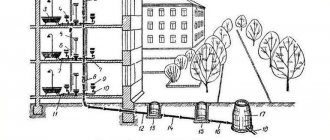

The chimney pipes that we see from the street, rising above the roof of the house, are only a small part of the entire complex structure, which is responsible for processing combustion products and removing smoke from the room. It does not matter what fuel you use for heating equipment; in any case, it must be equipped with a special system for the release of combustion products. It is very important to have an idea about the structure of the chimney system in your home, since this knowledge will help you use the gas boiler correctly and competently.

The chimney for a gas boiler must be designed in accordance with the requirements of SNiP II 35, and SNiP No. 2.04.05 “Design of smoke and ventilation ducts”.

It is worth remembering that everyone must have a SEPARATE disposal of processed combustion products from gas boilers, stoves, and other gas household appliances!!!

No. 1. Requirements for ventilation pipes

It’s good if the ventilation system is installed during the construction of the house, because in this case the air ducts can be hidden and they will not disturb the aesthetics of the room. Channels can be laid with bricks, but this is a long process. Today, special ventilation pipes are mainly used, which simplify and speed up the entire installation process.

Note that most often ventilation ducts in a private house are necessary to remove air . However, if it is necessary to take all air movements under maximum control, forced supply and exhaust ventilation . This is a complex system, but in this case, pipes will also be needed to bring in fresh air from the street .

The choice of duct material and its diameter depends on a lot of factors. First of all, this is the type of room and the characteristics of the air that needs to be removed (temperature, chemical composition, etc.). Be that as it may, and whatever option you choose, there are a number of requirements that the air duct must meet:

- perfect tightness;

- the ability to ensure the free passage of air flow of a specific volume and at a given speed;

- safety for human health (non-toxic) and minimal noise level during the passage of air masses;

- if the pipes are not hidden, then decorative qualities are also important.

Ventilation pipes are made from metal and plastic , with the latter being increasingly used today. Products with round and rectangular cross-sections and different sizes are produced.

Individual sections are connected using bends, connectors, tees, flanges and other elements. Thanks to the widest selection of pipes and connecting products, you can build a ventilation system of any complexity. Residents of Moscow and the region can find everything they need to organize ventilation in the GdeMaterial online store. Ventilation is installed for many years, so it is better to contact a trusted supplier who provides assistance in selection, competitive prices and prompt delivery.

Recommendations for installing a natural ventilation system

A system of this type must be installed in compliance with a number of technical requirements.

In order for natural ventilation to work efficiently and correctly, before its installation, the system is designed, a number of necessary calculations are carried out, on the basis of which the equipment is selected. At the initial stage of installation work, all elements of the system are fixed with special fasteners, and then grilles and supply valves are installed, which will ensure the flow of fresh air masses in the required volume. The installation of natural ventilation is completed by installing fans on the ventilation duct grilles; the fans will blow out contaminated air masses from the interior spaces of the room.

Note: do you want to achieve the highest quality and fastest air exchange in the room? When installing the system, use round-shaped pipe products.

No. 2. Metal pipes for ventilation

This group includes pipes made of stainless steel, galvanized and black steel . General advantages include the following qualities:

- resistance to high temperatures, pressure and aggressive environments;

- a wide choice of shapes and sizes, in which metal pipes are significantly superior to plastic ones;

- rigidity and strength;

- durability.

High weight, considerable price and complexity of installation are the reasons why many prefer to abandon metal pipes in favor of plastic ones. In private homes today, almost no one uses metal air ducts anymore - there is no need for them. They are more suitable for organizing ventilation in industrial premises.

To the general disadvantages, let us add the disadvantages of different types of metal pipes. Although galvanized steel The coating, of course, delays the onset of corrosion and slows down its development, but does not completely eliminate it. The weakest points in galvanized pipes are the joints. It is in these places that rust appears first, and as soon as it begins to develop, an unpleasant odor is formed. If we are talking about residential premises, then this is a very serious drawback.

Stainless steel behaves much better in operation. It is more resistant to corrosion and therefore more durable. This material has increased fire resistance and is suitable for transporting aggressive air masses. For production this is an ideal option, but at home it is justified to use massive metal pipes only if you got them for free and will be hidden in the wall.

