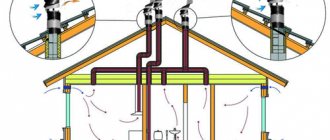

Winter preservation of the Astra septic tank

The procedure for a factory design must begin by disconnecting it from the network. After pressing the button at the station itself, do not forget about the machine, which is located in the room. Then proceed like this:

Preservation of Astra septic tank

- Open the cover and inspect the cameras. If there is less water in them than 3/4 of the total volume of the container, then add at least to this level.

- Rinse compartments containing non-degradable particles and household waste with clean water.

- Clean the septic tank stabilizer using a sump pump.

- Disconnect from electricity, remove and store in a warm place the air compressor and, if equipped, a clean water pump.

- Prepare several 1.5 or 2 liter plastic bottles. Fill with sand so that when lowered into the water they act like floats. Tie the necks with twine, tie all the ropes together and secure them with a knot somewhere on the edge of the container. The bottles should be evenly distributed over the surface of the water.

- Close the container with a lid and insulate it. Rags, old things, polystyrene foam, hay, etc. are suitable for these purposes.

How to insulate a sewer pipe in the ground with your own hands. Video

When laying sewer pipes outside in a country house, you must take care of their insulation. It is quite possible to insulate pipes without outside help if you follow our step-by-step instructions and tips. All pipes that are close to the surface of the earth or placed above the ground are at risk of freezing. We suggest you find out how to insulate a sewer pipe in the ground with your own hands.

Insulation of sewer pipes in a private house

The simplest method of insulation is to lay pipes below the freezing depth of the soil. The level of freezing depends on the region, soil characteristics, and proximity to water. If these indicators are outside the norm, this method is not suitable. If the ground freezes to a depth of one and a half meters, and groundwater flows at a depth of one meter, the sewer system will always be filled with water from the ground, and the pipes will freeze.

Another method involves the use of more expensive and efficient equipment. Laying pipes with a heating cable in a private house allows you to maintain a stable temperature and does not allow the water in the pipes to freeze. The self-regulating cable runs like a heating tape and heats the pipes along their entire length.

The heating power is 30 watts per meter of pipe. When using aluminum-coated tape, it is glued to the pipe. The cable can be cut to the desired size and plugs into a regular outlet. Such a system must be provided with uninterrupted power supply. Pipes with cable (tape) need to be thermally and waterproofed

Laying pipes with insulation in a country house allows you to efficiently and reliably protect the external sewer system

When purchasing insulation for pipes in your home, you need to pay attention to its characteristics.

Water resistance, durability, thermal conductivity, reusability, price - all this is very important when choosing

Types of materials for insulating sewer pipes in a house

The variety of materials for sewer insulation is quite wide, so you should choose taking into account the terrain and the characteristics of the operation of the pipes. Polystyrene foam is a compound of granules measuring about 0.5 centimeters. The granules bond when exposed to temperature. This insulation is a hollow cylinder that is placed on the pipe and secured with construction tape or clamps. Polyfoam is easy to use and safe.

Penoplex or extruded polystyrene foam consists of a foamed substance with a large number of granules. Penoplex can withstand significant loads underground. It has high rigidity and is used in wet conditions. Penoplex, in addition to insulating sewer pipes, is used for insulating foundations, basements and blind areas.

Foil-coated isolon is quite often used to insulate communications. It ensures that pipes are protected from freezing and destruction for many years. This high-quality and inexpensive material is quite easily mounted on pipes. The roll is cut into strips and wound in a spiral onto a pipe. The insulation is fixed using electrical tape, adhesive tape, and plastic clamps.

Insulation of sewer pipes is often carried out using ready-made or sprayed polyurethane foam (polyurethane foam). PPU is applied using a special installation. Instead of spraying an expensive substance, you can purchase ready-made blocks with any suitable diameter. The blocks are secured with clamps, aluminum tape or other connecting materials. This material is resistant to moisture and dampness. It is easy to remove and lasts a long time.

Watch the video: How to properly lay sewer pipes in a country house

Each method of insulation is good in its own way, so the material is selected individually. Knowing how and with what to insulate sewer pipes in a private house, you can save a lot. Protect your sewer system during the initial pipe installation to ensure your home renovations are inexpensive and long-lasting.

Rules for choosing insulation

There is a huge selection of insulation materials on the construction market, but not all can be used as insulation for sewer pipes.

The main task of insulation is not to heat the outlet, but to reduce heat exchange between the external environment and the liquid circulating through the pipes.

