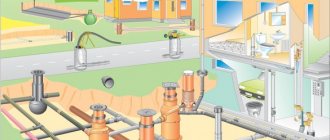

The heating system is the most important component of the coziness and comfort of a living space, providing warmth even in severe cold. But in order for this system to be reliable and not fail at the most inopportune moment, every homeowner must make the right choice, giving preference to the most rational, acceptable heating option available on the market.

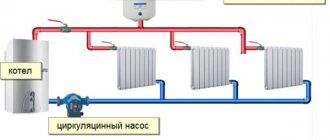

Today we will talk about the most popular version of a two-pipe heating system and reveal all its nuances and features, pros and cons, scope of application and principle of operation. So, let's get to work!

Categories of heating systems and operating principles

Space heating was invented by mankind 3000 years ago. Back in that distant era, ancient people used a system of pipes leading to hot water boilers to heat the palaces of influential people during the cold season. Today, a heating system is an essential attribute of modernity, offering a wide range of options.

There are two main categories of pipe heating systems: single-pipe and double-pipe.

The difference between the systems is as follows: a 1-pipe system operates on the principle of a closed ring. By circulating, the water passes through the boiler and imparts heat to the radiators, after which the cold water returns back. The 2-pipe heating principle consists of two circuits that distribute heat.

The type of system being installed will affect the size of the radiators and piping. It is also worth noting that the first option is more often used in small houses, while the second is used for large areas, for example, for heating cottages.

Technical installation rules

In addition to the generally accepted rules for installing two-pipe systems, there are a number of specific requirements.

You should not neglect them: this will lead you to mistakes, rework and, as a result, an increase in the cost of the project.

So, let's look at the basic installation rules:

- The calculation of a dead-end heating system is performed based on the internal diameters of the pipes. If you see “DN15” or “DN15” in the drawing, this is the internal size of the pipe. “F26x3” indicates the outer diameter and wall thickness. In this case, the internal one can be calculated by subtracting two thicknesses from the number 26 - 2x3. As a result, you will get the required size (26 – 2x3 = 20 mm). Be careful when purchasing materials.

- If the project provides for several dead-end branches, install shut-off and control valves on each of them. It is best to use taps equipped with fittings for draining water - they are easy to use.

- Regardless of what system you are installing - with forced or natural circulation - be sure to observe the slopes of horizontal pipelines. If there is a pump, they are limited to two to three millimeters per meter of pipe length; on gravity mains, the slope should be at least five millimeters per meter.

- Pay attention to the differences between thermostats designed for gravity flow and forced circulation. The former are characterized by greater throughput. If you accidentally install the wrong device, there will be no natural circulation.

And one more nuance: the pipe that connects the penultimate radiator to the dead-end radiator should be equal in diameter to the connections, not the mains.

Pros and cons of a 2-pipe system

The advantages of such heating include the following points:

- The system is more reliable and less vulnerable to defrosting;

- Parallel connection principle, providing greater heat output;

- Possibility of extension, both vertically and horizontally, which is especially convenient when expanding living space (extension of residential premises);

- Possibility of manual temperature control for each room.

The disadvantages include the following:

- Higher cost;

- Installation is somewhat more complicated;

- More consumables (pipes) will be required.

Comparison with other types

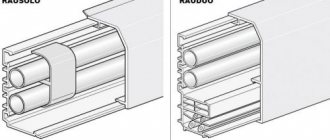

In the lower insert, the supply line is laid from below, next to the return line, so the coolant is directed from the bottom up along the supply risers. Both types of distributions can be designed with one or more circuits, dead-end and associated flow of water in the supply and return pipes.

Natural circulation systems with connections at the bottom are used very rarely, since they require a large number of risers, and the point of inserting pipes in this way is to reduce their number to a minimum. Taking this into account, such structures most often have forced circulation.

Roof and floors - meaning

In the upper supply line, the supply line is above the radiator level. It is mounted in the attic, in the ceiling. The heated water flows to the top, then through the supply risers it evenly spreads over the radiators. Radiators must be located above the return line. To prevent air accumulation, install a compensating tank at the very top point (in the attic). Therefore, it is not suitable for houses with a flat roof without an attic.