All metal air ducts have one more unpleasant property. Air passing through such a pipe and forming currents can cause significant noise. To reduce the amount of air turbulence, it is necessary to minimize the number of turns of the pipe and avoid 90-degree angles. In addition, the metal walls of the channel will resist the passage of air flow.

Services

Estimate documentation

The local estimate for the chimney is drawn up according to the “Methodology for determining the cost of construction products on the territory of the Russian Federation” - MDS 81 - 35.2004, put into effect on 03/09/2004...

more detailsChimney demolition

Before the start of demolition and dismantling of the chimney, a set of preparatory measures is carried out in accordance with paragraph 6.9 of SP 48.13330.2011.

The preparation of the territory and workplaces, warehousing, temporary tran… read moreOOS development

The purpose of developing the environmental protection section is to determine the impact of an existing or newly built boiler house, as well as after technical re-equipment, on environmental pollution, as well as to develop measures for ...

moreChimney installation

We provide quick and high-quality installation of boiler room chimneys of any type and height.

All work is carried out under the control of engineering and technical personnel, the work project and is accompanied by a warranty for a period... moreManufacturing

Chimneys are manufactured and installed according to individual projects, which include measures to ensure safe and durable operation.

We manufacture chimneys of various types: one... more detailsLight barrier

The light barrier is designed to warn aircraft of danger at night or in poor visibility.

Signal lights are installed on pipes on one or several tiers in height depending on the height of the building... moreAerodynamic calculation

Aerodynamic calculation determines the throughput of the structure at a minimum value.

The throughput must have such an indicator that will allow hot gases and other substances to freely pass through the chimney and escape into the atmosphere... moreStrength calculation

Optimal stability and strength are calculated taking into account several factors.

divided into two categories: -external (seismic activity, soil stability, amount and intensity of precipitation, wind rose); -operational (weight of the structure, number… more detailsDevelopment of QOL

KZh - working documentation for the manufacture of monolithic reinforced concrete structures at the construction site.

In the KZH section, all reinforcement components of reinforced concrete structures are studied in detail, dimensional drawings of the formwork, specifications of materials are provided... moreThermal insulation of chimney

Poor quality insulation or its complete absence leads to premature destruction of the gas outlet trunk.

There are several reasons that have a particularly strong impact on the integrity and functionality of the chimney. more detailsKM development

The company's experienced specialists are ready to develop design documentation for the CM stage (metal structures) in the shortest possible time.

We can develop both stage P (project), necessary for passing the examination, and stage P (working). more detailsKMD development

KMD design is carried out on the basis of KM calculations and represents the development of detail drawings of the designed metal structures.

This set of construction documentation is necessary for the manufacture of metal structures, t... more details

No. 3. Plastic pipes for ventilation

Plastic ventilation pipes have replaced galvanized ones from residential premises and are already actively used in some industrial buildings. Such air ducts are made from polyvinyl chloride (PVC), polyurethane and polypropylene , and the last two types have not become widespread. When people talk about plastic ventilation pipes, they usually mean PVC products.

Main advantages:

- price. Plastic pipes cost much less than metal ones;

- light weight, ease of cutting, easy technology for assembling and fastening pipes allow us to talk about maximum ease of installation;

- resistance to corrosion and rotting;

- smooth walls allow air flows to pass as freely as possible;

- excellent noise insulation, which is important;

- durability;

- nice appearance, so if you can’t hide pipes behind walls or ceilings, they won’t spoil the picture;

- in terms of the range of possible sizes, plastic pipes are, of course, inferior to metal ones, but in the vast majority of cases the existing choice will be enough to equip even the most complex ventilation system. Plastic pipes are available in lengths from 3 to 12 m, cross section from 16 to 1600 mm.

The main disadvantage of the material is its inability to withstand high temperatures. PVC retains its original performance qualities at temperatures not exceeding +800C. If we talk about ordinary home ventilation, then such temperatures never exist there. If we are talking about removing hot air, for example, from a fireplace or in a production environment, then you will have to make a choice in favor of a metal analogue.

A few opponents of plastic pipes blame the products for their low strength. It would be foolish to argue with the fact that plastic is softer than metal, but ventilation pipes, as a rule, are installed in a hidden manner, so the impact on them from the outside is minimal, which means that less strength cannot in any way affect durability.

Literature

Shishkov I.A. etc. Constructions...

