Hello dear reader!

Back in 1270, the French king Ludwig IX issued a law that prohibited residents of the upper floors from pouring sewage on the heads of passers-by. Instead, they had to go outside and carefully dump all the waste at their feet. The French tried to mask the unbearable stench with perfume.

Can you imagine the amber that permeated the air of medieval Paris?

It is not surprising that the average life expectancy then was about 35-40 years. And there was no need for any poisoned gloves or other cunning methods - people in such an atmosphere were already dying like flies.

Therefore, a well-equipped sewer system is not only a convenience, but also one of the most important factors in a healthy atmosphere at home.

In today's article I will talk in detail about sewer pipes. We will find out what modern pipelines are made of and try to calculate the sewerage parameters ourselves.

Kinds

There is simply a huge range of sewer pipes on the plumbing market today. There are options from different materials and with different characteristics. This diversity is due to the large number of manufacturers and the great demand for such products.

Cast iron

The most common and widespread is cast iron. Pipes made from it are characterized by high strength, fire resistance and durability (service life 60–80 years), as well as resistance to chemicals and temperature changes. Among the disadvantages of cast iron products are the high price and difficulties with installation due to their heavy weight. Plus, cast iron is characterized by a rough surface, which leads to a layer of fat inside the pipeline and its narrowing.

Methods for connecting cast iron pipes for sewerage

Steel

Steel pipes will cost less than cast iron pipes, but will last much less (maximum 30 years). They are much more susceptible to corrosion than their cast iron counterparts. In private homes, this option is extremely rare. If durability is not so important, then it is better to make the internal sewage system out of plastic.

Methods for connecting steel pipes

PVC pipes

The most common among plastic pipes are products made of PVC (PVC, polyvinyl chloride). They are cheap, light in weight, smooth inside and last about 40 years. Plus PVC pipes are resistant to corrosion and aggressive environments.

Their only serious drawback is the rather low maximum operating temperature. Water heated above +600 C with prolonged exposure gradually destroys polyvinyl chloride. In general, it is recommended to use a PVC pipe when laying an outdoor sewer section, where wastewater from different plumbing fixtures is already mixed and is not so hot.

Methods for connecting PVC pipes

Polypropylene

Compared to PVC, polypropylene is more durable and can easily withstand heat up to +1000C. Pipe products made from it are characterized by increased wear resistance and can last up to 100 years. But they are somewhat more expensive than PVC pipes for internal sewerage.

Methods for connecting polypropylene pipes

Polyethylene

Polyethylene analogues almost completely repeat the characteristics of the polyvinyl chloride version. They are only slightly more resistant to aggressive chemicals, but at the same time they will cost more than PVC pipes. Plus, polyethylene products are softer and are more easily damaged from the inside by abrasive particles (grains of sand or rust contained in wastewater from a private home).

Methods for connecting polyethylene pipes

Asbestos cement

Asbestos cement sewer pipes are usually used to lay the street part of the drainage system. They are distinguished by increased corrosion resistance and low cost. However, they will last a maximum of 25 years. Then the asbestos-cement pipe will definitely have to be replaced due to wear.

Methods for connecting asbestos cement pipes

Ceramics

The most durable, chemical-resistant, smooth and at the same time expensive is ceramics. Pipes for internal sewerage made of this material belong to the premium segment. However, they are quite fragile and difficult to install independently.

Method of connecting ceramic and cast iron pipes

Sewage requirements

Requirements for the sewerage system of an apartment and individual residential building are established by SNIP 2.04.01-85. 2.04.03-85 and SNiP 31-02.

I will list the most important ones:

- For sewage systems, the following types of pipes must be used:

- for gravity systems - concrete, cast iron, reinforced concrete, plastic, glass;

- for pressure - cast iron, plastic, reinforced concrete, asbestos-cement;

- It is not allowed to lay sewerage in the floor of living rooms, under the ceiling, in hospital wards and child care institutions, canteens, classrooms, libraries, electrical panels, transformer rooms;

- It is not allowed to connect the exhaust part of sewer risers with chimneys and ventilation systems and to cross the sewer with a gas pipeline.

- The diameter of the outlet hole is determined by calculation. It cannot be smaller than the diameter of the largest drain;

- Pipelines located outside the house must have a diameter of at least 150mm;

- To clean and maintain networks, wells must be installed;

- The outlets are connected to the external network at an angle of at least 90 degrees;

- The length of the pipeline from the plumbing fixture to the riser should not exceed 12 m;

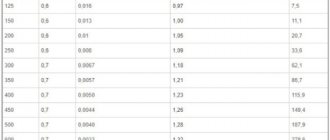

- The diameter of all utilities should be calculated based on their special formulas and standards, according to the planned volume of sewerage and the operating conditions of the sewerage system.

