The appearance of water in the basement can be due to a number of reasons. One of the most common problems is groundwater.

What causes water to seep into the basement from the ground? Firstly, there is improper drainage around the basement. Secondly, the drainage may become clogged. Thirdly, there is improper or damaged construction of the basement wall waterproofing. Fourthly, there may be too much groundwater supply due to above-normal precipitation or intense snow melting due to seasonal abnormal warming.

The problem of groundwater in the basement can be solved in various ways. Most of these methods can be done independently. But even after eliminating the problem of groundwater appearing in the basement, it must be removed from there. This can be done by pumping using various means and devices.

Peculiarities

The first step when water appears in the basement is to eliminate the cause of its formation. By eliminating the cause, you can prevent basement flooding. Particular attention should be paid to factors that influence the formation of water.

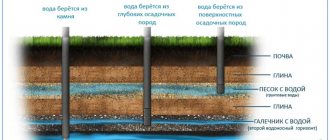

- Groundwater . In spring, the groundwater level rises above the location of the foundation, which is why it can leak through holes and cracks. This can also happen due to the fact that after snow melts or heavy precipitation falls, the earth absorbs water like a sponge and retains it within itself.

- Incorrect installation of the drainage or its clogging. If the walls and ceilings were waterproofed in the basement, but water still appeared in the basement, then you should pay attention to the insulating layer. It is necessary to check its integrity. To do this, you must first pump out all the water from the basement. In some cases, people neglect the drainage system in order to save money, however, because of this, dampness will be concentrated in the basement, since the waterproofing is unable to cope with this problem on its own.

There are situations when the basement was dry for a long period and suddenly flooded and dampness appeared. This may be due to changes in the soil around the base. In this situation, it is necessary to drain water from the walls and build a drainage ring around the perimeter of the foundation.

- A crack that has formed in the foundation of a house. Any violation of the integrity of the foundation can lead to the appearance of water in the basement. Damage to the foundation of a house can be associated with a number of errors made in the technological process. A surface that is damaged becomes vulnerable to moisture. Experts note that due to exposure to water, the amount of calcium in concrete decreases. This negatively affects reliability and strength indicators. Replacing the insulation will not help in this case, since work to eliminate this problem must be thorough, since the cause of water formation is at the level of the building's construction.

In addition to cracks and breaks, you should pay attention to the capillary penetration of excess moisture, due to which fungal spores and mold form in the basement. This problem can be caused by poor quality materials used for waterproofing. Another reason could be an ineffective ventilation system in the basement.

To pump out water, you can choose a unit such as an automatic electric pump. It is better to assemble it yourself, taking into account the recommendations of specialists. Installing and pumping dry will be a breeze.

Causes

Sometimes flooding is superficial. This happens most often either in spring or autumn.

But in some regions with heavy rainfall it is possible in summer. Flooding is caused by storm water or melt water.

In this case, problems arise if the abduction was initially done incorrectly .

The situation can be corrected by constructing a high-quality blind area around the perimeter of the house and reliable waterproofing of the foundation.

The second reason is groundwater entering the basement. They most often seep through cracks in the foundation and basement base. Here, too, there is one solution - correcting design defects, where possible.

Attention! After pumping out the water, it is necessary to dry the basement and waterproof it, but it will be more labor-intensive than in the first case. This is especially true for houses that were originally built too close to a pond or are located in a swampy area.

Drainage arrangement

This method is good because it allows you to combat the root cause of flooding - high groundwater levels. The result of the work will be its reduction. Unfortunately, this method is not applicable in every case. To understand why, let's take a closer look.

A drainage system is essentially a drainage system through ditches or special drainage pipes. Deep ditches on a site are dangerous and do not enhance its appearance, so they are not used for domestic purposes. With their help, you can, for example, drain a swamp in order to organize a place for a vegetable garden. Let's consider a system of pipes. A drainage pipe is a pipe of large diameter, at least 100 mm, with a network of small holes across the entire surface, buried to the drainage depth, that is, below the basement floor level, with a slope away from the house and a free exit. Thus, the use of such a system is possible only in areas that have their own slope. It is this that will ensure the natural flow of water and its free exit at the end.

Conclusion: if you have the opportunity to make a drainage system around your home, then it is necessary to do so. Either alone or in combination with other basement drainage measures, it will give excellent results and eliminate the root cause of flooding.

Alternative devices and methods for pumping water from the basement

If a one-time pumping of water is necessary and there is no possibility of purchasing an additional drainage pump, then you can use alternative methods.

