Performance characteristics and design features

Taking into account the different operating conditions of pipelines, customers are offered two types of sets of insulating materials: heat-shrinkable sleeve , designed for a maximum operating temperature of up to 60°C, and the TIAL-M80 sets with a wider operating temperature range of up to +80°C. Structurally, the heat-shrinkable cuff consists of a durable polyethylene base with heat-shrink properties and a lower contact layer of hot-melt adhesive.

Since the two-layer heat-shrinkable sleeve is installed on top of a two-component liquid epoxy primer previously applied to the cleaned metal, a durable three-layer protective coating is formed at the installation site on the surface of the pipeline. Despite the fact that this anti-corrosion system is applied in difficult conditions of the construction site, in composition, thickness and functionality it is almost similar to a three-layer factory VUS coating.

Physical basis - the top film layer of the heat-shrinkable sleeve consists of polyethylene with a radiation-modified molecular structure, which has increased resistance to solar ultraviolet radiation and heat-shrinkability. The bottom of the heat-shrinkable sleeve is covered with a hot-melt adhesive layer, which is a composition of vinyl acetate and ethylene copolymer. This compound is characterized by high adhesion to metal, the ability to resist cathodic disbonding and increased resistance to any shear deformation.

Heat-shrinkable cuff

When welding a pipeline joint, it is necessary to protect the joint; for this, a heat-shrinkable sleeve (cuff) is used. It is made of radiation polyethylene. The material is excellent for protection against water and corrosion, providing a complete seal.

Insulating pipe joints is important since they are not initially protected by polyurethane. The indentation makes it possible to carry out welding work in the future. The cuff is environmentally friendly and resistant to destruction in atmospheric conditions, as well as in contact with groundwater and soil.

The structure of most heat-shrinkable cuffs (HSC) consists of two layers, which include polyethylene and hot-melt adhesive. The use of couplings allows you to create multi-layer protection of the pipeline against corrosion. In this case, the technical properties of the insulation will be the same as those of the main coating.

How to use a heat shrink cuff

To use a heat-shrinkable sleeve, you do not need special knowledge or special equipment; only a gas burner will be needed for the work. Installation of joint insulation includes:

- cleaning the joint area from dust and moisture and polishing the steel pipe to a shine;

- pushing the coupling over the joint with the factory coating;

- alignment and heat shrinking with rolling of the coupling to the surface.

In order to ensure the satisfactory quality of the installation work performed, visual inspection of heat shrinkage is necessary. Glue should come out from under the overlaps of the coupling on all sides.

Installation procedure

At the first stage of work on applying an anti-corrosion heat-shrinkable sleeve to the joint area of the pipes, the metal is cleaned of dirt, rust and scale, followed by washing and thorough drying. To impart the necessary roughness to the edges of the adjacent VUS insulation, they are carefully treated with abrasives. Before applying the mixture of epoxy primer components, the joint area is heated to a temperature of at least 90°C.

The shrink sleeve is installed in place almost immediately after applying the primer, after which the end of the tape is fixed with a pre-heated locking plate. At the final stage of installation, the heat-shrinkable sleeve is heated using a propane torch and finally seals the installation site. According to the manufacturer, the estimated service life of the anti-corrosion coating made using TIAL-M cuffs is at least 45-50 years.

Advantages of the site

We offer heat-shrinkable cuffs, components, and other necessary materials for work at an affordable price. All products have quality certificates. Delivery is carried out to any region of Russia and neighboring countries.

Our company specializes in the production of a wide variety of insulating materials. We know everything in this area and are constantly improving our qualifications. Call and order the necessary goods, we will also answer any question related to materials, delivery, the work of the KhimStroyEngineering company and help you make the best choice.

Contents of delivery:

- Heat-shrinkable sleeve TIAL-M or TIAL-M80 (the length of the tape corresponds to the circumference of each pipe size).

- Locking plate TIAL-ZP (used to fasten a heat-shrinkable sleeve into a one-piece ring around the insulated section of the pipe).

- Two-component epoxy primer TIAL-L (preparatory composition used to cover the cleaned joint area and edges of pipe VUS insulation).

Taking into account the particular application, the heat-shrink sleeve can be supplied in the form of ready-to-install measuring sections, the appropriate number of locking plates and the required volume of epoxy primer, packaged in polyethylene cans (main component and hardener separately). The second delivery option assumes the possibility of shipping heat-shrinkable cuffs in rolls of 30 linear meters in length, which allows you to cut the required piece of tape directly on the job site.

Heat shrink sleeve

The main functional purpose of the cuffs is to reliably protect bends, joints and connections from the destructive effects of corrosion.

The main activity is the supply of materials for the construction and repair of pipelines. We offer only high-quality and certified products. This page presents heat-shrinkable sleeves for pipelines. They are made of two-layer materials based on an adhesive hot-melt coating and polyethylene.

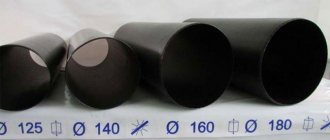

Heat-shrinkable sleeves have a slightly larger diameter than the pipe, which makes it possible to fix it to the surface without any problems. Technological features of product installation are based on heating the coupling, after which it cools, significantly decreasing in size and tightly fitting the structure. Thanks to this, a monolithic connection is obtained that reliably protects the highway from various negative factors.