The wiring from below has two pipes - supply and discharge - the heating radiators must be higher than them. It is very convenient for removing air pockets using Mayevsky taps. The supply line is located in the basement, in the basement, under the floor. The supply pipe must be higher than the return pipe. An additional slope of the line towards the boiler minimizes air pockets.

Both wirings are most effective in a vertical configuration, when the batteries are mounted on different floors or levels.

Varieties of 2-pipe system schemes

There are several variations of 2-pipe heating, each of which has its own nuances that should be taken into account when choosing.

Two-pipe direct return system

In a two-pipe direct return system, the total pipe length from the pump to each radiator is shorter for radiators closer to the pump and longer for radiators further away. For this reason, the pressure drop may be significantly higher at the nearest radiator than at the farthest radiator.

This must be taken into account when designing the system. The advantage of a direct return system is that pipe routing is easier compared to a reverse return system.

Two-pipe system with reverse return (Tichelman system)

In a two-pipe return system, the total length of pipe from the pump to each radiator is the same for all radiators on the same floor. This gives a favorable distribution of water.

Two-pipe system with top pipe

The distribution pipe is located in the suspended ceiling and the ventilation holes are installed in central positions. This type of system is common in large buildings as it is relatively easy to balance and adjust. It is also easy to expand the system.

Two-pipe system with floor piping

This system is very common in homes and buildings where piping cannot be installed in the accessible ceiling space. Distribution pipes are located under the floor. In multi-storey buildings, ventilation screws are required on radiators. Circulating, inline, single-stage pumps are commonly used for two-pipe heating systems in residential and commercial heating systems.

Shoulder connection

One of the types of dead-end mains is a shoulder heating system. Its implementation scheme involves lateral connection of radiators. The supply pipe is connected to the upper pipe, the return pipe is connected to the lower pipe, both are located on one side of the battery. In this case, the coolant can serve the entire system simultaneously, and each arm can function separately. As a result, it becomes possible to regulate the temperature in each specific room.

The shoulder connection shows good efficiency only when using batteries with a small number of sections. Large radiators will not warm up completely. If there is no other option for installing long heaters, a water flow extension will help solve the problem.

This layout allows you to use fewer pipes than other schemes, it is convenient and easy to install. It is easy to organize a bypass between the mains for installation of control equipment.

Most often, the shoulder system is used for heating multi-story buildings. To achieve maximum effect, a certain number of batteries are placed on each floor. For example, in a two-story house, the common heating main is divided in such a way that there are two dead-end branches on the first and second floors. On the first one, 9 radiators are installed (5 on the right shoulder, 4 on the left). 3 batteries are mounted at the top (2 on the right and 1 on the left). To divide the general contour into shoulders, tees are used. They are located in the supply and return pipelines.

Sometimes a heating system organized in a dead-end manner contains only one circuit of pipes. With this scheme, the coolant sequentially passes from the boiler to all heating devices in the forward direction, and is discharged in the opposite direction. To achieve uniform heating, forced transportation of the coolant is organized and the number of sections of distant radiators is increased.

Possible problems and solutions

Many buildings in large cities have existing one- and two-pipe steam heating systems.

Scheme of a two-pipe heating system

Both 1-pipe and 2-pipe systems have control problems from time to time, resulting in uneven heating, high fuel consumption and water hammer.

Let's now look at modern systems, best practices, and troubleshooting for maintaining a comfortable environment and saving energy.

Heating systems allow condensate and steam to move throughout the system within the same pipes.

As the boiler creates steam, it passes through the pipes and rises up to the radiators, where it heats the space and condenses. This condensate is then returned through the same pipe(s) back to the boiler.

The pipes and radiators are all sloped back towards the boiler to allow this system to operate by gravity.

For the system to work well, the steam flow must be balanced. Adjustable air valves must be installed on each radiator. Thus, radiators closest to the boiler may have a smaller opening on the air valve.

Radiators located further from the boiler may have a larger opening. This allows steam to flow more evenly throughout the system, as radiators closest to the boiler do not overheat, and radiators further away from the boiler do not overheat.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

Air valves can be used to shut off steam to unoccupied rooms. If the air valve is completely closed, no steam will flow into the radiator.

Air valves operate using a bellows filled with an alcohol-water mixture. The temperature is such that air can escape, but when steam is present at high temperature, it turns into gas, expanding the bellows which closes the valve. Air valves should be checked every three to five years as they can fail and are essential for the system to function properly.