- For example, an inexpensive submersible vibration pump of the “Springhead” type. If the depth is shallow and there is not a lot of water, then such a pump will cope with removing liquid. The main thing is to make sure that there is no debris in the water or to first remove the most dangerous foreign matter from the liquid.

When using an external drainage pump, so that it pumps out the water completely, you can resort to modifying the design of the system. When the water level in the basement decreases so much that the use of an external pump becomes difficult due to air getting into the mechanism, then use a 15-20 liter capacity. You can take a bucket. Place the hose for supplying water to the pump into a bucket and add water there with a scoop or shovel. Then all that remains is to remove the remaining puddles with a rag and dry the basement. This method can also be applied to some designs of submersible pumps, as well as when there is a large amount of debris and dirt in the water.

If there is a slope from the basement in the area, you can pump out the water by gravity. To do this, do the following:

- prepare a rigid plastic pipe, similar to an intake pipe for a surface pump;

- make an exit from the basement to the outside towards the slope;

- Immerse one end of the pipe, through the passage into the basement, into the water there;

- Place the second end of the pipe at the bottom of the area;

- if possible, suck the air out of the pipe (this can be done, for example, with a vacuum cleaner), and the water will flow out by gravity.

Purpose and characteristics

The main purpose of this element is to restrict access to that part of the building walls where the basement windows are located. The pit device protects the windows themselves and the basement as a whole. This structure will not allow snow, melt water, garbage and animals to enter the basement, and the windows will last much longer thanks to this protection.

The grille protects windows from mechanical damage and practically does not prevent light from entering.

An important purpose of a basement window is to allow daylight into the room. Light pits should be designed in such a way that maximum sunlight enters the basement through the windows. The presence of windows in the basement or cellar allows you to reduce energy costs for lighting, as it makes it possible to use natural daylight.

If the basement is well-equipped, daylighting greatly increases the comfort of people staying inside for a long time. Thus, the light pit is not just a protective structure, but an important functional element.

And if you use as much imagination as possible, you can turn this design into a spectacular decorative element of the facade of your home.

The dimensions of the pits are calculated depending on the size of the windows themselves and how deep into the ground they are planted. As a rule, the length of the pit (the part that runs parallel to the wall) should be one and a half times the width of the window. And the second side (perpendicular to the wall) should not protrude more than 1 m. The optimal option is 70–80 cm. The depth of the pit is determined based on the location of the lower edge of the window frame: its bottom should be approximately 20 cm below the window. It is also advisable to plan a slight slope of the well bottom (about 3–5 degrees).

The shape of this structure can be very different: semicircle, trapezoid, square. But still, the rectangular shape is the most convenient and practical.

There are also special SNiPs - these are building codes and regulations that structures must comply with. When designing, be sure to check what these standards are for your building.

Prevention of re-flooding

To avoid re-flooding, you need to waterproof the basement after draining . The materials used depend on the characteristics of the room. If its walls were made of concrete, it is necessary to use a special impregnation that penetrates deep into its structure.

Roofing felt has good waterproofing properties. It can be used to cover the floor in the basement. Sheets of roofing felt are laid on top of mastic, which itself has insulating properties.

How to drain melt and storm water from the foundation

Seasonal formations of surface water are eliminated by complex actions, including:

- roof drainage system;

- blind areas;

- drainage system.

A roof drain is needed to combine water flows after rain and melting snow. Before water from the roof is drained away from the house, water flows are redirected to storm drains under the gutters.

The removal of melt and storm water from the base is carried out by ring drainage. Such drainage involves trenches with pipes directed to the sewer system.

Integrated system for draining water from a drain Source krutostroi.com

What will you need?

There are various ways to pump water out of a basement, however, most of them involve the use of pumps. The pump is the main tool for carrying out this procedure. Therefore, it is extremely important to familiarize yourself with the existing types of this equipment in order to understand their characteristic features. We will talk about the most common of them in detail below.

Surface pumps

Such pumps must be installed on the surface of the water or above its level. Water is sucked in through a pipe having a rigid structure. Water is drained using a flexible garden hose. The main advantage of the presented system is that this pump is accessible for maintenance. The design is simple because it does not come into contact with water. This has a beneficial effect on the cost of equipment.

Since the pump operates outside of water, its operation is accompanied by loud noise. When the pump is in water, its thickness absorbs noise. As noted earlier, the design of such a pump is simple. This is expressed in the fact that the equipment does not have a sealed housing and other elements, which is why it needs to be protected from exposure to water or high humidity. Be sure to consider the placement of this device.