In order for pipe insulation to effectively perform its main function - heat preservation, it must meet 7 basic requirements:

- have a thermal conductivity coefficient as low as possible;

- retain their properties for a long time;

- withstand large temperature changes;

- have good waterproofing properties;

- be resistant to aggressive environmental influences;

- do not support combustion and do not emit toxic smoke;

- be easy to install.

External sewerage pipes and a main line laid in an unheated room are subject to insulation. The only exceptions are those regions where even in winter it never drops below 0°C.

For others, the only question is the choice of method and material. Insulation materials are chosen based on the reputation of the manufacturer or brand, but the surest way is to focus on the material of manufacture.

Most often, sewer pipes are insulated with mineral wool, expanded clay, styrofoam and polyurethane foam insulation. Liquid insulation also finds its use. All of them are used for passive insulation.

In addition to them, there are 2 more options for protecting pipes from frost - laying below the freezing level of soil layers and using active insulation. The latter includes cable insulation.

Is it necessary to insulate underground water pipes?

Many owners of private houses face the problem of water freezing in water supply systems laid deep underground or under paving slabs. In order not to be left without a normal water supply in the winter, and to avoid having to restore burst pipes in the spring, it is necessary to competently approach the organization of the installation of the water supply system.

It happens that home water pipes are laid in the ground without taking into account the depth of soil freezing. In severe frosts, the ground freezes, the water in the pipes turns into ice and the integrity of the laid water supply system is compromised. The amount of winter soil freezing depends on the climatic conditions of the region.

Soil freezing map

When planning the installation of a water supply network, it is imperative to pay attention to this factor. Although there are circumstances when the costs of placing pipelines, taking into account the freezing point, are too significant and exceed the provided cost estimate

Then you have to lay a water supply without taking into account the amount of soil freezing. In this case, you should worry about the insulation and responsibly approach the question of how to insulate a water pipe in the ground at a shallow depth.

Is it necessary to insulate the sewer system?

The most traditional insulation for an external sewage system is soil. For more than a century, it is the sufficient depth that has protected sewer systems from freezing in winter. In addition, before the advent of modern heat-insulating materials, there was practically nothing to provide insulation for underground communications.

If the communications are located at a sufficient depth, external sewer pipes do not require insulation. It is advisable to thermally insulate a section of sewer pipes in a cold underground or basement in the area from the exit from the building to the entrance to the heated volume, i.e. to the ceiling of the first floor.

Ideally, sewer pipes should be laid below the soil freezing level. But if the length of communication from the house to the well is large, then deepening the pipe leads to a significant increase in the volume of excavation work. Therefore, it is allowed to lay sewerage (the upper level of the pipe) above the freezing level by 300 mm. If the pipes are laid well and there are no bends or convex sections, the wastewater does not linger in the sewer system and practically cannot freeze, i.e. Insulation is practically not required.

When pipes need insulation

Sometimes there is a need for shallow or superficial installation of a sewerage system - in case of emergency restoration of the system, to reduce the volume of excavation work, or very close occurrence of stony or rocky rock in the ground. Shallow laying of insulated sewerage is necessary in northern regions where the soil freezes to a great depth.

Situations when insulation of the external sewerage system is necessary:

- When laying at shallow depths.

- For surface installation.

- Insulation is necessary for the places where the system is discharged into wells and septic tanks, the places where it rises when entering the building, and the drain pipe.

- When laying sewerage in an unheated basement or underground (especially if there are large open ventilation holes).

Other methods of pipeline insulation

It is worth considering how to insulate a water pipe without using insulating materials. There are the following methods for this:

- pressure support;

- heating cable.

To use the first method, a receiver is installed in the pipeline, and after the pump, a check valve is installed. The valve in front of the receiver is closed and the pump is started. Thus, the water supply will not freeze in winter and those living in the house can use water freely, without fear that it will freeze.

When installing an electric heating cable, you must remember that it can be placed both inside and outside the pipes. In this case, the water pipe is laid at a shallow depth. Instead of 2 m, it is enough to dig trenches 0.5 m deep. But this method has a drawback - dependence on electrical energy.

Now let’s talk about how to insulate a water supply system in a dacha using this method. There are 2 types of laying: longitudinal and spiral. Installation steps:

- a layer of insulating material is wound onto the pipeline;

- apply a protective film or coating;

- connected to the power supply.

One of the problems is considered to be the area in the wall of the building - the entry of water into the house. In order to prevent the problem from making itself felt during the winter period, you need to:

- Create high pressure in those pipes that are responsible for introducing water into the house. The water supply system is complemented by a receiver. When leaving the country house, it is turned on and the pressure is set at 3 atmospheres. This method will make it possible to insulate the input without freezing the water. Arriving at the summer cottage next season, the owner relieves the pressure and returns the water supply to normal. In order to apply this method, you need to make sure that the pressure in the system is uniform and that the pipes are strong (so that they are not damaged under increased pressure).