Information is provided on the designs of furnaces and chimneys, methods of their construction, equipment and construction mechanisms used in construction, building materials, working time costs and principles of organizing industrial construction...

moreRichter L.A., Knyazev A.M. Sun…

This textbook contains sections of the course “Auxiliary installations, equipment and pipelines of thermal power plants” on ash collectors, air protection issues and chimneys of thermal power plants, written by professors...

moreZach R.G. Boiler installations

The book is a textbook on the course “Boiler installations” for students of higher technical educational institutions.

The introduction examines and describes the general diagram of the boiler installation and gives basic definitions. The first part of the book is dedicated to… read moreAbdrakhmanov N.Kh. (ed.) About...

Industrial safety of industrial chimneys and ventilation pipes: a collection of scientific papers based on materials from a consulting and methodological seminar, [city.

Ufa, Republic of Bashkortostan], June 19, 2008 / Ex. on technological and environmental science… read moreZakharov I.V. Gas duct repair...

The book describes the organization and technology of repairing metal, brick and reinforced concrete gas ducts and chimneys of power plants.

The mechanization of repair of gas ducts and chimneys is considered. Information on safety precautions and fire safety... read moreParkani D. Chimney pipes…

The book by the author of the Hungarian Republic examines traditional and modern designs of chimneys for household stoves.

Their structure and operating rules are described. The main attention is paid to the issues of pipe laying and repair. For a wide range of… read moreBuilding Calculation Guide...

Recommended for publication by the section of the dynamics of structures of the scientific and technical council of the TsNIISK named after.

Kucherenko. Guide to the calculation of buildings and structures for the action of wind. - M.: Stroyizdat, 1978. . . . With. /Center, scientific research. inst st... more detailsMethodology for calculating smoke…

The book summarizes the experience of specialized expert organizations and provides the following: - methods for calculating the bearing capacity and service life of industrial buildings and structures to ensure industrial safety expertise;

- I... read moreElshin A.M. - Chimneys...

CHAPTER 1. Classification and main elements of industrial chimneys Classification of pipes by technological purpose and main structural material A classification of pipes by technological purpose and main design is given...

more

No. 4. Corrugated ventilation pipes

Ventilation pipes can be divided into two large groups:

- hard;

- corrugated.

The former keep the shape given to them at the factory, the latter, due to the presence of numerous ribs, can take on virtually any shape. Naturally, the installation process is greatly simplified, because there is no need to use all kinds of connecting elements, but not everything is so simple.

The main advantages of corrugated ventilation pipes include:

- flexibility and elasticity. The product can be bent at any angle and given the desired shape, and this is an invaluable quality when it comes to installing ventilation in difficult areas;

- strength;

- ease of installation;

- there is no need to use tees, adapters and other auxiliary elements.

It makes no sense to build the entire ventilation system only from corrugated pipes. Of these, only those parts of the air ducts are installed where, if rigid pipes were used, too many turns and connections would have to be made. Everyone knows that the more elbows, the worse the air will flow, but a smooth bend in terms of aerodynamics is much better than an angled turn, so a corrugated pipe is chosen between two evils.

Why is corrugation used only on short, complex sections ? Because it has many disadvantages :

- The ribbed surface worsens the air flow, slowing it down and reducing the efficiency of ventilation. If this is not particularly noticeable in short areas, then in long areas the effect will be impressive;

- the appearance of vibrations and noise with a consistently strong air flow;

- difficulties during fastening.

The fact that corrugation is not used on long sections is confirmed by manufacturers who do not produce connecting elements for this type of pipe.

Corrugated pipes can be:

- aluminum , more precisely, made of multilayer aluminum foil, they are slightly heavier than plastic, more susceptible to condensation, but tolerate higher temperatures;

- plastic pipe It is made on the basis of polymers that are reinforced with aluminum. Such products are lighter, less noisy, but will not withstand high temperatures.

Basic rules for installing a chimney

- The installation of a gas boiler should only be carried out when all the rules for installing a chimney are observed.

- It is necessary to ensure the correct selection of chimney parameters, on which the further operation of the gas boiler depends.

- It is important that all installation work is carried out by highly qualified workers, while observing all fire safety rules.

- All manufacturer's recommendations must be followed.

- It is necessary to choose the diameter of the chimney duct the same diameter as the device itself or perhaps a little larger.

- The air flow in the chimney duct should have a speed of 10-25 meters per second (NPB-98).

