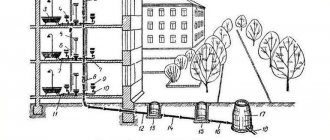

When building a country house, it is necessary to create a sewer system. This is necessary to discharge wastewater to a filtration field or to a septic tank. There are various designs in which wastewater moves both by gravity and by forced pumping of liquid. To do this, they use various fecal pumps for sewage – which one to choose is an important question.

Using fecal pumps to pump out sewerage

To pump out wastewater, two types of pumps are used - drainage and fecal. The difference between them is small, but important.

The former are used for pumping dirty liquids containing solid objects no larger than 5 centimeters in size. To protect the working part of the mechanism, a metal mesh is attached to the pump inlet.

Fecal water is noticeably different; it is a thick liquid that often contains fibrous clumps of wool, hair or fabric. They will quickly clog the screen and the pump will stop working. For this reason, a grinder is installed on sewage sewage pumps.

Design and principle of operation of a fecal pump

The main advantage of this small mechanism is the ability to move dense waste through a sewer pipe to a height of up to 7 m and a distance of up to 100 m.

Pump device

These are small but complex devices, the design of which includes:

- Frame. It is made of stainless steel, cast iron or plastic. Considering the operation of the mechanism in an aggressive environment, it is desirable to have a stainless steel case;

- Rotor and stator. Pump motor design elements;

- Shaft. Transmits rotation to the working body;

- Seals. Protects the inside of the mechanism from the ingress of aggressive substances;

- Working turbine. Pumps wastewater from the suction to the supply opening.

The mechanism is equipped with brackets necessary for attaching hoses and cables.

Materials

It is important to understand that the pump for pumping out fecal matter faces an aggressive environment. Therefore, the housing elements and its parts must be reliable. Depending on the manufacturer, the sewer apparatus is made of the following materials:

- Stainless steel.

- Plastic.

- Cast iron.

Plastic is used on budget installations. A drainage pump for sewerage made of plastic is relatively fragile and does not have high power. The most expensive device is made of stainless steel. But the high price is fully compensated by the quality and long service life. Cast iron is in the middle price category.

Of the listed materials, the best is stainless steel.

Operating principle and technical characteristics of the pump mechanism

Although this is a complex device, it works simply. When the turbine rotates, it carries wastewater under pressure into the sewer pipe, while simultaneously grinding solid inclusions.

Pumping wastewater under pressure is only necessary if plumbing fixtures are located below ground level (in basements or semi-basements). In this case, wastewater cannot flow from the collector into the septic tank by gravity; it must be pumped forcibly.

The daily volume of fecal water and the technical characteristics of the pump are important here:

- Productivity - the amount of waste that the mechanism is capable of pumping in 1 hour (for example, 100-200 l/hour);

- Power consumption - for use in a country house, a low-power pump is enough - no more than 400 W/hour;

- The height of the column (the pump is not at all below the soil level) or the immersion depth of the mechanism - for fecal pumps 15 m maximum;

- Mains voltage – in a private house, it is better to install pumps with an operating voltage of 220 V.

The characteristics of the equipment used for pumping fecal water are varied, but in each case it is possible to select the optimal parameters of the device.

Sewage pumps types/types/varieties

Although there are many different models of such pumps, they are all divided into several types:

Submersible mechanisms are made of durable materials; they always have a float mechanism for turning the device on/off. The pump has a sealed housing; all connections are equipped with gaskets that protect the inside of the device from exposure to aggressive environments. They are mainly used for emptying cesspools, but they are also suitable for pumping out storm drains. They are capable of solving many problems; a submersible fecal pump can even be used to drain a vegetable garden. They are installed at the bottom of the tank, secured to the suction pipe. The float switch is able to turn off the device in time, preventing it from being turned on after the container is empty (because of this, the pump may burn out). The pumped fecal water serves to cool the mechanism. A submersible pump is a very reliable device;

