Causes of leaks in the heating system

Depressurization can be caused by the following:

- Mechanical impact. Trying to move the battery or wall mounts, a strong blow.

- Factory defects or low quality materials. Most often, defects occur on threads or taps.

- Violation of installation or operation rules.

- Deterioration of the heating system.

- Depressurization of connections due to temperature changes.

- The use of antifreeze that causes disruption of joints.

Attention!

One of the common causes of leaks is an increase in coolant pressure. If this can be proven, the management company must take responsibility for the leak.

How to choose American taps for central heating radiators

When choosing fittings for connecting heating radiators, attention is usually paid to two points - the quality of the product and its technical condition.

The taps for installation in the battery are selected depending on the type of radiator and the manufacturer’s recommendations are taken into account. The correct choice depends on taking into account the size of the mounting hole in the battery, the type of thread and the diameter of the pipes used in the system.

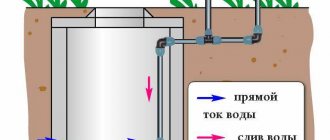

To connect to the system, straight and corner fittings with American females are used. This makes it possible to optimally select the installation option. In the connection diagram, you can install both American fittings and the control valve itself in the mounting socket.

When installing an American fitting into a battery, sealing tape or tow with sealant or paint is used.

Experienced builders recommend choosing American ones with a conical connection; it is stronger and more reliable, since it does not have a seal. In addition, when choosing, it is recommended to carefully examine the body of the parts - the thicker the body, the more reliable the connection. And be sure to pay attention to how many turns of thread are cut into the nut and into the body of the fitting. If there are only 2-3 turns, then such an American one is not worth buying.

Signs of depressurization of a heating pipe

It is quite easy to notice damage in a room when the coolant is supplied under pressure. Small defects are revealed during inspection - damp places, water on the floor under the heating system or wet spots on the ceiling of the neighbors below. After the end of the operating season, traces of rust on the pipes indicate a leak.

It is difficult to detect small leaks centrally - the automation compensates for a slight decrease in pressure. Pressure gauges help detect only significant coolant losses. Therefore, consumers should regularly check batteries and pipes, especially during the winter season when they are filled with water, and immediately repair the slightest damage.

In order to find a leak in a section of pipe that is located underground, thermal imagers are used. The picture from the damage site will be blurry. Moisture meters will help indicate the location of damage to a pipe laid in the floor or under the baseboard indoors. When humidity increases, a leak may be suspected.

Interesting!

Some mechanics listen to the wall above the heating system using a medical phonendoscope. Although the chance of hearing noise from oozing moisture is minimal.

The American is leaking - we are drowning our neighbors

AN63555

Well, the neighbors upstairs have a European-quality renovation, tiled floors, if this is possible, then of course it’s not a problem, but the craftsmen told us that it’s impossible to do this now, and the neighbors upstairs don’t need it at all, they’re already fine. We and the neighbor below are suffering. If only we try to its pipes, but we also have floor tiles, we won’t move them. Who would give competent advice?

Evgenik

do you think we are all the same? Every time different companies and specialists - and the same thing. Disappointment in people until you understand everything yourself - they cheat you, it’s even offensive, because we don’t do repairs every year and the pipes were changed for the first time, who would know. Before the repair began, not a single company was invited for consultation, and since we women understand little about pipes, we did not know the pitfalls, we did not even imagine that this could happen, that the iron could not be left. Not even all men understand the subtleties. Only those who face this problem first-hand. Moreover, the pipes did not leak for the first year. It all started a year later. We were told to just pull up the American girl. They pulled it up. But after the next hot water shutdown, it started dripping again. They came and said - the reason is that the pipe goes straight, we need to make an elbow. Done. Half a year later again. Another master came and said - a knee is not enough - and he twisted a whole caral for us. And so it started leaking from below - it didn’t leak from below for 3.5 years, then this donut started leaking from above, the rubber bands on the heated towel rail also rotted and started dripping. Now, as you can see, they have given us the letter P. In short, the P is complete. But financially there is also no way to redo the renovation, we did it this way, I will study the topic further, since the situation is the same in the rooms, it’s not dripping yet, but I don’t want to wait until it starts to leak.