When choosing between pumps, you also need to take into account the fact that the presented type is not able to completely eliminate water. This is due to increased accumulation of a certain volume of air in the pump. The equipment stops working when air enters the pipe along with water.

Therefore, you can choose this type of pump only if you have to use it infrequently. For example, it is necessary to pump out water from a basement during construction or during a season of heavy rainfall.

Submersible

This device is placed below the level of the liquid it will pump. This allows you not to worry not only about lifting liquid from a high depth, but also about engine overheating. Such a mechanism can be installed in wells, technological tanks or wells. The main advantage of such pumps is their reliable operation and long service life.

Before purchasing this equipment, check whether it can be used for pumping dirty water. There are designs that are focused exclusively on use with clean water, which is great for watering a garden or vegetable garden. Pumps that can be used for dirty water will do an excellent job of pumping liquid from contaminated wells, construction pits or basements.

Submersible pumps are distinguished by the presence of wider flow holes, which distinguishes them from conventional designs. This allows the “drainers” to pass particles whose diameter does not exceed 50 mm. Certain equipment may pump water that contains fibrous particles such as algae or hair.

In order for the mechanism to operate efficiently, it is necessary to select a model that is distinguished by the presence of a powerful engine. You should also pay attention to the depth from which the device is capable of pumping out water.

The main disadvantage of this type of pump is that it is difficult to maintain.

Universal

This category includes those pumps that are used to pump liquid from sewage pits. This device operates in immersed mode and is characterized by a large list of advantages. One of these advantages is that if you choose a high-quality unit, it will be distinguished by great power and reliable operation.

This design has a long service life. It has a grinding device, thanks to which it can be used for pumping dirty water. The pump is not afraid of small debris or sand.

Manual

Characterized by a cylindrical operating principle. Water is pumped in and out by means of a piston, which is driven by human action. A certain advantage of such equipment is that it does not depend on electrical equipment. The design is reliable and easy to use, while the cost of the pump is low.

Unit power

You need to choose the pump performance taking into account the area and depth of the basement. For example, for a room of up to 20 m2, you can use a device with a power of 100-120 l/min. For smaller basements, 40-50 l/min will be sufficient.

If the site has a slope from the basement, then water can be removed in the following way:

- prepare a hard plastic pipe, which is similar to the intake pipe used for the surface pump;

- make a hole from the basement towards the slope;

— the pipe should be immersed with one edge in water;

- the other should be located where there is the greatest slope on the site;

- in order for the water to start flowing by gravity, you can use a vacuum cleaner.

AllaAuthor of the article

Did you like the article?

Share with your friends:

Garage

Many garage owners have an inspection hole. This is a basement room located under the garage. It is needed for a better inspection of the car and repairs.

Don't forget about waterproofing the room

The appearance of moisture in the underground causes problems, primarily corrosion on the car. Therefore, waterproofing is needed in the garage in the cellar. There are 2 ways:

- protection during garage construction;

- creating waterproofing in a finished garage.

During construction, much attention is paid to the walls, floor and closing lid. Methods for waterproofing a garage pit:

- By creating a drainage system (without laying pipes, with laying pipes).

- For the inner surface of the walls - penetrating waterproofing (composition of sand, cement and chemicals). The solution penetrates deeply into the pores and cracks of the walls.

- Other methods are also used for interior wall treatment: liquid rubber, plaster with moisture protection.

- For the outer surface of the walls, roofing felt and bitumen mastic, slate are used.

- For the floor - reinforced concrete.

- A wooden cover is installed on the pit as additional protection.

Safety rules when working with pumps and pumps

Safety requirements when using submersible drainage pumps:

- During operation, do not touch the liquid, cable, or objects that come into contact with water - there is a danger of electric shock;

- After each use, run clean water through the pump or rinse it;

- do not forget to remove the plug from the socket after completing all tasks.

Safety requirements when using motor pumps:

- do not work in a closed, poorly ventilated area;

- Always stop the engine before refueling and allow it to cool;

- do not refuel the motor pump near an open flame, do not smoke during the process;

- Do not allow fuel to come into contact with the engine or muffler during refueling;

- install the motor pump at a distance of at least a meter from the walls, do not allow children and pets to be nearby - the device gets quite hot;

- Do not touch a running or just switched off engine with your bare hands.

A private house

When building a house on a site, it is important to determine the level of groundwater. You can determine it yourself, focusing on the degree of water filling in the well, or order geological exploration services.