Sewage pipes, regardless of material, must be:

- Durable;

- With a long service life;

- Resistant to external climate and temperatures of transported liquids;

- Frost-resistant;

- With smooth walls;

- Wear-resistant;

SNiP

Before you buy large-diameter sewer pipes, you need to familiarize yourself with the requirements of SNiP. There are systems designed for use in large cities; accordingly, they have larger diameters and communications that are used in urban-type settlements or villages. Based on the standards specified in sanitary norms and rules:

- For installation of sewerage systems in urban networks with a flow of more than 300 cubic meters in 24, pipes with a diameter of 150 mm are used;

- To install drainage for industrial premises - up to 130 mm, but it is necessary to use a sealing collar;

- Laying pipes for non-pressure sewers is permitted with communications up to 100 mm.

Various domestic and foreign companies are engaged in the production and installation of sewerage pipes. The price of communications directly depends on the diameter and material of the drain. Before installing already selected pipelines, it is advisable to consult with a specialist in order to prevent possible leaks and emergency situations due to a discrepancy between the requirements and the purchased pipes.

Choosing the right type of sewage system

The process of arranging a sewerage system

The choice of a sewerage system must be made at the stage of building a house; first of all, you should find out whether it is possible to connect to a centralized sewerage system.

If this is not possible, then you will have to start installing a local sewer system.

Owners of houses connected to a centralized sewer system do not need to independently maintain the sewer systems, but they should pay their bills for sewer use up-to-date, otherwise they may face such a problem as turning off the sewer system for non-payers.

When creating an autonomous sewer system, everything is much more complicated.

The first step is to decide on the type of sewer system, wisely weighing all the pros and cons of various systems.

For example, when choosing the type of autonomous sewage system, many people prefer a cheaper and easier-to-equip cesspool, rejecting the option of installing a modern system with wastewater treatment as expensive and difficult to install, without taking into account that the service life of the cesspool is noticeably shorter.

The construction of a system with treatment facilities requires at the initial stage certain costs for the hydraulic calculation of the sewer network, materials for installing the system, and wages for specialists installing the sewer system, but much less trouble arises during the operation phase.

The undoubted advantages of modern sewer systems over the same cesspools also include the absence of an unpleasant odor and a negative impact on the environmental installation,

In addition, simpler sewer systems require more financial investment in maintenance and repair.

Just to remove waste from the cesspool, you will have to call sewer trucks at least twice a month, whereas a conventional septic tank only requires annual cleaning of the chambers, and installations that carry out complete biological treatment of wastewater require even lower maintenance costs, since only replacement of the filter membrane is required once every 2-3 years.

All this allows modern sewer systems to recoup installation costs during the operation phase due to low maintenance costs.

Before you start building a country house, country house or cottage, you should study in detail the various types of sewage systems in order to have an idea of their advantages and disadvantages, and then choose the most suitable option, taking into account all sorts of factors, from the area in which construction is taking place to the amount , which can be spent on sewerage installations.

Previous entry What types of sewer manholes are there and why sewer manholes are made round Next entry Calculation and installation of external sewerage. Domestic and storm sewerage.

Purchasing HDPE pipes at wholesale prices

Every owner of a private home who has begun renovations faces the question of which pipes to buy for sewerage. This is also a pressing problem for owners of apartments and businesses, since it is important to initially build a sewer system so that problems do not arise after a few years.

The practice of many experts shows that polyethylene pipes are considered the best option. They attract with their affordable cost, reliability and ease of installation. Therefore, when choosing which pipes to use for pipe sewerage, many choose this option and subsequently do not regret their decision.

, which is the largest pipe manufacturer in the Far East, offers for purchase polyethylene pipes of various diameters that can be used for sewage. Thanks to our own production, we can offer favorable wholesale prices to all our clients. We guarantee high quality products and full compliance with GOST. To find out more about the products, leave a request on the website or call us - 8. We will answer any questions and help you choose the right option!

Fiberglass

Their main advantages:

- Even with their large dimensions, a diameter of over 500 mm and a length of 6 and 12 m, fiberglass products are relatively lightweight.

- The material of this type of pipe is durable and reliable, from an environmental point of view it is impeccably clean, and in terms of chemical aggression it is completely neutral.

- The service life of fiberglass pipes is more than half a century.

These pipes are connected to each other and to other shaped products using double-cone special couplings. On their inner side there are grooves for mounting elastomeric sealing rings - one on each side, and one ring is located in the center. Thanks to this mating, the joint is precisely centered and reliably sealed.

Main nuances when laying pipes:

When preparing a sewer system, it is important to know that the pipeline does not have to be laid deep. The standard option is when it is located above the pipelines of the general drainage system around a building or land plot. Despite the fact that the likelihood of storm drainage pipes defrosting is very small, experts still advise laying them at a depth slightly below the soil freezing level, which is typical for each region. If for some reason such actions cannot be performed, all pipes must be insulated and the thermal insulation layer covered with plastic film to prevent moisture from groundwater from entering it. For the system to function fully, the pipes must be laid at an angle in the appropriate direction. The slope of pipes for rainwater drainage, ensuring the free passage of waste liquid and its regular self-cleaning, should be from one to two centimeters per linear meter of pipeline

If this rule is not followed, the internal cavities of the system will often become clogged. Such unpleasant phenomena occur at pipe joints or corner turns.