Semi-submersible mechanisms have a smaller outlet pipe diameter. It is capable of pumping wastewater with solid inclusions of maximum 15 mm. But they must be equipped with a device for grinding solids, for this reason they can be used for pumping out wastewater. Semi-submersible mechanisms are mainly installed on a floating platform, which is always at the same level with the pumped liquid. When this device operates, the bottom of the pump is always immersed in liquid, and the top part is in the air;

Surface pumps are placed outside the tank with fecal waste, for this reason they require a protective casing. These mechanisms are low-performance; they can pump wastewater with solid inclusions up to 5 mm in diameter. But the long service life and low cost of the device make it attractive to owners of private houses;

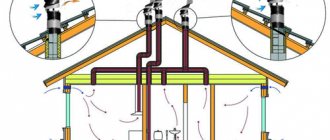

Domestic sewer stations are used for pumping waste fecal water; they allow solving several problems:

- Possibility of pumping out fecal water, along with water coming from other plumbing fixtures installed below the level of the sewer line. Such pumps make it possible to raise wastewater to a height of up to 15 m, thanks to this it is possible to install household plumbing in the basement or basement;

- The use of these devices makes it possible to transport wastewater and fecal matter over a distance of up to 100 m, without thinking about providing the necessary slope. There is no problem with seasonal soil movements, which can deform a long sewer pipe;

- The use of a grinder for large inclusions allows you to obtain a homogeneous mass of fecal waste, which allows you to lay a sewer pipe with a diameter of 40-50 mm;

- These pumps allow you to install a carbon filter, which will prevent unpleasant odors from entering the room.

To select a suitable pump, take into account:

- At what depth is the sewer system laid and are there any differences in the height of the laid pipe;

- Type of wastewater – composition of inclusions and temperature;

- The amount of wastewater that needs to be pumped;

- The need for automatic operation and a suitable way to control the pump.

Household sewage pumping units are small in size and do not require much space.

Feces grinders

First of all, you need to find out what materials need to be crushed:

- From the kitchen sink, where, in addition to fats, food debris gets into the sewer system, leading to clogged pipes;

- The washing machine and sink produce animal hair, hair and fibrous materials when washing fabrics. Combining with fats, they form dense blockages;

- Tampons, all kinds of napkins and paper end up in the sewer system.

All this waste must be processed by a shredder. This device works like a simple meat grinder. The device itself acts as an auger that moves the crushed material. Taking into account the characteristics of the waste being processed, the grids and knives of the mechanism are made from high-strength stainless and alloy steels.

Knives of several shapes are used:

- impellers with blades-knives;

- knife-like meat grinders;

- cylindrical scissors;

- cross secateurs;

- knives in the form of plates.

It is important that no stones or similar objects get into the shredder, otherwise the mechanism may break.

Selecting a fecal pump

To pump out sewerage, you need to choose a device taking into account several characteristics:

- Supply voltage, which affects the energy costs required for pumping wastewater. Usually in your own home you use a voltage of 220 volts, but you can also buy pumps designed for 380 volts;

- Power consumption for such a device, this characteristic should not be less than 400 watts. This directly affects the pressure of the pumped waste, which is necessary to overcome the resistance of the pipeline contents;

- For submersible pumps, the possible immersion depth of the device must be taken into account. And for external ones - the permissible length of the intake sleeve;

- The performance of the mechanism is important - the volume that can be pumped in a certain time. It should not be less than the calculated indicators of incoming wastewater. In most cases, 400 watts of pump power is enough to pump out 80-100 liters of wastewater per minute;

- Be sure to equip the device for removing waste with automatic on/off devices. Protection against engine overheating, short circuit, and electrical breakdown is required. It is necessary to provide for the installation of check valves that make the reverse flow of wastewater impossible.

It is important to consider the reputation of the equipment manufacturer. Now on the market you can find many fakes that copy equipment from reputable and well-known manufacturers. For this reason, it is necessary to study the source of origin of the pump and all quality certificates for the product.

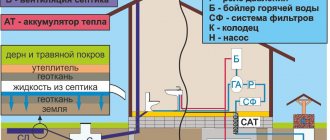

Sewage pumping station (SPS)

CNS is considered the most profitable option. This device for pumping out wastewater is made from durable plastic that can withstand an aggressive environment. The hydraulic tank is sealed, there is no need to worry about leaks. A submersible fecal pump is inserted inside the tank. Its task is to process waste that ends up in the sewer system and pump the wastewater further.