The latter method is more reliable, in which recommendations are given on the location of a private house, foundation and drainage system.

Attention! It is better to determine the water level in the spring when the snow melts or in the fall, during the rainy season.

The likelihood of a high occurrence can be determined by the plants that grow on the surface. Alder, willow, horsetail and reeds grow well.

At a high level (at a depth above 2 meters from the surface of the earth), a negative effect occurs on a house standing in water:

- The liquid that sits in the basement provokes dampness and mold development.

- Moisture can cause the foundation of a house to collapse.

- Excess water negatively affects the greenery and trees growing on the site, on the paths, washing them away, and washing away the walls of the house.

What are they pumping out with?

Pumped out from the cellar using automatic pumps.

Automatic pumps are:

- submersible – placed in a liquid;

- external - its upper part is on the surface, its lower part is under water.

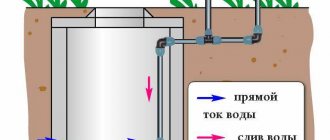

On the website you can find a layout diagram of the automatic water pumping system.

Installation algorithm:

- in the center of the basement a recess is made for a tank - a caisson. The caisson is needed to accumulate moisture;

- for better protection they are wrapped in geotextiles;

- install the pump in the tank;

- after filling, the pump turns on automatically;

- after pumping it turns off.

Read more: how to use a pump to pump water out of a basement.

The easiest way to pump out water is with a pump

Foundation drainage: types and features

In difficult hydrogeological conditions of the area, the underground part of the building is protected using three types of drainage arrangement:

- wall-mounted – for houses with a basement and ground floor;

- ring - for houses with all rooms above ground level;

- stratal - for a slab foundation below the waterproof layer.

The wall drainage system is located underground along the wall.

The ring drainage is located 1.5-3 m away from the walls. At the bends, the pipe is rounded or has an inspection well. Typically the system is located around the entire circumference of the building, but there are exceptions.

The reservoir drainage surrounds the pipeline ring, and a layered drainage bedding is located under the slab.

Reservoir drainage is arranged even before the foundation is poured Source readmehouse.ru

Pumping technique

There are several ways to eliminate water from the basement. Let's talk about each of them in detail.

Drainage arrangement

This is the optimal method for combating groundwater. In this case, water can be drained in one of two ways.

- Ditches that are not applicable for domestic purposes, since digging them on the site is dangerous, and they negatively affect its appearance. This method can be used to dry out the swamp.

- Special drainage pipes, the diameter of which is usually 10 cm. Small holes are drilled over the entire surface of these pipes. They need to be buried to a drainage depth located below the floor level on a slope. This will ensure free flow of water.

The drainage system can be installed separately or in conjunction with other methods of draining the basement, however, using this method, the cause of flooding can be eliminated. The presented technique for pumping water out of the basement demonstrates excellent results.

Organization of automatic water pumping

In a situation where the area is flat and there is no slope, you will have nowhere to lead the drainage pipe, so you will need a different method. An automatic pumping system is the simplest way.

To organize this system, you first need to create a pit inside the basement. Its size should be 50 x 50 centimeters, and the depth of the hole should be at least 0.5 meters. With the help of brickwork, it is necessary to strengthen the walls, preventing them from crumbling over time. The bottom needs to be covered with gravel. The thickness of this layer should be 10 cm.

Next, you need to install a drainage pump with an automatic control system in the pit. The hose connected to the system should be taken away from the building.

When the groundwater level rises, this can be observed in the pit. When the water reaches a certain level, the system will begin to automatically function and pump it out. Consequently, excess moisture will be removed by the pump. If water continues to accumulate, the pump will turn on again and pump it out. This will continue until the groundwater level drops.

This system is simple and reliable. The costs of its creation depend on the cost of purchasing the pump. As a disadvantage, it is worth noting that such a system does not eliminate the problem, but finds a temporary solution.

Waterproofing

If water appears regularly in the basement and is constantly concentrated, you need to take care of waterproofing. You can create a protective barrier using bitumen-based mastic and plaster.

To carry out this procedure, you will need materials including mastic, waterproofing compound, river sand, plaster mesh and cement. To work, you will need a spatula, a construction mixer, a container for mixing the mixture and a brush that has metal bristles necessary for mashing.

The basement must first be thoroughly drained. All surfaces must be cleaned of dirt and dust. Seams and corners are rubbed with a brush. Creation of waterproofing is carried out in several stages:

- The walls and floor should be treated with a waterproofing compound, which will seal cracks and prevent moisture penetration.