Recent data on prices for stormwater pipes have shown that when designing stormwater drains, the best option would be to use a corrugated multilayer stormwater pipe. Compared to similar types, its purchase will provide significant financial savings of up to 30-50%.

If you correctly calculate and correctly install the sewerage pipeline system, then in general the entire stormwater system will function without failures for a long time.

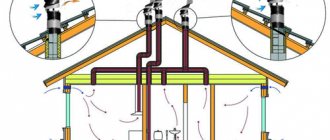

Features of installation of sewer pipes in one-story and two-story private houses

When a country house is one-story, the sewer pipeline is laid out with one riser in the toilet, as well as two horizontal outlets in the bathroom and kitchen. However, if the cottage has a large area and has several floors, the wiring diagram will have to be more complicated. For example, install 2 risers. One way or another, it is necessary to adhere to the basic rules for the disposal of wastewater from plumbing fixtures: it is important that the slope of the pipeline is directed towards the outlet from the house; all wastewater through sewer pipes is collected at the same point.

Adhere to the following principles to ensure that your sewer system functions without interruption for many years:

- we connect the bends and the riser not with a direct cross, but with parts with pipes, an angle of 30–40°;

- to fix the outlet pipes on a slope, we use clamps in increments of up to 150 cm;

- fill the areas where vertical risers pass through the floors with concrete;

- remove nicks from the ends of plastic pipes if they were cut with a hacksaw;

- we install siphons to make a water seal;

- We place the fan outlet at a great distance from balconies and windows.

According to the requirements of the joint venture, the sewer system in a country cottage can be either open or closed, for example in shafts or boxes made of non-flammable materials.

In the first case, you can always see if the sewage system is working properly, replace failed parts, and repair the pipeline. In the second case, the system will be hidden from prying eyes.

Many homeowners, wanting to reduce costs, place the vent pipe into the ventilation shaft. Doing this is not recommended. Otherwise, the acrid smell from the sewer will not come out, but will end up in the house.

The external route should be installed at a slope from the cottage in a prepared trench. It is important to place the pipe below the soil freezing level to prevent wastewater from turning into ice in the sewer system during the winter season. If you are forced to lay the pipeline higher, you will have to insulate the line. The outlet should be laid on a layer of sand, the thickness of which is 20–30 cm. The top and sides of the pipe should be sprinkled with sand to prevent the pressure of stones on it.

Each owner of a country house will be able to install a plastic sewer pipeline with his own hands. It is important to adhere to the rules described above, observe the required slope, and securely fasten the pipes. It will also be easy to think over a wiring plan. This job is much easier than designing a wiring diagram, which is not recommended to be done on your own unless you have experience with this type of work. In a private house, not many plumbing fixtures are used, so you can install sewer pipes without any problems.

;

Sewerage

Did you find this article helpful? Share it with your friends:

Choosing a diameter according to building codes

For sewer channels, pipes with an internal diameter of 50-110 mm are used. and wall thickness more than 3 mm. The dimensions are determined by the purpose of a particular channel:

- 50-75 mm. Relevant for organizing drainage from sinks.

- 90 mm. Suitable for an apartment bathroom.

- 100-110 mm. Used to connect a toilet.

To install utility lines for industrial or general purposes in the urban and private sectors, it is necessary to lay pipes with a larger internal diameter (160-200 mm to the collector unit and from 300 mm to the treatment plant with a wall thickness of more than 3.9 mm). These include risers of high-rise buildings, sewer channels that drain wastewater outside a particular building.

What to do if it is impossible to maintain the desired tilt

There are cases when difficulties arise during installation, leading to the fact that the angle of inclination of the sewer differs significantly from the permissible standards. In this case, take the following measures:

If calculations show that deviation from the specified standards is possible, then lay the pipes, but at the same time make additional tees at a certain distance through which the pipes will be cleaned.

When laying the pipe, still adhere to the recommendations, but in difficult areas, establish height differences, which are organized through additional wells. Thanks to this solution, it will be possible to install the pipe at the desired angle. There can be one or several such wells, but correct calculations and installation guarantee proper operation of the sewerage system.

There are several ways to achieve the desired slope of sewer pipesSource vodasovet.ru

As a last resort, if it is impossible to maintain the required slope and calculations show that the operation of the sewage system by gravity is impossible, then you will have to use a fecal pump. This device can be installed both on a local sewer branch and for the entire system.

When laying pipes made of plastic, you can be sure that they will need to be cleaned much less frequently than cast iron, since the smooth inner surface of the walls allows solid substances to slide.

Which material should you choose?

Since in the article we are considering the question of which pipes are better than a private house, we will summarize what to choose.

- Concrete and reinforced concrete - used in industrial construction. Local sewer networks are constructed from them. They differ in significant weight and dimensions.

- Cast iron is high-strength, temperature-resistant, but heavy. Now they are not used often. Even in multi-apartment construction, the volume of their use is decreasing. Even despite the long service life.