Installation of pump station

First you need to dig a pit to the required depth. So that when installing the container, there is only a hatch at the top. Compact the bottom of the pit well, add sand and crushed stone, and fill with concrete (10 - 15 cm). The result is a concrete pillow. It needs to be given time to completely harden, about 7 days. The pumping station is lowered into the pit prepared in this way. They do this strictly according to the level. Any deviation from the vertical should be avoided. Then a pump is installed in the container according to technology.

To ensure that the pumping station is properly secured from the outside, water is poured into the hydraulic tank. The outside of the water container is sprinkled with sand, not reaching the edge 10 - 20 cm. At this distance, turf is laid on the sand. When the station is securely installed, the water from the hydraulic tank can be drained.

The pipeline discharging wastewater is secured by soldering or welding.

Rules for using equipment

Every technically complex mechanism can quickly break down if used incorrectly. For example, the operation of a submersible pump after pumping liquid from a container. This type of pump uses pumped wastewater for cooling. If the drains run out and the pump continues to work, the engine will quickly burn out from overheating.

The same thing will happen if you use the equipment for other purposes. For example, it is dangerous to pump out drainage water with it. The reason is that there are a lot of hard stones in the pumped liquid. In the shredder, these particles will damage the knives, and the pump will no longer be able to work normally.

Before putting the fecal pump into operation, you must familiarize yourself with the operating rules. Violation of them may result in early termination of the equipment warranty.

Tips for use

In order for your household drainage pump to last as long as possible, it is important to follow several rules when servicing it:

- Once a month, remove the pump and check it for serviceability. For example, the quality of the pipe connection, electricity, etc.

- Check the blade mechanism from time to time.

- Household feces can become clogged with fat deposits. Therefore, it is recommended to rinse with hot water from time to time.

- Before lifting the pump, be sure to unplug it.

- Check the functionality of the automation once a week.

- Have an alternative power source, such as a generator.

- After carrying out maintenance, be sure to check the operation of the automation.

- Before starting the installation, clean water is connected and pumped. This will ensure that it is working correctly and correctly.

Main manufacturers of fecal pumps

This equipment is produced by many manufacturers. Common in our market:

Pedrollo pumps. Mechanisms of this brand are used for pumping very dirty wastewater. The most common are the VXm MC/MCm lines. Of these, the first ones are not very powerful; their operation requires power from a 220 volt network, the rated power of the pumps is 0.6 kW. These are the most common devices for pumping out fecal water in private homes. According to the instructions, it is allowed to pump wastewater with a solid element size of up to 35 mm. Technical characteristics of the equipment:

- voltage 220-380 volts;

- maximum liquid level to the bottom of the container – 40 mm;

- device productivity 15-66 l/hour;

- Pumps of this brand can be immersed to a depth of 8-22 m;

- the diameter of the outlet pipe is 1.5-2.5 inches.

Fecal pump Grundfos SEG. The unit is equipped with a grinder and is designed for pumping sewage, drainage water, and wastewater. It is capable of pumping wastewater over considerable distances, but the pipe size is limited to 40 mm.

Main characteristics of the equipment:

- body material – cast iron;

- the pump is equipped with an impeller adjustment system;

- 2 relays are installed to protect the device from overheating;

- used for pumping to a depth of 10 meters;

- the maximum permissible temperature of the pumped liquid is 40 degrees.

Sewage pumps Gillex. The company produces two types of pumps – Fekalnik and Drainazhnik, the names of which indicate their purpose. The permissible size of solid inclusions is 35 mm.

Main technical characteristics:

- productivity 160-260 liters per hour;

- immersion depth – 6-11 m;

- installation of a float switch.

Sulzer – pumps for pressure sewerage. This is a station for pumping fecal wastewater with its simultaneous processing into a liquid mass. Their advantage is that they are quick to install and get up and running. The station is equipped with a reliable check valve and a powerful solids grinder.