- Seams, small cracks, corners need to be coated with mastic. The entire surface is also treated. A layer of at least 2.5 centimeters.

- A metal mesh is installed on the surface of the walls, which is necessary for applying the plaster mixture. It is applied with a spatula. Layer 3.5 cm.

- It is also necessary to install a mesh on the floor and pour concrete mixture. The room is left in this position until completely dry.

Thanks to high-quality waterproofing, you can increase the wear resistance and strength of the concrete base, which has a great effect on extending the service life of the entire structure. This is an excellent alternative to drainage.

See below for more details.

What types of basement pumps are there?

All water pumps are divided into two subtypes:

- Mechanical.

- Electrical.

Mechanical or hand pumps are driven by human physical force. Based on their operating principle, such pumps are called piston pumps. It is the movement of the piston that sucks water into the pump bowl and then pushes it out.

These devices are indispensable in cases where there is no electricity in the area. However, it is worth noting that pumping water with such devices takes a lot of effort and time, so it is impossible to pump out large volumes of liquid and even in a short time.

Electrical devices are much more expensive than mechanical ones and require additional energy costs. However, these units are able to create maximum comfort and fulfill any user requirements without expending physical effort. In addition, almost all electrical units can be combined with various types of automation and switch them to fully automatic mode.

Submersible drainage pump design

Electric pumps have a wide range of installation methods, operating mechanism, manufacturers, types of automation, etc. Let's take a closer look at some of their subtypes, most often used in basements and other underground buildings.

Superficial

A surface water pump is used for one-time pumping of the tank. This is due to design features and technical characteristics. This type of unit, unlike a submersible one, is air-cooled and under no circumstances should it come into direct contact with the pumped liquid. The advantages of surface pumps include:

- low cost due to the simplicity of the design;

- ease of installation and maintenance. This type of pumping device is installed on the surface, making it easy to move, convenient to monitor and no problems with maintenance;

However, the surface pump has many disadvantages:

- maximum liquid lifting height – 9 meters;

- the inability to pump out water completely, because when air is sucked in, the device turns off automatically;

- noise, since the operation of the engine is not muffled by the environment (water, as is the case with submersible devices);

- leakage of the housing, due to which the pump must be protected from moisture and precipitation.

However, such units are almost always chosen if you just need to pump out a tank or water an area, since in these cases the described disadvantages practically do not play a role.

Installing a surface pump is very simple: a hard hose is lowered into the pumped out reservoir, and a soft watering hose is taken to the place where the liquid is drained. The basement pump is ready to go.

Surface drainage pump

At the end of pumping out the liquid, the pump is disconnected from the power supply, after which it can be removed or moved to another tank. These devices are small in size and weight, making installation, dismantling and transportation easy for anyone.

Submersible

Submersible pumps are usually used to install a stationary drainage system for a basement, cellar or basement. They are also very convenient for one-time pumping out of liquid, since they can remove it almost completely. However, few people can afford to buy such a device for one-time use, since they cost much more than surface ones.

The high cost of submersible pumps is due to their design features. Such units use materials that are not subject to corrosion under conditions of constant contact with water. In addition, submersible units must have a completely sealed housing. We also note that almost all submersible pumps are equipped with level automation - special senders that automatically turn on the pump when the liquid level rises to a certain level and turn it off when the liquid settles to a lower level.

Submersible models are capable of lifting liquid from great depths - 100 meters or more. Such deep characteristics are important for borehole and well pumps.

The aquatic environment in which such devices are immersed muffles the engine, making them much quieter than surface models. In addition, it is water that acts as a coolant for the entire mechanism.

According to their purpose, submersible pumps are divided into:

- borehole;

- wells;

- drainage;

- fecal.

We will not consider the first two types, since they are used exclusively for supplying clean water from great depths.

Installation diagram of a drainage pump in the basement

Drainage pumps are capable of pumping out both clean and dirty water with small inclusions of solid impurities. To prevent particles larger than the permissible diameter from entering, the intake part of the drainage device is equipped with a mesh filter with a specific cell.

Sewage pumps, by definition, are used to pump out sewer pits. Their main purpose is to pump liquid with large inclusions of solid impurities. To avoid damage to the mechanism, fecal devices are equipped with a cutting mechanism capable of grinding household waste to a homogeneous mass.