- Steel, ceramic and copper are too expensive and not very reliable for use in sewers. The installation and replacement process is complex.

- Asbestos-cement - resistant to biological and chemical influences. Quite suitable for sewer networks. However, fragility reduces their performance even before installation.

- Polymers are a relatively new type of product. There are models with different consumer characteristics. The class includes various plastic pipes for sewer networks. They are distinguished by significant strength, long service life, ease of installation and compatibility with other equipment.

- PVC pipes are the best choice for gravity sewerage. Suitable for installation of external and internal systems. Resistant to mechanical damage and ultraviolet radiation. Temperature does not affect performance. They do not tolerate exposure to household chemicals very well.

- Polypropylene - not exposed to aggressive chemicals. Resistant to mechanical damage. Capable of passing high temperature liquids.

The sewer pipe market is much broader than described in the article. Here are the characteristics of the most common materials. It is impossible to say for sure that one of the options is better than the others. For each pipeline, specific operating conditions must be taken into account. It is by taking into account all the nuances of the site that you can choose the best option.

We recommend reading:

- How to connect plastic sewer pipes;

- How to independently determine the diameter of the pipe;

- Methods for connecting a metal pipe to a plastic one

Distinctive properties of PVC and polypropylene pipes

The main differences between PVC pipes are their increased rigidity and the inability to use them when transporting hot (more than +60°C) liquid. Polypropylene pipes are more resistant to high temperatures and are therefore suitable for transporting both cold and hot water.

These qualitative characteristics determine differences in the areas of their application.

Application of PVC pipes

| Scope of application | Qualitative characteristics of the PVC pipes used |

| Cold water supply system in apartment buildings and private buildings. | Pressure pipes made of unplasticized gray PVC are used, as they are strong, rigid and durable and can withstand strong water pressure. Wall thickness is up to 3.2 mm, and diameter is from 50 to 160 mm. |

| Separate areas of cold water supply or internal sewerage. | Gray plasticized PVC pipes are used; they are less durable with a wall thickness of 1 to 2 mm and a diameter of 30 to 50 mm. |

| Dishwasher or washing machine drainage system. | Gray corrugated PVC pipes are used - the simplest and cheapest, not durable, but they can be easily replaced. |

| Protection of electrical wires in internal and external electrical networks. | Corrugated PVC pipes are used; during their production, a self-extinguishing additive (anti-peren) is added, which ensures fire safety. They are very flexible and durable, which makes it possible to lay electrical cables inside wooden or concrete walls, in wet rooms or in swimming pools. |

| External sewer system. | Rigid orange PVC pipes with a wall thickness of 3 mm and a diameter of 100 to 500 mm are used. These pipes easily withstand weather temperature changes and soil loads at shallow depths. |

| External sewer system at a depth of up to 15 m. | Corrugated multilayer PVC pipes of orange color are used. Due to the large number of stiffening ribs, they can withstand soil loads at a depth of up to 15 m. |

| Septic tanks and drainage wells. | PVC pipes of the largest diameter and orange color are used. |

Application of polypropylene pipes

| Scope of application | Qualitative characteristics of the polypropylene pipes (PP pipes) used |

| Internal cold and hot water supply system in apartments and houses. | White PP pipes are used, they are easily connected by welding or through fittings, can withstand high pressure and are the cheapest of PP pipes. |

| Centralized and individual heating system. | Gray PP pipes are used; they are chemical and thermal resistant and airtight. |

| Drainage and watering system on the street. | Black PP pipes are used, which have the highest resistance to ultraviolet radiation, drying out and exposure to aggressive weather conditions. |

| Summer irrigation system for a personal plot. | Green PP pipes are used - the most unstable to internal water pressure, but the cheapest. |

| Internal floor heating system. | To resist high temperatures and water pressure, three-layer PP pipes reinforced with aluminum or fiberglass are used. |

When producing plastic pipes, an information line with technical characteristics must be applied to them using a laser for ease of use and installation.

The choice between PVC and polypropylene pipes depends entirely on the scope of their application and can be based on the quality characteristics given above.

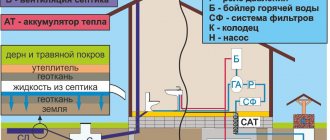

Which septic tank is suitable for the site: plastic or reinforced concrete

A modern sewer system in a private house will look correct if it is based on a septic tank. This option is chosen by the vast majority of homeowners.

In septic tanks, mechanical wastewater treatment occurs due to sedimentation, and only then due to the fact that bacteria living in the septic tank destroy organic matter in the absence of air. After settling and mechanically purified in septic tanks, the wastewater is sent either to filter devices.

LadomirModerator FORUMHOUSE

It is forbidden to pour effluent from a septic tank into a ditch; it is punishable and unhygienic.