The Vortex fecal pump is designed for pumping wastewater with strong fibrous contaminants. Used for domestic purposes. Main technical characteristics:

- power 450-1500 watts;

- pressure 9-18 meters;

- productivity 16-24 cubic meters per hour;

- solid inclusions of 15-42 millimeters are allowed;

- permissible liquid temperature is 40 degrees.

Using a pump for forced pumping of sewage is often a forced decision that is influenced by the surrounding landscape.

Maximum pressure and lift height

How a sewage pump works depends on the pressure indicator, which determines the height of the sewage rising through the pressure network. But, in addition to the vertical section of the waste liquid movement, there is also a horizontal section of the outlet pipe.

A simplified calculation of this parameter looks like this: the horizontal distance must be divided by 10 and added to the length of the vertical section from the pump to the edge of the tank.

If calculations are made in accordance with all indicators, then it is necessary to take into account:

- the temperature of the liquid, its composition and the amount of impurities contained in it;

- pipe material and the degree of roughness of their internal surface;

- the amount of pressure loss after the wastewater passes through the shut-off valves;

- speed of fluid movement;

- Atmosphere pressure;

- pipeline diameter and much more.

All of the above parameters are taken into account by engineers when developing a sewerage system project. If you decide to do it yourself, then it is better to purchase equipment with a large margin of pressure and power.

Installation of a fecal pump

Installing a fecal pump is not a difficult, but responsible job; you can do it yourself. In difficult cases, if there is no necessary experience, it is better to invite specialists.

Pump installation

Before installing the equipment, it is necessary to prepare the installation site and connect the electrical panel. Sometimes it is necessary to additionally install a fecal pump in a separate room - in the kitchen or bathroom, and so on. The most important thing in this case is not to connect the devices to one electrical panel; for each of them you need to provide its own connection and its own input into the sewer system.

Important! Take the wastewater temperature into account. A dishwasher or washing machine in the kitchen requires the use of a pump that is designed to pump hot liquid.

When installing a fecal pump, you need to follow a few simple rules:

- connect the mechanism to a separate electrical panel;

- secure the mechanism well;

- an external fecal pump is mounted on the edge of a container with waste water;

- the submersible pump must be lowered directly to the bottom;

- semi-submersible pump - install so that the upper part is at the top and the working mechanism is lowered into the liquid.

Installing the device in a toilet is characterized by the use of a larger diameter sewer pipe, and it is necessary to install a pump with a grinder - it is necessary to grind toilet paper and feces. The mechanism should be located no further than 40 cm from the toilet.

After the pump is finally installed and connected to the electrical network, it is necessary to test the equipment and adjust the operation of the float switch according to the liquid level. Ev container is filled with water to the minimum level, this will be the shutdown point. After this, water is poured in until the pump switch is activated. If you notice noises or malfunctions in the operation of the equipment, it is advisable to eliminate them immediately. If there are no comments, you need to seal the well.

Submersible pumps

This type of pump is placed in the sewer with its entire body. It is lowered to the bottom of the tank or suspended on a strong rope. All elements of the units are made of cast iron or stainless steel, so that during their contact with an active and aggressive environment they do not quickly fail.

Submersible pumping equipment usually operates automatically. As the container is filled with liquid, a special float rises along with it. After it reaches a certain point, the installation begins to operate in pumping mode.

When the reservoir is empty, the float switch turns off the unit. In this case, dry operation is practically eliminated. A deep pump for sewage is usually chosen because it has high performance and the presence of a grinder. Its cutting elements are capable of grinding various coarse waste to sizes that are not dangerous for such equipment.

Almost all models of submersible units are sold with built-in grinders. Their rotating knives can easily cut through hard and fibrous particles, as well as paper.

How to choose a fecal pump for sewage

If you need equipment for pumping out wastewater, it is important to pay attention to several characteristics of the device when purchasing.

The mechanism will work for a long time if you take into account:

- required performance;

- sewer pipe diameter;

- total amount of wastewater;

- pump immersion depth;

- pressure;

- type of mechanism;

- pump power;

- additional options – chopper, liquid volume control;

- the manufacturer of the product.