Drainage electric pumps

An electric drainage pump is a device specially designed for pumping water out of a flooded room. The equipment has a narrow specialization. Using the pump for activities not specified in its instructions is highly undesirable. However, many homeowners often set difficult tasks for the device and look for unusual uses for it. There are cases when enterprising owners tried to replace the fecal drainage pump.

The equipment can pump out liquids with light contamination. Solid impurities should not be larger than 3-4 mm; the exact indicators depend on the indicators of the device. At the same time, the fecal electric pump provides for working with aggressive liquid. The design of the drainage pump is represented by the following elements:

- Electric motor.

- An impeller, the location of which is the shaft. It provides the function of passing liquid through the device.

- Pumping unit. It contains an intake pipe. Water enters the pump by passing through holes in the tube.

- Frame. Includes all available working parts of the unit.

- Circuit breaker. Performs the function of switching off and on, which depends on the amount of liquid, and also prevents dry operation and flooding of the drainage hand pump.

To ensure normal operation of the device, the presence of solid components inside the chamber should not exceed 10% of its capacity. In addition, the range of equipment is not used for pumping hot water. There are two types of devices - surface and submersible.

Motor pumps

Motor pumps operate using centrifugal force. Appliances for domestic use are equipped with gasoline engines. An important technical detail: the higher the device is located above the injection point, the less efficiently it will work.

Advantages of motor pumps:

- mobility;

- independence from access to the electrical network;

- efficiency;

- high performance;

- wide range of applications.

Disadvantages of motor pumps:

- limited time of continuous operation;

- Regular inspection, oil and filter changes are required;

- limited depth of water intake;

- work only with clean and slightly contaminated water;

- harmful emissions;

- high noise level;

- impossibility of working near a muddy/sandy bottom;

- inability to work indoors.

Manual

Such equipment is suitable for homes where it is not possible to use sockets or where electricity has not yet been supplied. They pump out small volumes of water. Diving is only possible to 5-9 meters. The principle of operation is similar to a piston, which creates a vacuum of pressure and lifts water upward.

Mechanized

Depending on the energy source, pumps differ in:

- Units with a gasoline engine or running on diesel fuel;

- Electrically powered equipment that uses electricity.

Vibrating electric pumps

They have such advantages as low power consumption and low price. However, when used, they are subject to strong vibration, which harms the mechanism during operation. The design itself is very simple. The components of the device are represented by the following spare parts:

- Electromagnet. Has a core and winding.

- Vibrator. Includes an anchor in which the rod is pressed.

- Frame. It is equipped with a valve that closes the inlet.

To date, the production volume of these units is over 1,000,000 units per year. But at the same time, the demand for vibrating electric pumps for pumping out dirty water is still not satisfied, because the equipment copes well with pumping out liquid in a flooded basement, and if treated with care and attention, it can become your assistant for many years.

There are vibration pumps

To get started, simply place the device on a hard surface and plug it into a power outlet. If you want to purchase this type of equipment, you should familiarize yourself with the characteristics of the mechanism. The main indicator to pay attention to is productivity. Some companies offer up to 1200 liters of pumped water per minute of operation.

Attention! When purchasing equipment, you should take into account the distance of the outlet and select a design with the appropriate cord length.

Screw well or borehole types

A screw well pump is classified as a submersible type of water equipment. When pumping out liquid, the device is lowered into the water and takes it in, generating the pressure required for lifting from the depth. To carry out the process, several schematic models are possible, let’s analyze one of them.

The unit is available from a wide range of manufacturers in a large assortment. There may be some differences in configuration and design, but the general plan for the functioning of the device in such devices is the same.

Methods for pumping out cesspools

There are two main methods that allow you to pump out a cesspool:

- On one's own.

- Using a sewer truck.

The second option at first glance looks much simpler: just contact a specialized company, and the problem will be solved. There are a number of nuances here that must be taken into account - otherwise the risk of trouble is quite high.

- the cost of services for pumping out cesspools is quite high: calling a specialized vehicle will cost a large amount;

- any machine for pumping out cesspools has rather large dimensions, and they do not always allow one to approach the pit at a distance sufficient for pumping;

- some companies provide services for pumping out cesspools without having special permits for this: in this case, all pumped out waste can be taken to an illegal place, and all responsibility for this will fall on the owner of the pit;

- ordering a sewer truck does not always guarantee high-quality pumping, and a poorly cleaned pit will not perform its duties efficiently, so calls for sewer trucks will become more frequent.

All these shortcomings allow us to come to the conclusion that pumping out cesspools can be done with your own hands, because a good owner will definitely take care of the high-quality and competent operation of this system.