No. 5. Ventilation from sewer pipes: is it possible or not?

For a domestic person, the thirst for savings is probably in his blood. Someone once noticed that sewer and ventilation pipes are made from the same PVC, but for some reason the air ducts are several times more expensive. And since the products are the same, why pay more? Surely it is possible to adapt sewer pipes for air removal? Or is it still impossible?

Two factors usually prevent the use of plastic sewer pipes in the ventilation system:

- discrepancy between the diameters of ventilation and sewer pipes;

- There is information that plastic used in sewer pipes releases harmful substances.

Indeed, sewer and ventilation pipes do not match in diameter. Difficulties can be avoided when arranging ventilation from scratch. If you immediately lay a ventilation duct everywhere from sewer pipes, then there will be no problems. Difficulties arise when it is necessary to connect the ventilation corrugation to such an air duct. It will also not be easy to expand an existing ventilation system made from conventional ventilation pipes using a section of sewer pipe. But craftsmen find a way out here too, hermetically connecting sections of pipes of different sizes with tape. They believe that a narrowing of 10 mm will not affect the efficiency of ventilation.

The rules for constructing a ventilation system say that switching to a different pipe diameter is not recommended, but a smooth transition, without the so-called "steps". It can be quite difficult to provide this.

As for the theory about the toxicity of plastic, there is no substantiated evidence for it. However, even the most cautious people in this regard safely use sewer plastic to organize exhaust ventilation.

When choosing sewer pipes for building an air duct, remember that in this case hidden installation is a necessity.

Selecting the required design

When purchasing pipes for ventilation, you need to take into account that they should have a diameter smaller than the opening of the hood itself. If we neglect this rule, the noise level during operation of such a system will be much higher, and the load on the motor will also increase and, as a result, the productivity of the system will decrease.

It is also worth considering that 1 rotation of the exhaust pipe by 90° reduces the functional characteristics of the system by 10%. If the bend exceeds the size of a right angle, this may lead to a complete failure of the structure due to the fact that the outflow of air will be disrupted.

To cope with backdraft, the design provides for the installation of a valve that regulates the air flow and prevents it from circulating in the opposite direction. To ensure proper operation, the rotary axis is mounted in a vertical plane. Air is usually exhausted through the roof or wall. It is allowed to use a combined grille that has holes for normal ventilation.

According to technical rules, the optimal length of the air duct is 3 m. Each subsequent meter reduces the performance of the structure by 10–15%.

The outlet of the ventilation duct must be located vertically; for this, the pipe is often routed through the roof

No. 6. Form and method of production

Ventilation pipes come in the following shapes:

- round and oval , they are easier to manufacture, have better aerodynamics, and are used more often in industrial buildings;

- square and rectangular They are more often used in houses and apartments, since they are easier to install, and they use space more efficiently. If the ventilation ducts are not covered by anything, then rectangular pipes in the color of the walls will be minimally noticeable. Minus - worse aerodynamics.

Round pipes are spiral and straight-seam , square pipes are only straight-seam. Spiral pipes are considered more rigid, but they are also more expensive.

The pipes are attached in increments of 1-2 m; if the distance is made larger, you may encounter sagging and disruption of the ventilation system. Keep in mind that if there is a significant difference in temperature inside the duct and outside, condensation may form. For example, in winter, heated air is discharged through the ventilation duct, and if it passes through an uninsulated attic, condensation will appear on the walls, which, with constant influence, reduces the durability of the system. The solution is to insulate the ventilation pipes yourself or buy already insulated products.

System for removal of combustion products

To heat private houses, gas water heaters are often used, which are connected to ventilation to remove combustion products. Here we will not talk about how to make such a system correctly, because in this case, amateur performance is a big risk not only to health, but also to human life.

If you incorrectly calculate the draft, you will end up with an ineffective system that throws combustion products, such as carbon monoxide, into the room. Entrust this matter to a specialist to protect yourself and your home.

Conclusion

The ventilation system is a necessary part of most country houses, cellars and other structures. In order to correctly design such a complex structure, it is necessary to have certain knowledge and construction experience, because a poor-quality ventilation system often completely loses its meaning, so sometimes it is worth using the services of specialists who have been doing this for many years.

A system built by professionals will always differ in its efficiency from a home-made one, especially saving on professional work in organizing the removal of combustion products is out of place.