Almost every chimney that has been in use for several years will show signs of water damage from the brick joints to the cracked base. Chimney leaks are especially common, but not everyone knows why liquid comes out of the chimney. Most often, condensate flows and collects on the internal surfaces of the smoke exhaust duct. This becomes a source of destruction of gas ducts. Owners of gas equipment and wood boilers are equally faced with this problem. Before you decide what to do to fix it, you need to understand why water is flowing from the smoke ducts.

Causes of chimney leaks

Condensation occurs during cooling of flue gases containing water vapor and other chemical elements. In some cases, so much moisture accumulates on the internal walls that it turns into drops that flow down the pipe. If there is severe frost outside, the resulting condensate freezes, and when defrosted, the water again flows through the channels.

The sources of liquid formation are explained by the following factors:

- Absence or missing thermal insulation of the chimney system. If a pipe section in the attic or protruding above the roof freezes, the flue gases in this section will begin to condense due to a sharp temperature difference.

- The roof is leaking due to leaks in the roof covering near the chimney.

- Incorrect chimney installation. Exorbitantly long or narrow spans, a huge number of turns or other clumsy errors made during the design lead to the fact that the exhaust gases move through the channels for an infinitely long time and cool.

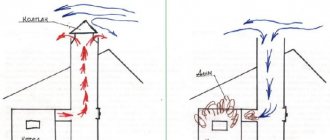

- An extremely powerful or weak vacuum also affects the formation of water in the smoke duct. When the draft is poor, the combustion of the fuel is also of poor quality, and therefore, the flue gases leave the boiler at a low temperature. The dew point in this case will be located in the smoke exhaust channels, and not outside its boundaries. With powerful draft, air masses partially fly out through the chimney, bypassing the combustion chamber and not taking part in the fuel combustion process. The moisture in the air will also, in turn, begin to condense in the smoke ventilation system.

- A similar problem is possible if the chimney is clogged, the use of raw fuel and other reasons. In any case, when water flows from a pipe, you should not put off fixing the problem, as this phenomenon can lead to dire consequences.

- Use of low-quality mortar and poor masonry. Incorrect chimney size. If it is too large for the device, the flue gases will condense. For wood-burning boilers, this means excessive creosote build-up, which can lead to a fire in the chimney. For gas appliances - accumulation of moisture in the system, which can lead to deterioration of the masonry and the entry of flue gases into the house.

The leak may be due to incorrect installation of the chimney

Why does condensation appear?

Condensation in the chimney pipe can form for the following reasons:

- The chimney pipe is clogged. The accumulation of blockages leads to a decrease in draft, which is why the heated gas does not move through the pipe as quickly as it should. As a result, it interacts with air, which leads to condensation.

- Temperature difference when gas exits. In winter and autumn, the temperature inside the chimney is quite low. When heated gases rush into it, a wet sediment forms.

- Significant fuel moisture. To heat a private home, it is recommended to use well-dried firewood or other types of fuel. Otherwise, when exposed to fire, internal moisture begins to evaporate, followed by its settling inside the chimney.

- External influences. This mainly happens due to precipitation if it has the opportunity to get inside the chimney.

It is important to know how to get rid of condensation in a chimney pipe. These problems in the chimney pipe are eliminated by cleaning it, insulating it or protecting it from precipitation. The method is selected depending on the identified cause of this phenomenon.

Possible consequences of the problem

Water has a powerful destructive ability. For brick flues, condensate can freely seep into both small cracks and large crevices. During temperature surges, water expands, thereby contributing to the destruction of the brickwork. If such violations are not corrected in a timely manner, then with a high probability it is possible to predict the complete destruction of the pipes and the need for a major overhaul of the entire system. Such condensate, falling down through smoke channels and down wells, destroys in its path not only smoke channels, but also the surfaces of boilers, stove structures and fireplaces.

Owners of stainless chimneys should not relax either. Since such gases contain compounds that form acids and alkalis with condensate, which are so aggressive that they can even damage stainless steel. The presence of water in the chimney system impairs draft. Due to this, the exhaust gases cannot be completely removed through the pipe and enter the room. Such a dangerous phenomenon can be a source of carbon monoxide poisoning for households; therefore, it is not permissible to neglect this phenomenon.

A reliable and simple solution can be waterproofing the external surfaces of chimneys, but if the chimney system was not installed correctly, then more serious measures will need to be taken.

How and with what to seal the gap between the pipe and the roof - different options for different materials

Installing a chimney is usually not a difficult process, however, in some places, such as floor crossings, some difficulties may arise. An important point is to ensure proper waterproofing. We will talk about this and other nuances related to how to seal a chimney pipe in this article.

Even if the pipe is placed as tightly as possible on the roof, minor gaps will still remain. When it rains, moisture will constantly enter the attic through them, which over time will lead to damage to the roofing structures. This is why roof pipe sealing is so important.

Methods for eliminating leaks at the junction of the chimney and roof

If, during the period of natural precipitation, liquid flows down a chimney or flue, then the prerequisite for the creation of leaks is damage to the insulation at the area where the chimney exits the roof. In cases where the roof is leaking close to the pipe, it is possible to eliminate the leak using the following options:

- Laying bitumen tape.

- Placement of a sealing collar made of heat-resistant rubber materials.