- Insulation of water supply pipes is possible by heating the inlet pipes with an electric wire. In problematic areas, they are wrapped with cable and connected to the power supply. But this method has disadvantages - additional energy consumption and the inability to warm up during a power outage. But there is a way out of this situation, which is to buy a generator.

- Now let’s talk about how to insulate a pipe with cold water using air. When deepening a water supply system into the soil, it is taken into account that it is heated by the earth from below, and cold (air masses) affects it from above. If the pipes are thermally insulated around them, they will be protected not only from the cold, but also from the natural heat coming from the soil. Therefore, in this embodiment, an insulating casing is used, its shape resembles an umbrella.

- The pipe-in-pipe method involves placing smaller products into larger ones in size or diameter, and the gap between them is filled with thermal insulation material: expanded clay, polystyrene foam, mineral wool, polyurethane foam, etc. Sometimes the interpipe space is filled with hot air. In this case, laying is done in the ground, and if the soil is wet or loose, in a brick tray.

In addition to these methods, in order for the sewerage system to be insulated, there is another way - placing the pipes 0.1 m below the freezing point of the soil.

When laying external sewerage, earthworks are carried out, trenches are prepared, and a pit for a septic tank is prepared. If the freezing level is 1.7 m, then the minimum depth of the pipeline will be 1.8 m. And since the water supply system requires a slight slope, it will ultimately lie at a depth of 2.6-3 m. If it is necessary to repair the system, this will complicate work. Therefore, install the water supply system at the dacha yourself according to the instructions:

- prepare trenches 0.6 m wide, 0.1 m deep than the freezing point of the soil;

- trenches must have a slope of up to 2% of the total length of the pipeline;

- a sand cushion (0.1 m) is placed in the trenches and compacted;

- all elements of the plumbing system are laid out along the dug grooves;

- make connections and strengthen everything with sealant or silicone, using cuffs (for sealing);

- put heat-insulating material on the pipe and secure everything with tape;

- everything is covered with sand, and compacted on the sides;

- Then they cover everything with soil (mound), after a while it will settle.

Now there will be no questions about how to insulate pipes yourself. After all, every reader can do this. But if there are no installation skills, then it is better to invite specialists who will not only carry out the correct installation of the water supply system, but also calculate the required amount of material, which means that the consumer will save his budget and will not make unnecessary expenses.

How can you insulate a septic tank when living seasonally in a country house or dacha?

Basically, when living seasonally at a dacha, the problem of how to insulate a septic tank does not arise. You can carry out the simplest insulation after the end of the summer season. To do this, it is enough to cover the entire location of the septic tank with branches, spruce branches or straw, pressing it all down with stones or old boards.

Additional insulation will be facilitated by snow that falls in winter (if there is insufficient snow cover, snow can be additionally heated over the entire area of the septic tank). Such a simple measure will completely solve the problem of insulating the septic tank. The water remaining in the septic tank is guaranteed not to freeze; under no circumstances should water be completely removed from the septic tank.

Inlet and outlet pipelines, if a slope of two centimeters per linear meter is observed when laying them, there is no need to insulate them. To be on the safe side, before the onset of cold weather, you need to clean the bottom of the septic tank so that the resulting sludge cannot coke.

Insulation of pipes on the street

If you are faced with the task of insulating outdoor heating pipes on the street, then you should take into account contact with moisture. Therefore, waterproofing is mandatory in any case. Otherwise, the whole point of thermal insulation is nullified.

Algorithm for a standard insulation scheme:

- a layer of mineral wool;

- winding with silk threads;

- a layer of roofing material to limit contact with moisture;

- winding using corrosion-resistant wire (aluminum or galvanized).

Insulating heating pipes is a serious and responsible task. And if you want to significantly save your heating budget, then this procedure should be mandatory.

If you decide to do everything yourself, then pay attention to the choice of material, its resistance to various external factors, including moisture resistance. Remember that if moisture gets on the insulation structure, all work will be useless, since under the influence of water the thermal insulation becomes wet and loses all its properties

Otherwise, seek help from specialists, but be prepared to pay a considerable amount for such work. Although in fact the work itself, which consists of finishing external heating pipes, does not cause any difficulties.