The septic tank must have a bottom and be sealed. The construction of septic tanks is regulated by the standard for organizing autonomous sewage systems with septic tanks and soil underground filtration of wastewater - STO NOSTROY 2.17.176-2015. This document provides for the following distances of the septic tank from other objects on the site:

- to the house – 5 meters;

- to a well or borehole in areas with clayey soil or loam - 20 meters in areas with clayey soil;

- to a well or borehole in areas with loam, sandy loam or sand - 50-80 meters;

- to the side of the road – 5 meters;

- to the border of the site - 4 meters;

- to trees - 3 meters;

- to the bush - 1 meter;

- to a river or stream – 10 meters;

- to a pond or lake – 30 meters;

- to the underground gas main - 5 meters.

In the table, all septic tanks are divided into plastic and septic tanks made of concrete rings. For do-it-yourself sewerage in a private house, septic tanks made of reinforced concrete rings . They are the most budget-friendly, they are durable, almost eternal, can withstand heavy loads under soil pressure and are easy to install yourself. But such septic tanks are unacceptable when there is high water and high groundwater level.

Plastic septic tanks can also be installed in areas with high groundwater levels; they are lightweight, but many plastic structures are fragile, can be deformed during frost heaving of the soil and require anchoring. When buying a plastic septic tank, it is recommended to look at the internal partitions and stiffeners along the body - the more of them, the higher the rigidity of the product. Horizontal plastic septic tanks clean wastewater better, but vertical ones are more compact.

Like a cesspool, a septic tank must be periodically cleaned with a sewer truck, but if you choose the right volume, this will have to be done no more than once a year.

Calculating the volume of a septic tank is quite simple: it should be three times the daily volume of drainage. This also follows from the main book of all home engineers, “Engineering Systems of a Country House,” authored by V. Sinelnikov.

The constantly filled part of the well (hydraulic volume) should be equal to three times the daily inflow.

Vadim (spb) FORUMHOUSE Moderator

3 cubes is enough for 4 people. And it doesn’t matter, in my opinion, how the filtering is organized. The volume of the septic tank does not depend on it.

LadomirModerator FORUMHOUSE

According to the Standard, the volume of the septic tank must be at least 2.4 cubic meters, even if 0.5 people live irregularly.

Why do you need a slope angle?

In order for wastewater in the sewer to take dense particles with it, pipes must be laid at a certain slope. The angle of inclination must be set according to fixed, established SNiP standards. To reduce installation time or with the work of unqualified craftsmen, many end up with a sewer system that operates with irregularities or does not cope with the task at all:

- not paying attention to the fixed norm for setting the slope or when maintaining the slope angle at a value below the minimum, the operation of the entire system is disrupted. With such errors, water flow will be at a reduced speed. This will quickly clog the drain. The drain will need to be cleaned frequently. For example, when installing a toilet, measures to set the pipe slope in the correct position were ignored, then the remains of human activity will not be washed away thoroughly. They will begin to accumulate and decompose. This will lead to the rapid spread of an unpleasant odor throughout the living space;

- if the slope is significantly exceeded, then blockage cannot be avoided. Wastewater passes through communications at high speed, washing solid elements without taking it with it. This will lead to the accumulation of a fetid odor and spread throughout the house;

- If the established angle of inclination of the pipes is not observed, siltation of the main system will occur. The entire sewer system will stop working. An unpleasant odor will arise, and there will be a reason for replacement and cleaning;

- in an apartment building, in the absence of standards for setting the slope, a leakage or breakdown of communications may occur. All residents will have problems with drainage until the problem is resolved;

- plastic pipes installed in the wrong position will suffer from silting and blockages. Cast iron communications are susceptible to corrosion, which leads to leakage - all waste will penetrate into the basement, spreading a stench throughout the entire entrance.

Video on the topic:

Sewage slopes and their setting methods:

and video

How to choose the correct sewer slope:

Also, if there are no problems with corrosion during unsloped installation of plastic, then holes may appear in the cast iron pipe. It will begin to leak water and sewage into the basement.

Previously, in multi-storey buildings, sewers were not installed with a slope, which is why there were so many cases of flooding in an apartment on the first floor or a breakthrough of the entire sewer system.

Popular model: EKODIN 5

up to 5 people

recycling 1 cubic m. per day.

Max. dump 250 l.

Check prices

Your own home surrounded by nature, as an ecologically clean area, can be an ideal place to live. But this is only possible with careful preparation of all the necessary elements of comfort, which include sewerage.

You don't notice it when it is installed according to all the rules. But at the slightest violation, it can remind itself of itself with leaks and an unpleasant odor.

The most important task when installing a sewer system is the correct choice of pipes, the properties of which determine the final result of the work. On this specific issue, let us turn to the experience of specialists.

Main stages of work

Installation work is carried out in stages. Sometimes the order of events changes - much depends on the readiness of the premises and the specific layout.

But you still need to strive for the generally accepted order:

- Laying the outlet - a pipe connecting the internal and external systems. It passes through the wall, so it must be placed in a sleeve - a heat-insulated safety casing. There should be no connections or joints in the wall crossing area.