Maximum head

This characteristic indicates the pressure that the pump can create. This is the second most important indicator of the effectiveness of the mechanism. It is measured in meters, as this allows you to understand to what height the pump is capable of pumping liquid. It is necessary to choose a pump so that its pressure is sufficient to lift the liquid to the required height. Greater pressure can only be achieved by using expensive, high-performance devices.

Suction/immersion depth

It is necessary to take into account the characteristic of the device, which depends on the location of the personal plot - the immersion depth. This indicator is determined by the purpose of the mechanism, and affects the ability to pump wastewater; it happens within 3-20 m.

Power

When choosing a suitable pump for pumping sewage, consider its power. This directly affects the performance of the equipment, the ability to pump out viscous substances containing solid particles and the energy costs during operation. This characteristic affects the pressure; the power depends on the manufacturer and model.

Working temperature

Any fecal pumps intended for domestic sewage are divided into 2 types:

- For cold wastewater - the liquid temperature does not exceed 45 degrees;

- For hot wastewater – liquid temperature up to 90 degrees.

When only cooled liquid enters the sewer, it is better to use models designed for cold water, but it is not prohibited to install pumps for hot water (but they are more expensive). These pumps are used in private homes. Hot water enters the sewer system from the washing machine and dishwasher and during emergency discharges of coolant from the heating system.

Automatic control

To control the pump when pumping out wastewater manually, you will have to turn it on and off yourself all the time, and this is inconvenient. Will be required to be near equipment frequently. It is better to purchase devices that include:

- A float is an element that determines the height of wastewater in a tank; it allows you to turn the equipment on and off in a timely manner;

- Thermal relay is a device that is triggered when the electric motor is significantly heated, this allows you to turn off the power to the pump in a timely manner, preventing overheating.

To reduce the risk of clogging of the pump with a grinder, manufacturers sometimes install a self-cleaning device for the mechanism that crushes large particles. This makes it possible to increase the service life of equipment without stops and interruptions in operation. Cleaning the chopper yourself further reduces the risk of motor overheating.

The most efficient and most reliable fecal pumps are devices with a metal body and working part. For this purpose, stainless steel and cast iron are used. Plastic products cost less, but when working in an aggressive environment they will fail faster.

Surface Models

The easiest installation is for surface-type sewage pumps. The device itself is placed on the ground, and only the hoses are lowered into the container.

Surface models of fecal or drainage pumps are attractive for their mobility

The most serious drawback of such models is the phenomenon of cavitation, which occurs when pumping liquids from great depths. Cavitation is the saturation of the pumped medium with air bubbles. If such a mass gets into the working part of the pump, it will fail. This is why it is not recommended to use surface fecal pumps at depths greater than those for which they are intended. In the case of pumping a septic tank or storage well, the use of such models is justified. Their depth is small, and even not the most powerful motor will cope with the task. You just need to choose the right power of the unit.

| Name | Type | Power | Lift/pressure | Performance | Notes | Price |

| Caliber NBC-380 | self-priming | 380 W | 25 m | 28 l/min | No idle protection | 30-35$ |

| Whirlwind PN-370 | self-priming | 370 W | 30 m | 45 l/min | No idle protection | 38-42$ |

| Gilex Jumbo 60/35 N | self-priming | 600 W | 35 m | 60 l/min | No idle protection, maximum particle size 0.8 mm | 104$ |

| Gilex Jumbo 70/50 P 3701 with ejector | self-priming | 1100 W | 50 m | No idle protection, maximum particle size 0.8 mm | 115$ |

Please note that all surface pump models are designed to pump water. Only some of them can pump viscous liquids, and this must be indicated in the description or data sheet. The disadvantage of this equipment is that it requires a homogeneous environment - the maximum particle size that they are able to pump is 0.8 m. The price is undoubtedly attractive, but among submersible models there are very inexpensive ones - for example, Gilex and Ebara. The latter also have a stainless steel body and a wide range of models with different pressure and performance.