Installing a waterproof barrier in the basement

There is a solution to the problem of basement flooding in houses on flat areas, which, although it does not eliminate the cause itself, like drainage, allows you to completely do without any temporary devices. We are talking about organizing a waterproof barrier inside the basement - essentially a “trough” over the entire surface of the walls and floor. How this is done will be discussed further.

Generally speaking, there is no need to make such a barrier along the entire height of the basement walls. It is enough to raise its level 100 mm above the highest groundwater level. Of course, you can simply make a barrier to the soil level - water simply cannot rise higher, but the high price of the materials used in this method requires corresponding savings, and this can only be achieved by avoiding overspending. Accordingly, the first thing that needs to be done is to determine the level of the primer and, thereby, determine the upper limit of waterproofing.

Next, you need to decide what exactly needs to be done to create a waterproof barrier. There are two options here:

- If the basement is a reinforced concrete monolith-trough, poured in one go, then it will be enough to treat it from the inside with impregnating waterproofing. This is a special mixture that penetrates into the pores and microcracks of concrete and contains additives that crystallize in water. The crystals formed clog all the pores in the concrete, thereby forming a waterproof barrier - what we need.

- Any other case, including a reinforced concrete monolith poured several times, because even this option cannot be considered a full-fledged monolith, since each new pour over the existing concrete creates a highly permeable boundary between different layers; for water it is, in fact, almost a crack. Penetrating waterproofing, which clogs only microcracks and pores, will be powerless here. What can we say about all sorts of combined options, for example, walls made of concrete blocks or bricks, the floor is a monolith. In this case, it is necessary to make an additional inner layer of waterproofing materials. Coating or adhesive waterproofing is not suitable here, since it has an increased risk of peeling, especially under water pressure. It is necessary to use materials that have high adhesion to concrete and brick surfaces and create a high-strength layer that does not crack over time. This is exactly the option we will consider.

First, let's decide on the necessary materials and tools. We will need:

- Sand concrete mixture.

- Impregnation waterproofing.

- Reinforcing waterproofing.

- Mixer and kneading container.

- Brushes, rollers, brushes.

- Spatulas.

Let's get to work.

We have a basement with walls made of concrete blocks, the floor is a monolith, which was poured after the walls were built. When spring comes, the basement floods. By the way, this also happens in case of prolonged rains.

It is quite obvious that the main problem areas are the junction of the walls with the floor and the tile joints.

1. Pump out water from the basement. This can be done manually or using any suitable pump, such as a baby pump. Please note that they come in two types: with lower or upper water intake. It is clear that it is better to use with the lower one. By fixing it vertically, you can pump out almost all the water. In our case, there was no such pump, so pumping had to be done in two stages: pumping to the minimum possible level - approximately 30 mm, and manual residual pumping.

As the pump drains, it will emerge from under the water. Very important! It only cools down when it is in water, so you need to constantly water it to keep it from overheating. Next, we place the pump in a large bucket, where we scoop out the water with a suitable tool.

We sweep the remaining water into one puddle with a brush and pump it out in the same way. As a result, we get an almost dry room. The water, of course, will rise. If the work is done slowly and does not interfere, then you can move on to the next stage. Otherwise, the work will have to be postponed until a more suitable time.

2. We process the junctions of walls and floors, as well as seams. We mix the sand-concrete mixture and use a spatula to form skirting boards with a height and width of about 40–50 mm along the entire perimeter of the room. We putty the seams between the slabs with the same mixture. Leave to dry. The next day, when the baseboards are in place, we move on to the next stage - treatment with impregnating waterproofing. High humidity in the room will not hurt - the impregnation works in water, the main thing is that there are no puddles. We pump them out using the method described above.

3. Mix the waterproofing mixture with a mixer according to the attached instructions.

4. Use a brush to cover the entire surface to be treated with the resulting creamy mass.

Leave to dry. After the time specified according to the instructions, apply the second layer. After treatment, water will not flow through the surface of the concrete - these are the planes of the blocks and the entire floor. The seams and junctions remain. We will process them when the second layer of penetrating waterproofing dries.

5. If necessary, pump out the water again.

6. Mix the armoring solution according to the instructions.

7. Similar to penetrating waterproofing, apply the resulting solution with a brush to the entire surface to be treated. We pay special attention to the seams between the slabs and the junctions.