So I came here for a consultation, everyone has their own opinion, but things are still there. I began to study the issue myself. Now we need to make the box again and attach the sink back. And all this is not free of course. There would be money. And how the doors were made - they redid it several times, also unfortunate specialists, until she took it upon herself and studied the issue. But everyone must mind their own business and do it well. Unfortunately, life turned out to be not so simple. The financier is already studying the installation of doors and the laying of pipes... You should have seen how we sawed old birch trees at our dacha this summer... according to the contract, the company. As a result, a birch tree almost fell on the house, and we were sitting in the house, dragging the head of this company with us - he was screaming like crazy, rolling on the ground - a broken sacrum and coccyx, a broken porch... so come back. I had to study the cutting technology myself again and control it in the future. There are few good specialists, and finding one is a great success.

How to fix a leak in a pipe

Repairs can be carried out without draining the water by temporarily reducing the pressure. To do this, they use welding or soldering joints, installing clamps and bandages, and also use chemical compounds - sealants, adhesives, cold welding.

Sometimes owners have to find a way to fix a leak in a heating pipe without welding. After all, while you are filling out an application, a sufficient amount of time passes. And a small hole, when coolant enters under pressure, can quickly turn into a large one and cause significant material damage.

What is "American"

Among the methods of connecting pipes and heating devices, two main methods are used - using bends and couplings, using nuts and fittings, or in other words, American ones.

In technical language, this connection is referred to as a union nut connection. Unlike traditional couplings and fittings, the American one is a separate unit with a thread for installation in a radiator and in a pipeline connected by a union nut. Both halves have a connecting unit in the form of a cone and a funnel. When tightening, the parts of the connection fit tightly against each other and are tightened with a nut.

Unlike drives and couplings, when connecting with an American, fewer operations are performed, firstly, and secondly, the connection is more dense and reliable.

Traditional methods of sealing leaks

At home, you can use the following methods to eliminate a leak:

- Using rubber and serpyanka. First, the problem area is wrapped in sickle or canvas folded in several layers, and the top is lubricated with a rubber compound.

- Using a rubber band. Clean off the rust, tighten it with a rubber band, and secure it on top with wire. Self-tapping screws or bolts with a rubber washer are inserted into the pipe under the rubber.

- Any automotive metal polymer can be used. The area at the leak site is cleaned of rust and the old paint is removed, the composition is pressed into the defect, then a layer of serpyanka (canvas) is applied and the polymer is applied again - 2 cm around the defect. After the composition has dried, the dried layer is polished with sandpaper, and the composition is applied again, covering an area 40-45 cm wide. When everything is dry, the pipe is painted.

If the Mayevsky valve, used as an air valve, leaks, spot repairs are not enough. The tap is unscrewed, the gasket is removed from the rubber, the threads and the place of the rubber are lubricated with gel, and the tap is put back in place. Remove the remaining gel and leave for 15 minutes so that the composition on the problem area hardens.

One of the sealing methods used at home is using table salt. Can even be used on pipelines with coolant supplied under pressure. Used only in cases where there are no other materials at hand. Soak a medical bandage in strong brine (brine) and wrap the pipe. When it dries, it forms a dense shell around the problem area.

Interesting!

Here's what to do if the crack is microscopic and moisture is oozing out slightly: plug the hole with a toothpick, and then cover it with any sealing compound.

Using a clamp and rubber as a means to eliminate radiator leaks

If you cannot find a special remedy for eliminating radiator leaks, then you can simply cut pieces of rubber from a bicycle inner tube - the strips should be 30-35 centimeters long and 4-5 centimeters wide. Using a clamp, you can stop the leak for a while. For this reason, it doesn’t hurt to have a few clamps in stock at home - their price is low.

Store products

Sealants can be used for straight sections of heating system pipes and threaded connections:

- Silicone - they are elastic, harden easily, penetrating into hard-to-reach places. This group includes silicone sealant “Moment”.