- Installation of an iron apron. Before you make it, you need to decide to purchase a finished product in a retail chain or make it yourself.

Bitumen tape

Making an apron from bitumen tape is a very simple and effective method to eliminate a leak in a pipe or chimney at the point of exit from the roof.

To carry out the sealing procedure you will need:

- Bitumen tape;

- large roofing scissors;

- metal brush;

- roofing gas burner.

Work procedure:

- An iron brush is used to clean the area of the chimney roof near the chimney and the bottom of the chimney.

- Use moistened rags to collect fragments of debris and dirt.

- At the junction of the pipe and the roof, a piece of tape insulation is laid with a layer to the bottom.

- Using a burner device, the tape is heated and pressed against the roof plane and pipe.

- For strength, the apron can be secured with a board or block.

Bitumen tape - a means to eliminate chimney leaks

Rubber cuff

Construction stores suggest using Master Flash rubber aprons or Wakaflex waterproofing tape.

Master Flash is a flexible rubber penetration in the shape of a stepped funnel, with an aluminum reinforced mesh in the middle. It is used for roofs with different slopes and all kinds of roofing coverings. The rubber product thoroughly protects the construction gap from water ingress. In order to accurately attach the apron to the pipe, it is heated and cut to the required diameter. On the roof it is secured with self-tapping screws, and attached to the pipe using an iron clamp.

Wakaflex is a rubber product in the form of tapes on an adhesive base. It is used to isolate the joints of soft roofing and chimney walls. The internal area is reinforced with reinforcing aluminum mesh. It has good extensibility, can take on any configuration, and is simply fixed on the slope. Vakaflex is used in combination with decorative collars.

Laying technology:

A hole is made at the top of the cuff, with a diameter slightly smaller than the chimney. The prepared cuff is put on the outer part of the smoke duct and goes down to the roof level.

In order to eliminate the possibility of a secondary leak, you need to apply sealant at the point of contact between the roof and the cuff. Certain types of cuffs are difficult to glue to the roof; they are allowed to be screwed to the roof with self-tapping screws, but not for tile and slate surfaces.

Metal apron

If there is a roof leak in the pipe area, installing an iron apron will be a safe way to eliminate the leak:

Metal apron installation technology:

- An apron is made from an iron sheet, the dimensions of which are suitable for the outlet chimney. You can also purchase the finished product in a retail chain.

- The upper section of the part is secured to the pipe using a crimp clamp.

- The lower part is fixed to the roof with self-tapping screws.

- In order to ensure greater density, the lower section of the product is strengthened over the roofing material, and the upper section is placed under the sheathing.

Sealing with mortar

To seal the gap between the chimney pipe and the slate or tile roof, use moisture-resistant cement mortar and a decorative collar. This is the most affordable way to insulate the attic and rafters from moisture with your own hands. This requires dry mortar, water, a mixing container, steel corners and a collar. Installation work is carried out in the following order:

- The gap between the roof and the outer wall of the pipe is lined with stainless steel corners. If the chimney is oval or round in shape, you can use a rubber seal with an adhesive backing.

- A decorative collar made of galvanized steel is put over the chimney head and secured with self-tapping screws.

- A pre-mixed viscous solution is poured into the gap between the collar and the pipe and allowed to harden for 1 day.

- After a day, check the quality of the filling and the degree of hardening of the solution. A surface for liquid drainage is made from a sheet of sheet steel. To do this, a hole is cut out in it, the diameter of which corresponds to the size of the collar, put on the head and fixed with self-tapping screws.

Important! To ensure that the structure is reliable and does not collapse during the first serious downpour, high-quality waterproof cement is used. Otherwise, cracks will appear on it, through which water will leak into the rafter frame.

Prevention measures

Moisture in any chimney is a huge problem, and as a result, modern smoke exhaust design contains many techniques to combat it. However, none of the options is considered flawless, and all chimney systems require maintenance and careful inspection before the new heating season.

Prevention consists in installing a system to prevent moisture from entering the chimney, for example a cap. Next, during the annual inspection, the integrity of the pipes and connections is checked. In addition, you will need to perform annual maintenance of the smoke ventilation system:

- Cleaning chimneys, channels and wells.

- Remove leaves from gutters.

- Repair of a faulty gutter near the chimney.

- Trimming trees near the pipe to prevent rain and dew from damaging the masonry.

- Check for drainage problems.

- Repair any leaks between the roofing material and the chimney.

Cleaning the chimney is included in the measures to prevent chimney leaks.

In fact, in order to protect the chimney, it will not take much time and money, but it will save significant money and help preserve the health of the residents of the house. The most effective method of protecting against moisture ingress is waterproofing the pipe, which will extend its service life for many years.

Seal gaps between chimney and slate roof

Sometimes the question arises of how to seal the gap between the pipe and the slate.

Related article: How to make a barn roof with your own hands

The technology provides the following sequence:

- First, a round hole is cut in the steel sheet that will be needed to finish the ridge.

- Next, a ring of sheet asbestos cement is placed on the pipe.

- For absolute sealing, so that in the future there will be no problems with the leaking pipe on the roof, the joint between the pipe and the roof is sealed with an asbestos cement solution (proportion 1:2).

- In addition, the same solution is used to fill the gap between the chimney pipe and the slate sheet. To do this, you can temporarily make a limiter out of cardboard.