The simplest and most inexpensive way to insulate a country septic tank

As soon as summer comes to an end and the harvest is harvested, there is often no need to live in the country, and, accordingly, the need for constant operation of the treatment plant also disappears. If you are afraid that the septic tank may freeze in winter and want to somehow protect the equipment, then it is enough to throw straw on top (on the part that protrudes above the ground). In winter, the natural snow cover will take on the role of an additional insulating layer. By the way, when there is not enough snow, you can throw it directly on the septic tank. Since mice and rats often hide under straw in winter, it is better to mix it with dry pine needles. Of course, rodents pose virtually no danger to treatment equipment, but next year they can cause serious harm to the future harvest.

Functions of heat insulators for heating pipelines

If we consider a private house, the heating boiler can be located inside the building in the basement or outside in a separate technical extension. The latter option is often used in the absence of a gas pipeline and the use of solid dirty materials as fuel - coal, firewood, peat, briquettes, pellets.

Many private houses have outdoor baths or saunas, so as not to complicate the design by installing a separate tank for heating water; it is supplied into the premises from the boiler, and the distance between the objects can be quite significant. When deciding how to insulate heating pipes, choose materials that meet the conditions below.

Reduced heat loss

The principle of operation of any insulation is to protect the insulated surface of the protected object from contact with the environment. At the same time, due to the low thermal conductivity of the insulator, heat loss is reduced, and the equalization of air temperatures and the hotter pipeline proceeds much more slowly than in the absence of a heat insulator.

Any heating main can be placed on the surface of the earth or under the ground; in the first case, soft insulation is usually installed for heating pipes in the open air; when placed underground, protection from hard materials is installed due to soil pressure.

Rice. 3 Mineral wool is a popular thermal insulation material for heating pipes

Frost protection

If hot water in an individual heating system is supplied from the boiler to an object located at a considerable distance from it, the water supply is usually laid underground at a distance from the surface below the freezing point. At the same time, it is not always possible to place the pipeline at a sufficient depth, so if the supply of hot water is interrupted for a long time, the remaining and cooled liquid in the pipes may freeze in severe frosts. To protect the underground line from freezing, it can be thermally insulated by placing it in hard shells or soft shells located in pipe channels.

Prevents condensation formation

Construction regulations prohibit the laying of metal pipes in the ground in the absence of insulation or protection of the outer shell with auxiliary materials; the situation is different indoors, where steel, galvanized steel, and copper pipelines are quite often laid. When the heating is turned off, the liquid in metal pipes cools down and condensation appears on their surface, water drops cause corrosion of the outer wall and, if there is a large accumulation, fall down to form puddles on the floor - this can cause damage to the flooring.

To combat this phenomenon, porous heat-insulating materials for pipelines that are resistant to water or with good vapor permeability are used.

Rice. 4 Foamed polyethylene - thermal insulation for outdoor heating pipes

Protection against thermal burns

In municipal and household services, the temperature of the coolant transported through pipes can reach values close to 100 ° C, so the task of protecting service personnel or residents of a private house from burns when coming into contact with pipes becomes urgent. To do this, their outer walls are covered with thermal protection from various types of heat insulators, the shell of which cannot have a high temperature by definition.

Neutralization of geometric deformations

The ability of all materials to expand when heated is well known, so a hot pipeline, when passing through walls or floor slabs, is placed in steel sleeves of larger diameter. A heat-insulating shell is placed on the pipe, protecting the assembly from hard contact of the enlarged shell with the wall of the sleeve.

When laying pipelines in walls or under the floor, their expansion can lead to cracks in the plaster or screed, so the use of an elastic shell that absorbs part of the thermal expansion helps to avoid problems associated with geometric deformation of the pipes.

Rice. 5 Expanded polystyrene shell - material for insulating heating pipes in the ground

Application of foamed polyethylene

Foamed polyethylene is often used as insulation for sewer pipes. This is not a very dense material - up to 40 kg/mᶾ. The thermal conductivity coefficient is within 0.05.

Does not change its properties when used in the temperature range -50°С – + 90°С. The small thickness of the material allows you to save space, so its use is justified where there is a very small gap between the pipes and the wall.

Foamed polyethylene tolerates well even prolonged exposure to moisture. It is fire resistant. Withstands more than 300⁰. When the material burns, its emissions into the atmosphere do not contain dangerous toxins

The advantage of insulation is lightness, durability, and affordable price. This insulation is produced by such manufacturers as Magniflex and Penofol , Energoflex , Thermoflex . It is produced in the form of cylinders of different diameters and in rolls. There are foil one and two sided options.

This option of thermal insulation in the installation of sewer pipes is rarely used; it is used to insulate communication areas located in basements and above ground.