Automatically adjustable air valves

They can be set to different temperatures from room to room. Although they are more expensive than simple air valves, they actually respond to subtle changes in temperature, not just the amount of steam in the radiator. The control is noticeably better and it is a higher quality product than simple air valves.

Dead-end heating branches

This scheme can be seen in cottages and country houses. Now such a system has begun to be used in high-rise buildings. In this case, the network consisting of radiators is presented in the form of several two-pipe branches. The coolant also flows along one part towards the battery, and through the other - back to the boiler. The work itself occurs due to the circulation pump, which is placed near the boiler. The average pressure in the entire structure is 1-2.5 bar. To compensate for the expansion of the liquid, the unit contains a membrane tank - it is installed in the boiler room. You can see the insertion point in front of the circulation pump. There are also additional elements for getting rid of excess air: Mayevsky cranes and a safety group are used. The design contains a pressure gauge to monitor the pressure status and a safety valve. Here, the bottom horizontal wiring is most often used: both pipes are mounted under the radiator in an open manner.

Dead-end heating branches

Modern control for single-pipe systems

The boiler is usually controlled by a single thermostat, which provides poor control, especially in townhouses. The thermostat will only take into account the temperature of the floor or room in which it is located.

For example, if the thermostat is located on the ground floor next to the boiler, then it will read the temperature of that floor.

The steam will reach the radiators first, quickly heating the floor. This means that the thermostat will turn off the boiler before the steam can fully heat the radiators on the floors furthest from the boiler, resulting in lower temperatures on those floors.

To eliminate this problem, it is proposed to place temperature sensors on several floors with an averaging thermostat.

This ensures more even heat distribution.

Larger single-pipe steam heating systems may require the use of a thermal timer control.

Kromax IDEAL-4

Our TOP continues with another representative of Kromax. The IDEAL-4 bracket is an excellent solution in cases where you want to mount the TV on the wall and do not need to rotate it from time to time. This tilting bracket is ideal for both small TVs and large panels with screen sizes up to 65 inches. The reinforced design allows it to withstand loads of up to 50 kilograms. A huge number of mounting holes will allow you to install a TV from any manufacturer. This bracket is also notable for its minimum distance to the wall, which is only 23 millimeters, which allows you to install the TV almost flush against the wall and there will be no large gaps when viewed from the side. As for the installation, you can do it yourself. The design of the bracket has a built-in level that will allow you to position it parallel to the floor and ceiling so that your TV hangs perfectly level. Also, the design of the bracket provides the ability to adjust the angle of the TV from 0 to 10 degrees and there is protection against falls, which will eliminate the risk of damage to expensive equipment.

- Inclined.

- Diagonal: 22 - 65 inches.

- Distance from wall: 23 mm.

- Tilt angle: 0 - 10⁰.

- Max. load: 50 kg.

- Built-in level.

- Fall protection.

- VESA holes: from 50x50 mm.

Modern control for two-pipe systems

The two tube steam systems have steam supply lines and separate condensate return lines. If the system is operating correctly, only a small amount of condensate will be present in the steam lines. The key to even and comfortable heating is again a balanced flow of steam to the radiators and return of condensate to the boiler.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

When the boiler produces steam, it passes through the supply pipe and reaches the radiator, where it releases heat and condenses. It then returns to the boiler through a check valve.

The return lines are arranged as single pipe systems so that the condensate can operate under the influence of gravity. The supply lines also have a slope leading to the return line. There are some systems that have condensate pumps or vacuum pumps that facilitate the movement of steam and condensate, however most systems will have pitched pipes.

What is a salt lamp

This is an ordinary lamp, the lampshade of which is made from a single piece of rock salt. This salt is mined mainly in the Carpathians and Himalayas. Halite may contain impurities in the form of algae, plants or other minerals. Due to this, salt blocks come in different shades. Rock salt contains 84 natural elements and helps restore the body.

A salt lamp can serve as an unusual decoration for your home. Recently, salt monoliths, mainly due to advertising, are considered useful and healing. But is this really so? Let's figure out whether the salt monolith is useful or can it harm?