- Installation of a riser - a vertical pipe running through all floors and ceilings. Usually, 1 riser is installed, but if the length of the internal pipeline exceeds 10 m, then it is better to install a second one.

- Layout of pipes - bends leading to plumbing equipment. The diameter of the pipe leading from the toilet is the largest - 100-110 mm, the rest are 50 mm each.

And only after the installation of sewer pipes, the devices are connected, followed by testing of the system.

Recommendations for performing installation work:

Metal pipes and fittings have not been used for a long time. Cast iron was replaced by lightweight and practical polymers: PVC (gray), PP (light gray or white).

Plastic pipes have a perfectly smooth inner surface, excellent resistance to heat and aggressive substances. They are easy to handle and install due to their low weight.

No. 7. Size and diameter of sewer pipes

Before you start purchasing and installing sewer pipes, it is best to draw up a project where you indicate all the drain points and the type of plumbing equipment. This will help you figure out what diameter and length of pipes are needed. At this stage, it also doesn’t hurt to determine the number of auxiliary parts, which will depend on the number of turns and branches. Take into account the change in pipeline diameter in individual sections.

Depending on the type of plumbing fixture being connected, pipes with different diameters are selected:

- a sewer pipe with a diameter of 25 mm is suitable for a dishwasher and washing machine;

- for bathrooms, showers and kitchen sinks – 40-50 mm;

- for washbasin and bidet – 30-40 mm;

- for pipe routing – 40-50 mm;

- bends from the riser – 65-75 mm;

- the central riser and pipe from the toilet are 100-110 mm.

It is better to add a margin of 10% to the calculated length.

Pos

No. 2. Cast iron pipes for internal sewerage

Several decades ago there was no particular alternative to cast iron pipes, so they are widely found in old houses. Today, cast iron is being replaced by plastic, but is still used. Such pipes are made from gray cast iron by centrifugal casting. To protect the material from corrosion and make the internal surface smooth, the pipes outside and inside are coated with a bitumen compound. The diameter of cast iron pipes ranges from 5-15 cm, the wall thickness is 10-12 mm.

Advantages of cast iron pipes:

- durability. The service life reaches 50 years and often exceeds this mark. Some data suggests a longevity of 90-100 years;

- high strength and resistance to deformation. On the other hand, the material does not tolerate shock loads well;

- the ability to withstand long-term exposure to hot waste (from a washing machine or dishwasher, for example);

- resistance to temperature changes;

- fire resistance;

- environmental Safety;

- good sound insulation.

Surely, cast iron pipes would have remained among the leaders if not for significant shortcomings:

- the walls become overgrown with sediment over time. This is all due to the roughness of the material, which even with a bitumen coating cannot be completely eliminated. The process of overgrowing leads to a narrowing of the pipe lumen and a decrease in its throughput. Anyone who has seen what a pipe looks like after many years of use will never forget this terrible sight;

- heavy weight of pipes, which complicates transportation;

- complex installation, which is explained not only by the large weight, but also by the peculiarities of connecting pipe sections. In order for the sewer system to be airtight, it is necessary to correctly connect the elements. Usually they use the method of caulking or caulking using a heel;

- susceptibility to corrosion processes;

- high price.

Cast iron pipes are not used today to build a new sewer system, but they may be needed when existing systems are being reconstructed. At the moment, the use of cast iron pipes is also justified when arranging external sections of private sewers and intra-house risers.

When choosing, it doesn’t hurt to carefully examine the products and tap each of them. This way, it is easy to detect cracks and other defects that form when the manufacturing process is disrupted. A defective pipe does not have a long service life. Various types of fittings, plugs and sockets are produced for connecting cast iron pipes.

No. 5. Polyethylene sewer pipes

Polyethylene pipes are rarely used in the construction of internal sewage systems. Typically, either low-density polyethylene or cross-linked polyethylene . The first option can withstand a maximum of +400C, so it makes sense to use it only in places with cold drains. Cross-linked polyethylene is designed to operate at temperatures of 0...+950C; for a short time it can withstand temperatures from -50 to +1200C, so it is usually used. The material has the following advantages :

- high strength, wear resistance and flexibility;

- corrosion resistance;

- smoothness of the walls and almost complete resistance to the formation of growths;

- light weight;

- resistance to pressure changes;

- durability;

- flexibility and easy installation;

- relative availability in terms of price.

Minuses:

- fear of ultraviolet rays;

- Oxygen can pass through the material, which will damage the metal elements in the system. The manufacturer applies a special coating, but it is quite delicate, so during installation you must be extremely careful so as not to damage it;

- low abrasion resistance.

Technical means, materials

To create any sewer system you will need building materials and tools. Below are the most necessary ones.

Brief list of materials:

- sewer pipes. Types of pipes are discussed in more detail in the next paragraph.

- connecting elements (adapters, corrugated pipes, corners). Using these means, toilets, sinks, and other plumbing fixtures are connected to the drain or water supply system

- sealing agent. Silicone-based sealants can be used

- mixture for cement. Particularly useful when arranging external sewerage

- sand

- shovels. Shovels will be useful for the entire period of work, from initial marking to digging a pit for a well.