8. The first layer is the base layer. It is necessary to wait the required time for setting and apply the second layer. Before this stage, all flaws will be clearly visible, in the form of oozing microholes. The water leaves clearly visible marks; in the photo there is a whitish stripe. In this case, the location of the leak can be seen.

The result is puddles that need to be drained.

9. Mix the solution a little thicker and treat the leakage areas. Fill the floor with the next creamy mixture. It is convenient to distribute the finished mixture with a roller:

or with a flat brush:

As a result, we get a very durable, absolutely waterproof layer of waterproofing.

If after the second layer there are still holes with oozing water, then you need to repeat the procedure in the leakage areas as many times as necessary. Usually after the third layer there are no such places left.

So, the described methods for draining the basement will certainly allow you to get rid of unnecessary water and protect the internal basement from high humidity, but which option to use must be decided individually, based on specific cases and goals.

Pipe for drainage water

The optimal solution for draining drainage water from the basement is a low-resistance HDPE pipe. Such a tube can be laid without connections. The diameter corresponds to the pump discharge pipe. It is advisable to first lay the pipe vertically to a level equal to the discharge mark. The passage in the basement wall must be made through a casing, carefully sealing the passage with cement mortar and applying a layer of penetrating waterproofing. Outside the building, the pipe is laid in a trench. The laying depth can be higher than the freezing depth of the soil if its slope towards the discharge is greater than 0.005. Open pipe installation is not recommended.

Creating a pit for drainage

The easiest and most affordable way to remove water from the basement is to create a pit. Even a novice master can install a pit near a private house for effective water drainage.

All work is carried out according to the following scheme:

- A hole with a volume of 1 cubic meter is dug in the central part of the basement. m. The larger the basement area, the larger the recess.

- In the center of the pit, another hole is dug the size of an ordinary bucket.

- A stainless steel bucket is placed in the recess and compacted around the perimeter.

- The inner walls of the future pit are lined with solid bricks and fixed with a layer of cement mortar. The optimal height of the cement layer is 3 cm.

- Next, a belt of reinforcing bars is installed. The width between the rods should allow for convenient pumping of wastewater using a basement drainage pump.

- To arrange the drainage, narrow ditches are made in the finished pit and covered with tiles. The resulting seams between the individual tiles will perform a drainage function for the pit.

Such a system is easy to set up and maintain, and does not require significant financial investments or the involvement of third-party specialists. All work can be done independently with a minimum set of tools.

Cleaning a pit without a pump

How to clean a cesspool without pumping? If there is no pump, but the hole needs to be pumped out, then you will have to do it yourself. Improvised tools will be suitable for the job, but the work process itself will be quite unpleasant.

The algorithm for performing actions will be as follows:

- A few days before cleaning, it is necessary to homogenize the liquid using special substances.

- To carry out cleaning work, you need to wear suitable clothing, and you need to choose from those things that you don’t mind. All things must cover the body from accidental ingress of waste.

- Now you can take an ordinary bucket and rope, with the help of which you scoop out the waste. When the next portion of sewage is raised, it must be poured into a specially prepared container for further waste disposal.

- The pumped out sewage is disposed of. The water raised from the pit can be poured out, but sewage waste must be taken to specially designated places.

- After cleaning, the pit must be rinsed with water, preferably using pressure, so that deposits do not appear on the walls of the tank, interfering with normal functioning.

- The last stage is cleaning the sewer pipes, which must be done as thoroughly as possible.

Schematic overview of the well pump design

- The housing combines all existing elements of the electric pump. The material for its manufacture is metal, since the polymer is not able to withstand the load exerted on a mechanical object.

- The rotor provides pumping of excess moisture. By making rotational movements, it pumps out water, which falls into the hose under pressure.

- The rotor rotates via a rigid shaft. In addition, many different elements are responsible for the workflow. A high-quality device is equipped with a more complex technical device, but at the same time it has a longer service life due to reduced wear of spare parts.

Selection of sanitary equipment

Considering that sewerage is being installed in the bathhouse, there are features in choosing plumbing equipment for it:

- It is recommended to install a brass sink in the bathroom, the sewage system to which is connected via a siphon with a water seal.

- A simple shower head can be installed in the shower room. Drains are discharged through drains - floor drains with a water seal, closed with gratings. They can be cast iron, steel or plastic. The floor is arranged for water drainage with a slight slope towards the ladder.

- As a rule, a wooden font is installed in the dressing room, which is filled with a mixer equipped with a shower net. The water is drained in the same way as a regular bathtub.

- In the steam room, the floors are made with a mandatory slope towards the water inlet.