The child is safe

Steam traps

To control the flow of steam and condensate, the two liquids must be separated. The usual method is to install a steam trap at the outlet of each radiator. This device allows air and water to exist in the radiator, but not vapor. If the traps do not work, the system cannot be monitored.

The interior of a failed trap can be easily replaced by a plumber. Of course, if your traps don't work, then it's reasonable to assume that all the traps in the building should be checked.

If the system is old, it would be wise to replace all radiator thermostatic traps.

Now that the steam and water are separated, we can move on to controlling the radiators. A thermostatic radiator valve (TRV) is used to control temperature in two-pipe steam systems. The expansion valves monitor the temperature near the radiator and are attached to the steam supply pipe.

You can then manually set the temperature: the settings are usually displayed numerically, with a temperature range corresponding to each element of the system. When the desired temperature is reached, the valve will close the steam supply to the separate radiator. If the radiator is installed in a housing, then it is necessary to use the capillary tube model.

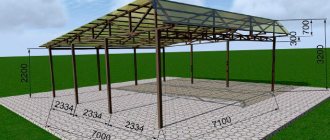

This may be useful

Below are some useful information and uses of polycarbonate.

- For fastening polycarbonate, manufacturers often supply special profiles of the same color as the polycarbonate panels themselves. The properties of profiles are absolutely no different from panels.

Docking profiles for polycarbonate

- If the polycarbonate is destroyed, parts of the panel do not pose a danger to others.

- You don't need any special tools to cut the panel into pieces.

- Polycarbonate is chemically resistant to almost all substances (with the exception of ammonia).

Cutting polycarbonate with a knife

Question answer

What is the difference between a 2-pipe system and a 1-pipe system?

A 1-pipe system operates using a complete ring of piping with flow and return from the boiler. The disadvantages of this system tend to outweigh the advantages, so they are used less and less.

The 2-pipe system has become popular since the 1970s, and is still the most common method of feeding radiator circuits. Water circulates here both through the circuit and through the radiators, which, in turn, increases the heating rate of the radiators.

What advantages does such a system have?

It is more practical and affordable for autonomous heating of housing.

What should you pay attention to when choosing a heating system?

In everyday life you can come across various heating schemes, but note that the choice is influenced by several factors. Preference is given to one or another scheme, based on the availability of funds from the homeowners, the expected effect and the design features of the residential building. The 2-pipe version is more often used in practice due to its high efficiency, reliability and ease of setup.

What is the operating principle of 2-pipe heating?

The principle of operation is quite simple: the coolant circulates from the boiler to the radiators through two circuits. The first pipe directly supplies heat from the boiler to the radiators, while the second is designed to transport the cooled coolant back.

Of course, this option has some technical difficulties associated with installation, but reliability, ergonomics and efficiency have made the 2-pipe heating principle the most popular for decades. But still, when choosing a system, pay attention to the characteristics of the living space, its square footage, as well as your own selection criteria and financial capabilities.

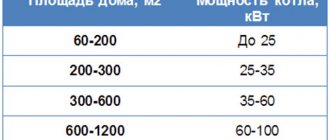

Choosing the right boiler

The main element of any autonomous heating system will be a hot water boiler, which can operate on various types of fuel. Today, the following types of boilers are most widespread:

- Gas.

- Electrical.

- Solid fuel.

If a private house has a connection to the central gas main, most homeowners give preference to blue fuel boilers, which is explained by its affordable cost. In remote farmsteads and villages where there is no central gas supply, devices running on solid fuel are popular. In recent years, such installations have been significantly improved, which has made it possible to both increase their efficiency and extend the operating time of the boiler from one load.

Modern gas heating boilers are equipped with automatic control systems , have numerous security systems, and the possibility of stepwise power adjustment can significantly reduce fuel consumption, reducing the homeowner's costs for utility bills. Gas and electric heating boilers are available in wall-mounted and floor-standing versions; they are distinguished by their power ratings, the ability to connect several circuits at once, and are excellent for implementing a dead-end heating circuit.

An excellent option for a summer house and a small private house would be an electric heating boiler, the use of which is not particularly difficult. All that needs to be done is to run a separate power cable to the boiler, thereby eliminating the possibility of overvoltage of the standard electrical wiring and the occurrence of a short circuit in the network. Such electric boilers are efficient, they consume a minimum of fuel and provide quick heating of a small room.