- buckets

- sharp knife

- keys, screwdrivers

- pipe cutter (hacksaw with fine teeth)

- clamps for fastening. When installing internal sewerage, clamps are indispensable

- roulette

- level

Three-section septic tank

Electrical tools that may come in handy:

- Bulgarian. Used for cutting metal. If metal pipes will be used during construction, the desired size can be achieved by cutting them

- hammer drill Communications inside the house will pass through the walls and flooring. Holes in them can be made using a hammer drill

- screwdriver Pipes will need to be fixed to the walls

The set of tools and necessary materials greatly depends on the scope of work and the type of sewer chosen. But the above, as a rule, always apply.

You have determined the type of waste disposal system, stocked up on the necessary tools, and you can move on to construction. Let's start with intra-house communications.

Projects of country houses for 6-10 acres: 120 photos, description and requirements | The most interesting ideas

How does a filtration well work?

A filtration well is the simplest and most compact of all filter structures that you can build yourself. Almost all owners of private houses would prefer a filtration well when installing a sewer system, but their installation is limited by a number of conditions:

- — moderate volume of wastewater (less than 1 cubic meter per day);

- — good filtering ability of the soil (For stable operation of the system, sand and sandy loam are needed; even black soil and loam are suitable, but with a predominance of sand). But the lighter the soil, the slower the well will silt up!

- — low groundwater level (below 3.5 m).

The FC can be made from available materials, from tires and bricks to large-diameter concrete rings, the main thing is that holes with a diameter of up to 50 mm are evenly made in the walls of the well. The total area of the holes is 10% of the total area of the well walls.

Unlike a septic tank, which must have a bottom, the FC does not have a bottom; it is placed on a gravel-crushed stone base with a height of at least 30 centimeters. The lower part of the well is covered with coarse river sand and gravel, and the height of the filter depends on the soil: if there is sand, then 25-30 cm, and if there is loam, then up to a meter. The size of the backfill fraction also depends on this: from 40 mm on sandy soils to 3-10 mm in loams.

The FC is buried to a depth of 2.5 - 3 meters, and the outside is also covered with a layer of gravel and crushed stone, the width of the layer is 30 cm, the height is up to the pipe that comes out of the septic tank. The outer backfill is covered with a geomembrane and covered with earth. The well must be covered with a lid with a built-in hatch.

.How this system works: the septic tank retains and partially dissolves “undissolved contaminants” from the toilet, feces, etc., and passes the rest into the filtration well. The liquid in the well slowly passes through the filter base and is absorbed into the soil; the organic matter that it contained is dissolved and processed by bacteria, “dying peacefully in a few weeks.”

AlexeyL Member of FORUMHOUSE

In addition to the septic tank itself, a “soil filter” is required, a structure that will take the clarified runoff below the freezing depth of the soil and distribute it over an area sufficient for absorption into the soil. Sometimes it is made in the form of 1-2 rings with a lid; The cross-sectional area of the ring works, but not on all soils this is enough for water to escape into the soil. It is advisable to do a soil absorption test before construction.

LadomirModerator FORUMHOUSE

The main thing is that the soil around the well is capable of receiving the amount of runoff you need.

The foundation pit is dug manually, and in order not to harm the filtering capacity of the future well, it is not raining and “trampling” on the bottom of the pit. If necessary, several filtration wells are installed in the autonomous sewage system.

How to choose fan pipes

What pipes to choose for installing a drain system in a house? We will try to figure out what needs to be taken into account in order to avoid mistakes and create a sewer system that will serve for a long time and without complaints.

First of all, it is important to understand what requirements such pipes must meet.

- Durability is an important factor. The sewerage system must work flawlessly for many decades, and if the pipes are fragile, then after a fairly short time you will again have to spend money on its arrangement. In addition, due to possible pressure on the pipe walls, fragile options can quickly become damaged, which will lead to leaks and even emergency situations.

- Resistant to chemicals and temperatures. Sewage is a very aggressive and sometimes quite hot environment. Therefore, good vent pipes should easily withstand these factors. In addition, it is desirable that they are resistant to UV rays and not afraid of mechanical damage.

- Smooth surface inside. It will ensure the longevity of the system without clogging. Rough pipes tend to accumulate sediment inside, which will lead to blockages over time.

- Ease of installation is an important factor, especially if you do everything yourself. The easier it is to install the pipe, the better.

Types of pipes and fittings for sewerage

When choosing pipes for drains, it is important to consider the conditions of their use. For example, to create internal and external systems, different types of products are used, which will have different properties

Likewise, different pipes are used in homes and businesses. Thus, all types of sewer systems can be divided into three groups - storm, external and internal. Each of them has specific requirements for the use of materials.

Now let's talk about the diameter of the pipes. It also depends on the conditions under which the products are used. For a system inside the house, pipes with a diameter of 50-100 mm are suitable; outside it is better to use larger ones - 110-600 mm.