- Polyurethane - resistant to external factors. They come in one- and two-component types, form stable compounds with metal, and protect against corrosion. The downside is the high cost. One of these sealants is TYTAN.

- Liquid sealants. For each type of connection, their own compositions are used: for pipes installed in water, for contact with antifreeze, for metal and plastic pipes.

Hermetic seal to eliminate leaks

Such a composition polymerizes upon contact with air, and as a result of hardening, a strong filling is formed, which gives time for significant repairs. Some sealants are two-component polymer compounds, and harden as a result of mixing their two components. Other products harden as a result of a chemical reaction with air. Using sealants designed specifically to fix leaks, you can solve the problem in a matter of minutes.

How to use correctly

Wrap a folded or twisted ribbon around the edge of the American one, approximately two turns. Then make two more turns on top across the entire width of the tape. There's not a lot of winding required here. Two turns is quite enough since the tape very quickly takes the shape of the product.

Today, the American coupling is the most universal, widely in demand and indispensable device, which is used in the construction of industrial and domestic pipelines of various configurations. The market offers a huge selection of American women made of various materials and different models: copper, plastic, brass, galvanized, steel (stainless steel), with internal thread, with threaded fitting. We talked about the simplest, most affordable and widely popular types of couplings for American women.

Tools and materials

To obtain a strong and reliable connection, in addition to high-quality fittings and nuts, you also need reliable tools. This applies, first of all, to the keys for installing fittings into the radiator body.

The design of the fitting provides for the use of a key for the internal volume of the fitting. To avoid damaging the thread during installation, the inner surface is made in the form of a hexagon or has two protrusions for gripping with a special key.

This feature is extremely important during installation work. Experienced experts recommend not making mistakes, but immediately purchasing keys for American women. I can recommend a key for American women, Good-natured Plumber, this is the optimal price/quality ratio for this type of tool. The key is a stepped cone with grooves. Each diameter corresponds to the size of the inner diameter of the fitting. For operation, a ratchet handle is used, which allows you to change the direction of tightening. For hexagonal shapes, regular hexagons are used.

The external threads of the fittings on many models are jagged. This shape is not something unusual; it’s just more convenient to wrap sealing tape or hemp tow on such a thread. When screwed into the battery, it is the notches that prevent the seal from sliding along the threads. This connection turns out to be quite reliable. As for the sealant, it is recommended to use sealing tape for modern radiator models, and for traditional cast iron radiators to use the classic method - packing tow.

Design Features

The standard design of the device consists of:

- steel or brass body;

- two fittings;

- sealing gaskets;

- union nut;

- locking element;

- rotating mechanism.

We recommend that you familiarize yourself with: Types and rules for installing valves of shut-off flange connections

At the heart of the product is a ball locking element that performs a locking and regulating function. The principle of its operation is the same as that of other spherical valves: inside the body there is a metal ball with a hole in the middle. It rotates on silicone or rubber O-rings and is actuated by a valve.

In the open position of the tap, the hole of the sphere is located parallel to the body, ensuring the unhindered movement of water through the pipes. When the lever is turned, the hole in the sphere is perpendicular to the flow area of the valve, blocking the flow of the working medium. This principle provides the device with greater reliability compared to conventional plate locking mechanisms.

How to properly install an American on a heating radiator

Installation of shut-off valves is done in the battery according to the installation diagram. To install a radiator in a private house, a diagonal pattern is usually used, and for an apartment building, a one-sided pattern is usually used. After the transportation plugs are removed from the seats and the threads are inspected, they proceed to installing the valve under the American one.

The algorithm looks like this:

- The type of thread in the radiator seat is determined;

- The sealing tape is wound onto the threads of the fitting;

- The fitting together with the nut is screwed into the thread and secured with a key;

- The valve is tried on in the pipeline, the fitting is installed in the pipe and fixed;

- After this, according to the installation diagram, the tap is fixed with a union nut on the radiator;

- The next step is to fix the tap with a union nut on the pipeline side.

- Finally, both nuts are tightened using a wrench, and the connection is finally sealed.