Don't forget about soundproofing

Any pipes should not conduct sound well, which is especially important for those located inside residential buildings. Cast iron pipes are considered well soundproofed

But plastic conducts sound very well, and after installation it must be additionally insulated with foam or mineral wool.

It is very important to consider the load on the pipeline system. There is always internal pressure in the system, but it is important to take into account that for some reason it may increase, and the pipe must withstand short-term heavy load

Another important point. Pipes in the house should not be toxic. Otherwise they will be dangerous to use. Try to choose those that are made from environmentally friendly materials.

No. 4. Polypropylene sewer pipes

Polypropylene pipes today are actively used in the arrangement of heating systems, cold and hot water supply. The properties of a material strongly depend on its structure. Pipes made from a copolymer of propylene and ethylene ( PPR ) are suitable for internal sewerage; they can withstand temperatures up to +700C. the PPs type behave even better , which can easily withstand temperatures up to +950C and short-term exposure to even higher temperatures. Reinforced pipes will be more durable, and fiberglass reinforcement is considered optimal. The product labeling also indicates the operating pressure: for internal sewerage, PN10 (withstand 1MPa), but more often they take PN20.

Advantages:

- durability up to 50 years;

- resistance to corrosion and almost all aggressive substances (acids, alkalis and salts will not damage the material);

- high strength of pipes and connections. Polypropylene is stronger than polyethylene and PVC, it is more resistant to cracks, and joints are less likely to depressurize;

- light weight;

- an absolutely smooth inner surface, so there will be no problems with pipe overgrowing;

- resistance to high and low temperatures, which allows the pipes to be used in almost any conditions. The pipes are not deformed;

- relative ease of installation. The connection of individual sections is made with a special welding machine, which almost anyone can learn to work with;

- relatively low price, but polypropylene pipes will cost more than polyvinyl chloride pipes;

- polypropylene type PPs belongs to the group of flame-resistant materials.

Among the disadvantages of polypropylene pipes, one can note only temperature deformation, so they will either have to be insulated or equipped with compensators.

Installation of sewer system

Installation of sewer system

Now let’s answer the question of how to install a sewer system in a country house.

First of all, we will determine the location for the collection container.

And it doesn’t matter what it will be - a hole, a well or a plastic container. The optimal location is at the lowest point on the site. But keep in mind that if you chose the first two options and plan to clean the collection tank using a sewer truck, you will have to take care of the access road

But keep in mind that if you chose the first two options and plan to clean the collection tank using a sewer truck, you will have to take care of the access road.

Once the location has been established, we begin excavation work. Sometimes their volume is so large that an excavator has to be used. If you decide to do everything manually, then it is better to dig a hole for the container and trenches at the same time.

The depth of laying sewer pipes should be 10-15 centimeters greater than the freezing level of the soil. This is the law.

True, in some northern regions this figure can reach more than 2.5 meters. In such cases, you have to use thermal insulation materials or install a heating cable so as not to dig deep.

The depth of the pit for the collection tank will depend on the depth of the sewer pipes. The fact is that the sewer pipes must have a slope from the house towards the tank. It is 2-3 centimeters per 1 meter of sewer network length. And the further the collection is from the house, the deeper it will have to be buried in the ground.

For country sewerage, the optimal material for pipes is polymer. And their diameter should be 110 millimeters. Such pipes are connected with couplings. But if there are side circuits, for example, sewage from a bathhouse or swimming pool, then the connection is made with tees or crosses.

Before laying the pipes, the trench must be filled with sand, making a kind of cushion. However, you cannot change the slope.

Installation of tanks and sewer pipes

And a few finishing touches. It remains to connect the collection tank and sewer pipes, as well as two parts of the sewer system - internal and external. And now you can fill the pipes and containers with soil.

As you can see, the design of a country sewer system has a fairly simple scheme, but it is necessary to follow the rules for carrying out installation work.

And finally, let us recall those key points without which it is impossible to build a country sewer system. You will:

- Selecting the type of sewer network.

- The choice of collection container, on which the quality of operation of the entire system depends.

- The choice of materials from which containers, pipes, fixtures and additional products are made.

- Proper execution of the installation process and excavation work, especially maintaining the slope.

- Determination of the depth of groundwater and the level of soil freezing.

- Preparing the access road if you plan to use the services of sewage disposal companies for pumping.

Of course, these are not global things, but without them there is no point in talking about high-quality installation and uninterrupted operation of the country sewer system.

Summarize

Materials for sewer construction have many similar characteristics: immunity to aggressive environments, relative smoothness inside, strength. But at the same time, plastic pipes are always light and, in addition, elastic. Installation and docking are simplified. At the same time, pipes made of different plastics are easily connected to each other. Therefore, internal and external sewerage can be made from different, most suitable polymers. It is obvious that plastic pipelines are the future for both internal and external sewage systems.

These articles may also be of interest to you:

- Soldering copper pipes. Soldering restoration

- Plumber tools for soldering copper pipes

- Cold welding - eliminating pipe leaks without welding

- Selection and installation of a drainage system